Method for improving strength of laser stitch welding joint of copper and steel dissimilar metal

A technology for dissimilar metals and welding joints is applied in the field of improving the strength of copper-steel dissimilar metal laser stitched welding joints, which can solve the problems of low efficiency, reduce joint strength, and increase welding, so as to achieve wide application prospects, improve metallurgical reaction, and tensile strength. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

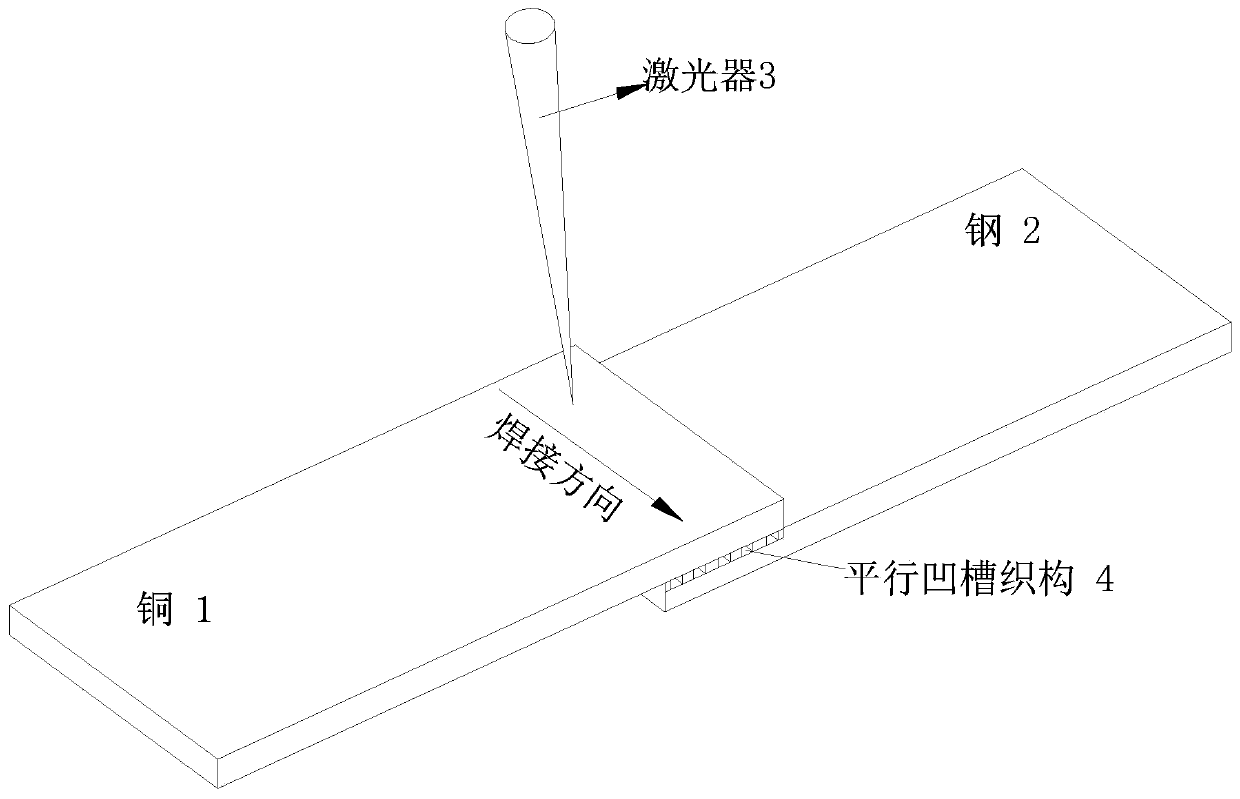

[0029] T2 red copper and 304L stainless steel plates with a thickness of 1mm are used.

[0030] Polish the surface of the workpiece to be processed (T2 copper plate, thickness 1mm) with sandpaper to remove surface metal oxides; clean the surface of the processed workpiece with absolute ethanol to remove surface grease and other stains. Through the above treatment, a relatively clean workpiece surface is obtained.

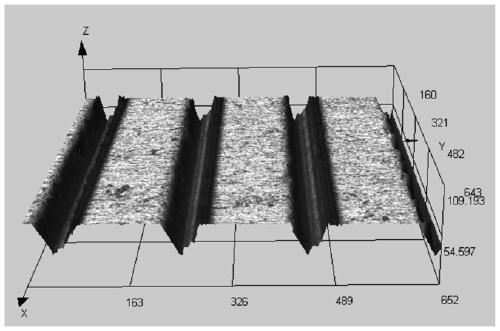

[0031] Use the picosecond green laser with a wavelength of 515nm after frequency doubling to etch a parallel groove texture on one end of the stainless steel surface along the laser processing direction; the texture process parameters are as follows: the laser power is 40% of the peak power, the laser frequency is 400kHz, The pulse width is 10 ps, the scanning speed is 0.5 m / s, the defocus amount is 0, and the scanning times are 70 times; the depth of the formed micro-grooves is 34.865 μm, and the surface roughness is 4.367 μm.

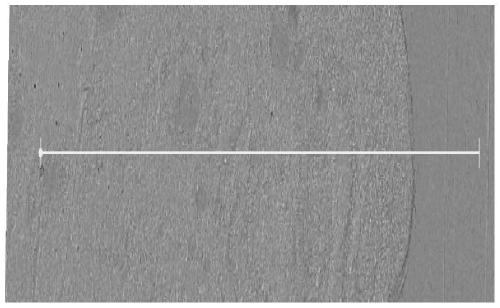

[0032] The stainless steel plate w...

Embodiment 2

[0035] T2 red copper and 304L stainless steel plates with a thickness of 1mm are used.

[0036] Polish the surface of the workpiece to be processed (T2 copper plate, thickness 1mm) with sandpaper to remove surface metal oxides; clean the surface of the processed workpiece with absolute ethanol to remove surface grease and other stains. Through the above treatment, a relatively clean workpiece surface is obtained.

[0037] Use the picosecond green laser with a wavelength of 515nm after frequency doubling to etch a parallel groove texture on one end of the stainless steel surface along the laser processing direction; the texture process parameters are as follows: the laser power is 40% of the peak power, the laser frequency is 400kHz, The pulse width is 10 ps, the scanning speed is 1 m / s, the defocus amount is 0, and the scanning times are 90 times; the depth of the formed micro-grooves is 23.206 μm, and the surface roughness is 3.591 μm.

[0038] The stainless steel plate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com