Plasma chemical vapor deposition nano super-hydrophilic anti-fog coating and preparation method thereof

A chemical vapor deposition and anti-fog coating technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as lack of performance, restricting product market applications, etc., to improve anti-fog performance and enhance hydrophilicity effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

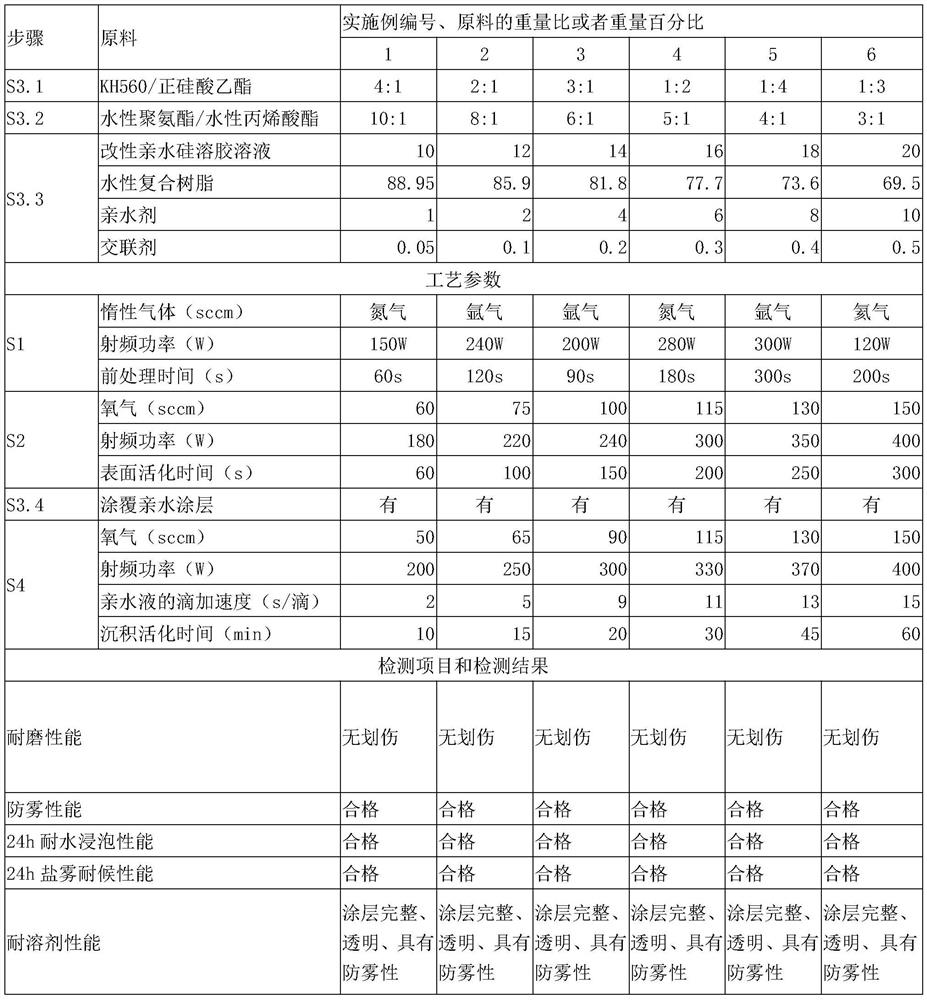

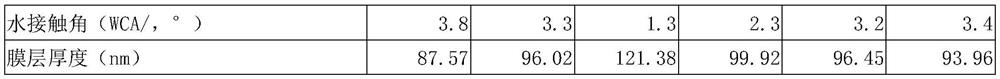

[0036] A method for preparing a nanometer super-hydrophilic anti-fog coating by plasma chemical vapor deposition, comprising the following steps:

[0037] S1) cleaning the surface of the substrate;

[0038] S2) activating the surface of the substrate;

[0039] S3) the preparation of hydrophilic coating, comprising:

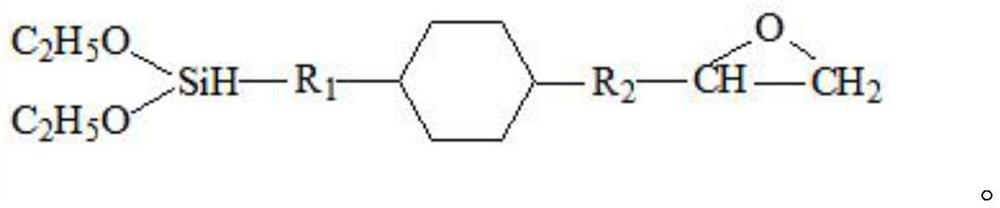

[0040] S3.1) Preparation of a modified hydrophilic silica sol solution: in an alkaline solution of ethyl orthosilicate, a surfactant is added to carry out a hydrolysis reaction to obtain the modified hydrophilic silica sol solution;

[0041] S3.2) Preparation of water-based composite resin: mixing water-based polyurethane and water-based acrylate according to a preset ratio, adding an appropriate amount of deionized water for dilution, mixing evenly and stirring for 30 minutes, to obtain the water-based composite resin;

[0042] S3.3) Stir and mix the prepared modified hydrophilic silica sol solution and the water-based composite resin according to the set ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com