Liquid phase synthesis method of ultra-thin molybdenum diselenide nanosheet

A liquid-phase synthesis technology of molybdenum diselenide, which is applied in the direction of binary selenium/tellurium compounds, nanotechnology, metal selenide/telluride, etc., can solve the problems of strict preparation conditions, harsh synthesis conditions, and expensive equipment, and achieve Uniform and flat shape, simple method and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a liquid-phase synthesis method of ultra-thin molybdenum diselenide nanosheets, which is characterized in that it comprises the following steps:

[0025] Mixing molybdenum source, selenium source and organic amine, removing impurities to obtain a mixed solution;

[0026] Reacting the mixed solution at 240-300°C for 20-60 minutes to obtain ultra-thin molybdenum diselenide nanosheets;

[0027] The molybdenum source is selected from one or more of ammonium molybdate, sodium molybdate, ammonium phosphomolybdate, molybdenum trioxide, molybdenum acetylacetonate and molybdenum acetate;

[0028] The selenium source is selected from one or more of selenium powder, selenomethionine and dibenzyl diselenide.

[0029] The method provided by the invention adopts common precursors as raw materials, and prepares large-area, ultra-thin molybdenum diselenide nanosheets with relatively uniform and smooth appearance through solution phase synthesis, and the operatio...

Embodiment 1

[0040] Weigh 0.0469g of ammonium phosphomolybdate and 0.034g of dibenzyl diselenide into a 50mL three-necked flask, then add 10mL of oleylamine, and obtain a reaction medium by ultrasonication at room temperature, and introduce argon gas into the reaction system. The reactant was heated to 150°C under low temperature, and kept for 30 minutes to remove some low-boiling impurities, then raised to 240°C, and kept for 30 minutes to complete the reaction. After the reaction, it was naturally cooled to room temperature, and the obtained product was washed several times with n-hexane and acetone, and dispersed in toluene for later use.

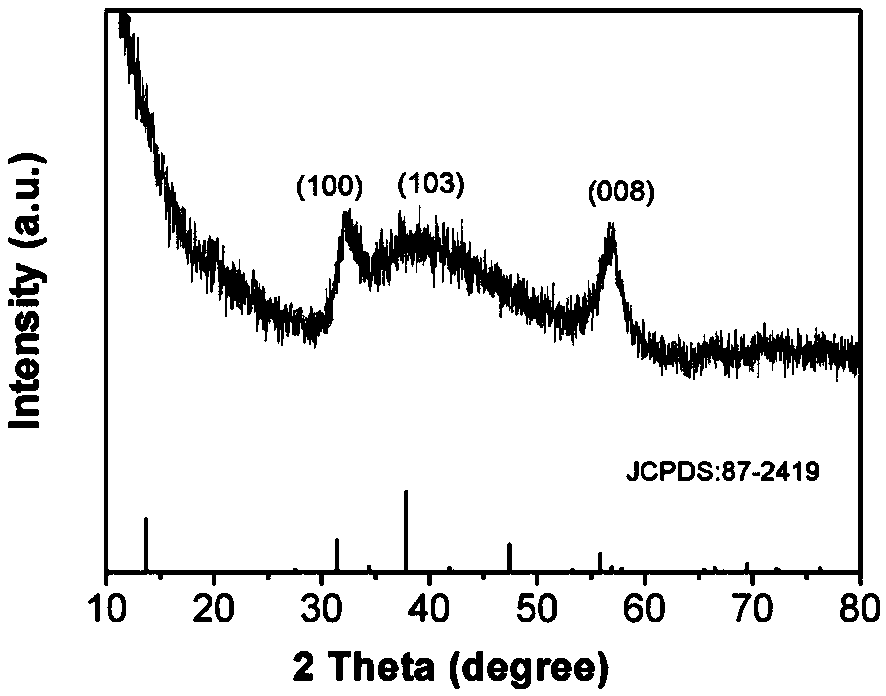

[0041] figure 1 It is the X-ray diffraction spectrogram of the molybdenum diselenide nanosheet obtained in Example 1 of the present invention;

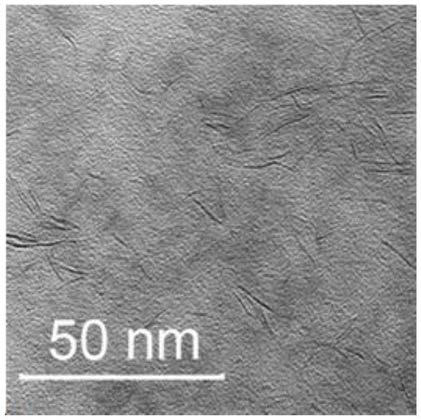

[0042] figure 2 It is a transmission electron microscope photo of molybdenum diselenide nanosheets obtained in Example 1 of the present invention;

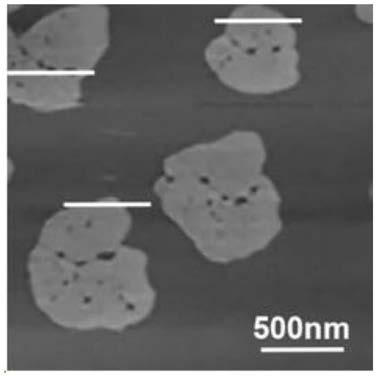

[0043] image 3 It is an atomic force microscope phot...

Embodiment 2

[0050] Weigh 0.0469g of ammonium phosphomolybdate and 0.051g of dibenzyl diselenide into a 50mL three-necked flask, then add 10mL of oleylamine, and obtain a reaction medium by ultrasonication at room temperature, and feed argon into the reaction system, The reactant was heated to 150°C under low temperature, and kept for 30 minutes to remove some low-boiling impurities, then raised to 260°C, and kept for 30 minutes to complete the reaction. After the reaction, it was naturally cooled to room temperature, and the obtained product was washed several times with n-hexane and acetone, and dispersed in toluene for later use.

[0051] The quality of the product synthesized according to the ratio of Example 2 is 27 mg, the theoretical synthesis product quality is 38 mg, and the yield is 71%.

[0052]As can be seen from the above examples, the present invention provides a liquid-phase synthesis method for ultra-thin molybdenum diselenide nanosheets, comprising the following steps: mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com