Preparation method of phosphorus, nitrogen and molybdenum ternary codoped nanometer TiO2 photocatalyst

A photocatalyst and co-doping technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limiting TiO, achieve excellent photocatalytic performance, good degradation effect, and improve photocatalytic performance. The effect of absorbing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

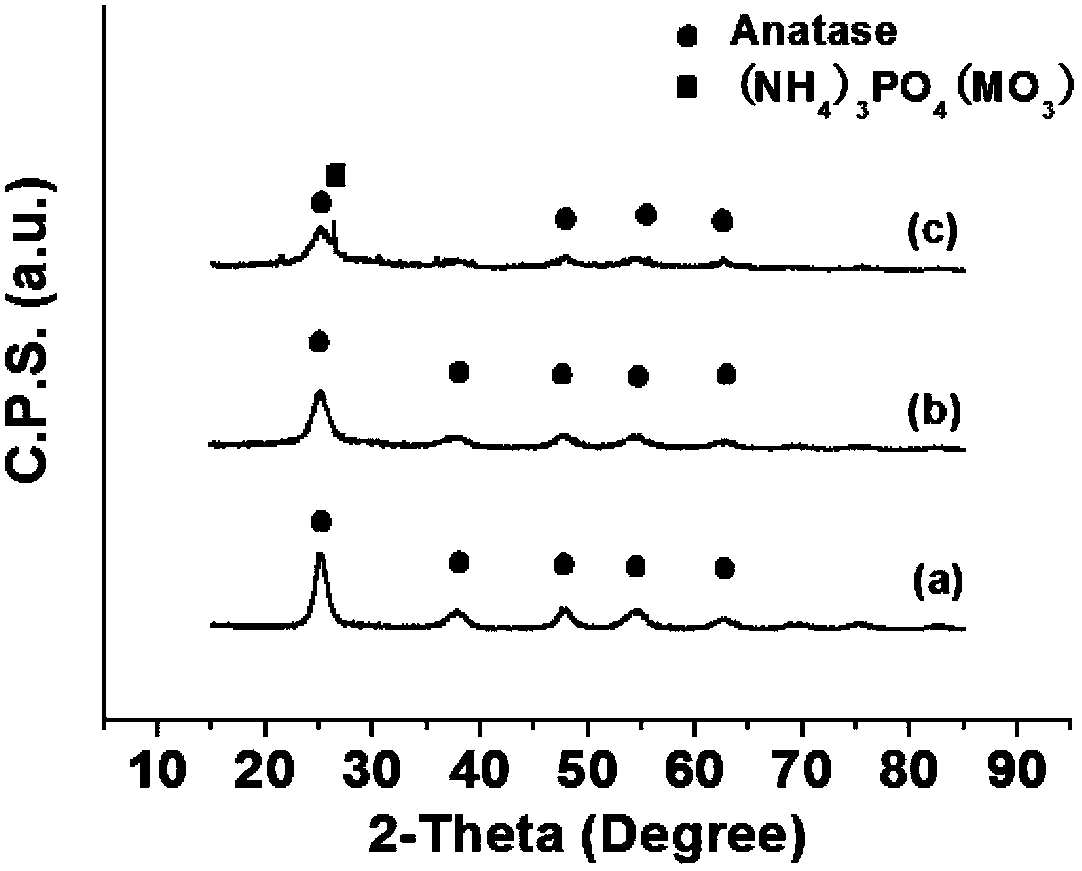

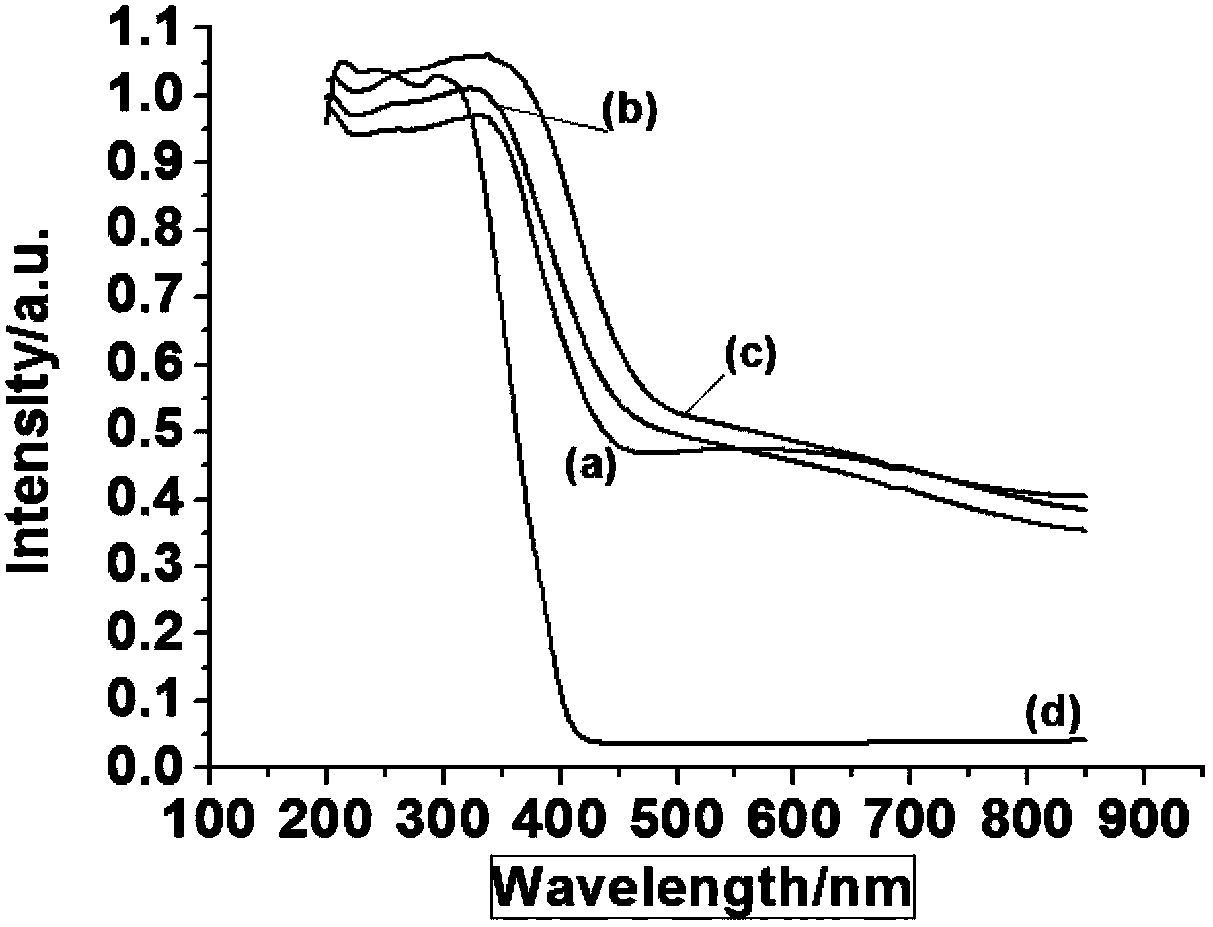

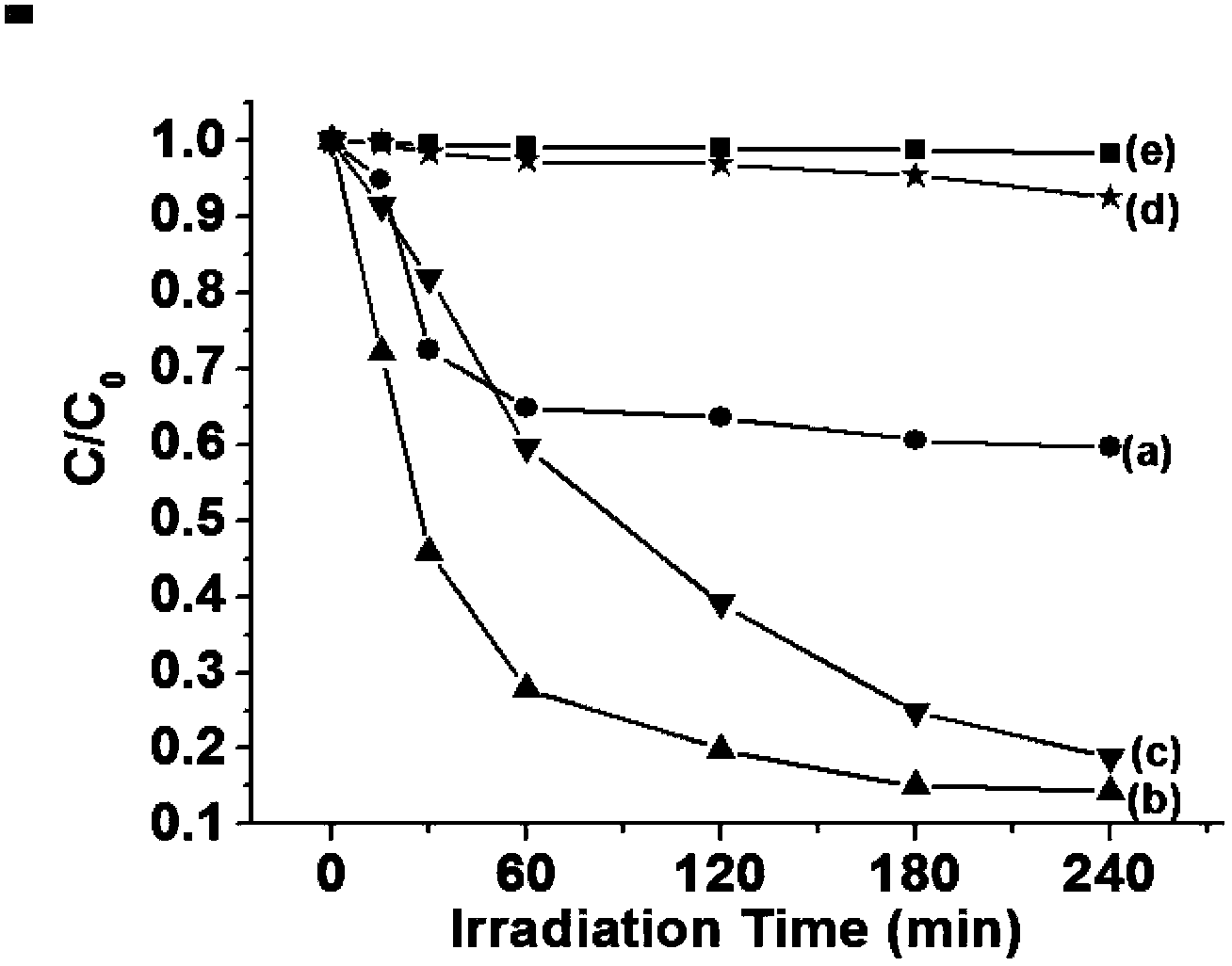

[0024] Preparation of ternary co-doped nano-TiO by sol-gel method 2 Photocatalyst (0.005P,Mo,N)-TiO 2 , in which tetrabutyl titanate is used as the precursor of titanium, ammonium phosphomolybdate is used as the precursor of P, Mo, and N doping elements, and cetyltrimethylammonium bromide (CTAB) is used as the surfactant. The specific operation steps are as follows: add 17mL tetrabutyl titanate to 44mL ethanol, stir for 30 minutes until the mixture is uniform, and obtain solution A; then add 15mL secondary deionized water, an appropriate amount of 70% concentrated nitric acid, 44mL ethanol, 1gCTAB Mix with 0.4788g ammonium phosphomolybdate, stir evenly to obtain solution B; under the condition of vigorous stirring, add solution B dropwise to solution A (0.1L / h), to obtain a yellow-green sol; Gel at ℃ for 24 hours, then dry at 60℃ for 10 hours to obtain xerogel; finally bake the xerogel in air at 400℃ for 4 hours to obtain TiO 2 catalyst of light. figure 1 Middle curve (a) i...

Embodiment 2

[0026] Preparation of ternary co-doped nano-TiO by sol-gel method 2 Photocatalyst (0.01P,Mo,N)-TiO 2 , in which tetrabutyl titanate is used as the precursor of titanium, ammonium phosphomolybdate is used as the precursor of P, Mo, and N doping elements, and cetyltrimethylammonium bromide (CTAB) is used as the surfactant. The specific operation steps are as follows: add 30mL tetrabutyl titanate to 80mL ethanol, stir for 30 minutes until the mixture is uniform, and obtain solution A; then add 28mL secondary deionized water, an appropriate amount of 70% concentrated nitric acid, 80mL ethanol, 2gCTAB Mix with 1.9154g of ammonium phosphomolybdate, stir evenly to obtain solution B; under the condition of vigorous stirring, add solution B dropwise to solution A (dropping speed is 0.1L / h), to obtain a yellow-green sol; The sol was gelled at 25°C for 24 hours, then dried at 60°C for 10 hours to obtain a xerogel; finally, the xerogel was baked in air at 400°C for 4 hours to obtain TiO ...

Embodiment 3

[0028] Preparation of ternary co-doped nano-TiO by sol-gel method 2 Photocatalyst (0.03P,Mo,N)-TiO 2 , in which tetrabutyl titanate is used as the precursor of titanium, ammonium phosphomolybdate is used as the precursor of P, Mo, and N doping elements, and cetyltrimethylammonium bromide (CTAB) is used as the surfactant. The specific operation steps are as follows: add 8mL tetrabutyl titanate to 25mL ethanol, stir for 15 minutes until the mixture is uniform, and obtain solution A; then add 7mL secondary deionized water, an appropriate amount of 70% concentrated nitric acid, 25mL ethanol, 1gCTAB Mix with 1.4365g ammonium phosphomolybdate, stir evenly to obtain solution B; under the condition of vigorous stirring, add solution B dropwise to solution A (dropping speed is 0.1L / h), to obtain yellow-green sol; The sol was gelled at 25°C for 24 hours, then dried at 60°C for 10 hours to obtain a xerogel; finally, the xerogel was baked in air at 400°C for 4 hours to obtain TiO 2 cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com