Patents

Literature

72 results about "Ammonium phosphomolybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium phosphomolybdate is the inorganic salt of phosphomolybdic acid with the chemical formula (NH₄)₃PMo₁₂O₄₀. It contains the phosphomolybdate ion complex.

Self-lubricating chromium-free passivator and preparation method thereof

ActiveCN104451638AAvoid harmSimple processMetallic material coating processesChromium freeCerium nitrate

The invention belongs to the technical field of inorganic-organic composite materials and particularly discloses a self-lubricating chromium-free passivator and a preparation method thereof. The self-lubricating chromium-free passivator per liter comprises the following components: 20-100g of a mixture of cerium nitrate and ammonium phosphomolybdate, 5-50g of a coalescing agent, 6-20g of a lubricant, 20-40g of silica sol, 5-10g of an oxidant, an appropriate amount of a pH adjusting agent and the balance of water, wherein the appropriate amount of the pH adjusting agent is used for adjusting the pH of the self-lubricating chromium-free passivator to 1. By the passivator having self-lubricating property disclosed by the invention, the problem of the environmental pollution caused by hexavalent chromium contained in the hexavalent chromium passivator is solved, the passivated steel plate does not need to be subjected to lubrication treatment during press molding and furthermore, the steel plate subjected to press molding can be directly coated, and thus the steps during the galvanized sheet processing and application are decreased.

Owner:武汉迪赛新材料有限公司

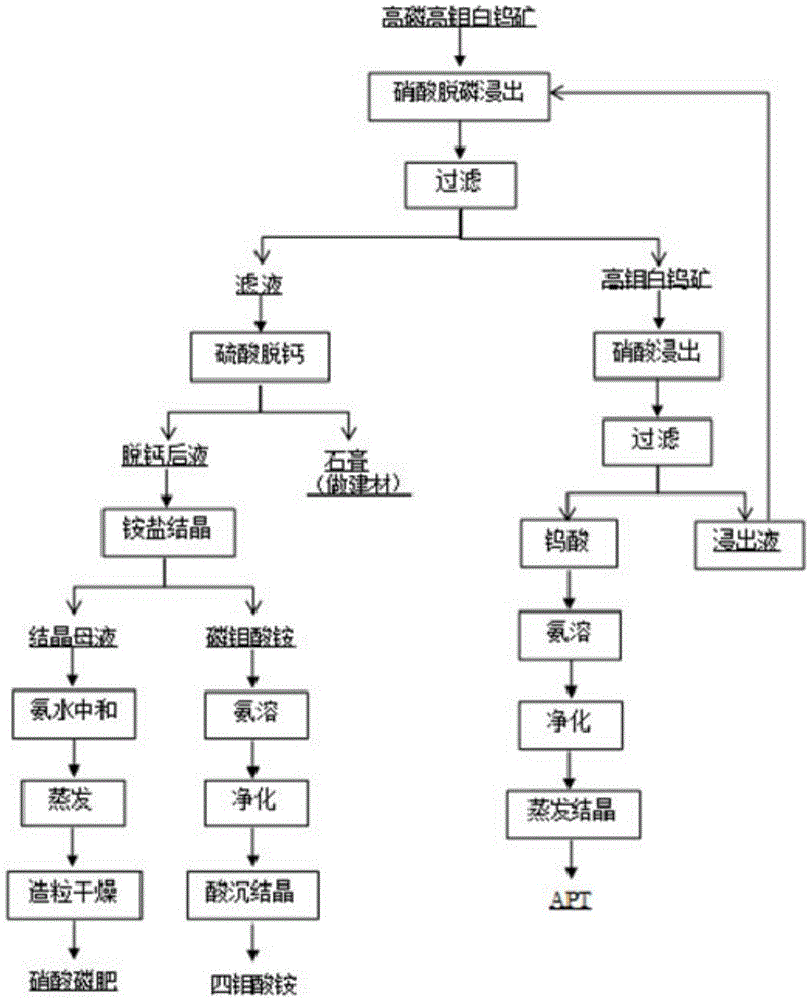

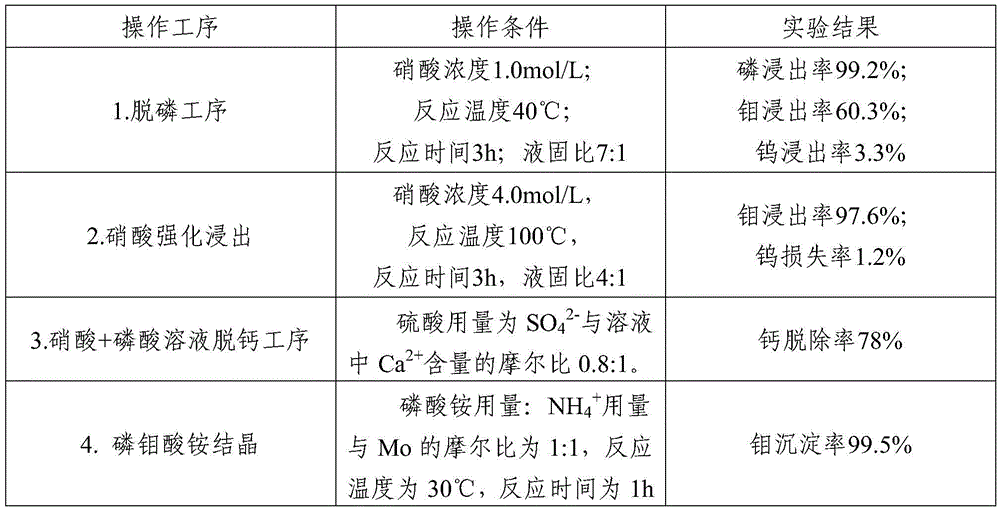

Treatment method for high-phosphorus high-molybdenum complex scheelite

The invention discloses a treatment method for high-phosphorus high-molybdenum complex scheelite. The treatment method includes the following steps that phosphorus minerals in the high-phosphorus high-molybdenum scheelite are selectively leached out through nitric acid, and through filtration, a mixed solution of the high-molybdenum scheelite and phosphoric acid nitric acid containing molybdenum is obtained; sulfuric acid is added to the solution for decalcification treatment; after decalcification, NH4+ is supplemented into the solution to prepare ammonium phosphomolybdate trihydrate crystals, and the ammonium phosphomolybdate trihydrate crystals are subjected to the working procedures of ammonia neutralization, purification and acid precipitation to prepare ammonium tetramolybdate; crystallized mother liquid is subjected to the working procedures of neutralization, vacuum evaporation, pelletizing and drying to prepare nitric phosphate; the high-molybdenum scheelite subjected to nitric acid intensified leaching dephosphorizing treatment is adopted and tungstic acid obtained through filtration is subjected to ammonium hydroxide solution conversion and purification impurity removal to prepare ammonium paratungstate; and the nitric acid is supplemented into a leaching solution and the dephosphorizing working procedure of the high-phosphorus high-molybdenum scheelite is executed again. By the adoption of the treatment method, the high-phosphorus high-molybdenum complex scheelite can be treated, tungsten, molybdenum and phosphorus in the minerals are comprehensively recycled, treatment equipment is simple, operation is convenient, and industrialization is easy to achieve.

Owner:CENT SOUTH UNIV

Supported composite sulfur phosphide hydrotreatment catalyst, preparation and applications thereof

ActiveCN102989492AThe operation process is simple and convenientLow costMolecular sieve catalystsCatalyst activation/preparationHydrodesulfurizationSulfur

The present invention relates to a supported composite sulfur phosphide hydrotreatment catalyst, preparation and applications thereof. The preparation comprises: respectively dissolving a soluble transition metal salt and a soluble alkali in water, and mixing the obtained two solutions; placing the obtained filter cake in deionized water, adding H3PO2 or a H3PO2 solution in a dropwise manner until precipitate is completely dissolved, and adding a complexing agent and a transition metal salt to the obtained solution; or dissolving a transition metal salt, a phosphorus source and a complexing agent in water; or dissolving a transition metal salt, ammonium phosphomolybdate or ammonium phosphotungstate, and a complexing agent in water; or dissolving hypophosphite containing Ni or Co, a transition metal salt and a complexing agent in water; adding the prepared clear solution to a carrier, and drying to obtain a precursor; and carrying out pre-sulfurization on the precursor to obtain the catalyst. The catalyst has good performances of hydrogenation desulfurization, denitrification and dearomatization, and has characteristics of simple operation process, low cost and no requirement of high temperature. In addition, the catalyst can be combined with the traditional catalyst to effectively use the existing equipment so as to achieve industrialization.

Owner:PETROCHINA CO LTD

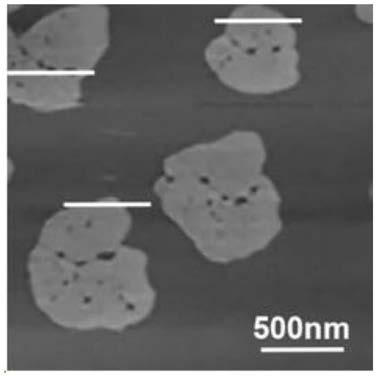

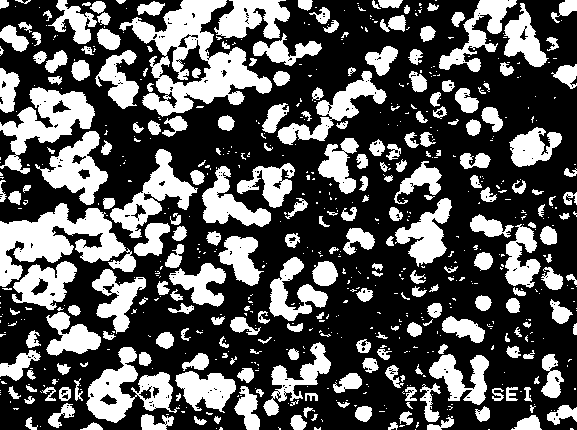

Preparation method and application of core-shell hollow structured MoO3 @ mSiO2 microspheres

ActiveCN103433027AHigh esterification rateNot corrosiveMaterial nanotechnologyOrganic compound preparationDispersityMicrosphere

The invention discloses a preparation method of MoO3 @ mSiO2 microspheres, belonging to the technical field of nano material preparation. The preparation method comprises the following steps: through taking hexadecyl trimethyl ammonium phosphomolybdate as a core, coating the core with a layer of SiO2 by using a sol gel method, and then calcining the obtained product so as to obtain a core-shell hollow structured MoO3 @ mSiO2 microsphere. The MoO3 @ mSiO2 microsphere is good in dispersity, has a particle size of 200-900 nm and is of a hollow core-shell structure, the core is MoO3, and a shell is porous SiO2. The microsphere has a good catalytic effect on an esterification reaction between acetic acid and butanol for synthesizing butyl acetate; and under the reaction conditions that the reaction temperature is 150 DEG C, the molar ratio of acetic acid to butanol is 1:5, the application amount of a catalyst accounts for 36% of the mass of the acetic acid and the reaction time is 3h, the esterification rate of the acetic acid can reach 93.8%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

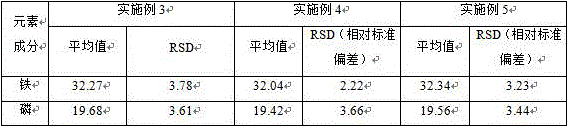

Fluorescence analysis method for measuring element content of lithium iron phosphate

InactiveCN105842266AFast detection methodEasy to operateMaterial analysis using wave/particle radiationEnvironmental resistanceX-ray

The invention discloses a fluorescence analysis method for measuring element content of lithium iron phosphate. The method comprises the following steps: equally dividing a lithium iron phosphate sample into three parts; processing a first part of the lithium iron phosphate sample by the use of hydrochloric acid, filtering and carrying out standard solution titration with potassium dichromate, and measuring content of iron element; processing the second part of the lithium iron phosphate sample by the use of hydrochloric acid, filtering and measuring content of phosphorus element by an ammonium phosphomolybdate volumetric method; preparing six standard samples with different contents from the third part of the lithium iron phosphate sample; respectively compressing into flaky pieces, and measuring fluorescence intensity of iron and phosphorus elements in each flaky standard sample by X-ray fluorescence spectrometry; drawing an XRF standard curve; compressing the lithium iron phosphate sample to be measured into flaky pieces, and measuring fluorescence intensity; and obtaining iron and phosphorus contents through the XRF standard curve. The method of combining a wet chemistry method and an X-ray fluorescent spectrometry is fast and high-speed, is simple to operate, has little error and long consumption time, and is environmentally friendly.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Novel long-acting coolant

InactiveCN104673200AReduce lossEliminate pollutionHeat-exchange elementsOctanoic AcidsPolyvinyl alcohol

The invention discloses a novel long-acting coolant which is prepared from the following raw materials in parts by weight: 25-50 parts of ethylene glycol, 10-15 parts of sorbitol, 5-10 parts of ammonium phosphomolybdate, 3-6 parts of tetramethyl orthosilicate, 2-6 parts of decanedioic acid, 3-7 parts of octanoic acid, 4-8 parts of sodium citrate, 3-5 parts of castor oil triethanolamine, 7-10 parts of sodium nitrate, 1-8 parts of sodium nitrate, 2-7 parts of polyvinyl alcohol, 3-7 parts of tall oil, 4-7 parts of molybdate, 4-8 parts of organosilicate, 1-5 parts of succinic acid, 2-6 parts of undecanoic acid and 3-7 parts of sodium benzoate. The novel long-acting coolant has the advantages of reasonable formula, high corrosion resistance and favorable storage stability.

Owner:QINGDAO KERUN PLASTIC MACHINERY

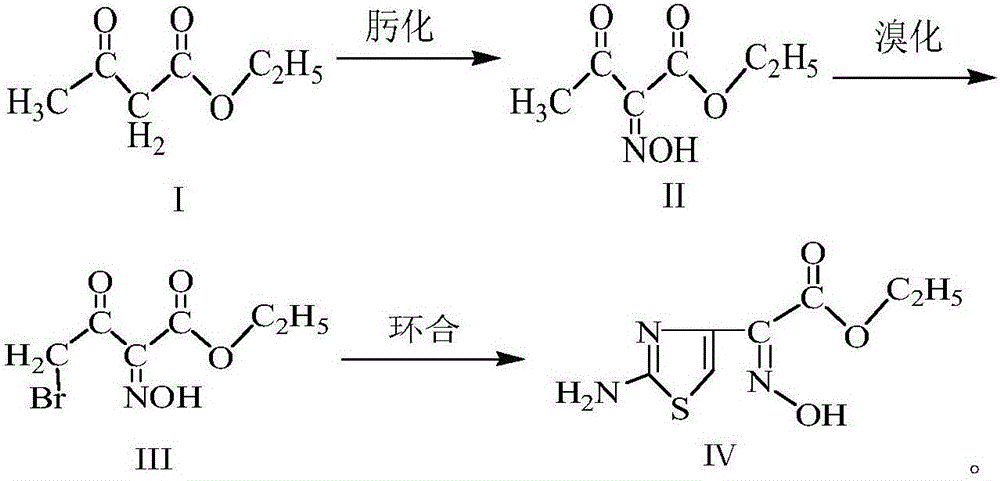

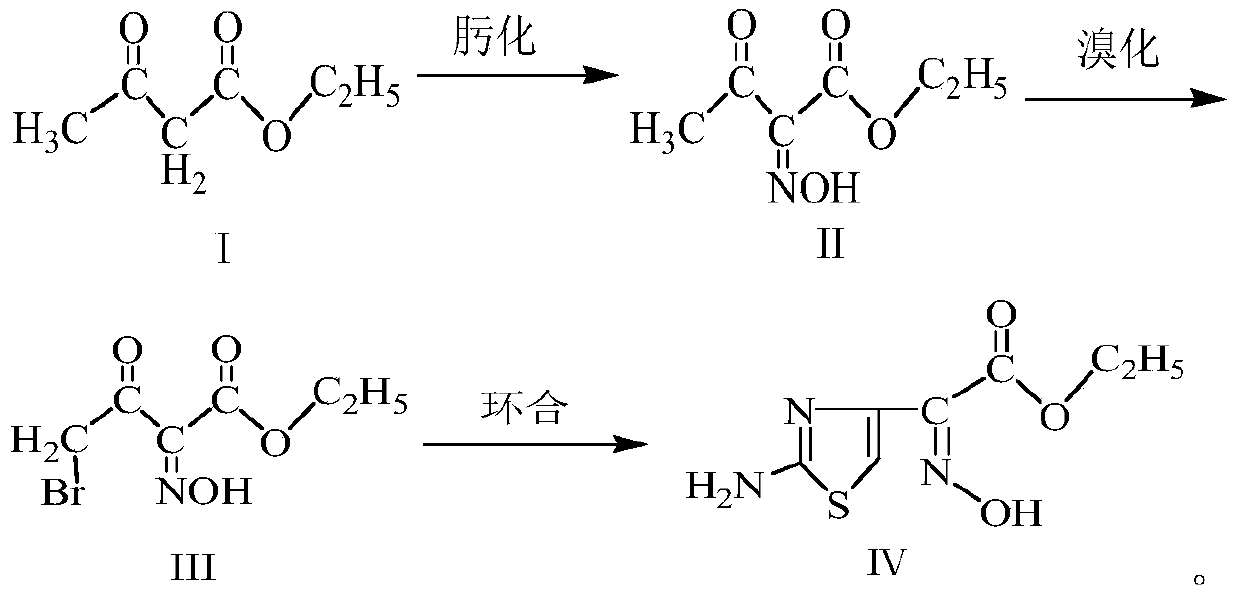

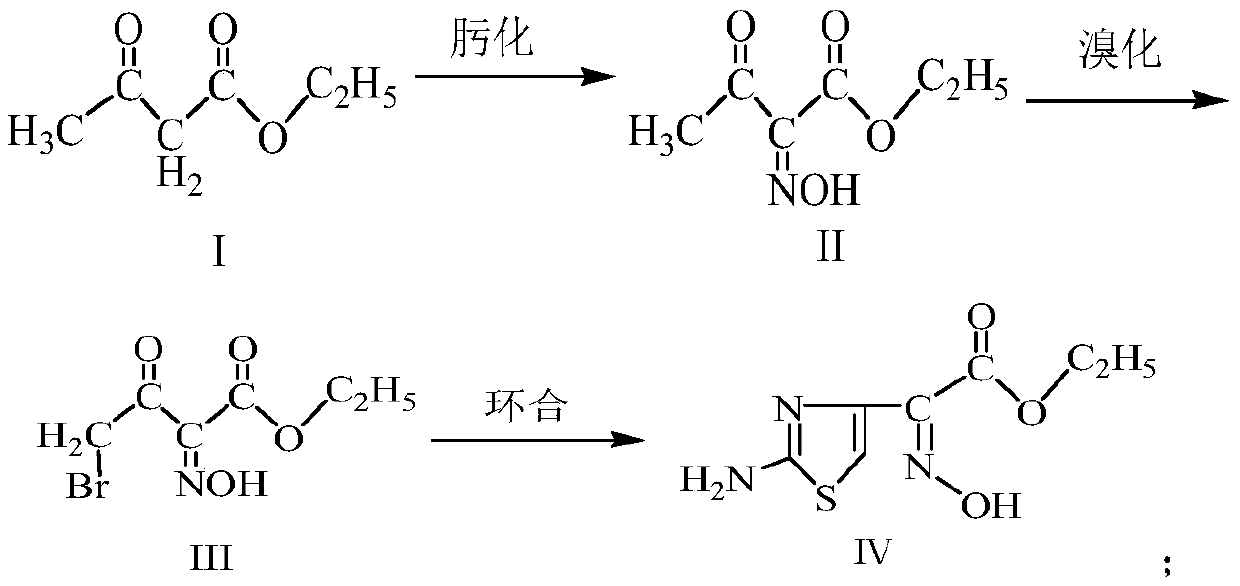

Method for synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate

The invention relates to a method for synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate, and belongs to the technical field of the preparation of antibiotic drug intermediates. The method provided by the invention comprises the following steps: using ethyl acetoacetate, sodium nitrite and concentrated sulfuric acid as raw materials; using purified water as a solvent; performing oximation reaction first, and then performing halogenation reaction; then adding thiourea; using 12-ammonium phosphomolybdate (AMP) as the catalyst, and using methanol as a solvent to perform cyclization reaction, thereby obtaining ethyl2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate. The method provided by the invention is simple in process, shortens the reaction cycle, increases the reaction yield, and reduces corrosion to equipment; the used catalyst is separated from the product easily and can be reused, thereby reducing the production cost, greatly reducing the 'three wastes' pollution, and having an extremely high industrial application value.

Owner:YIYUAN XINQUAN CHEM

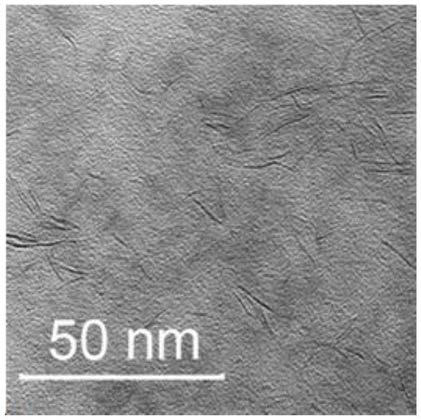

Liquid phase synthesis method of ultra-thin molybdenum diselenide nanosheet

InactiveCN109626340AUniform and flat shapeMild conditionsNanotechnologyMetal selenides/telluridesSelenium methionineSynthesis methods

The invention provides a liquid phase synthesis method of an ultra-thin molybdenum diselenide nanosheet, which comprises the following steps of: mixing a molybdenum source, a selenium source and organic amine, and removing impurities to obtain a mixed solution; reacting the mixed solution at 240-300 DEG C for 20-60min to obtain an ultra-thin molybdenum diselenide nanosheet; wherein the molybdenumsource is selected from one or more of ammonium molybdate, sodium molybdate, ammonium phosphomolybdate, molybdenum trioxide, oxymolybdenum acetylacetonate and molybdenum acetate; the selenium source is selected from one or more of selenium powder, selenium methionine and dibenzyl diselenium. According to the invention, a precursor source (a molybdenum source and a selenium source) of a specific kind and an organic amine solvent are selected to promote spreading to form an ultra-thin molybdenum diselenide nanosheet with a large area and an uniform and smooth appearance; the raw materials are common raw materials, the conditions are mild, and the method is simple; the method has short preparation period and high yield. The nanosheet has a single-layer or several-layer morphology. That the molybdenum diselenide is a coexistent phase of 1T phase and 2H phase, which can be seen from a photoelectron spectrogram and a high-angle annular dark field image and is beneficial to the improvement ofthe conductivity.

Owner:UNIV OF SCI & TECH OF CHINA

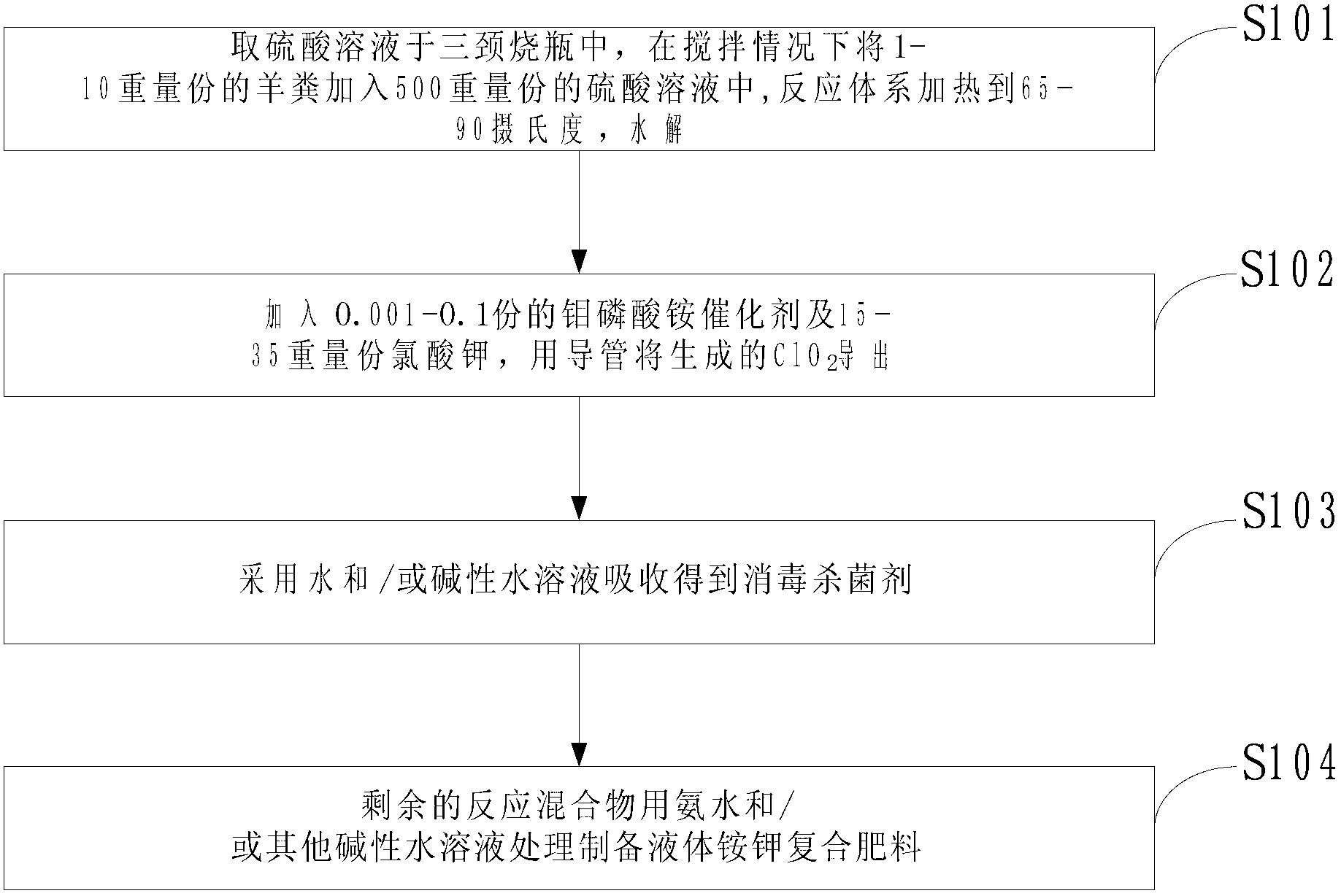

Method for preparing sanitizer and liquid ammonium-potassium compound fertilizer from sheep manure

InactiveCN103300062ARealize comprehensive utilizationMild reaction conditionsBiocideClimate change adaptationPotassiumAmmonium phosphomolybdate

The invention discloses a method for preparing a sanitizer and liquid ammonium-potassium compound fertilizer from sheep manure. The method comprises the following steps of: firstly, placing a sulfuric acid solution in a three-necked flask, adding 1-10 parts of sheep manure by weight in 500 parts of the sulfuric acid solution by weight under a stirring condition, heating a reaction system to 65-90 DEG C and implementing hydrolyzation; secondly, adding 0.001-0.1 part of ammonium phosphomolybdate hydrate and 15-35 parts of potassium chlorate by weight and leading out generated ClO2 by a conduit; thirdly, implementing absorption by water and / or an alkaline aqueous solution to obtain the sanitizer; and thirdly, treating the remaining reaction mixture by ammonia water and / or other alkaline aqueous solutions to prepare the liquid ammonium-potassium compound fertilizer, wherein the reaction time is longer than 80 minutes. Environment pollution caused by the sheep manure is eliminated through the method. Besides, the method has significance for developing featured agriculture and a deep processing industry of agricultural and sideline products, and extending an agricultural production chain.

Owner:HENAN UNIV OF URBAN CONSTR

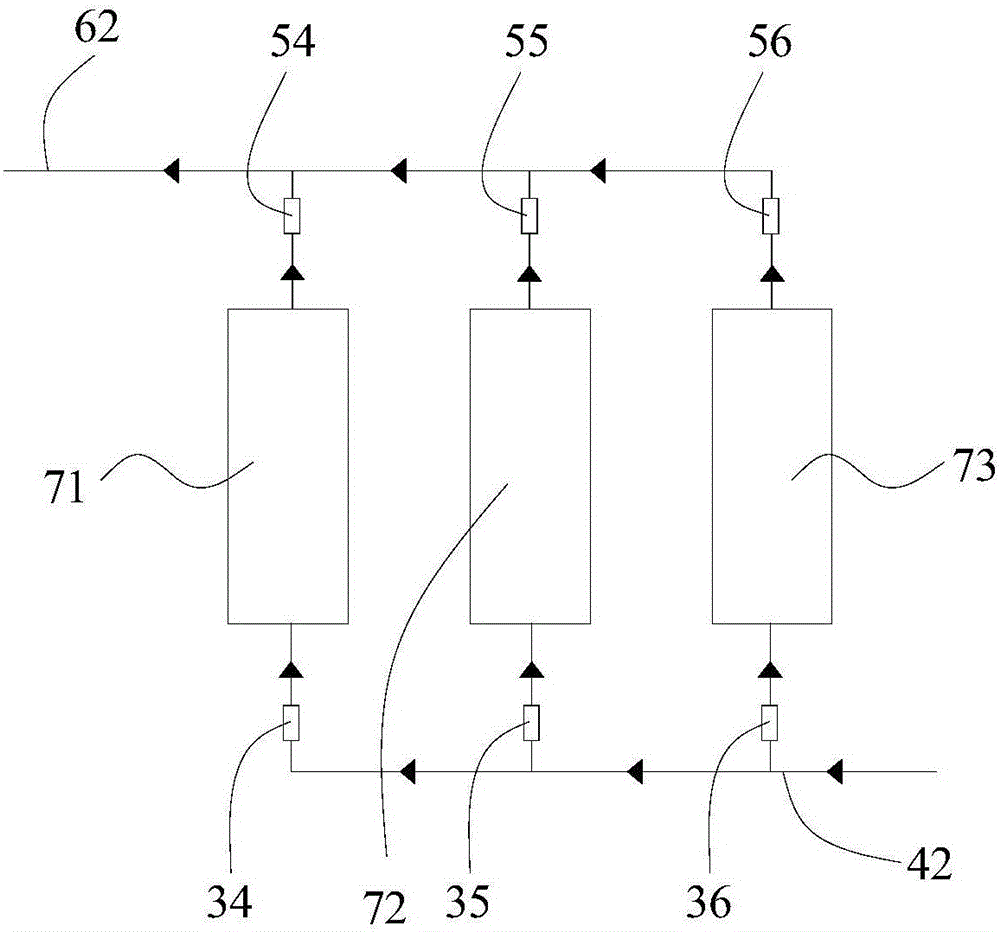

Compound adsorbent for absorbing rubidium ions as well as preparation method and application of compound adsorbent

ActiveCN105664845AEasy to prepareRaw materials are cheap and easy to getOther chemical processesWater contaminantsRefluxSorbent

The invention discloses a preparation method of a compound adsorbent for absorbing rubidium ions. The preparation method comprises the following steps: (A) providing activating zeolite; (B) processing the activating zeolite into alkylated zeolite by virtue of a silane coupling agent; and (C) dissolving ammonium phosphomolybdate into an oxidant to obtain a first mixture, adding the alkylated zeolite into the first mixture, carrying out boiling reflux for at least 8 hours, filtering to obtain a first filter residue and first filtrate, and drying the first filter residue, so as to obtain the compound adsorbent. The invention further discloses the compound adsorbent prepared by virtue of the preparation method and application of the compound adsorbent in the absorption of the rubidium ions. The compound adsorbent has good selective adsorbability, and furthermore, the preparation method is simple; meanwhile, by applying the compound adsorbent to the absorption of the rubidium ions, the continuous stable absorption-elution operation can be realized.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

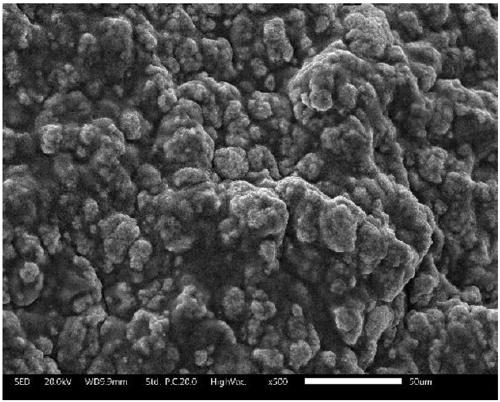

Preparation method for ammonium phosphomolybdate composite gel adsorption material

InactiveCN109289754AReduce clumpingReduce crosslink densityOther chemical processesAlkali metal oxides/hydroxidesMechanical stabilityDistilled water

The invention discloses a preparation method for an ammonium phosphomolybdate composite gel adsorption material. The preparation method comprises the following steps: (1) dissolving sodium alginate and PG in deionized water under the condition of heating, and carrying out uniform and complete stirring; (2) adding an ultrasonically-dispersed ammonium phosphomolybdate aqueous solution into an obtained mixed solution, and carrying out uniform mixing under complete stirring; (3) adding the above-mentioned mixed solution into a boric acid solution of calcium ions in a dropwise manner by using an injection syringe so as to form a composite gel; and (4) separating, carrying out complete washing with distilled water, and carrying out drying so as to obtain a composite gel adsorption material. Thecomposite gel adsorption material provided by the invention has the advantages of simple preparation process, low cost, good permeability, acid-alkali tolerance, adsorption selectivity, mechanical stability and recyclability, and capability of being extensively applied to comprehensive development and utilization of salt lake brine and geothermal water resources.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Preparation method of porous AMP/CNC-PUF adsorption material and application thereof

The invention relates to a preparation method of a porous AMP / CNC-PUF adsorption material and an application thereof and belongs to the fields of nano composite materials and environmental pollution repair. In order to overcome the technical defects that in the prior art, ammonium phosphomolybdate is poor in mechanical strength, hard to form and recover and complex in treatment process if being used for adsorption of radioactive elements, for example, rubidium and caesium, the invention provides the preparation method of the porous AMP / CNC-PUF adsorption material and the application thereof. The adsorption material is prepared by the steps: loading ammonium phosphomolybdate on nano carbon microparticles; and then capsulating the nano carbon microparticles in foamed polyurethane sponge. The treatment process after adsorption is simplified, the adsorption activity part can be fully exposed, and the adsorption efficiency is improved. The prepared composite material for repairing caesium ion polluted environments such as a water body and soil has a wide application prospect in the field of repairing a nuclear polluted environment.

Owner:BINZHOU UNIV

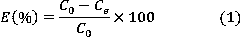

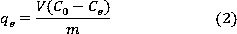

Preparation method of dry powder extinguishing agent containing allophanate

PendingCN113827906AOutstanding fire extinguishing efficiencyFire suppressionFire extinguisherAluminum silicatePhosphoric acid

The invention relates to a preparation method of a dry powder extinguishing agent containing allophanate, and belongs to the technical field of extinguishing materials. The dry powder extinguishing agent is obtained by prefabricating extinguishing components through a mechanochemical method, synthesizing the extinguishing components through a hydrothermal / solvothermal method and then performing surface modification through a modifier. The fire extinguishing components of the fire extinguishing agent comprise potassium allophanate and / or sodium allophanate, and at least two of potassium bicarbonate, sodium bicarbonate, zinc carbonate, zinc borate, zirconium phosphate, manganese hypophosphite, ammonium phosphomolybdate, ammonium molybdate, hexadecyl trimethyl ammonium bromide, urea, ferrocene, molybdenum disulfide, ferric chloride, aluminum silicate and magnesium hydroxide. The prepared dry powder extinguishing agent can absorb heat in a fire scene and release non-combustible gas, a large number of active chemical particles are generated to capture flame free radicals, and the extremely outstanding extinguishing effect is achieved. In addition, through surface modification of the modifier, the dry powder extinguishing agent further has good hydrophobicity and flowability, and storage, transportation and application of the extinguishing agent are better facilitated.

Owner:CIVIL AVIATION UNIV OF CHINA

Preparation method of filter core capable of fast and efficiently adsorbing caesium

ActiveCN103357386AGood water permeabilityResistant to oxidationOther chemical processesPretreated surfacesDecompositionAmmonium phosphomolybdate

The invention discloses a preparation method of a filter core capable of fast and efficiently adsorbing caesium. The preparation method comprises the following steps of based on the weight of a substrate material, adding 1-3wt% of a coupling agent and 1-10wt% of ammonium phosphomolybdate into the substrate material, heating them to a temperature of 160-220 DEG C, uniformly stirring so that the substrate material is coupled with ammonium phosphomolybdate, carrying out filament spraying by micropores of 5 microns, wherein the sprayed filaments form an adsorption filter core having the thickness of 5-50mm on a revolving cylindrical framework material, uniformly coating ammonium phosphomolybdate on an outer surface of the adsorption filter core, and carrying out heating stable-aging at a temperature of 80-120 DEG C for 3-12h. The filter core has good water permeability and oxidation resistance, can be immersed in hot water at a temperature of below 100 DEG C for a long time, can resist irradiation decomposition, has stable adsorption performances, a fast detection rate, high efficiency and high precision, and can determine an adsorption rate without stable cesium measurement.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Composite building decorative material

The invention discloses a composite building decorative material. The material is composed of 20% of brucite, 8% of aluminum hydroxide, 12% of ammonium polyphosphate, 28% of magnesium aluminosilicate, 15% of a flame retardant and 13% of ammonium phosphomolybdate (molybdotungstophosphate). For usage, the above raw materials are mixed, ground and stirred according to routine to obtain a finished product. The product provided by the invention has the technical characteristics of no toxicity, no harm and no fading; the film effectively integrates with the substrate to realize the effects of fire prevention, water prevention, no deformation, smoke resistance, easy cleaning, acid and alkali resistance, no breaking at low temperature, radiation resistance, light weight, high compressive strength, high flexural strength, safety and no toxicity; in addition, the technological operation is simple.

Owner:HARBIN LONGDI BUILDING MATERIAL

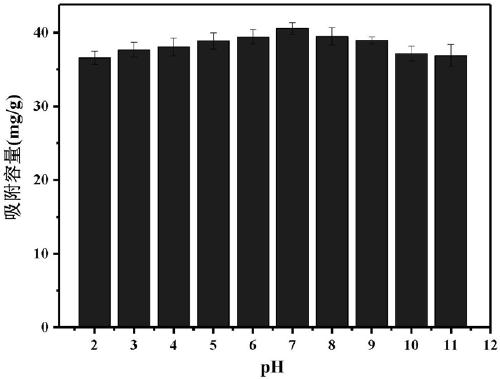

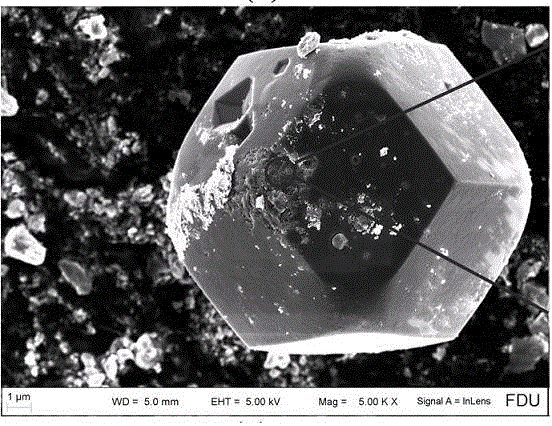

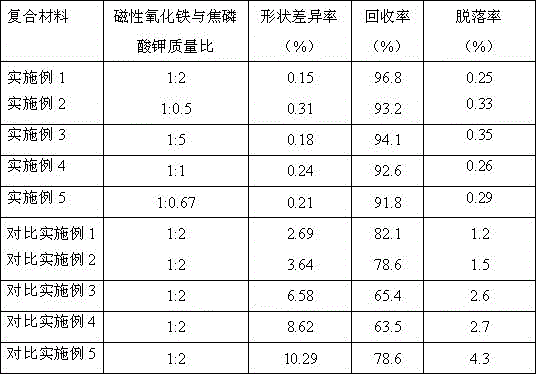

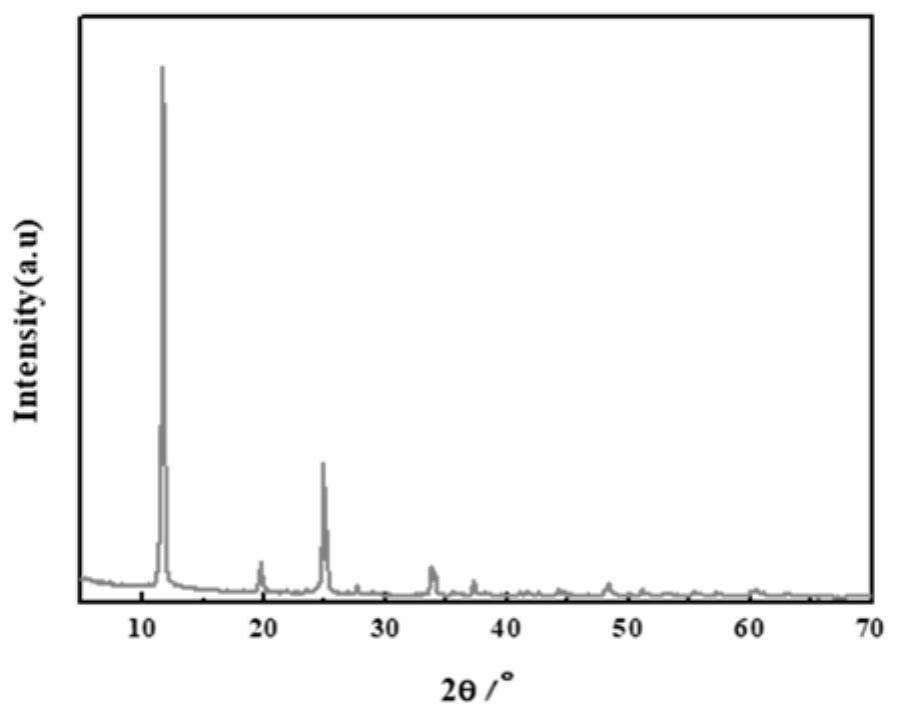

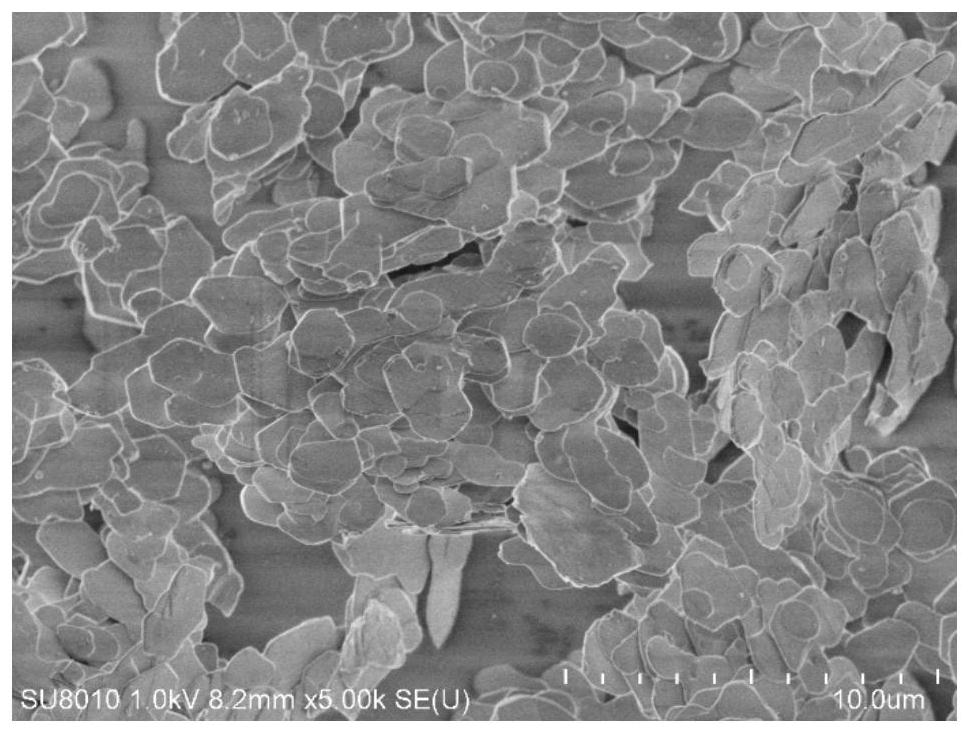

Preparation and application of magnetic ferric oxide/ammonium phosphomolybdate porous composite material

ActiveCN106215906ALarger than surfaceGood dispersionOther chemical processesRadioactive contaminantsNano compositesAmmonium phosphomolybdate

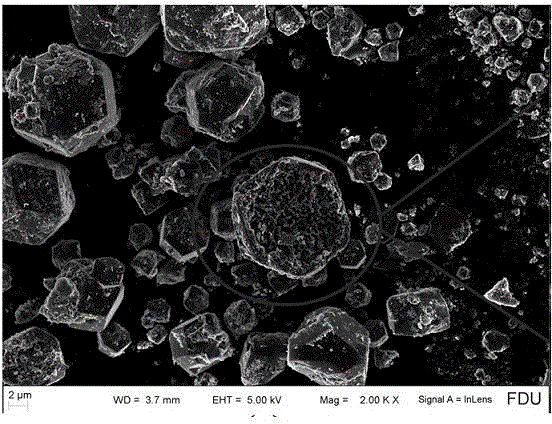

The invention relates to a preparation method of a magnetic ferric oxide / ammonium phosphomolybdate porous composite material and application, and belongs to the fields of nano-composite materials and environmental remediation. According to the preparation method, the prepared magnetic ferric oxide nanoparticles are added in the self-assembling synthesis process of ammonium phosphomolybdate polygonal crystals, the materials are subjected to surface modification, and the magnetic ferric oxide / ammonium phosphomolybdate porous composite material is synthesized finally. In the composite material obtained by the preparation method, the magnetic ferric oxide nanoparticles are inlaid in the porous structures of the ammonium phosphomolybdate polygonal crystals uniformly, so that the magnetic ferric oxide / ammonium phosphomolybdate porous composite material has the magnetic recovery characteristic and the preferential adsorption characteristic of ammonium phosphomolybdate on caesium ions, has low shape difference rate and low falling-off rate during use, and has better application prospect in the fields of nuclear pollution treatment and the like.

Owner:河北久亿有色金属科技有限公司

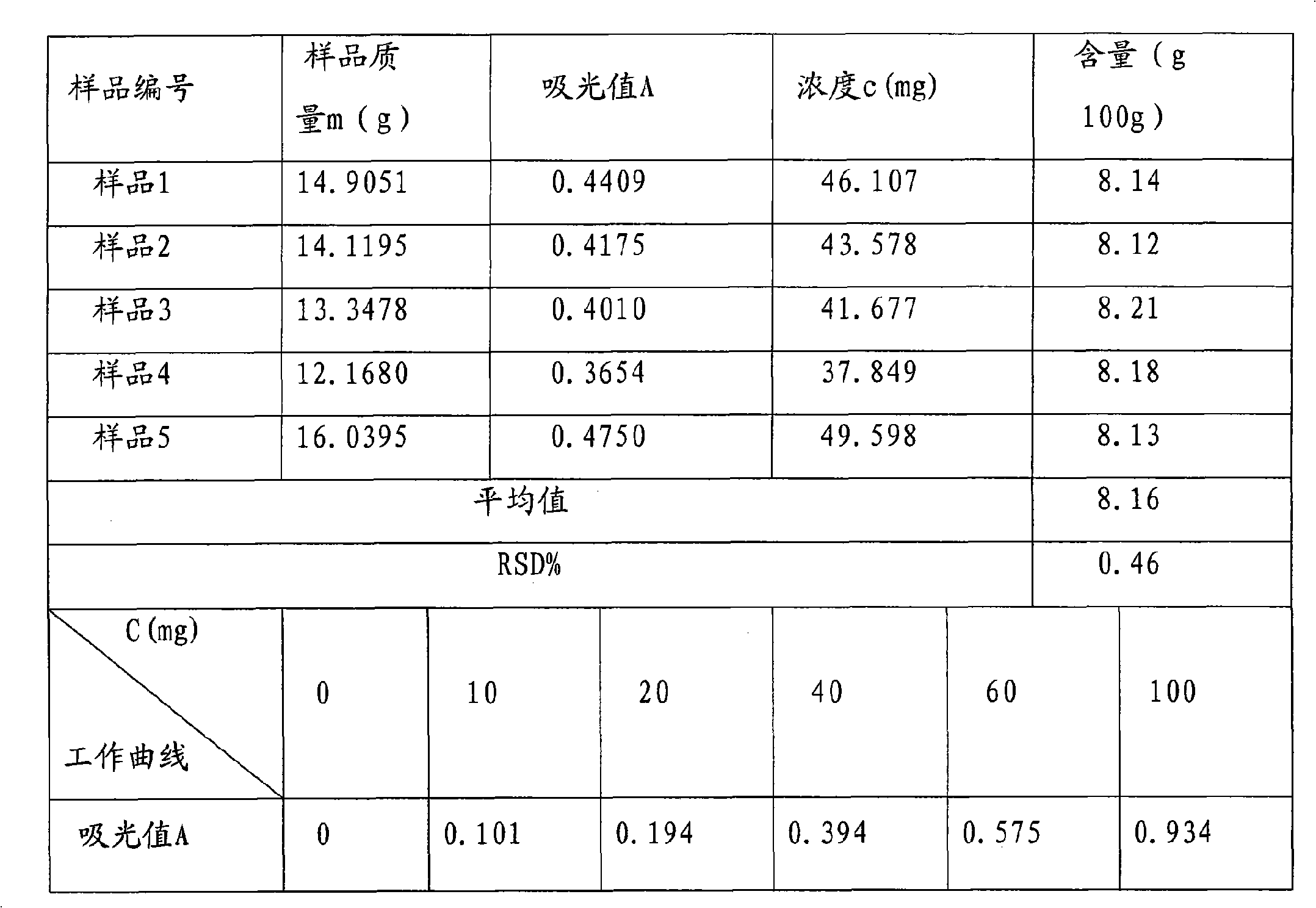

Simple egg lecithin content measuring method

InactiveCN101556241AEfficient extractionMeet testing needsPreparing sample for investigationColor/spectral properties measurementsMolybdenum bluePhospholipid

The invention relates to a simple spectrophotometry lecithin content measuring method for fresh eggs. The principle of the method comprises the following steps of: separating egg yolk from egg white after the fresh eggs are boiled in boiling water and denatured, then thoroughly extracting grease of the egg yolk with anhydrous ether and transforming the lecithin into inorganic phosphorus compound. Ammonium phosphomolybdate is produced in acid condition and becomes blue molybdenum blue by reduction reaction. Color comparison is conducted under 650nm, phosphorus content is measured, and egg lecithin content is finally computed. As to egg products, the direct adoption of the method can meet the demand of analysis and measuring of daily laboratory. The simple egg lecithin content measuring method has the advantages of easy operation, high selectivity, reliable measuring result and being capable of getting rid of the disturbance of inorganic phosphorus of eggs.

Owner:谱尼测试集团股份有限公司

Seawater radionuclide analysis pretreatment method

InactiveCN104215999ANo interference issuesSimple methodRadiation measurementPretreatment methodAmmonium phosphomolybdate

The invention relates to a seawater radionuclide analysis pretreatment method. The method includes 1, adjusting the pH value of the acidity of a seawater sample to range from 1 to 2; 2, adding a mixed carrier into the seawater sample; 3, adding 0.15 to 0.25g ammonium phosphomolybdate and 0.15 to 0.25g ammonium sulfate in the seawater sample per liter; 4, depositing and drying; 5, adjusting the pH value of the acidity of the filtrate to range from 8 to 10; 6, depositing and drying; 7, depositing and combining. According to the mixed carrier, Rho (Cs+)=5 to 7mg / mL, Rho (Co2+)= 18 to 22mg / mL, Rho (Fe3+)=38 to 42mg / mL, Rho (Ba2+)= 38 to 42mg / mL, and Rho (Pb2+)= 38 to 42mg / mL. By the aid of the method, gamma nuclide and total alpha and beta analysis and combined sample preparation can be implemented, the problem of influence by residue is avoided, the method is simple and easy to implement, and the accuracy is improved greatly.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

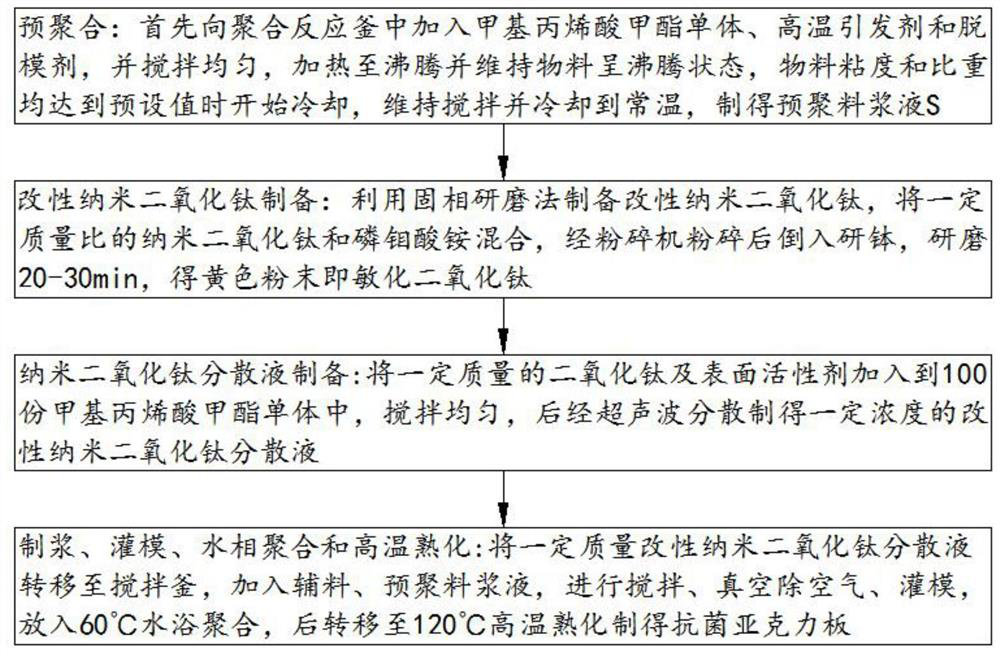

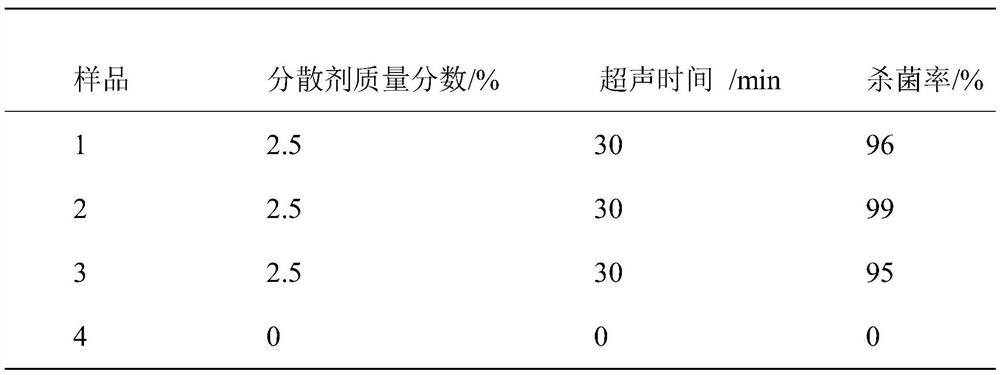

Antibacterial organic glass plate and preparation method thereof

The invention relates to an antibacterial organic glass plate which comprises the following raw materials in percentage: 75-90% of a methyl methacrylate monomer, 0.5-2% of an initiator, 0.5-1% of a release agent, 5-20% of nano titanium dioxide, 0.5-10% of ammonium phosphomolybdate and 1-3% of a surfactant. The antibacterial organic glass plate has the beneficial effects that the antibacterial property of the acrylic plate can be greatly improved by adding the modified nano titanium dioxide in the batching process, the acrylic plate with excellent antibacterial property is obtained, organic matters in bacteria react under the illumination condition, and the titanium dioxide is used as a catalyst to be oxidized to generate CO2 and H2O so as to kill the bacteria; meanwhile, OH and H2O attached to the surface of titanium dioxide are oxidized into. OH. OH which has very strong oxidizing capacity, unsaturated bonds of organic matters are attacked or H atoms are extracted to generate new freeradicals, a chain reaction is excited, and finally bacteria are decomposed. The acrylic plate prepared by adding titanium dioxide is high in sterilization efficiency, free of waste, safe, environmentally friendly and suitable for large-scale production.

Owner:ANHUI XINTAO OPTOELECTRONICS TECH CO LTD

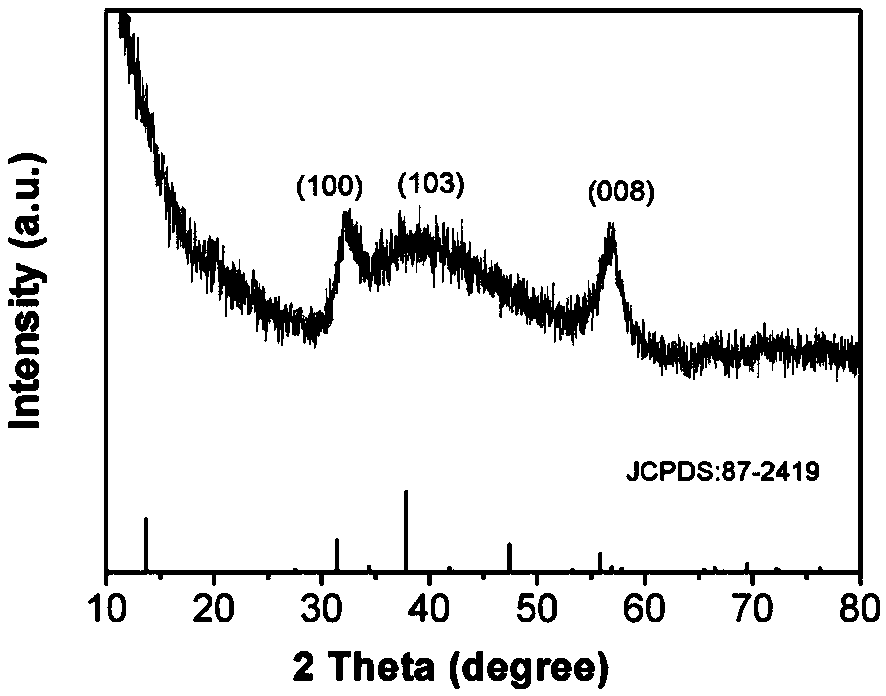

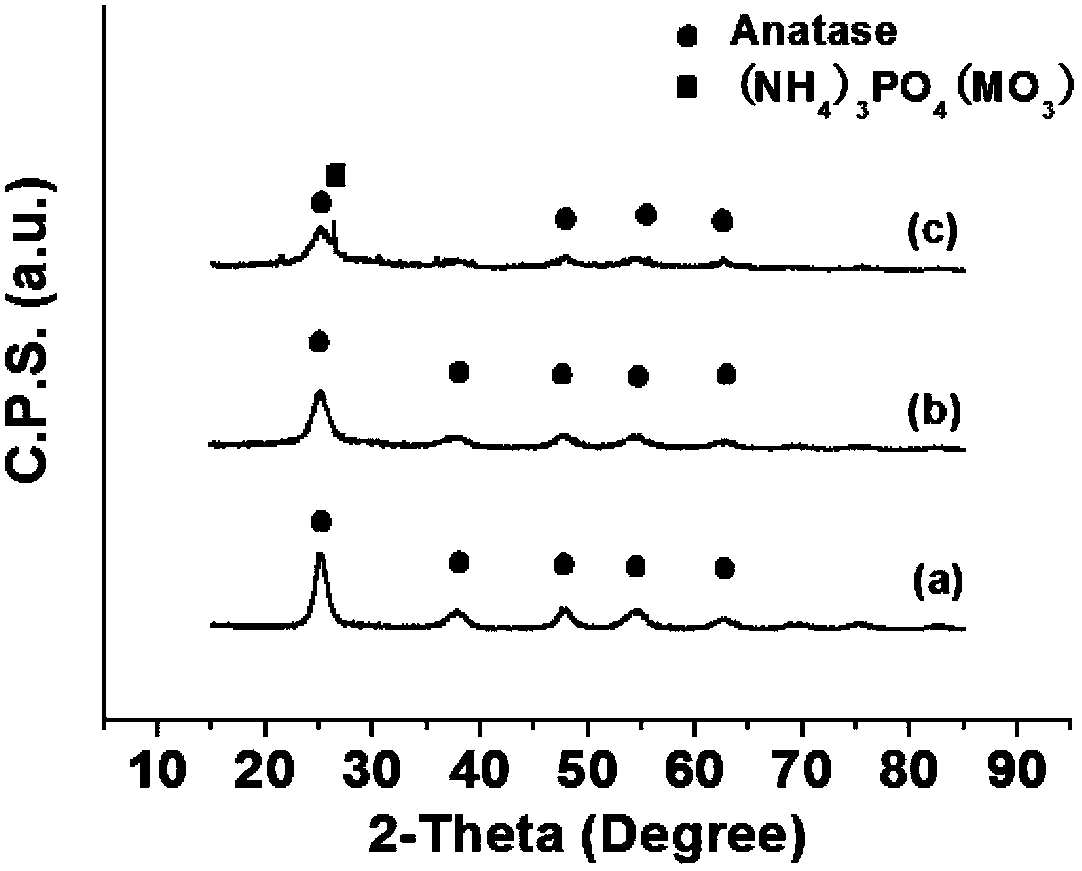

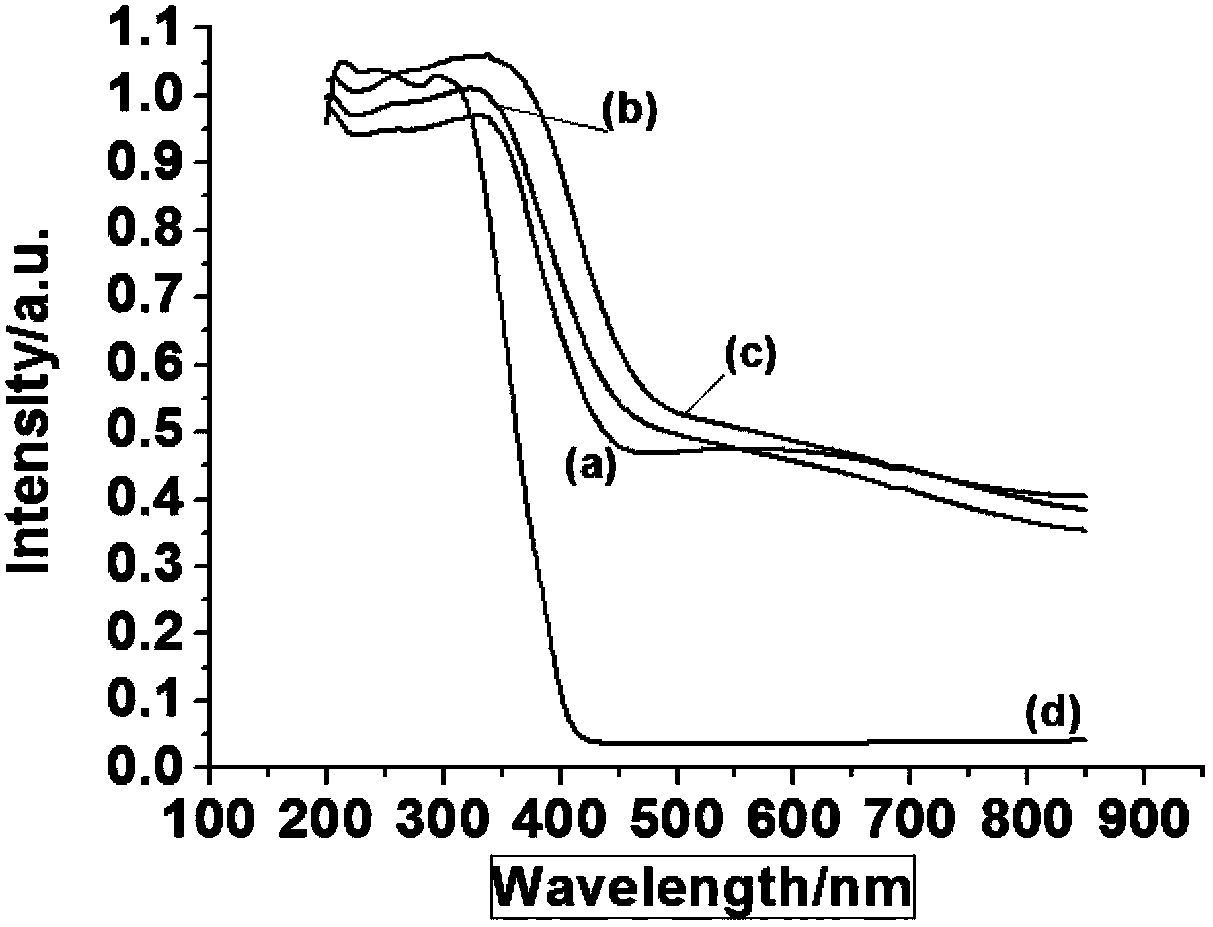

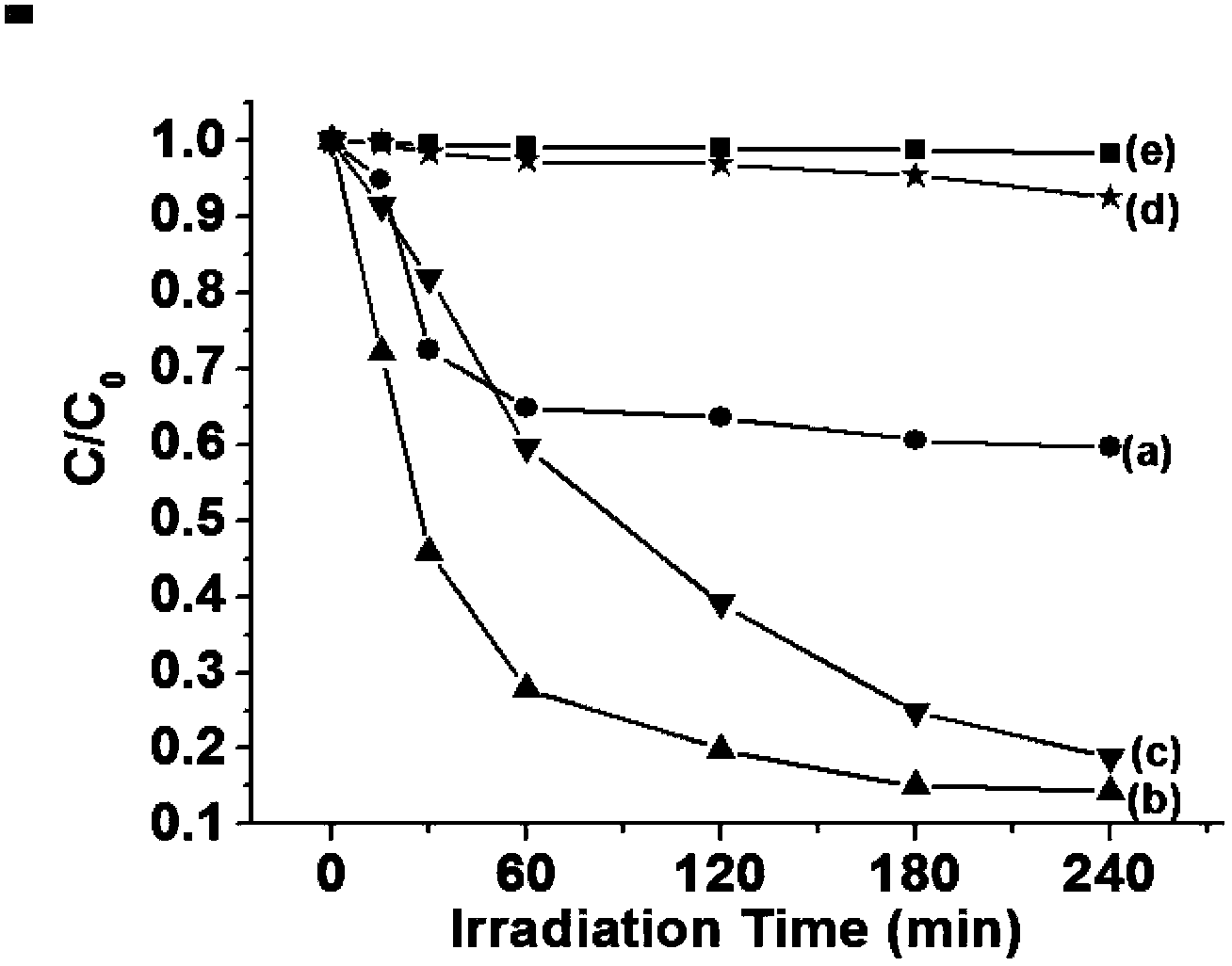

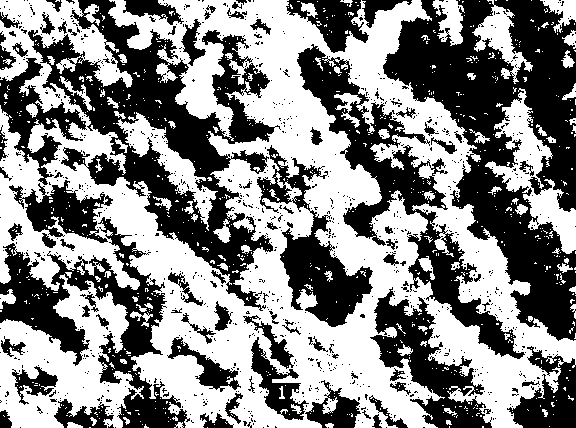

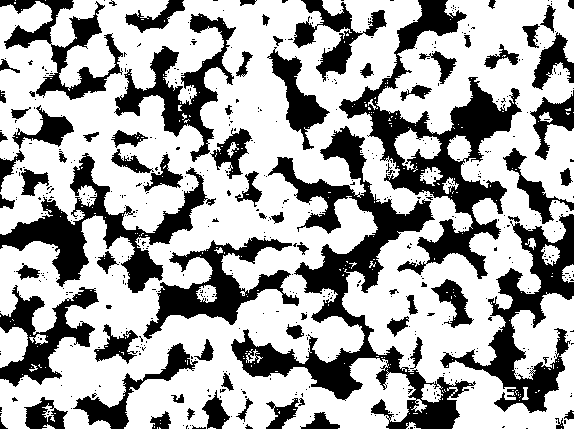

Preparation method of phosphorus, nitrogen and molybdenum ternary codoped nanometer TiO2 photocatalyst

InactiveCN103464188APromote degradationReduce stepsPhysical/chemical process catalystsWater/sewage treatment by irradiationNitrogenOrganic matter

Belonging to the technical field of nanometer photocatalytic materials, the invention discloses a preparation method of a phosphorus, nitrogen and molybdenum ternary codoped nanometer TiO2 photocatalyst. The method takes ammonium phosphomolybdate as a precursor of doping elements, and adopts a sol-gel technique to prepare the phosphorus, nitrogen and molybdenum ternary codoped nanometer TiO2 photocatalyst. Due to proper selection of the doping precursor, the three elements P, N and Mo can be incorporated into TiO2 by one step, thus greatly reducing the operation steps, and being in favor of improving preparation efficiency and saving cost. The (P, Mo, N) ternary codoped nanometer TiO2 shows excellent photocatalytic properties under visible light, has good degradation effects on both dyes and organic matters not absorbing visible light, and its photocatalytic efficiency exceeds that of the internationally renowned TiO2 commodity DeussaP25. In short, the preparation method disclosed in the invention is simple, and has good industrial prospects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-flame-retardancy electrostatic spraying paint

InactiveCN106752783AImprove heat resistanceImprove impact toughnessFireproof paintsPolyester coatingsAcrylic resinPolyamide

The invention discloses a high-flame-retardancy electrostatic spraying paint which is prepared from an unsaturated polyester resin, an acrylic resin, a methylphenyl silicone resin, a curing agent, fumed silica, polyamide wax, modified glass microspheres, kaolin, erbium oxide, titanium white, octadecendioic acid, a flame retardant, a leveling agent, a degasifier and a dispersing agent. The flame retardant is prepared from magnesium oxide hydrate, hydrated alumina, a melamine formaldehyde resin, ammonium phosphomolybdate, di(ethanediol) phenylphosphate and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide. The high-flame-retardancy electrostatic spraying paint has the advantages of high adhesive force with the substrate, excellent flame retardancy and favorable heat resistance.

Owner:TIANCHANG JINLING ELECTRONICS

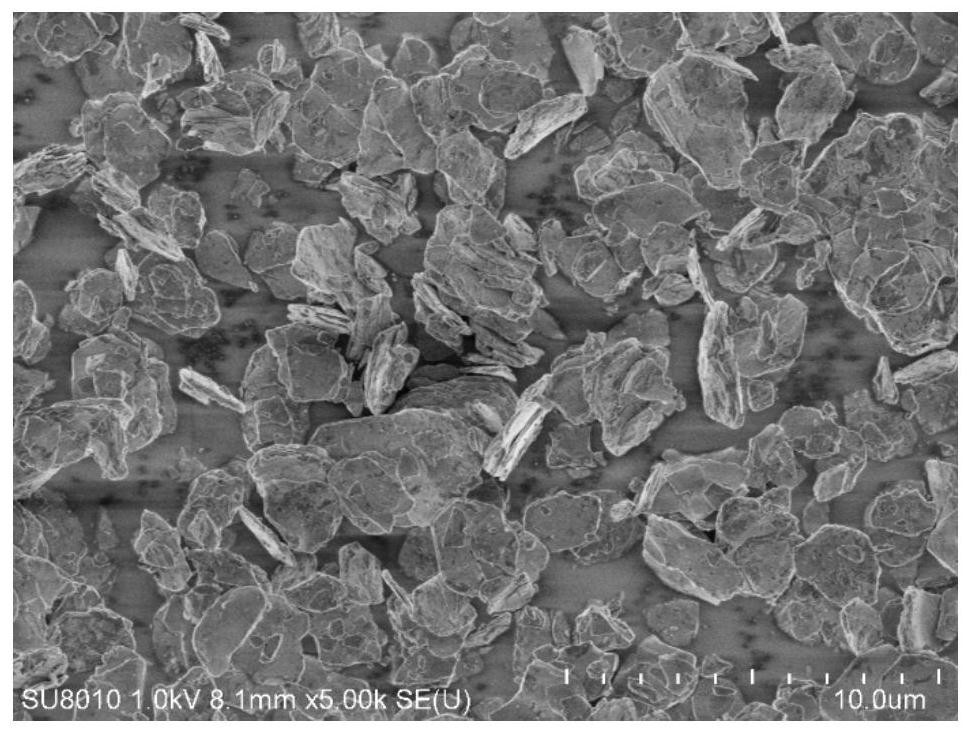

Surface-modified ammonium phosphotungstate/ammonium phosphomolybdate ultrafine particle and preparation method thereof

ActiveCN103073925ASimple stepsRaw materials are cheap and easy to getPigment treatment with macromolecular organic compoundsPhosphomolybdic acidPyrrolidinones

The invention discloses a surface-modified ammonium phosphotungstate / ammonium phosphomolybdate ultrafine particle and a preparation method thereof, and belongs to the technical field of ultrafine particles. The surface-modified ammonium phosphotungstate / ammonium phosphomolybdate ultrafine particle means that the surface of the ammonium phosphotungstate / ammonium phosphomolybdate ultrafine particle is coated with a polyvinylpyrrolidone modification substance or a polyethylene glycol modification substance, the particle size is 200-1000nm, and the weight of the modification substance accounts for 0.05-10% of the total weight of the ultrafine particle. The preparation method comprises the following steps of adding phosphotungstic acid / phosphomolybdic acid, ammonium salt or urea, polyvinylpyrrolidone or polyethylene glycol into a reaction medium, stirring for reaction for 0.5-12h at 20-100 DEG C, filtering after the reaction, drying, and obtaining the ultrafine particle. The method has the characteristics that the steps are simple, raw materials are cheap and easy to obtain, and the reaction conditions are mild. The method is high in yield, and low in production cost, and is suitable for large-scale industrial production. As surface modification is conducted on ammonium phosphotungstate or ammonium phosphomolybdate with polyvinylpyrrolidone or polyethylene glycol, the dispersion stability of the particle in water can be greatly improved.

Owner:HENAN UNIVERSITY

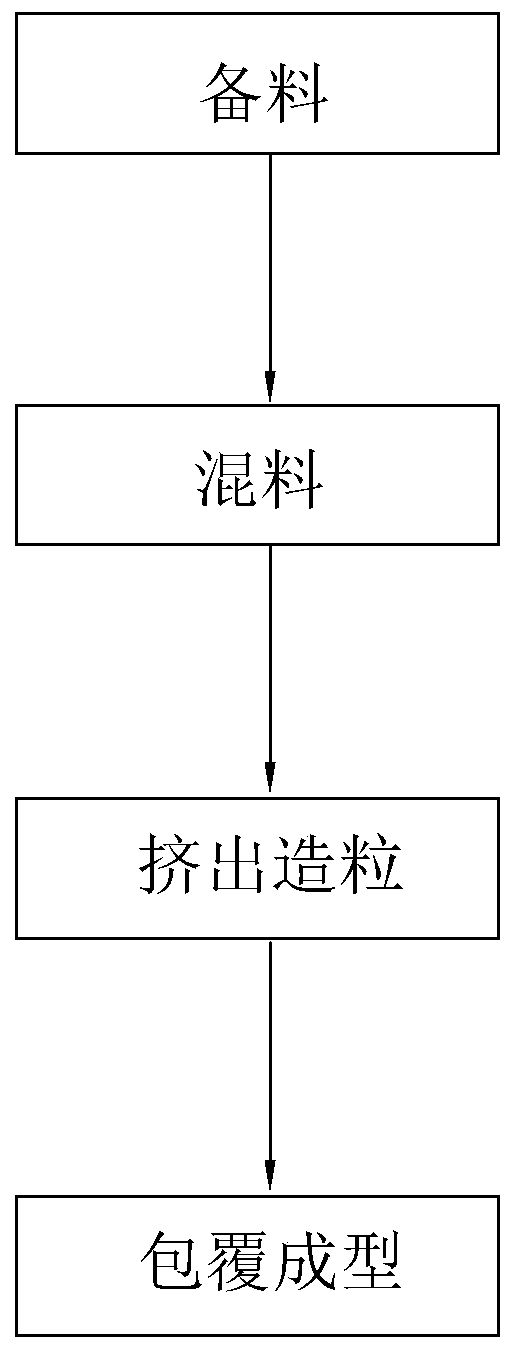

Low-smoke flame-retardant cable and preparation method thereof

The invention discloses a low-smoke flame-retardant cable and a preparation method thereof, and relates to the technical field of wires and cables. The problem is solved that a large number of polluting fumes are easily generated as a cable is burning and thus the overall application effect of the cable is poor. The low-smoke flame-retardant cable includes a cable conductor and a cable material. The cable material includes, by weight, 90-110 parts of a PVC resin material, 6-10 parts of ammonium phosphomolybdate, 1-4 parts of calcium carbonate , 3-5 parts of hydrotalcite powder, 8-12 parts of aprocessing agent , 6-15 parts of a plasticizer, 1.5-2.5 parts of a char- forming agent, 5-10 parts of a stabilizer and 0.5-2 parts of color masterbatch. When the low-smoke flame-retardant cable is burning, few polluting fumes are generated, pollution to the environment is less, and thus the cable has a good application effect.

Owner:JIANGTONG SHENGHUA (SHANGHAI) CABLE CO LTD

Flame-retardant PP (propene polymer) foaming plate and preparation method thereof

The invention discloses a flame-retardant PP (propene polymer) foaming plate and a preparation method thereof. The flame-retardant PP foaming plate comprises, by weight, 85-100 parts of polypropylene, 40-60 parts of brominated polystyrene, 34-48 parts of aluminum ash, 25-35 parts of red mud, 20-30 parts of chlorinated polypropylene, 17-23 parts of dawsonite, 19-27 parts of oil shale residues, 10-15 parts of decabromodiphenyl ether, 2-3 parts of p-toluenesulfonhydrazide, 8-14 parts of antimony phosphite, 5-10 parts of zinc aluminate, 5-10 parts of ferrocene, 10-15 parts of ammonium phosphomolybdate, 12-18 parts of pentaerythritol bis-dimethyl silicate ester, 1-2 parts of trihydrazine s-triazine, 3-6 parts of dibasic lead stearate, 4-9 parts of citric acid and 11-17 parts of ethylhexyl diphenyl phosphate. According to the foaming plate, the brominated polystyrene, the decabromodiphenyl ether, the dawsonite, the pentaerythritol bis-dimethyl silicate ester and the like are added and serve as flame retardants, the zinc aluminate, the ferrocene, the ammonium phosphomolybdate and the like are added and serve as smoke suppressants, the raw materials mutually cooperate, the oxygen index of the PP foaming plate is improved, the smoke amount of the PP foaming plate is reduced, and physical and mechanical properties of products cannot be affected.

Owner:郭云鹏

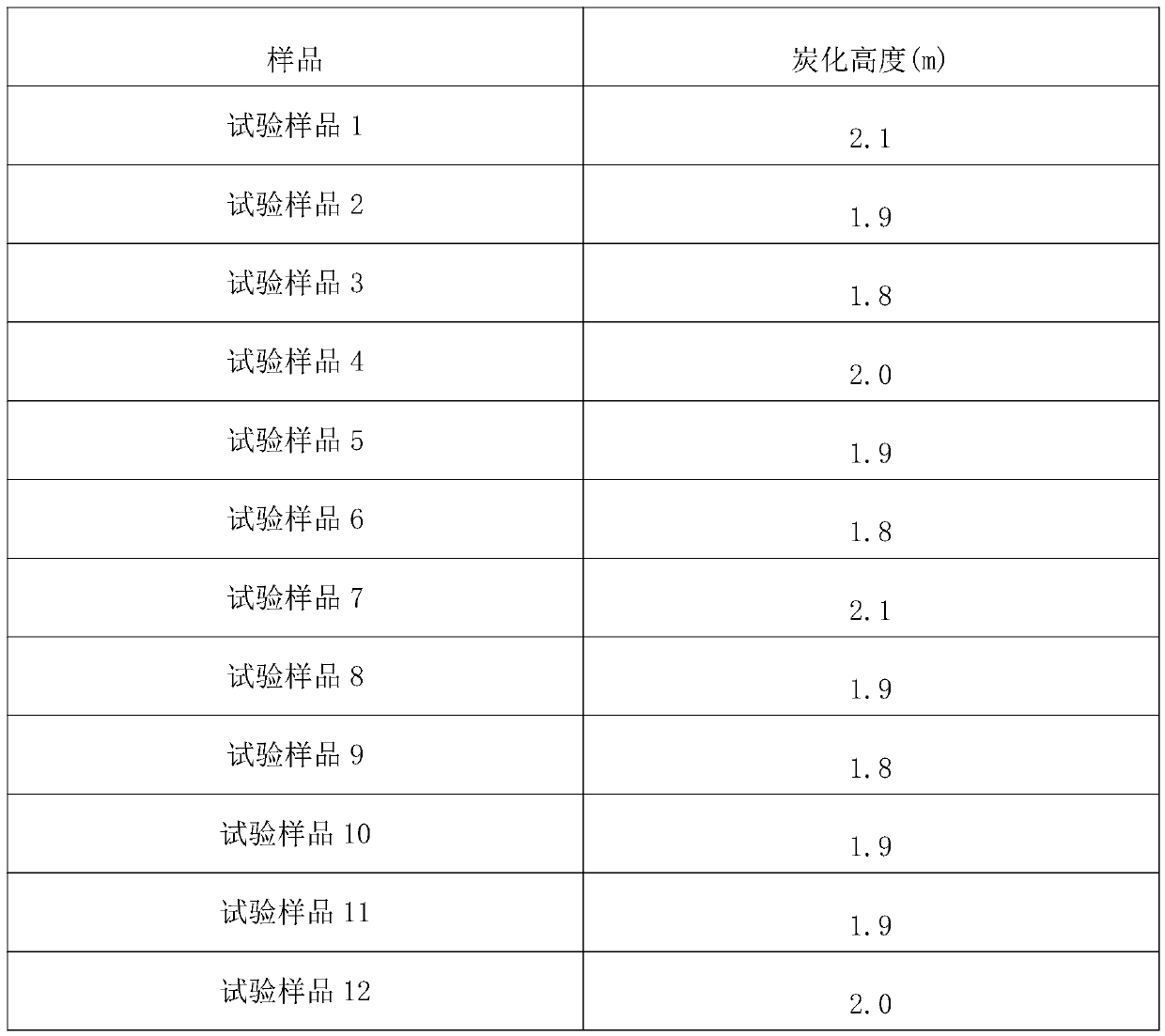

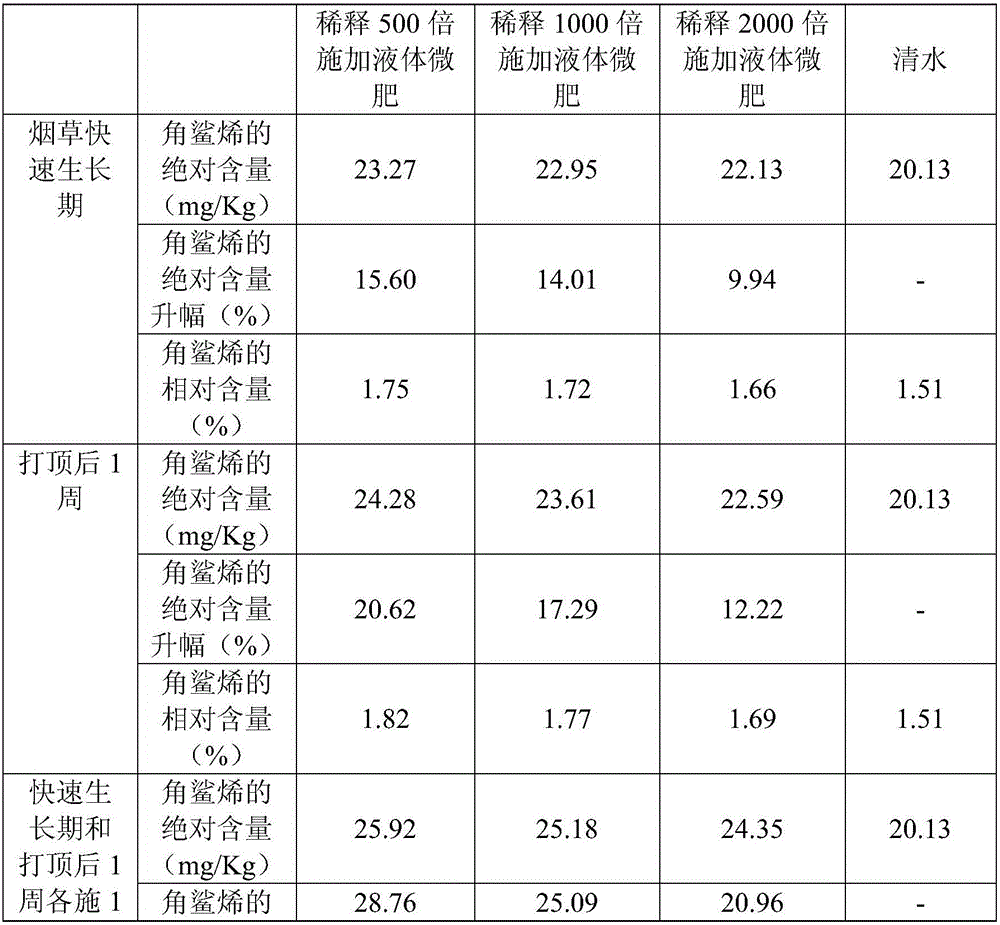

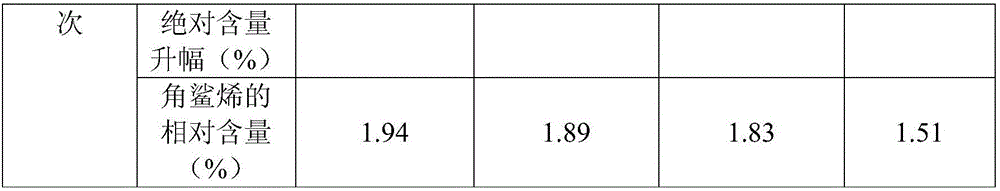

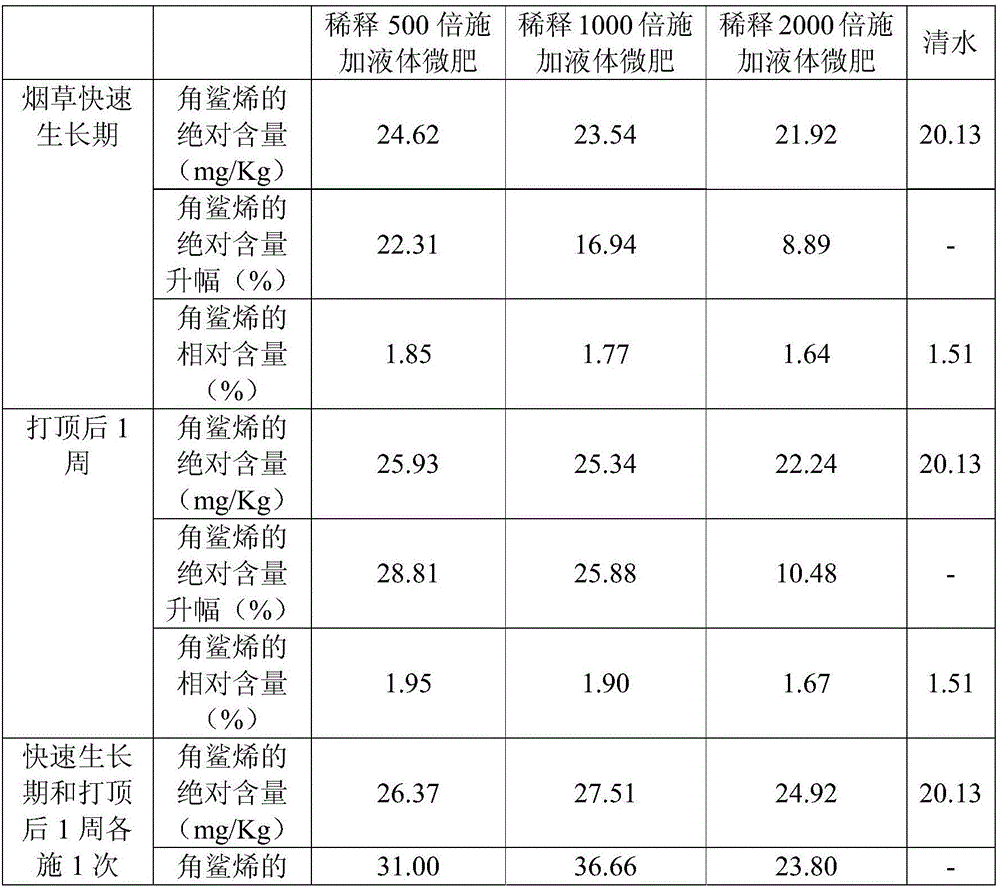

Liquid microelement fertilizer and application thereof to improve squalene content in tobacco leaves

InactiveCN106116749AHigh economic valueIncrease contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAmmonium phosphomolybdateEthanol

The invention discloses a liquid microelement fertilizer and an application thereof to improve a squalene content in tobacco leaves. The liquid microelement fertilizer comprises, by weight percentage, 0.2-5% of EDTA-Zn, 0.5-10% of ammonium phosphomolybdate, and 5-10% of ethanol, with the balance being water. During a growth process of tobacco, through addition of the liquid microelement fertilizer, the squalene content in tobacco leaves is obviously improved, and the economic value of tobacco leaves is increased.

Owner:CHINA TOBACCO GUANGXI IND +1

Halogen-free flame-retardant scratch-resistant antibacterial polypropylene material as well as preparation method and application thereof

The invention discloses a halogen-free flame-retardant scratch-resistant antibacterial polypropylene material as well as a preparation method and application thereof. The halogen-free flame-retardantscratch-resistant antibacterial polypropylene material is prepared from the following raw materials in parts by weight: 76-89 parts of polypropylene; 4-10 parts of an intumescent flame retardant; 2-12parts of silver ammonium phosphomolybdate intercalation modified zirconium phosphonate; 1-5 parts of ceramic fiber powder; 0.5-4 parts of silicone master batch; 0.3-1 part of an antioxidant; and 0.2-1 part of white oil. The silver ammonium phosphomolybdate intercalation modified zirconium phosphonate, the ceramic fiber powder and the silicone master batch are added at the same time, so that the compatibility with polypropylene can be greatly improved, the flame retardant property of the material is improved, the addition amount of a flame retardant is greatly reduced, the scratch resistance of the material can be improved, the material has excellent antibacterial property, and the material has excellent comprehensive performance when applied to the field of intelligent toilet lids.

Owner:WANHUA CHEM GRP CO LTD +1

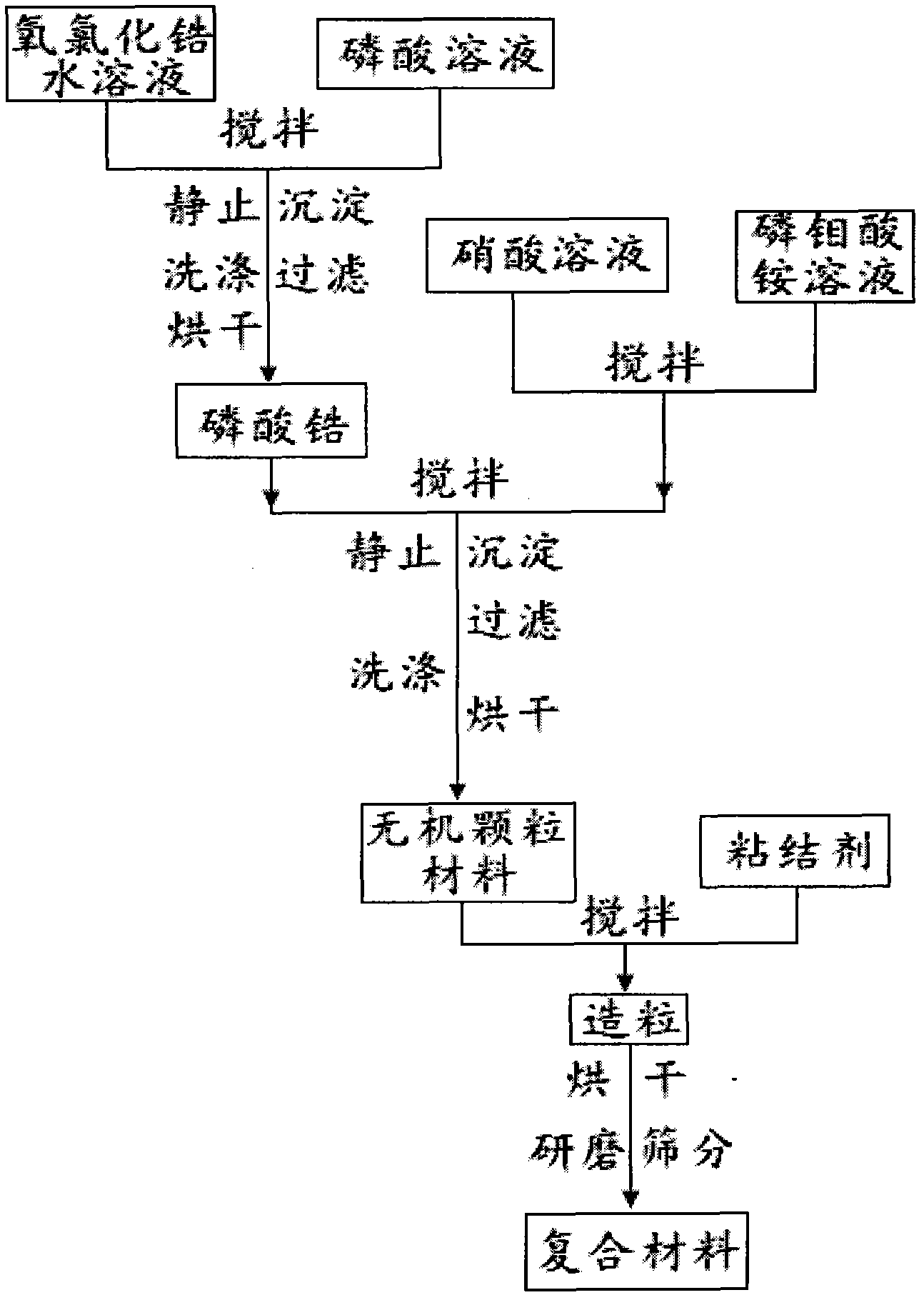

Preparation method for cesium-137 extracting composite material

InactiveCN103127898AHigh selectivityFacilitate desorptionIon-exchange process apparatusOther chemical processesO-Phosphoric AcidAdhesive

The present invention provides a preparation method for a cesium-137 extracting composite material, wherein the preparation method has a characteristic of simple operation. The method comprises the following steps: (1) stirring dissolved zirconium oxychloride and a phosphoric acid solution; (2) carrying out standing, precipitation, filtration and drying to obtain zirconium phosphate; (3) adopting a nitric acid solution to dissolve ammonium phosphomolybdate; (4) adding the zirconium phosphate to the ammonium phosphomolybdate solution, and stirring; (5) carrying out standing, precipitation, filtration, washing and drying to obtain an inorganic particle material; and (6) adopting an adhesive to carry out granulation, and carrying out drying constant weight, grinding and screening to obtain the composite material. The method has characteristics of simple operation and easy condition control. The material provides high selectivity for Cs, and is easy to desorb. The material particles have a high mechanical strength, and can meet cesium extraction requirements of column operation.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

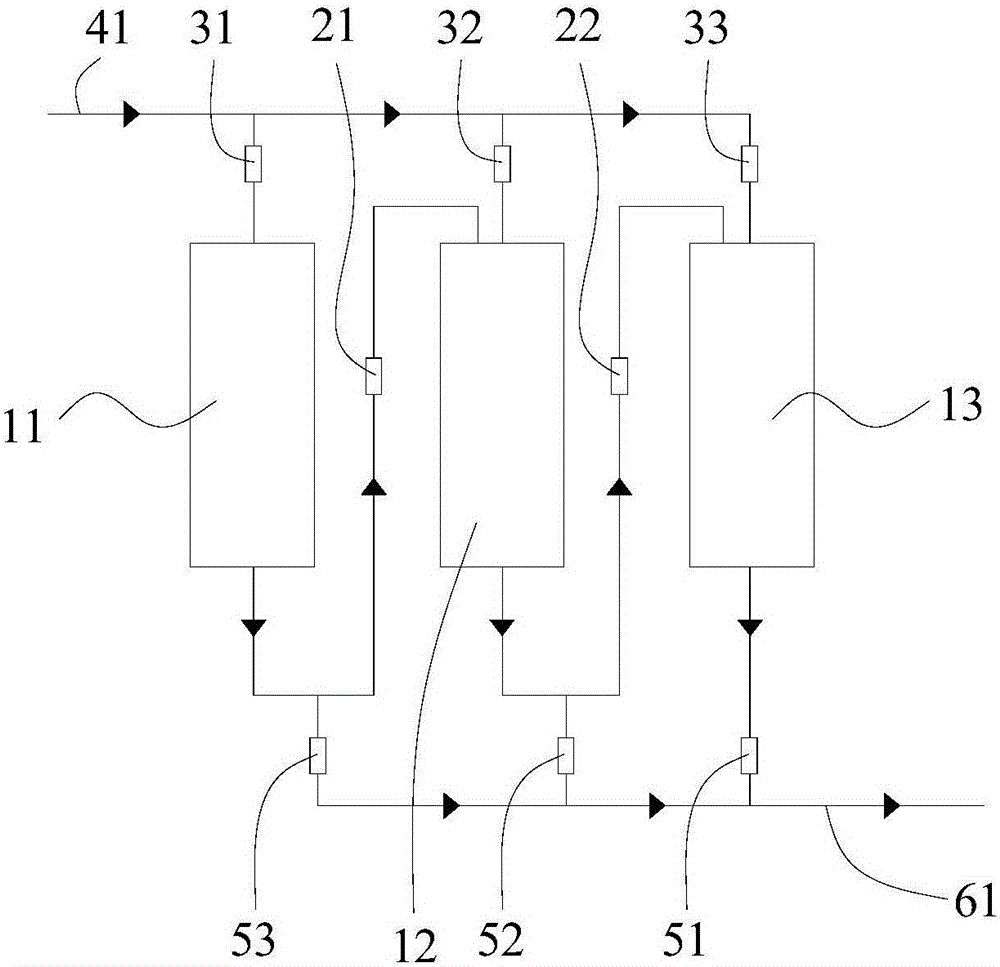

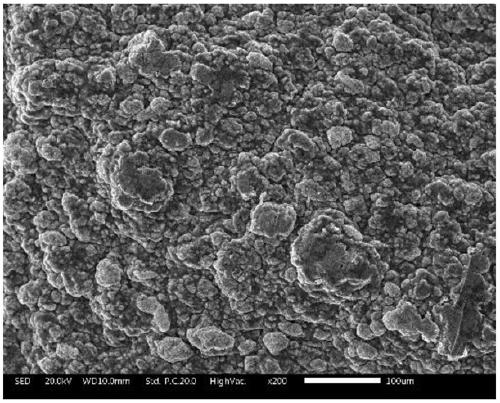

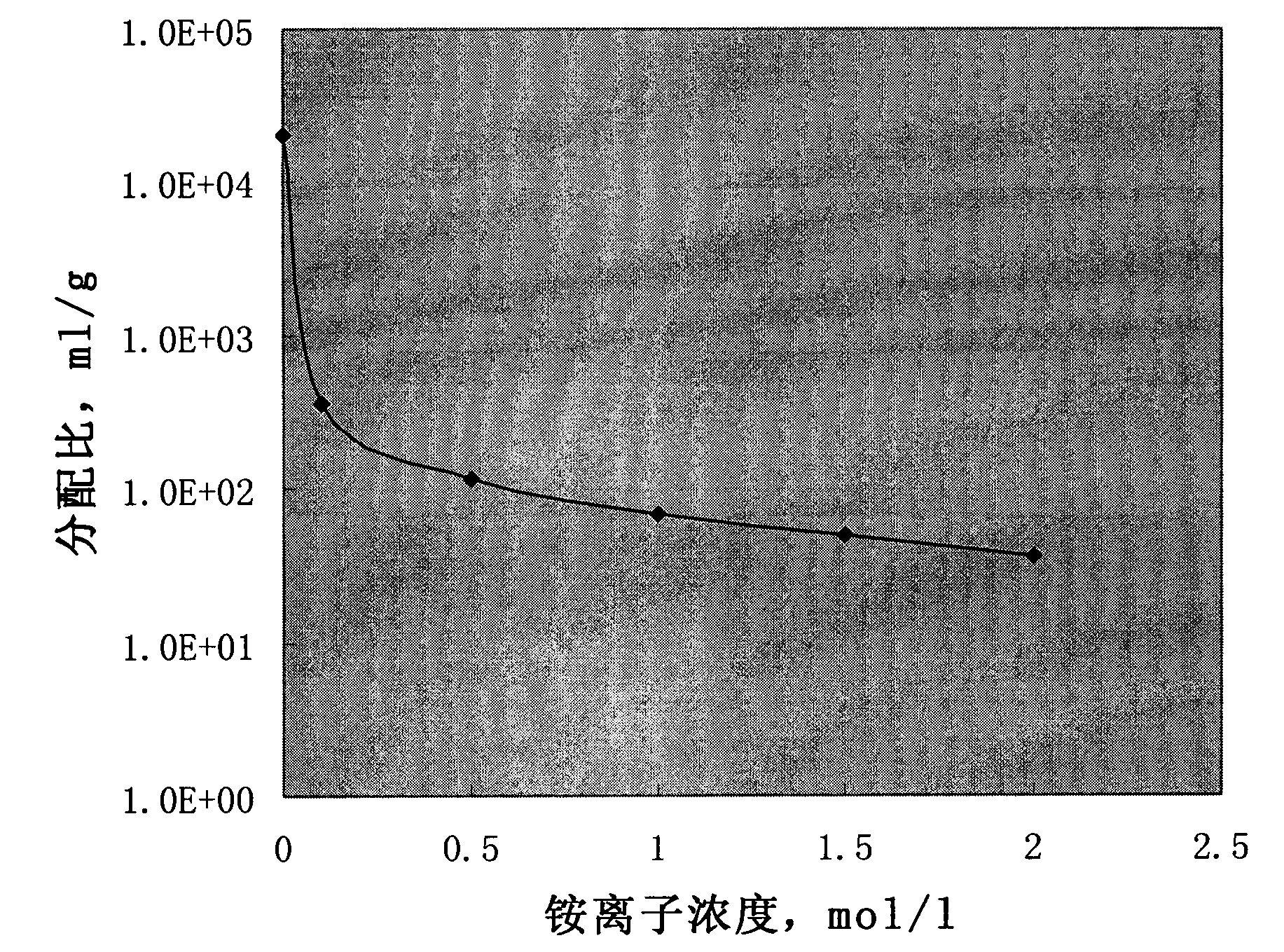

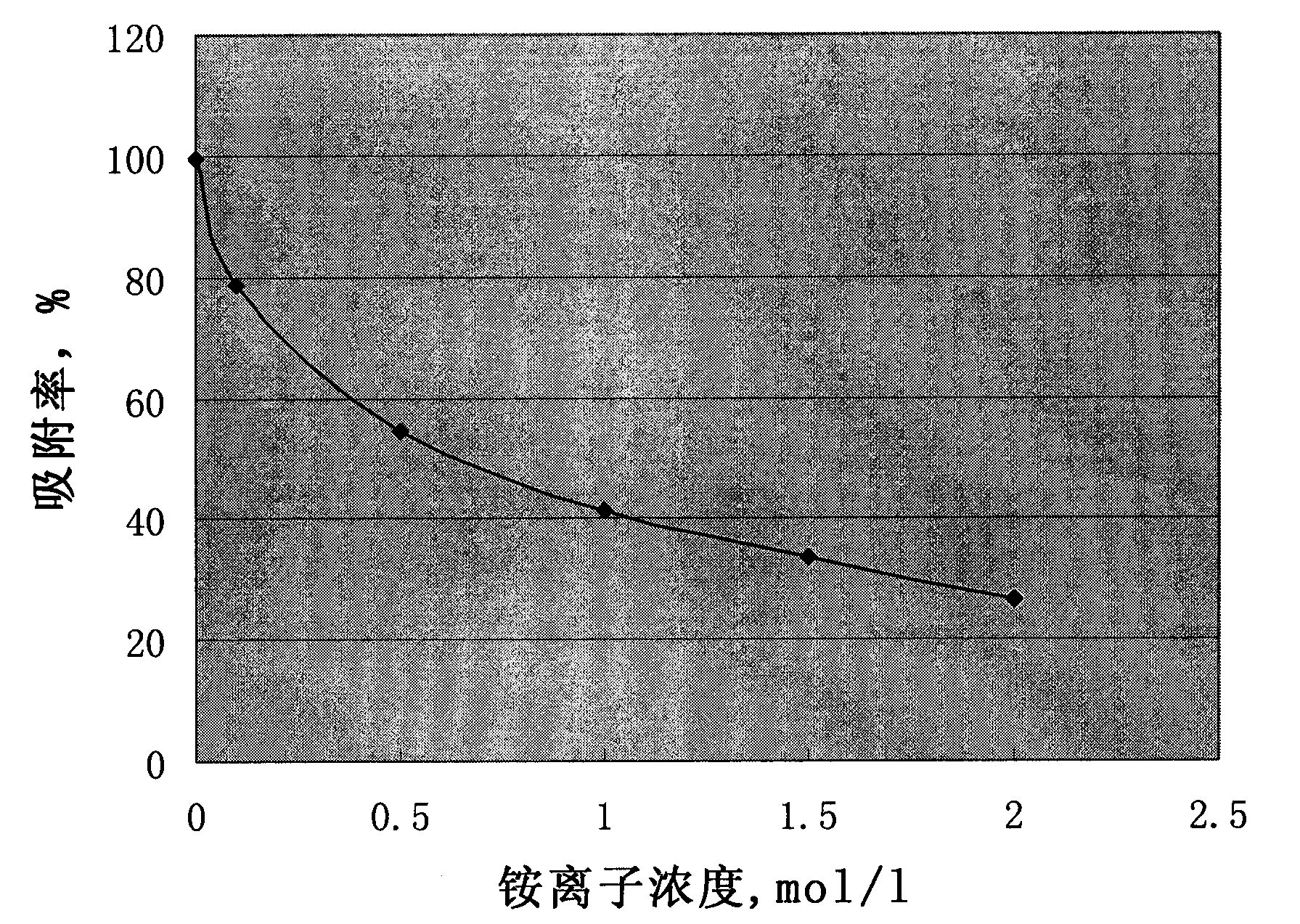

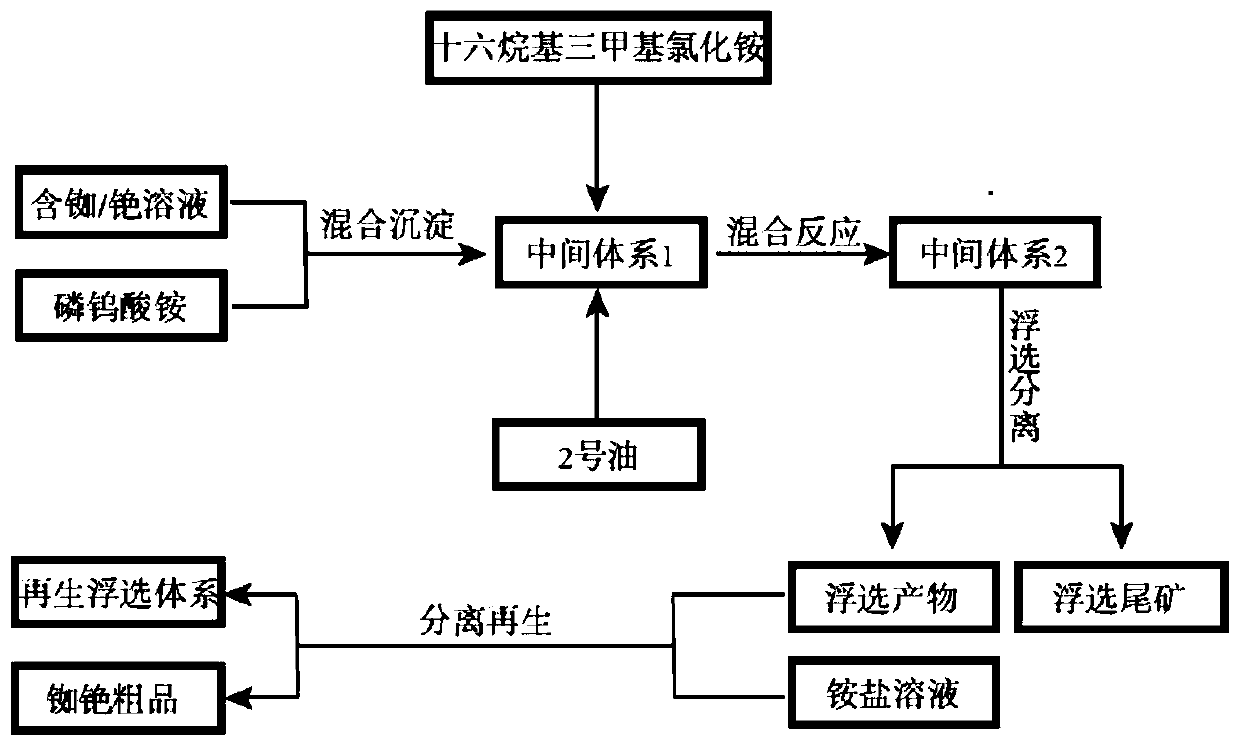

Precipitate flotation separation system of rubidium and cesium in aqueous solution and application thereof

InactiveCN110293003AOvercoming complexityReduce dosageFlotationProcess efficiency improvementFoaming agentRubidium

The invention discloses a precipitate flotation separation system of rubidium and cesium in an aqueous solution and application thereof. The precipitate flotation separation system comprises a precipitant, a collecting agent and a foaming agent, wherein the precipitant at least comprises phosphomolybdate, and the collecting agent and the foaming agent at least include a cationic surfactant. The invention also discloses a flotation separation method of rubidium and cesium ions in the aqueous solution. The flotation separation method comprises the steps of adding the precipitant, the collectingagent and the foaming agent into the aqueous solution containing the cesium ions for a reaction to precipitate the cesium ions, wherein the precipitant at least comprises phosphomolybdate, and the collecting agent and the foaming agent at least comprise the cationic surfactant. Precipitated solids obtained by the reaction are collected through flotation separation treatment. The precipitate flotation system taking phosphomolybdate as the precipitant is provided through the combination of precipitation and flotation processes, can be used for separating and extracting rubidium and cesium resources or removing rubidium and cesium ions in radioactive waste liquid, and can solve the problems of dissolution loss of loaded ammonium phosphomolybdate adsorbents, complex material preparation and the like in a use process.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

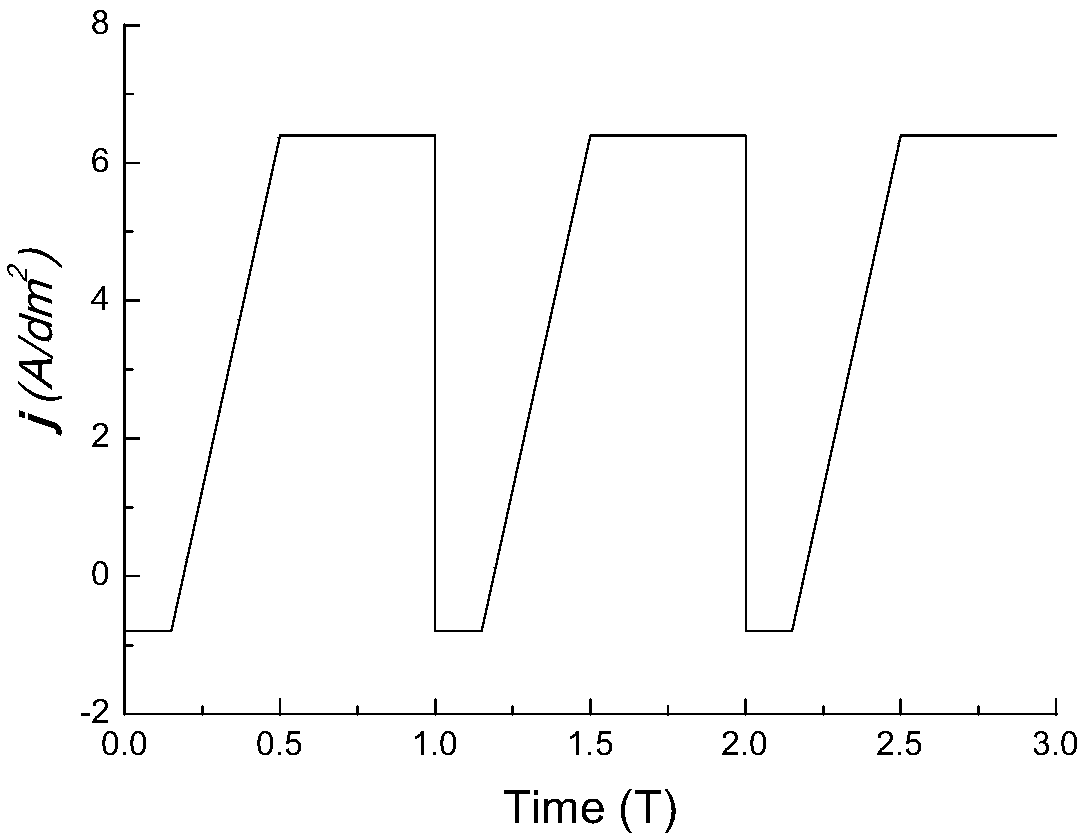

Electrolytic preparation method for composite phosphating film

ActiveCN107630243AShort processing timeHigh film forming efficiencyPhosphatisationRare-earth elementElectrolysis

The invention discloses an electrolytic preparation method for a composite phosphating film. A composite phosphating film treating fluid mainly consists of phosphoric acid, nitric acid, zinc oxide, nickel sulfate, sodium phytate, sodium hexafluorophosphate, succinic acid, ammonium phosphomolybdate, hydroxylamine sulphate, cerium nitrate, hydrogen peroxide and water, and can be used for cold machining and machine manufacturing. According to the preparation for the composite phosphating film disclosed by the invention, an inert material is taken as a working electrode, and a special current applying method is adopted to treat to form an organic phosphating-inorganic phosphating composite protective layer which is excellent in performance and is doped with rare-earth elements on the surface of a workpiece substrate. During operation and use, the electrolytic preparation method has the characteristics of a medium-low temperature, short treatment time and high film-forming efficiency; and atreated workpiece has excellent stretching ductility and excellent extruding property, and can be popularized to various precise forming pre-treatment processes.

Owner:ZHEJIANG WUYUAN TECH CO LTD

The synthetic method of ethyl demethylthiaxamate

The invention relates to a method for synthesizing ethyl 2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate, and belongs to the technical field of the preparation of antibiotic drug intermediates. The method provided by the invention comprises the following steps: using ethyl acetoacetate, sodium nitrite and concentrated sulfuric acid as raw materials; using purified water as a solvent; performing oximation reaction first, and then performing halogenation reaction; then adding thiourea; using 12-ammonium phosphomolybdate (AMP) as the catalyst, and using methanol as a solvent to perform cyclization reaction, thereby obtaining ethyl2-(2-aminothiazole-4-yl)-2-hydroxyiminoacetate. The method provided by the invention is simple in process, shortens the reaction cycle, increases the reaction yield, and reduces corrosion to equipment; the used catalyst is separated from the product easily and can be reused, thereby reducing the production cost, greatly reducing the 'three wastes' pollution, and having an extremely high industrial application value.

Owner:YIYUAN XINQUAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com