A kind of fluorosilane modified titanium dioxide nanomaterial and its preparation method and application

A technology of titanium dioxide and nanomaterials, applied in the field of nanomaterials, can solve problems such as difficulty in adapting to application requirements, and achieve the effects of excellent hydrophobicity, excellent high and low temperature resistance, and antibacterial and anti-ultraviolet rays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

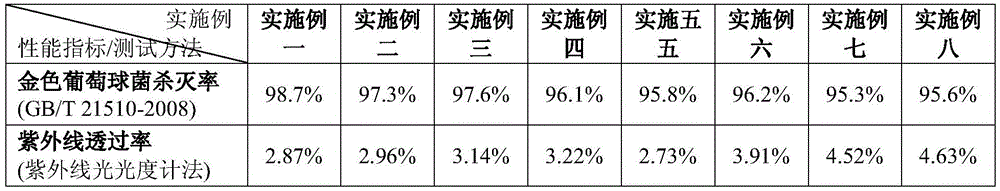

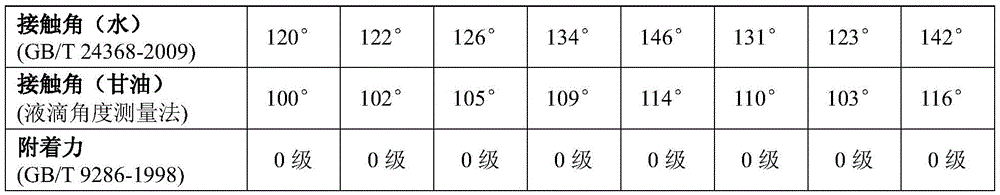

Examples

Embodiment 1

[0028] The preparation method of the present embodiment fluorosilane modified titanium dioxide nanomaterials, its steps are as follows:

[0029] (1) Add 100g of ethyl titanate into 400g of absolute ethanol and stir to obtain mixed solution A;

[0030] (2) 200g of water, 360g of absolute ethanol, and 40g of glacial acetic acid were stirred and mixed to obtain mixed solution B;

[0031] (3) Slowly add the mixed solution B into the mixed solution A at a temperature of 35° C., dropwise add hydrochloric acid to adjust the pH value to 1, and stir for 1.5 hours to prepare a transparent titanium dioxide sol solution;

[0032] (4) Add 10 g of tridecafluorooctyltrimethoxysilane to the titanium dioxide sol solution, stir and react at 35° C. for 2 hours to obtain a transparent solution, and filter the reaction product to obtain fluorosilane-modified titanium dioxide nanomaterials.

Embodiment 2

[0034] The preparation method of the present embodiment fluorosilane modified titanium dioxide nanomaterials, its steps are as follows:

[0035] (1) Add 90g of propyl titanate to 500g of ethylene glycol and stir to obtain mixed solution A;

[0036] (2) 250g water, 700g ethylene glycol, and 100g nitric acid were stirred and mixed to obtain mixed solution B;

[0037] (3) Slowly add the mixed solution B to the mixed solution A at a temperature of 40° C., dropwise add hydrochloric acid to adjust the pH value to 2, and stir for 2 hours to prepare a transparent titanium dioxide sol solution;

[0038] (4) Add 10 g of tridecafluorooctyltriethoxysilane to the titanium dioxide sol solution, stir and react at 45° C. for 3 hours to obtain a transparent solution, and filter the reaction product to obtain fluorosilane-modified titanium dioxide nanomaterials.

Embodiment 3

[0040] The preparation method of the present embodiment fluorosilane modified titanium dioxide nanomaterials, its steps are as follows:

[0041] (1) Add 80g of butyl titanate into 600g of isopropanol and stir to obtain mixed solution A;

[0042] (2) Stir and mix 220g water, 450g isopropanol, and 80g hydrochloric acid to obtain mixed solution B;

[0043] (3) Slowly add the mixed solution B into the mixed solution A at a temperature of 45° C., dropwise add hydrochloric acid to adjust the pH value to 3, and stir for 3 hours to prepare a transparent titanium dioxide sol solution;

[0044] (4) Add 10 g of heptadecafluorodecyltrimethoxysilane to the titanium dioxide sol solution, stir and react at 50° C. for 4 hours to obtain a transparent solution, and filter the reaction product to obtain fluorosilane-modified titanium dioxide nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com