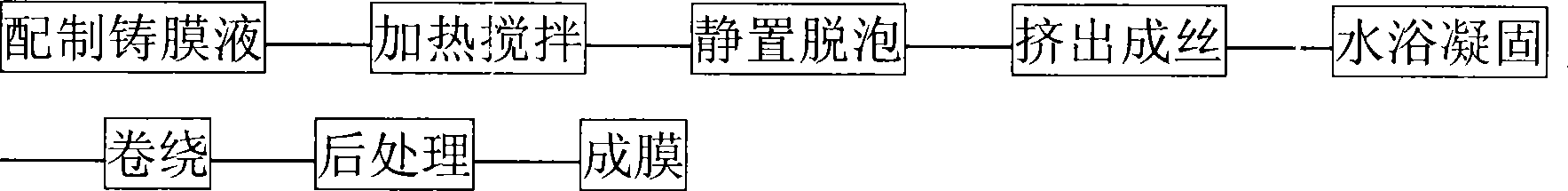

Method for preparing hollow fiber hyperfiltration membrane with low molecular weight cut-off

A technology with molecular weight and low cut-off, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex membrane production process, large footprint of membrane modules, high cost, etc., and achieve simple membrane production process , Excellent film-forming performance and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

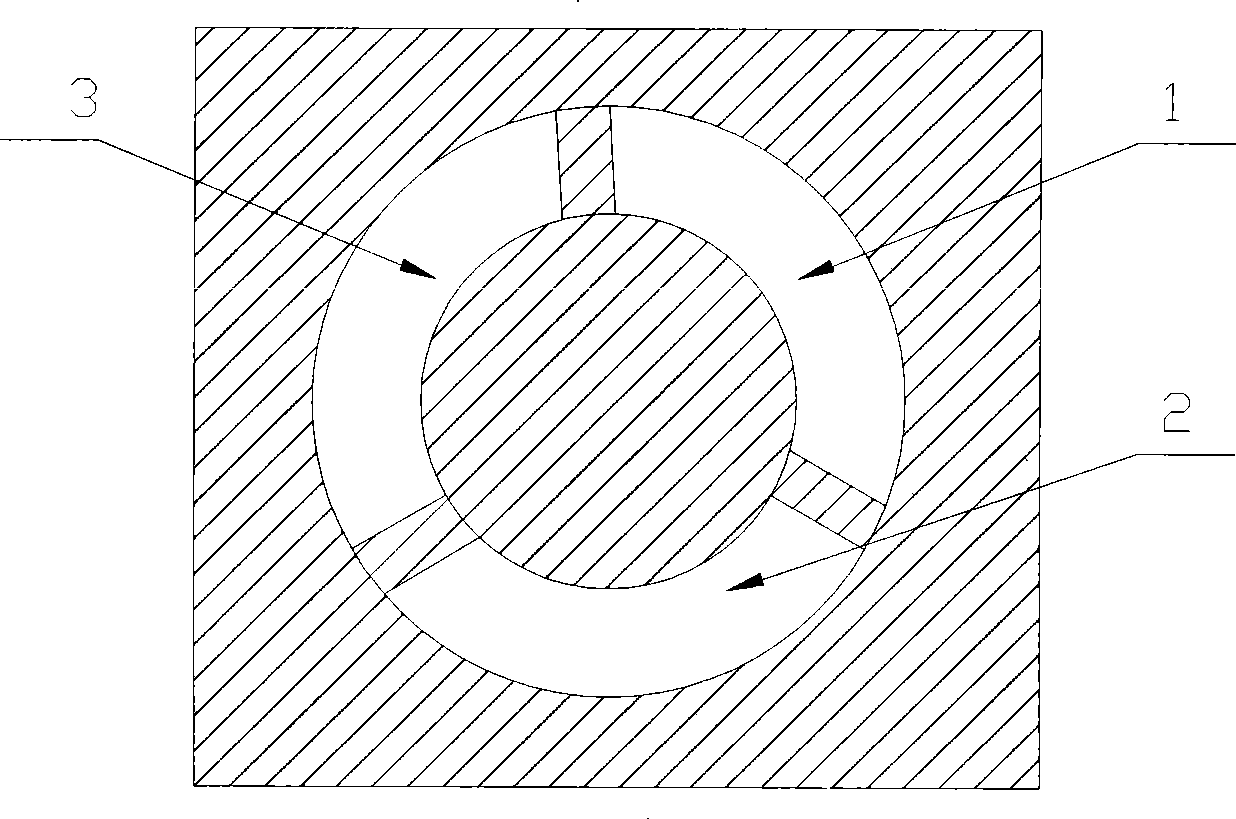

Embodiment 1

[0025] The raw materials were weighed according to the following weight percentages: polysulfone (PS) 30%; dimethylacetamide (DMAC) 60%; polyvinylpyrrolidone (PVP) 10% to prepare the casting solution. The preparation process is as follows: add 10% PVP into 60% DMAC solvent in the spinning kettle and heat it to 50°C to stir and dissolve. After the PVP is completely dissolved, add 30% PS and stir to dissolve. After stirring for 24 hours at a temperature of 50° C., the stirring was stopped, and the mixture was allowed to stand for 24 hours for defoaming. Extrude the defoamed casting solution from the 3C spinneret with a spinning metering pump, the extrusion speed is 9 rpm, the extrusion temperature is 50°C, and the extruded casting solution passes through a 5mm air The segment is injected into a water bath to solidify into a hollow fiber ultrafiltration membrane, the water bath is distilled water, and the temperature of the water bath is 30°C. The solidified hollow fiber ultrafi...

Embodiment 2

[0027] Weigh raw materials according to the following percentages by weight: polysulfone (PS) 30%; dimethylformamide (DMF) 65%; polyvinylpyrrolidone (PVP) 5% is formulated into a casting solution, and the process of Example 1 is repeated to obtain a hollow fiber Ultrafiltration membrane, 200 hollow fiber ultrafiltration membranes are bundled into a Φ32×500 cylinder for centrifugal casting to obtain the finished ultrafilter 2.

Embodiment 3

[0029] Weigh the raw materials according to the following weight percentages: polysulfone (PS) 20%; dimethylacetamide (DMAC) 60%; polyvinylpyrrolidone (PVP) 20% to prepare the casting solution, and the preparation process is: in the spinning kettle First add 20% PVP into 60% DMAC solvent and heat to 40°C and stir to dissolve. After the PVP is completely dissolved, add 30% PS and stir to dissolve. After stirring for 24 hours at a temperature of 40° C., the stirring was stopped, and the mixture was allowed to stand for 24 hours for defoaming. Extrude the defoamed casting solution from the 3C spinneret with a spinning metering pump, the extrusion speed is 9 rpm, the extrusion temperature is 40°C, and the extruded casting solution passes through 2mm of air The segment is injected into a water bath to solidify, the water bath is distilled water, and the temperature of the water bath is 10°C. The solidified hollow fiber ultrafiltration membrane is rinsed with ultrafiltration water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com