Rubidium ion adsorption microsphere and application thereof

A technology for adsorbing microspheres and rubidium ions, applied in the field of composite materials, can solve the problems of restricting the popularization and application of the rubidium ion exchange adsorption method, poor molding effect and mechanical properties, poor swelling resistance and mechanical properties of particles, etc. , excellent mechanical properties, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

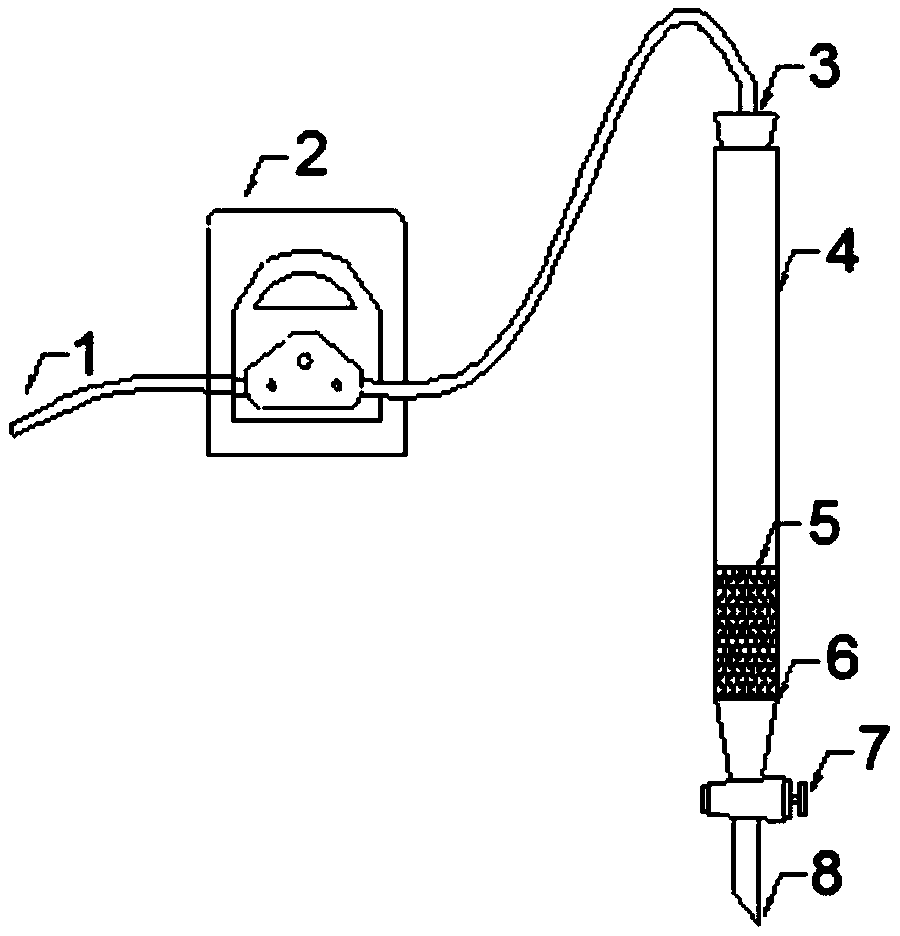

Method used

Image

Examples

Embodiment 1

[0049] A rubidium ion adsorption microsphere, comprising preparing a solution according to the following mass percentages:

[0050]Polyvinyl alcohol 14%, sodium alginate 1.5%, sodium silicate 0.4%, ammonium phosphomolybdate 24.1%, water 60%.

[0051] Among them, add 14% polyvinyl alcohol to the water and heat and stir until it dissolves, then add 1.5% sodium alginate and 0.4% Na 2 SiO 3 , make a mixed solution and cool it below 50°C, add 24.1% ammonium phosphomolybdate and mix evenly;

[0052] In 100mL 50% Na 2 SO 4 Add 15g AlCl to the solution 3 (solid), obtain mixed cross-linking agent solution;

[0053] Use a microcapsule granulator to drop the above mixed solution into the mixed crosslinking agent solution to obtain yellow spherical particles with a diameter of 2-4mm, soak and age them for 24 hours, wash and dry to obtain rubidium ions Adsorbed microspheres.

Embodiment 2

[0055] A rubidium ion adsorption microsphere, comprising the following raw materials in mass percentage:

[0056] Polyvinyl alcohol 10%, sodium alginate 1%, graphene oxide 1%, ammonium phosphomolybdate 45%, water 43%;

[0057] Among them, 10% polyvinyl alcohol is added to the water, heated and stirred until dissolved, then 1% sodium alginate and 1% graphene oxide are added to make a mixed solution, cooled to below 50°C, and 45% ammonium phosphomolybdate is added to mix Uniform;

[0058] Prepare 500mL of 1.5% AlCl respectively 3 , 500mL50%Na 2 SO 4 Obtain cross-linking agent solution;

[0059] Utilize the microcapsule granulator to drop the above mixed solution into the AlCl 3 In the cross-linking agent solution, yellow spherical particles with a diameter of 2-5 mm were obtained, which were taken out after aging for 1 hour and then immersed in Na 2 SO 4 Cross-linking in solution, aging for 24 hours, washing with water and drying to prepare rubidium ion adsorption microsp...

Embodiment 3

[0061] A rubidium ion adsorption microsphere, comprising the following raw materials in mass percentage:

[0062] Polyvinyl alcohol 6%, sodium alginate 0.8%, graphene oxide 1.5%, ammonium phosphomolybdate 60%, water 31.7%

[0063] Among them, add 6% polyvinyl alcohol to the water, heat and stir until it dissolves, then add 0.8% sodium alginate and 1.5% graphene oxide to make a mixed solution, cool it below 50°C, add 60% ammonium phosphomolybdate and mix well ;

[0064] In 100mL 50% Na 2 SO 4 Add 15g AlCl to the solution 3 (solid), obtain mixed cross-linking agent solution;

[0065] Use a needle to drop the above mixed solution into the prepared crosslinking agent solution to obtain yellow spherical particles with a diameter of 1.0-2.0mm, soak and age them for 24 hours, wash and dry to obtain rubidium ion adsorption Microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com