Dialysis/adsorption difunctional nanofiber composite-based hemodialysis membrane and preparation method thereof

A nanofiber membrane and nanofiber technology, applied in dialysis systems, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as difficult liquid matrix, difficult to recycle, secondary pollution, etc., achieve good adsorption and realize scale The effect of chemical production and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

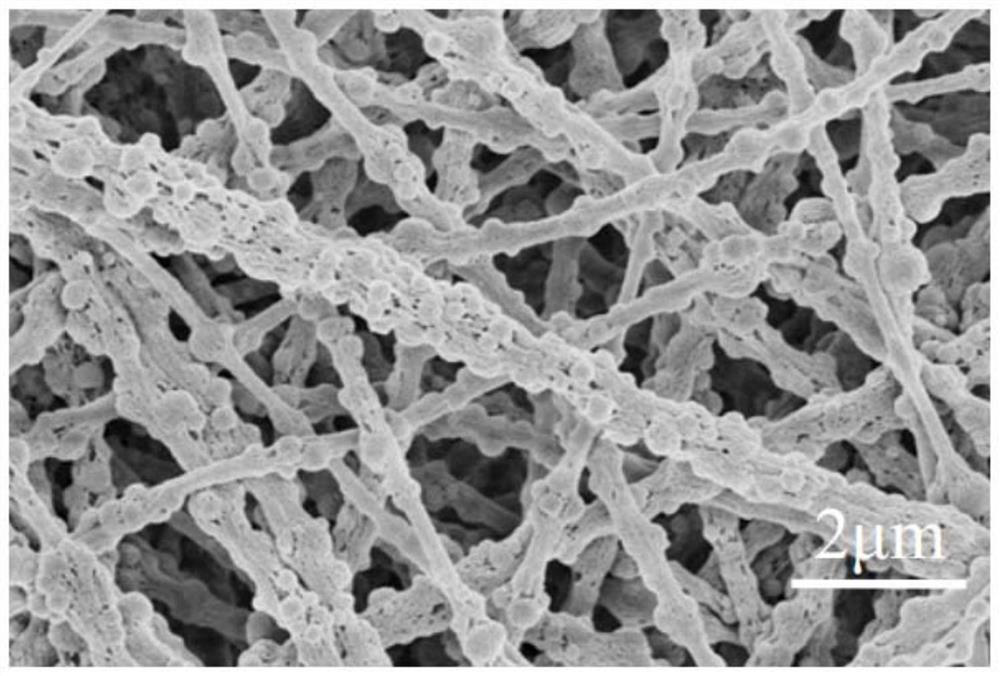

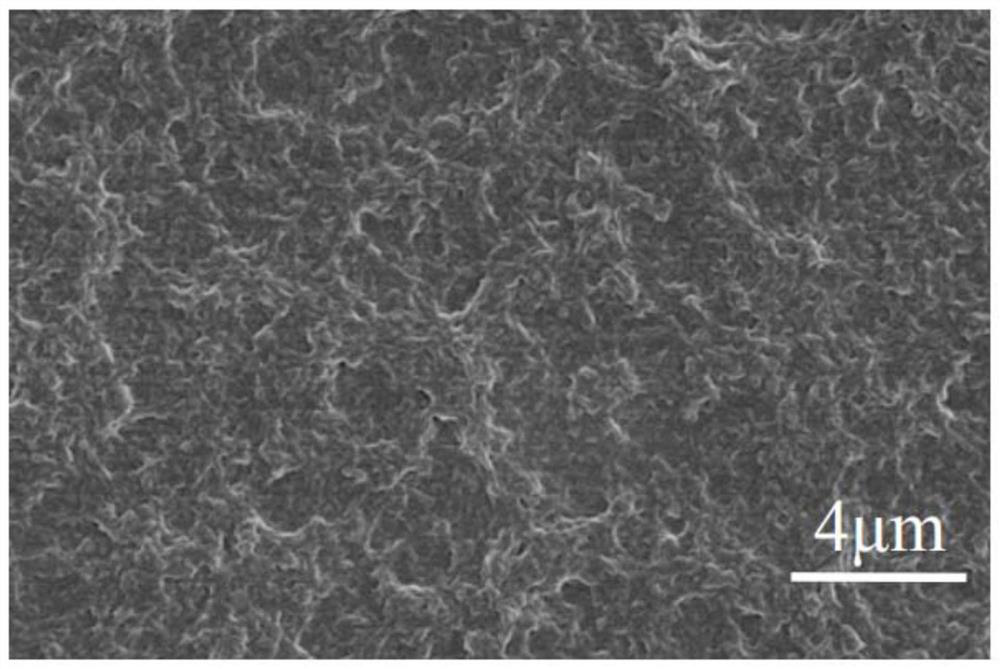

[0027] A dialysis / adsorption dual-functional nanofiber composite-based hemodialysis membrane, which sequentially includes polyvinyl alcohol hydrogel cortex and UiO-66-(COOH) 2 The nanofibers adsorb the nanoparticles to the support layer. The thickness of the polyvinyl alcohol hydrogel layer is about 0.6 μm; the thickness of the nanofiber adsorption support layer is about 100 μm, and the porosity is 75%.

[0028] The preparation steps of the dialysis / adsorption bifunctional nanofiber composite-based hemodialysis membrane include:

[0029] Step 1: Weigh 5.08g of pyromellitic acid and 4.86g of zirconium tetrachloride and dissolve them uniformly in a mixed solution of water and acetic acid, wherein water is 120mL and acetic acid is 80mL. After ultrasonication for 20 min, it was transferred to an oil bath, and heated and stirred at 100 °C for 24 h to obtain white powder UiO-66-(COOH) 2 . Finally, the resulting UiO-66-(COOH) 2 The powder was washed three times with anhydrous met...

Embodiment 2

[0034] A dialysis / adsorption dual-functional nanofiber composite-based hemodialysis membrane, which sequentially includes polyvinyl alcohol hydrogel cortex and UiO-66-(COOH) 2 The nanofibers adsorb the nanoparticles to the support layer. The thickness of the polyvinyl alcohol hydrogel layer is about 0.6 μm; the thickness of the nanofiber adsorption support layer is about 120 μm, and the porosity is 80%.

[0035] The preparation steps of the dialysis / adsorption bifunctional nanofiber composite-based hemodialysis membrane include:

[0036] Step 1: Weigh 4.06g of pyromellitic acid and 3.89g of zirconium tetrachloride and dissolve them uniformly in a mixed solution of dehydration and acetic acid, wherein water is 96mL and acetic acid is 64mL. After ultrasonication for 20 min, it was transferred to an oil bath and heated at 100 °C for 24 h to obtain white powder UiO-66-(COOH) 2 . Finally, the resulting UiO-66-(COOH) 2 The powder was washed three times with anhydrous methanol, s...

Embodiment 3

[0041] A dialysis / adsorption dual-functional nanofiber composite-based hemodialysis membrane, which sequentially includes polyvinyl alcohol hydrogel cortex and UiO-66-(COOH) 2 The nanofibers adsorb the nanoparticles to the support layer. The thickness of the polyvinyl alcohol hydrogel layer is about 0.6 μm; the thickness of the nanofiber adsorption support layer is about 150 μm, and the porosity is 80%.

[0042] The preparation steps of the dialysis / adsorption bifunctional nanofiber composite-based hemodialysis membrane include:

[0043] Step 1: Weigh 4.06g of pyromellitic acid and 3.89g of zirconium tetrachloride and dissolve them uniformly in a mixed solution of water and acetic acid, wherein water is 96mL and acetic acid is 64mL. After ultrasonication for 20 min, it was transferred to an oil bath and heated at 100 °C for 24 h to obtain white powder UiO-66-(COOH) 2 . Finally, the resulting UiO-66-(COOH) 2 The powder was washed three times with anhydrous methanol, soaked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com