Preparation method of polyethylene imine/sodium lignin sulfonate composite membrane

A technology of sodium lignosulfonate and polyethyleneimine, which is applied in the field of separation membranes, can solve the problems of low elasticity, high price, and high brittleness of organic nanofiltration membranes, achieve improved separation performance, simple membrane manufacturing process, and improved separation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0030] Pretreatment of the basement membrane: the polysulfone membrane was cut to a size of 14×14 cm and soaked in deionized water for 12 h. After soaking, immerse in 0.5 wt% NaOH aqueous solution, and keep in a constant temperature water bath at 50 °C for 1 h. Then the membrane was taken out and washed with deionized water until neutral. Drain the pretreated basement membrane with deionized water, seal it in a ziplock bag and store it in the refrigerator for later use;

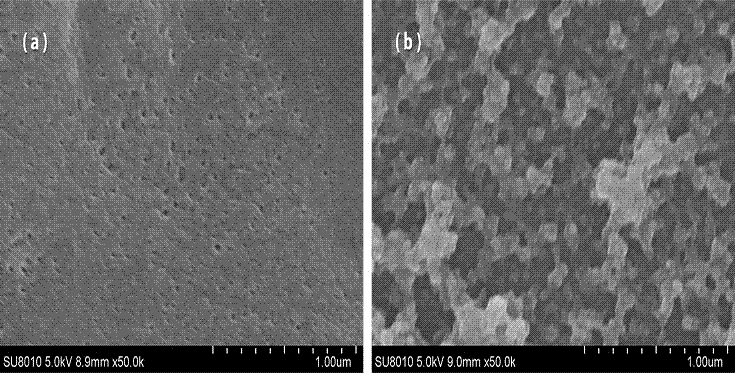

[0031] Self-assembly of the polyelectrolyte composite layer: the four corners of the polysulfone base membrane were fixed on the bottom of the culture dish with waterproof tape, and the base membrane was cleaned with deionized water. Pour an appropriate amount of 0.15 wt% PEI solution into the Petri dish and let it stand for 30 min. Pour out the PEI solution and rinse it several times with deionized water to remove excess polyelectrolyte adsorbed by weak force on the surface of the membrane. Then pour abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com