Lubricant film material, raw material composition, preparation method and applications

A raw material composition, lubricating film technology, applied in spinning solution preparation, chemical instruments and methods, wood-layered products, etc., can solve the problems of complex process, short service life, harsh reaction conditions, etc., and achieve a simple film-making process , Excellent thermal viscosity, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

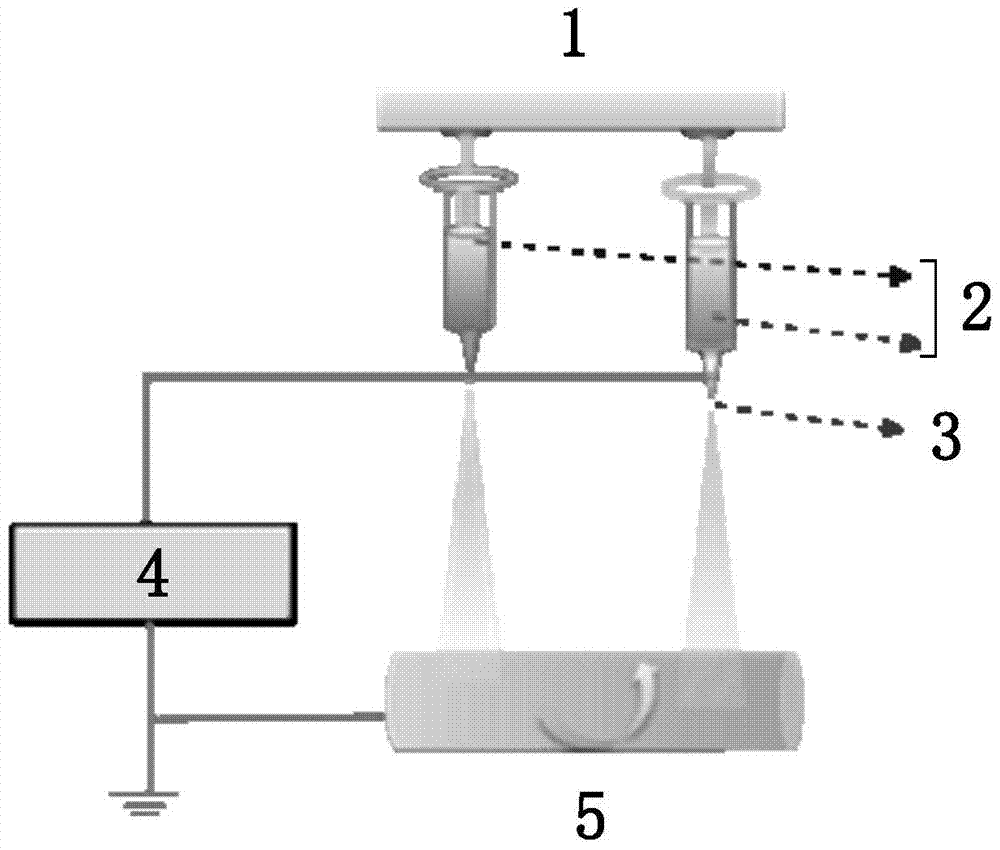

Method used

Image

Examples

Embodiment 1

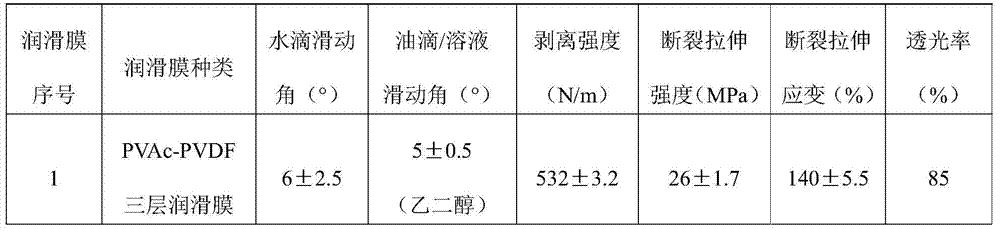

[0045] Example 1 PVAc-PVDF electrospinning three-layer lubricating film material (lubricating film 1)

[0046] The first step: at a room temperature of 25°C, mix 2g of PVAc (Mw=250,000, T m =60°C) and 2g PVDF (Mw=300,000, T m = 170°C) were dissolved in two parts of 18g DMF solvent respectively, magnetically or mechanically stirred evenly, and then dissolved in an oven at 60°C for 24h to obtain spinning solution PVAc and spinning solution PVDF with a mass fraction of 10%, respectively.

[0047] Step 2: Place the spinning solution PVAc and the spinning solution PVDF in two closed syringes respectively. At room temperature, control the applied voltage to 15kV, the injection speed to 0.5mL / h, and the receiving distance to 15cm. On the electrospinning equipment, the spinning solution PVAc is firstly spun for 3 hours, then the spinning solution PVAc and the spinning solution PVDF are blended for 2 hours, and finally the spinning solution PVDF is electrospun for 3 hours, and finally...

Embodiment 2

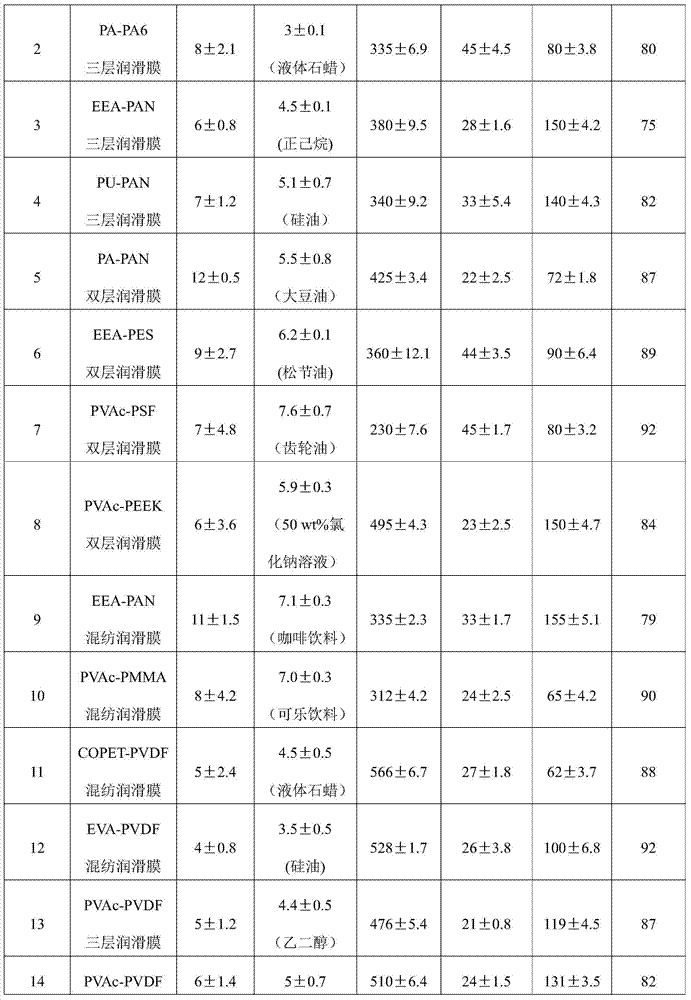

[0050] Example 2 PA-PA6 electrospinning three-layer gradient film material (lubricating film 2)

[0051] The first step: at room temperature 25 ℃, 3g PA (Mw=200,000, T m =100°C) and 3g PA6 (Mw=500,000, T m = 260°C) were dissolved in two parts of 17g THF solvent, magnetically or mechanically stirred evenly, and then dissolved in an oven at 60°C for 24h to obtain spinning solution PA and spinning solution PA6 with a mass fraction of 15%, respectively.

[0052] The second step: put the spinning solution PA and spinning solution PA6 obtained in the first step into two airtight syringes respectively, and at room temperature, control the applied voltage to 15kV, the injection speed to 0.5mL / h, and the receiving distance to be 15cm, firstly, the spinning solution PA is electrospun on the double-nozzle electrospinning equipment for 4 hours, then the spinning solution PA and the spinning solution PA6 are blended for 4 hours, and finally the spinning solution PA is electrospun for 4 ho...

Embodiment 3

[0055] Example 3 EEA-PAN electrospinning three-layer gradient film material (lubricating film 3)

[0056] The first step: at room temperature 25 ℃, 2g EEA (Mw=600,000, T m =120°C) and 3g PAN (Mw=200,000, T m =317°C) were dissolved in 18g and 17g of DEF solvent respectively, magnetically or mechanically stirred evenly, and then dissolved in an oven at 60°C for 24h to obtain spinning solution EEA and spinning solution PAN with a mass fraction of 10%, respectively.

[0057] Step 2: Place the spinning solution EEA and spinning solution PAN obtained in the first step into two airtight syringes respectively. At room temperature, control the applied voltage to 15kV, the injection speed to 0.5mL / h, and the receiving distance to be 15cm, firstly, the spinning solution EEA is electrospun on the double-nozzle electrospinning equipment for 4 hours, then the spinning solution EEA and the spinning solution PAN are blended for 3 hours, and finally the spinning solution PAN is electrospun fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com