Method for preparing microgel resin and UV-cured contamination resistant coating prepared from microgel resin

A microgel and resin technology, applied in the field of coatings, can solve the problems of anti-fingerprint printing, insufficient skin oil contamination ability, difficult to lasting anti-contamination, weak bonding and other problems, and achieves good anti-skin oil contamination performance, Adjustable compatibility and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add isobornyl acrylate (50g), n-butyl acrylate (40g), tripropylene glycol diacrylate (6.36g), S-n-dodecyl-S' to a 500mL ordinary glass reactor in sequence -(α,α'-dimethyl-α"-acetoxy) trithiocarbonate (1.77g), photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (0.34 g), toluene (150g), nitrogen exhaust 1h to this system.Cut off short-wave ultraviolet radiation with light-cutting glass, use long-wave ultraviolet-visible radiation as initiation source, polymerization process is protected with nitrogen, and the reaction times is 5 hours, single The overall conversion rate is greater than 95%. Then add (2-perfluorohexylethyl) acrylate (40.5g) and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (0.68g), continue The photoinitiated polymerization is carried out, and the reaction time is 3 hours to prepare the microgel resin, and the conversion rate of the fluorine-containing monomer is greater than 98%.

[0032] (2) Take the above-mentioned microgel resin soluti...

Embodiment 2

[0038] (1) Add isobornyl acrylate (50g), n-butyl acrylate (40g), TMPTMA (4.60g), S, S'-bis(α,α'-dimethyl- α "-acetoxy) trithiocarbonate (2.09g), (1-hydroxycyclohexyl) benzophenone (0.25g), toluene (230g), blow nitrogen to the system and exhaust oxygen for 1h. Short-wave ultraviolet radiation is removed, and long-wave ultraviolet-visible radiation is used as a source of initiation, and the polymerization process is protected with nitrogen, and the reaction times is 4 hours. The total conversion rate of the monomer is greater than 95%. Then add acrylic acid (2-perfluorooctylethyl) ester ( 21g) and (1-hydroxycyclohexyl) benzophenone (0.15g), continue photoinitiated polymerization, and the reaction time is 3 hours to prepare microgel resin, and the conversion rate of fluorine-containing monomer is greater than 98%.

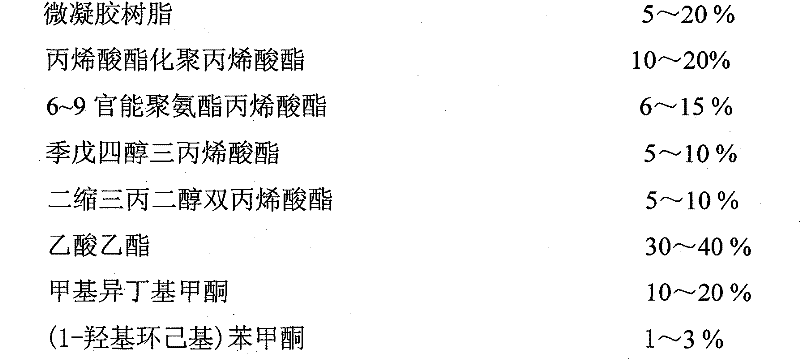

[0039] (2) Take the above-mentioned microgel resin solution (20g), acrylated polyacrylate (15g), hexafunctional urethane acrylate (10g), pentaerythritol triacrylate (...

Embodiment example 3

[0045] (1) Add isobornyl acrylate (90g), tripropylene glycol diacrylate (6.05g), S-n-dodecyl-S'-(α,α'-di Methyl-α″-acetoxy) trithiocarbonate (1.68g), photoinitiator 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (0.33g), n-heptane (75g ), isopropanol (75g), nitrogen exhaust 1h to this system. Cut off the short-wave ultraviolet radiation with cut-off glass, use the long-wave ultraviolet-visible radiation as the initiation source, the polymerization process is protected with nitrogen, and the reaction times is 5 hours. Single The total conversion ratio of the body is greater than 95%. Then add dodecafluoroheptyl acrylate (37.2g) and 2,4,6-trimethylbenzoyl-diphenylphosphine oxide (0.34g), continue photoinitiated polymerization, The reaction time is 3 hours, the microgel resin is prepared, and the conversion rate of the fluorine-containing monomer is greater than 98%.

[0046] (2) Take the above-mentioned microgel resin solution (15g), acrylated polyacrylate (15g), hexafunctional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com