Quaternary ammonium salt cationic surfactant and preparation method thereof

A technology of quaternary ammonium salt cations and surfactants, applied in botany equipment and methods, chemical instruments and methods, biocides, etc., can solve the problems of large residues in water, stimulating degradation, mechanical rust, etc., and achieve ecological Low toxicity, good degradability, high charge density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

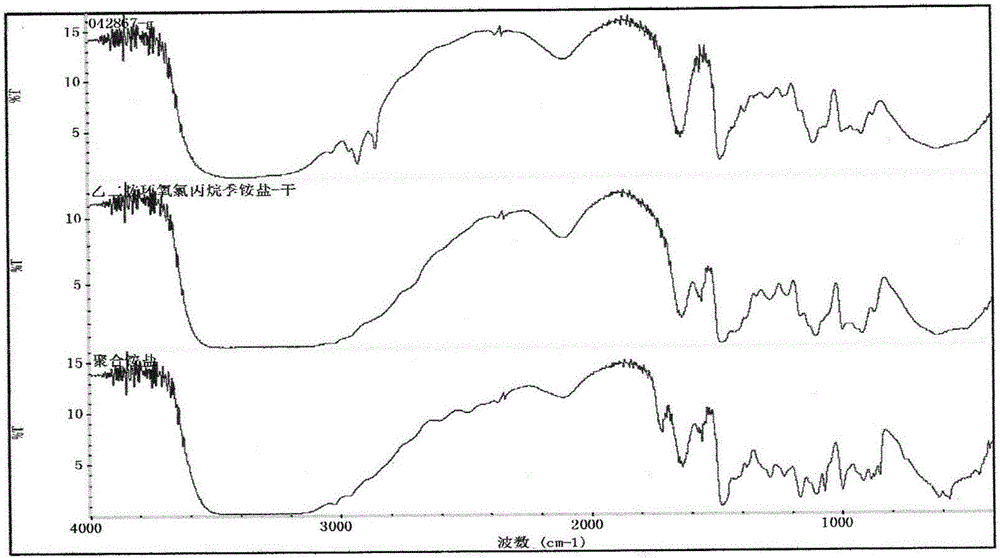

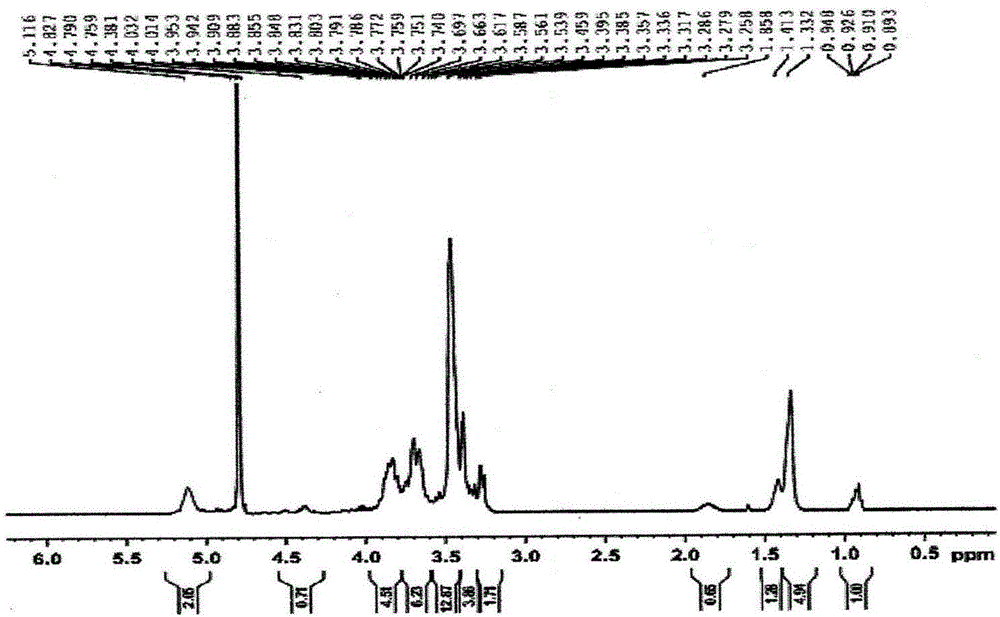

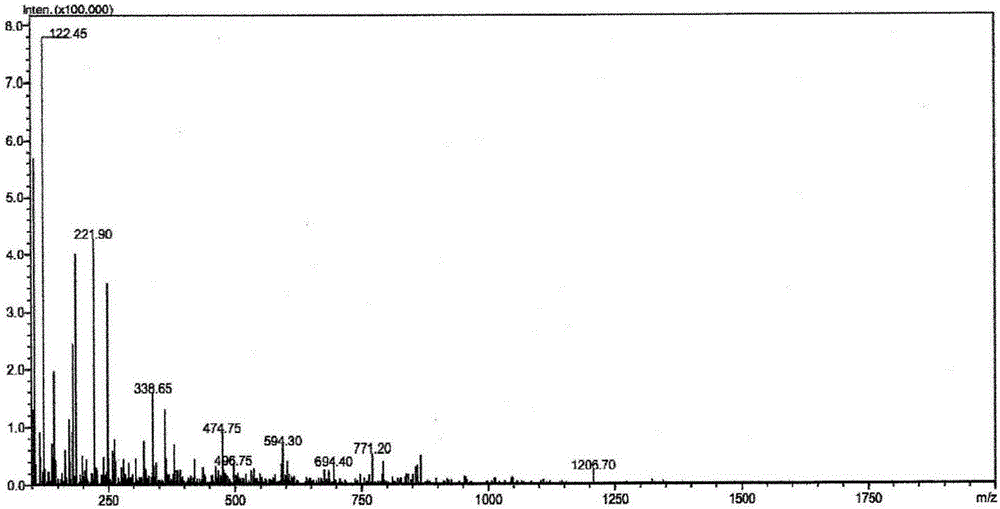

[0027] The preparation method of this quaternary ammonium salt cationic surfactant is: (1) at T 1 =0~40℃, under normal pressure, slowly add dimethylamine and (C10~C18) linear alkyl tertiary amine dropwise into the mixture of 1-chloro-2,3-epoxypropane, mix evenly to obtain a mixture liquid; among them, T 1 Preferably 10-30°C; straight-chain dimethylalkyl tertiary amine: 1-chloro-2,3-epoxypropylene: dimethylamine = 1.0: 4.0-20.0: 3.01-20.01 (mole), preferably 1: 10:9.01~10.01 (mole); Linear dimethyl alkyl tertiary amine is preferably selected from dodecyl dimethyl tertiary amine, dodecyl tertiary amine dimethyl tertiary amine, tetradecyl tertiary amine dimethyl tertiary amine, ten One or more of hexa-tertiary amine dimethyl tertiary amine and octadecyl tertiary amine dimethyl tertiary amine, preferably dodecyl tertiary amine dimethyl tertiary amine and fourteen-tertiary amine dimethyl tertiary amine, ten The di-tertiary amine dimethyl tertiary amine accounts for 70 wt%, and th...

Embodiment 1

[0031] Embodiment 1: This quaternary ammonium salt cationic surfactant is produced by the following specific process.

[0032] Add 4.39mol of 1-chloro-2,3-epoxypropane into the reactor, turn on the stirring, lower the temperature to 10°C, start to add dropwise 4.43mol of 40wt% aqueous solution of dimethylamine, and dodecyl tertiary amine dimethyl tertiary Amine and tetradecyl tertiary amine dimethyl tertiary amine (dodecyl tertiary amine dimethyl tertiary amine 70wt%, tetradecyl tertiary amine dimethyl tertiary amine 30wt%) 0.439mol; After dropping, the temperature is raised to 80°C, and the constant temperature reaction is 4 Hours; turn on the vacuum pump, adjust the vacuum to about 0.1atm, raise the temperature to 95-100°C, add 100kg of water while distilling, until about 100kg of distillate is distilled, cool down, stop the vacuum; cool down to 60°C, take samples and measure the content by drying at room temperature. Adjust to 40wt% after adding water, obtain described surf...

Embodiment 2

[0034] Embodiment 2: This quaternary ammonium salt cationic surfactant is produced by the following specific process.

[0035] Add 4.39mol of 1-chloro-2,3-epoxypropane into the reactor, turn on the stirring, and start to drop a 40wt% aqueous solution of dimethylamine 3.96mol at 20°C, and dodecyl tertiary amine dimethyl tertiary amine and Fourteen tertiary amine dimethyl tertiary amine (dodecyl tertiary amine dimethyl tertiary amine 70wt%, fourteenth tertiary amine dimethyl tertiary amine 30wt%) 0.439mol; after dropping, the temperature was raised to 75°C, and the temperature was reacted for 4 hours; Turn on the vacuum pump, adjust the vacuum to about 0.1atm, raise the temperature to 90-95°C, add 100kg of water while distilling, until about 100kg of distillate is evaporated, lower the temperature, stop the vacuum; lower the temperature to 50°C, take a sample to measure the content, and add water to adjust to 40wt %, obtain the aqueous surfactant solution; measure the aqueous su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com