Normal temperature solidified titania sol

A titanium dioxide, room temperature curing technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, colloidal chemistry, etc., can solve the problems of nanoparticle agglomeration and high price of organic titanium raw materials, and achieve low operating temperature, low raw material cost and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 5ml of metatitanic acid solution with a concentration (based on titanium dioxide content) of 80g / l into the container, heat it to 55°C, adjust the pH value to 3.0 with a NaOH solution with a concentration of 90g / l, and then keep it warm for 0.5 Hours, the seed crystal transparent sol was obtained; after the obtained seed crystal transparent sol was continued to be heated to 80° C., 20 ml of 80 g / l metatitanic acid solution was added to the seed crystal transparent sol, and the reaction system was continued to be heated to 140 Boiling at ℃ for 1 hour, a white precipitate was obtained, which was filtered and washed to obtain a white filter cake; the obtained white filter cake was completely dispersed in 20ml of 3M HCl solution, and degummed at 25℃ for 8 hours to obtain a light blue transparent normal temperature Cured titanium dioxide sol.

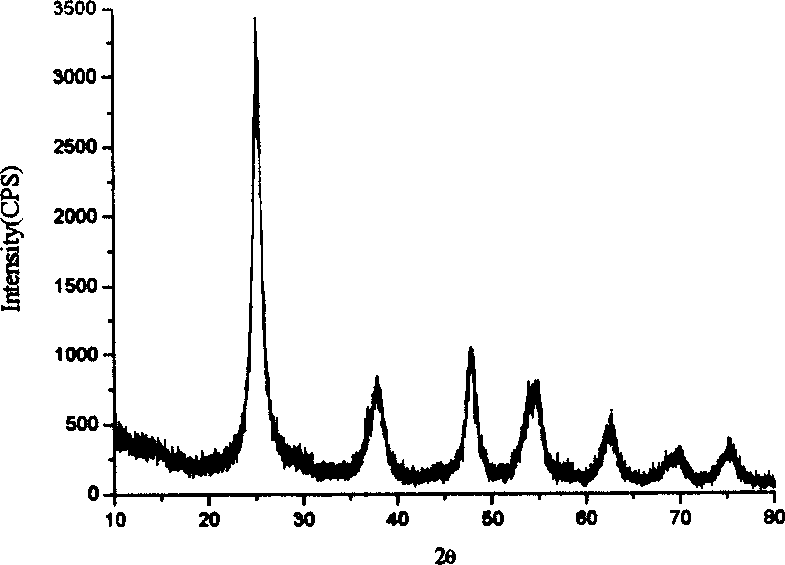

[0033] Get a small amount of the above-mentioned white filter cake, after drying at normal temperature, the XRD test shows that ...

Embodiment 2

[0036]Add 3ml of titanyl sulfate solution with a concentration (based on titanium dioxide content) of 200g / l into the container, heat it to 28°C, adjust the pH value to 2.5 with a KOH solution with a concentration of 98g / l, and stir the above mixed solution for 30 Minutes later, the reaction system was heated to 35° C., and kept under stirring for 180 minutes to obtain a seed crystal transparent sol; then 30 ml of a 200 g / l titanyl sulfate solution was added to the prepared seed crystal transparent sol, and The reaction system was continued to be heated to 100°C and reacted for 5 hours. The resulting white precipitate was filtered and washed with 3% ammonia and water to obtain a white filter cake; the resulting filter cake was divided into two and dispersed in 10 and 20ml of 1.5 M HNO 3 In the solution, degumming at a temperature of 60° C. for 4 hours can obtain light blue transparent titanium dioxide sols with concentrations of 200 g / l and 100 g / l respectively.

[0037] Acco...

Embodiment 3

[0039] Add 10ml of titanium tetrachloride solution with a concentration (in terms of titanium dioxide content) of 200g / l into the container, heat it to 50°C, and adjust the pH value to 3.0 with a NaOH solution with a concentration of 140g / l, and then the reaction The system was heated to 85° C. and kept under stirring for 40 minutes; then the reaction system was further heated to 105° C. and reacted for 0.5 hour. The obtained white precipitate was filtered and washed repeatedly to obtain 10 g of filter cake. This 10 g filter cake was added to 30 ml concentration of 0.05M H 3 PO 4 The solution was degelized at 85° C. for 5 hours to obtain a light blue transparent titanium dioxide sol.

[0040] According to the measurement method of Example 1, the white filter cake titanium dioxide crystal form obtained in this example is anatase type; the particle size distribution is narrow and uniform, and the range is 30-80nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com