Antiviral and antibacterial functional film and preparation method thereof

An anti-virus and thin-film technology, applied in the direction of film/sheet adhesive, biocide-containing paint, anti-fouling/underwater coating, etc., can solve problems such as uneven antibacterial properties, complicated preparation, and secondary infection , to achieve strong anti-virus and anti-bacterial effect, simple preparation method, good anti-scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

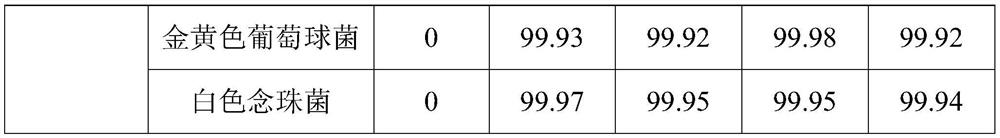

Examples

Embodiment 1

[0025] An antiviral and antibacterial functional film proposed by the present invention includes a substrate, an antiviral and antibacterial coating fixed on the upper surface of the substrate, and a low-viscosity organic adhesive layer fixed on the lower surface of the substrate layer;

[0026] Among them, the material of the substrate is PET; the low-viscosity organic adhesive layer is an acrylic adhesive layer;

[0027] The thickness of the antiviral and antibacterial coating is 0.2 μm, which is obtained by coating the substrate with a coating solution containing a nano-inorganic / organic composite antiviral and antibacterial treatment agent and a transparent resin;

[0028] Specifically, the coating liquid is composed of the following components by weight: 20 parts of nano-inorganic / organic composite antiviral and antibacterial treatment agent, 10 parts of transparent resin, 25 parts of co-solvent, 1 part of dispersant, 0.5 part of anti-fingerprint agent, 3.5 parts of spray...

Embodiment 2

[0036] An antiviral and antibacterial functional film proposed by the present invention includes a substrate, an antiviral and antibacterial coating fixed on the upper surface of the substrate, and a low-viscosity organic adhesive layer fixed on the lower surface of the substrate layer;

[0037] Among them, the material of the substrate is BOPP; the low-viscosity organic adhesive layer is silicone pressure-sensitive adhesive;

[0038]The thickness of the antiviral and antibacterial coating is 20 μm, which is obtained by coating the substrate with a coating liquid containing nano-inorganic / organic composite antiviral and antibacterial treatment agent and transparent resin;

[0039] Specifically, the coating solution is composed of the following components by weight: 1.5 parts of nano-inorganic / organic composite antiviral and antibacterial treatment agent, 20 parts of transparent resin, 35 parts of co-solvent, 2 parts of dispersant, 1.0 part of anti-fingerprint agent, 5.0 parts ...

Embodiment 3

[0047] An antiviral and antibacterial functional film proposed by the present invention includes a substrate, an antiviral and antibacterial coating fixed on the upper surface of the substrate, and a low-viscosity organic adhesive layer fixed on the lower surface of the substrate layer;

[0048] Among them, the material of the substrate is PMMA; the low-viscosity organic adhesive layer is silicone pressure-sensitive adhesive;

[0049] The thickness of the antiviral and antibacterial coating is 5 μm, which is obtained by coating the substrate with a coating solution containing a nano-inorganic / organic composite antiviral and antibacterial treatment agent and a transparent resin;

[0050] Specifically, the coating solution is composed of the following components by weight: 0.33 parts of nano-inorganic / organic composite antiviral and antibacterial treatment agent, 2 parts of transparent resin, 10 parts of co-solvent, 0.02 part of dispersant, 0.001 part of anti-fingerprint agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com