Surface-modified ammonium phosphotungstate/ammonium phosphomolybdate ultrafine particle and preparation method thereof

A technology of surface modification and ultrafine particles, which is applied in dyeing polymer organic compound treatment, fibrous fillers, etc., can solve the problems of poor dispersion, unsatisfactory application effect, and large size of ultrafine particles, and achieve low production cost and high yield High and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Weigh 14.4g (0.005mol) phosphotungstic acid, 0.8g ammonium chloride, 1.44g polyvinylpyrrolidone (PVP, K16-18, weight average molecular weight 8000) into a 2L reactor, add 50ml distilled water and 950ml ethanol, stir React for 0.5h, and the reaction temperature is controlled at 20°C. After the reaction is completed, filter and dry, and the product obtained is ammonium phosphotungstate superfine particles whose surface is modified with polyvinylpyrrolidone.

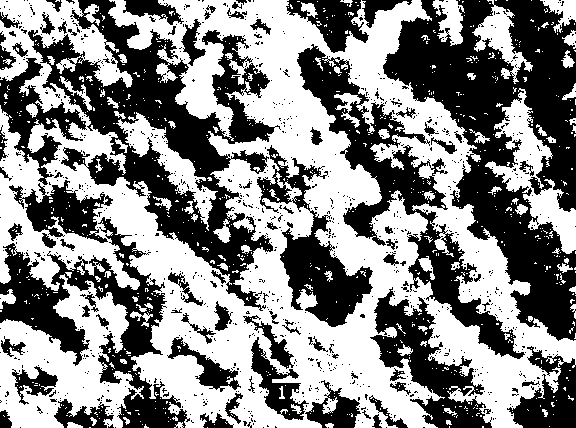

[0025] figure 1 It is a scanning electron micrograph of the product obtained, and it can be seen from the figure that its particle size is 200-300nm. Figure 7 Curve a in the middle is the XRD pattern of the product obtained in Example 1, and the product obtained in Example 1 is confirmed to be the target product after analysis.

[0026] Weighed 0.1g, 0.5g, 1g, 5g of the product obtained in this example in turn, and added them to 1000g of water respectively, all of which were well dispersed and remained...

Embodiment 2

[0027] Example 2: Weigh 57.6g (0.02mol) of phosphotungstic acid, 0.54g of ammonium chloride, and 0.035g of polyethylene glycol (PEG, number average molecular weight 6000) into a 2L reactor, add 950ml of distilled water and 50ml of ethanol, and stir for 8 hours. The reaction temperature of the system is controlled at 80°C. After the reaction is completed, it is filtered and dried, and the product obtained is ultrafine ammonium phosphotungstate particles whose surface is modified with polyethylene glycol.

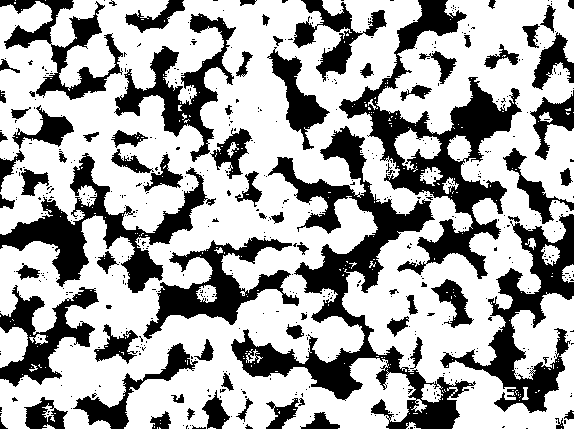

[0028] figure 2 It is a scanning electron micrograph of the resulting product, and it can be seen from the figure that its particle size is 500-800nm. Figure 7 Middle b curve is the XRD pattern of the product obtained in Example 2, and the product obtained in Example 2 is confirmed to be the target product after analysis.

[0029] Weighed 0.1g, 0.5g, 1g, 5g of the product obtained in this example in turn, and added them to 1000g of water respectively, all of which were w...

Embodiment 3

[0030] Example 3: Weigh 86.4g (0.03mol) of phosphotungstic acid, 2.7g of urea, and 6.9g of polyethylene glycol (PEG, number average molecular weight 2000) into a 2L reactor, add 1000ml of distilled water, control the system temperature to 100°C, and stir the reaction After 12 hours, filter and dry after the reaction, the product obtained is the superfine ammonium phosphotungstate particles whose surface is modified with polyethylene glycol.

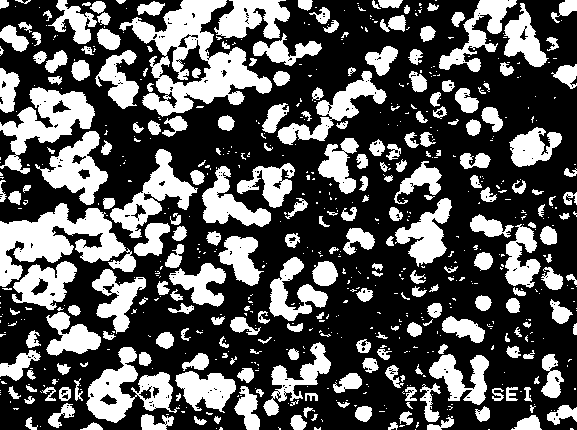

[0031] image 3 It is a scanning electron micrograph of the product obtained, and it can be seen from the figure that its particle size is 200-500nm. Figure 7 The middle c curve is the XRD pattern of the product obtained in Example 3, and the product obtained in Example 3 is confirmed to be the target product after analysis.

[0032] Weighed 0.1g, 0.5g, 1g, 5g of the product obtained in this example in turn, and added them to 1000g of water respectively, all of which were well dispersed and remained unchanged for 3 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com