Composite carbon diaphragm with mesoporous and microporous gradient structure and preparation method for diaphragm

A pore structure, composite carbon technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effects of simple and easy preparation process, high mechanical strength, and high separation selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolving 10g of mesoporous phenolic resin in DMAc is configured into a film-making solution with a mass percentage concentration of 58%, and is coated on the surface of a porous carbon plate or a carbon tube support body with a pore size of 360nm by spin coating. Dry at a temperature of 80°C for 30 hours to make a composite polymer film; put it into a carbonization furnace, and under the protection of nitrogen with a flow rate of 200ml / min, heat it to 750°C at a heating rate of 1°C / min for high-temperature carbonization. After 1h, it was naturally cooled to normal temperature to obtain a composite interlayer carbon film with a mesoporous structure; The imide membrane-making solution was sprayed on their surfaces to form a separation layer, and dried at a temperature of 30°C for 20 hours, and then at a temperature of 80°C for 25 hours to form a mesoporous composite polymer membrane. Then put it into a carbonization furnace, under the protection of nitrogen with a flow ...

Embodiment 2~4

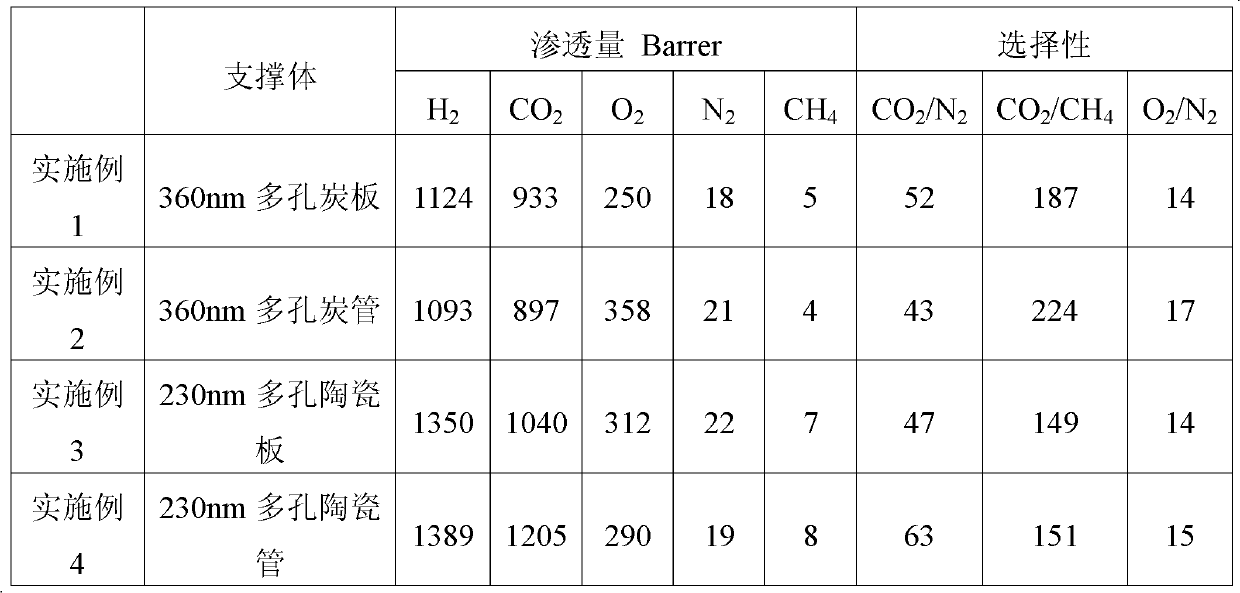

[0030] The procedure of Example 1 was repeated on the supports specified in Table 1 below, where the test results are listed.

[0031] Table 1

[0032]

Embodiment 5

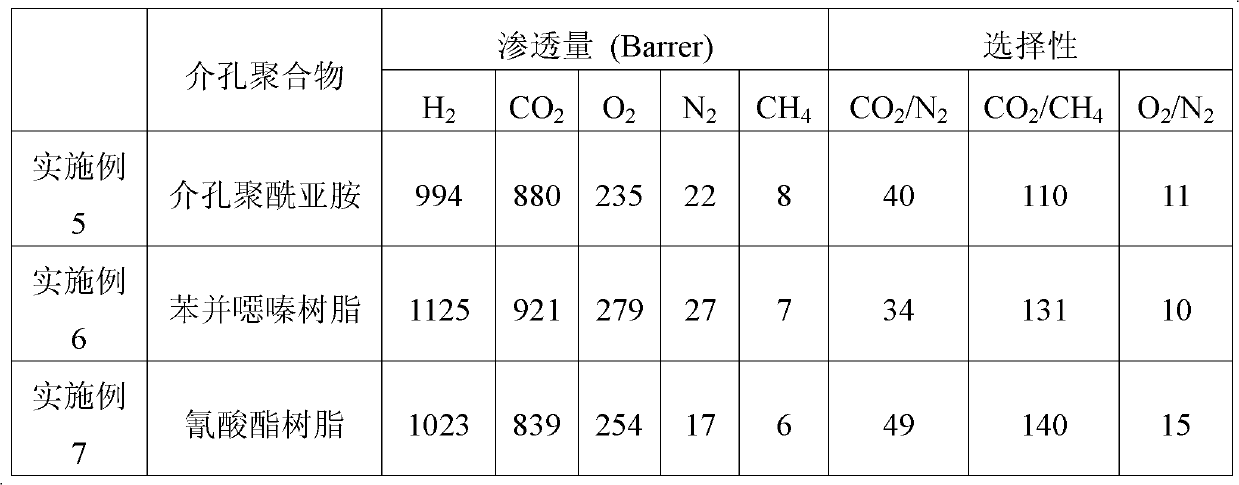

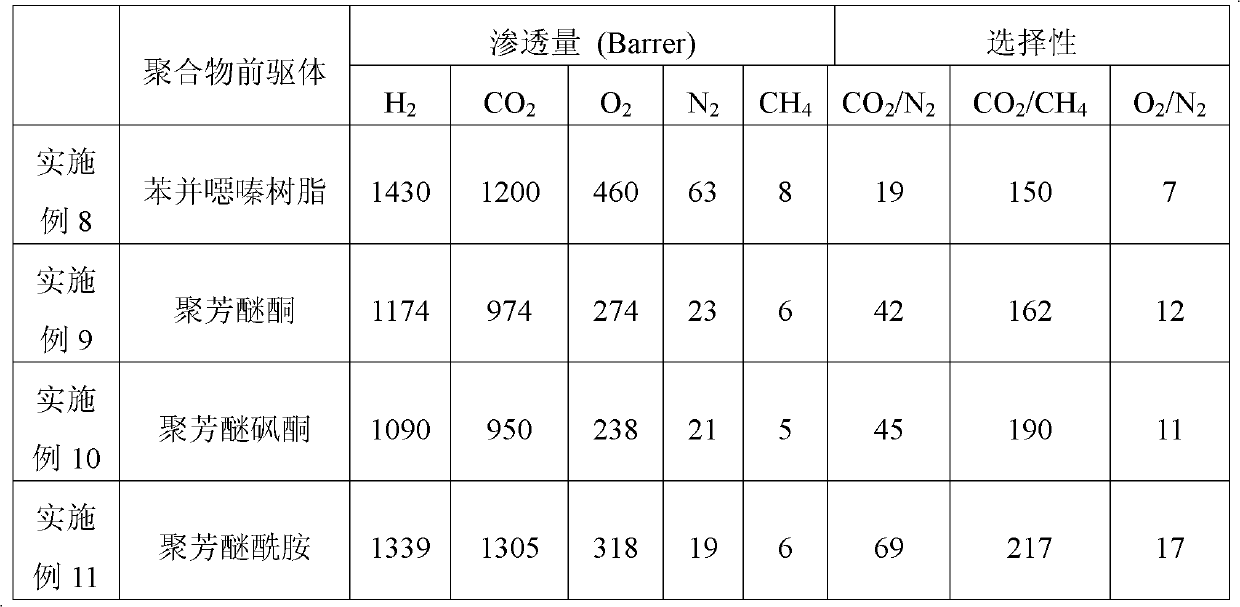

[0034]The 10g mesoporous polymer specified in Table 1 is configured in DMAc as a film-making solution with a mass percentage concentration of 20%, and is coated on the surface of a porous carbon plate support with a pore size of 230nm by scraping. Dry at ℃ for 28 hours to make a composite polymer film; put them into a carbonization furnace respectively, under the protection of nitrogen with a flow rate of 200ml / min, heat to 800℃ at a heating rate of 2℃ / min for high-temperature carbonization, and the constant temperature time is 2h After that, it was naturally cooled to room temperature to obtain a composite interlayer carbon membrane with a mesoporous structure. Then adopt the method of spin coating to spray the microporous cyanate resin film-making liquid with a mass percentage concentration of 13% and the solvent of N-methylpyrrolidone on the surface to form a separation layer, and first dry it at a temperature of 40 ° C. 15h, and then dried at 80°C for 20h to make a mesopor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com