Preparation method of super-hydrophobic aluminum surface with freezing prevention performance

A super-hydrophobic, aluminum surface technology, which is applied to the device for coating liquid on the surface, special surface, pre-treated surface, etc., can solve the problems of complicated process, limited substrate, high cost investment, etc. The method is simple and easy, The effect of weak surface adhesion and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Polish the aluminum substrate with a size of 20*20*2mm with 7000-grit sandpaper for 1min, then perform ultrasonic cleaning, and dry it in a drying oven to remove the oxide layer on the surface;

[0019] Preparation of surface micro-nano structure: put the pretreated aluminum base into 2.9mol / L hydrochloric acid solution, place the aluminum base in the solution for etching for 45 minutes at room temperature, then ultrasonically clean and dry in a drying oven;

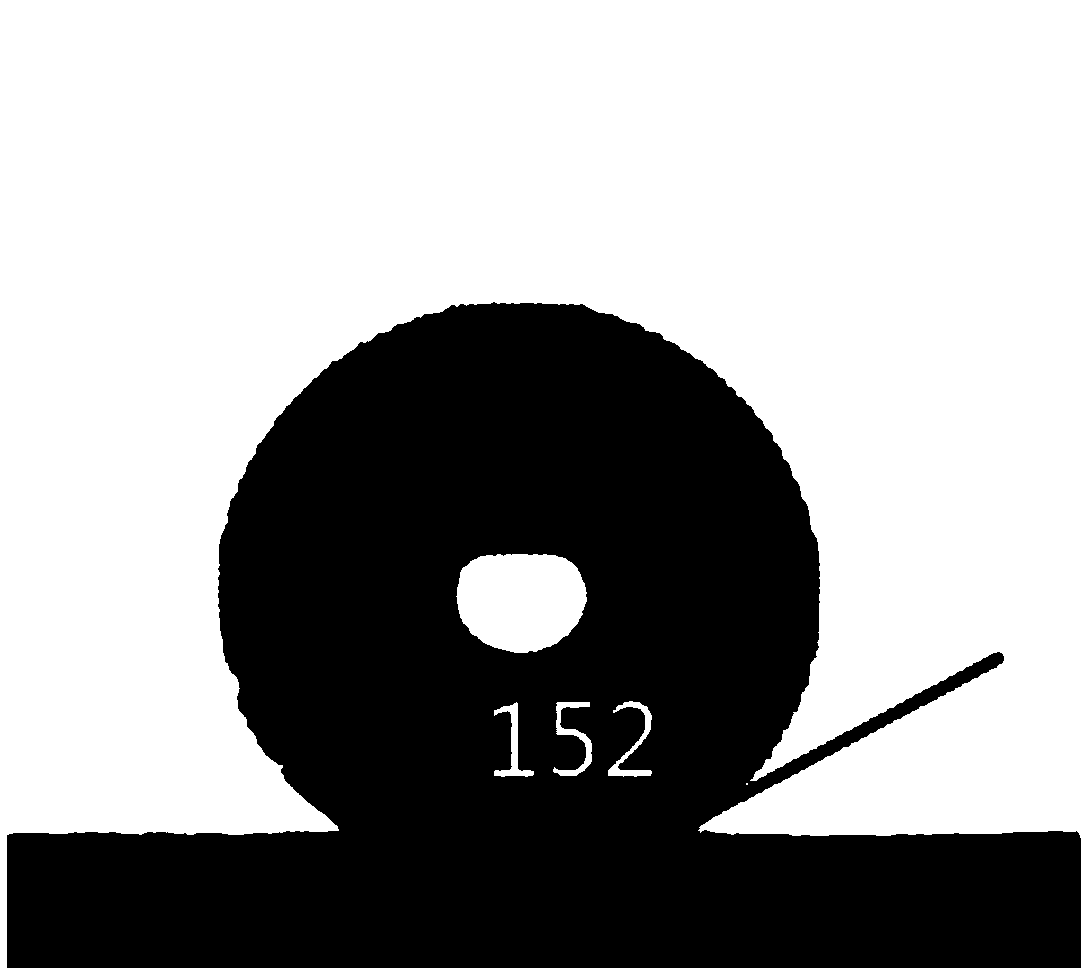

[0020] Reducing the surface energy: Put the etched aluminum base into the prepared 0.5mol / L stearic acid absolute ethanol solution, modify the aluminum base in a water bath at 53°C for 1 hour, and then place it in a drying oven at 110 After drying and curing for 30 minutes at ℃, the treated aluminum substrate was subjected to a drip test by a contact angle measuring instrument, and the contact angle of static water droplets on the surface of the aluminum substrate was measured. The results are as follows: figure 1...

Embodiment 2

[0022] Polish the aluminum substrate with a size of 20*20*2mm with 7000-grit sandpaper for 0.5min, then perform ultrasonic cleaning, and dry it in a drying oven to remove the oxide layer on the surface;

[0023] Prepare the surface micro-nano structure: put the pretreated aluminum base into 2.9mol / L hydrochloric acid solution, place the aluminum base in the solution for etching for 40 minutes at room temperature, then ultrasonically clean and dry in a drying oven;

[0024] Reduce the surface energy: put the etched aluminum base into the prepared 0.1mol / L stearic acid absolute ethanol solution, modify the aluminum base in a water bath at 55°C for 1.5 hours, and then place it in a drying oven at 110 Dry and solidify at ℃ for 30 minutes. The treated aluminum substrate is subjected to a drop test with a contact angle measuring instrument to measure the contact angle of static water droplets on the surface of the aluminum substrate. The contact angle of water droplets on the surface...

Embodiment 3

[0026] Polish the aluminum substrate with a size of 20*20*2mm with 5000-grit sandpaper for 1.5min, then perform ultrasonic cleaning, and dry it in a drying oven to remove the oxide layer on the surface;

[0027] Prepare the surface micro-nano structure: put the pretreated aluminum base into 2.3mol / L hydrochloric acid solution, place the aluminum base in the solution for 60 minutes etching at room temperature, then ultrasonically clean and dry in a drying oven;

[0028] Reduce surface energy: Put the etched aluminum base into the prepared 0.5mol / L stearic acid absolute ethanol solution, modify the aluminum base in a water bath at 50°C for 1 hour, and then place it in a drying oven at 110 After drying and curing at ℃ for 30 minutes, the treated aluminum substrate was subjected to a drop test using a contact angle measuring instrument to measure the contact angle of static water droplets on the surface of the aluminum substrate. The contact angle of water droplets on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com