Long-acting anti-fog dripping coating liquid for agricultural plastic greenhouse film and preparation method of long-acting anti-fog dripping coating liquid

A technology of anti-fog dripping and coating liquid, applied in the direction of coating, alkali metal silicate coating, etc., can solve the problems of short duration of anti-fog dripping, high cost, poor transparency, etc., and achieve good anti-fog And dripping, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

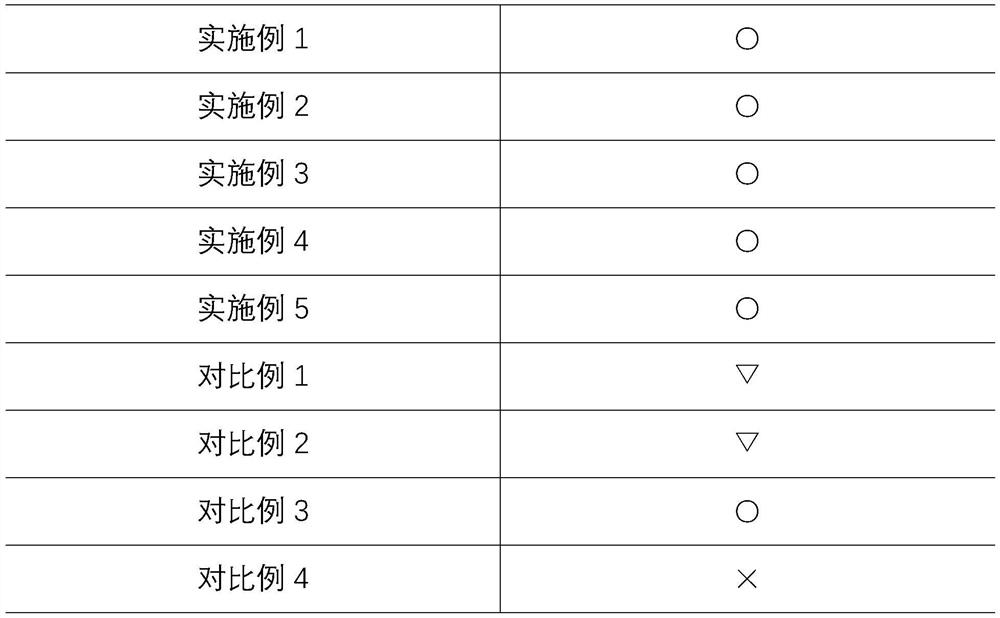

Examples

Embodiment 1

[0025] 1. Preparation of latex:

[0026] ①. Add 500ml of OP-10 emulsifier solution (3%) into the beaker. Then slowly add 34 g of polyvinyl alcohol under stirring, and raise the temperature to 80° C. until the polyvinyl alcohol is completely dissolved (dissolving time is about 1 hour).

[0027] ② Stop heating, cool down to about 65°C, and add 8 grams of butyl acrylate, 8 grams of perfluoroalkyl acrylate and 20 grams of hydroxyethyl methacrylate into the emulsion at one time, heat to 75-85 degrees, and stir 10 minutes.

[0028] ③. Slowly add 40ml of 1.2% ammonium persulfate solution into the reaction system drop by drop (about 15 minutes), and maintain the reaction temperature at 80-85°C until white latex appears.

[0029] 2. Preparation of coating solution

[0030] Take 10 grams of magnesium silicate, 85 ml of latex liquid and 5 grams of coconut oleic acid diethanolamide, add it, heat to 60 degrees, and stir for 2-3 hours to obtain the required coating solution. When using,...

Embodiment 2

[0032] 1. Preparation of latex

[0033] ①. Add 500ml of OP-10 emulsifier solution (3%) into the beaker. Then slowly add 34 g of polyvinyl alcohol under stirring, and raise the temperature to 80° C. until the polyvinyl alcohol is completely dissolved (dissolving time is about 1 hour).

[0034] ② Stop heating, cool down to about 65°C, and add 8 grams of styrene, 34 grams of perfluoroalkyl acrylate, 8 grams of butyl acrylate and 8 grams of styrene monomer at one time and stir, then restart heating to 80-85 °C (stir for about 15 minutes).

[0035] ③. Slowly add 40ml of 1.5 ammonium persulfate solution into the reaction system drop by drop (about 15 minutes), and maintain the reaction temperature at 80-85°C until white latex appears.

[0036] 2. Preparation of aluminum silicate:

[0037] Dissolve 12 grams of sodium silicate in 500 ml of water, and dissolve 13.6 grams of aluminum sulfate in 500 ml of water. Gradually add aluminum sulfate to the sodium silicate solution with stir...

Embodiment 3

[0041] 1. Preparation of latex

[0042] ①. Add 500ml of OP-10 emulsifier solution (3%) into the beaker. Slowly add 34 g of polyvinyl alcohol under stirring, and raise the temperature to 80° C. until the polyvinyl alcohol is completely dissolved (dissolving time is about 1 hour).

[0043] ② Stop heating, cool down to about 65°C, add 8 grams of methyl methacrylate, 8 grams of perfluoroalkyl acrylate and 30 grams of hydroxyethyl methacrylate monomer at one time and stir, and restart heating to 80-85 °C (stir for about 15 minutes).

[0044] ③. Slowly add 40ml of 1.5% ammonium persulfate solution into the reaction system drop by drop (about 15 minutes), and maintain the reaction temperature at 80-85°C until white latex appears.

[0045] 2. Preparation of coating solution

[0046] Mix 20 grams of lithium silicate, 85 ml of latex liquid and 5 grams of coconut oleic acid diethanolamide, heat to 60 degrees, and stir for 2-3 hours. That is, the desired coating solution is obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com