Preparation method for cesium-137 extracting composite material

A composite material and uniform mixing technology, applied in chemical instruments and methods, ion exchange, other chemical processes, etc., to achieve the effects of high mechanical strength, convenient desorption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

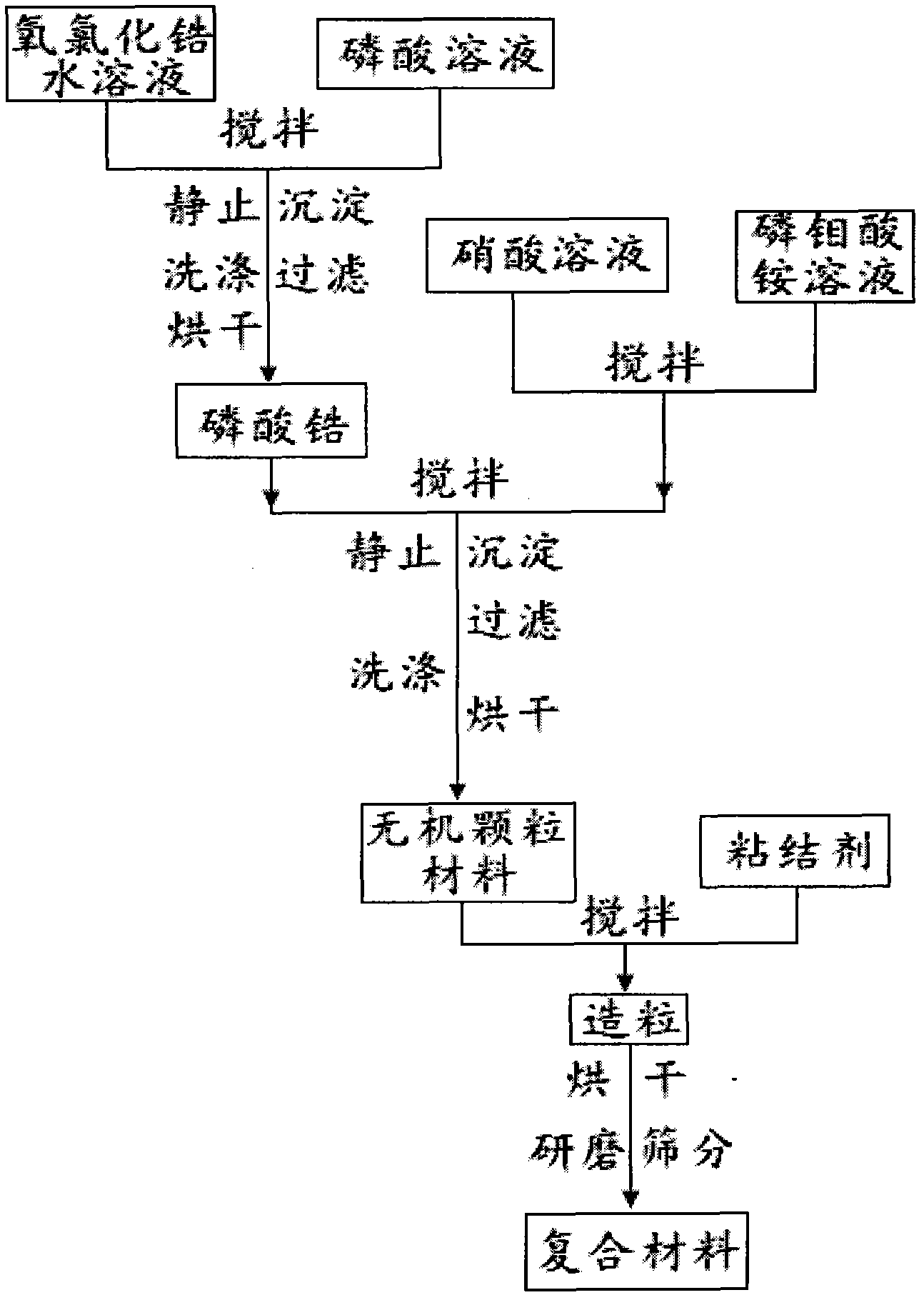

[0026] Accurately weigh 32.2g of zirconium oxychloride in a 1000mL beaker with an electronic balance, then add 100ml of deionized water to completely dissolve the zirconium oxychloride. Then take 10ml of 85% phosphoric acid from the sampler, slowly add it into the beaker, and stir for about 2 hours to fully react. Then, stand at room temperature for about 4 hours, and pour off the supernatant. Next, use a vacuum filter to filter under a vacuum of 0.1 MPa to obtain a precipitate. Finally, the precipitate is placed in a constant temperature drying oven at 120-130° C. and dried to a constant weight to obtain zirconium phosphate ZrP particles.

[0027] Use an electronic balance to accurately weigh 25g of ammonium phosphomolybdate (AMP) into a 1000ml clean beaker, then use a graduated cylinder to measure 200ml of 3mol / L nitric acid solution and pour it into the beaker, then stir with a glass rod to fully dissolve it. Then, 25 g of ZrP particles synthesized by the above method wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com