Tung oil modified organosilicon multifunctional coating and preparation method thereof

A silicone, multi-functional technology, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve the problems of low surface tension of tung oil-modified silicone multi-functional coatings, and no guidance plan is given. Achieving insect and fire resistance, widening the range of influence, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

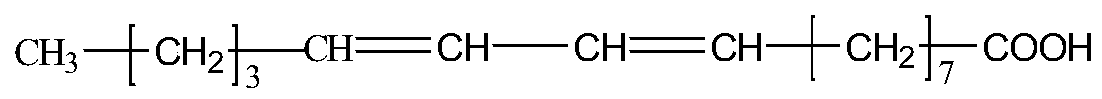

Image

Examples

Embodiment 1

[0025] Embodiment 1: the tung oil modified organosilicon multifunctional paint of the present invention is to make resin first and then make paint, specifically:

[0026] (1) Preparation method of resin: Weigh 35 parts of dodecene and 38.5 parts of triethoxysilane in parts by mass and add them to a four-necked flask equipped with a thermometer, reflux condenser and mechanical stirring (machine stirring, stirrer) , turn on the mechanical stirring, at this time the coagulation is an orange opaque liquid, the oil bath is heated to 70°C, the moisture in the raw materials is removed, high-purity nitrogen is passed, the temperature is raised to 95°C, and 0.25 parts of isopropanol chloroplatinate is added Solution, reacted for 4 hours, the content of catalyst chloroplatinic acid in the isopropanol solution of chloroplatinic acid was 16ppm, then added 7 parts of tung oil, continued to react for 2 hours, at 105°C, the vacuum degree was 90Pa to remove small molecule 1.5 hours (the yield...

Embodiment 2

[0030] Embodiment 2: the tung oil modified organosilicon multifunctional coating of the present invention is to make resin first and then make coating, specifically:

[0031] (1) The preparation method of resin: refer to embodiment 1.

[0032] (2) Preparation method of the coating: adopt method (2), take 10 parts of the above-mentioned prepared resin, 85 parts of ethanol, 1 part of hexadecyltrimethoxysilane, and 0.5 part of γ-aminopropyltriethoxysilane 10 parts of isopropanol are added to the beaker, stirred evenly, 0.5 part of dibutyltin dilaurate is added, stirred evenly, and set aside for later use to obtain the coating applied on the cable by the dip coating method; The product (coating) in the method (2) is solidified into a mold at room temperature for 10 minutes. The performance test of product (coating) in embodiment 2 is shown in Table 2.

[0033] Table 2

[0034] Shore hardness / degree 55 Volume resistivity / Ω.cm 5 Tensile strength / MPa 6.5 ...

Embodiment 3

[0035] Embodiment 3: the tung oil modified organosilicon multifunctional coating of the present invention is to make resin first and then make coating, specifically:

[0036] (1) The preparation method of resin: refer to embodiment 1.

[0037] (2) The preparation method of the coating: adopt method (3), take 16 parts of the above-mentioned prepared resin, 70 parts of ethanol, 10 parts of ethylene glycol monomethyl ether, 3-(phenylamino) propyltrimethoxysilane 5 parts 0.5 part and 0.5 part of tetrabutyl titanate were added to a beaker, stirred evenly, and left to stand for later use to obtain a paint for spraying on the wall in a room. When using, spray the product (paint) in method (3) on the wall in the room, and dry it at room temperature for 48 hours before moving in. The performance test of product (paint) in embodiment 3 is shown in table 3.

[0038] table 3

[0039] Exterior colorless translucent Shore hardness / degree 75 Reflectance / absorption ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com