Treatment method for high-phosphorus high-molybdenum complex scheelite

A processing method and technology for scheelite, which is applied in the processing field of complex scheelite with high phosphorus and high molybdenum, and achieves the effects of efficient separation, convenient operation and simple processing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

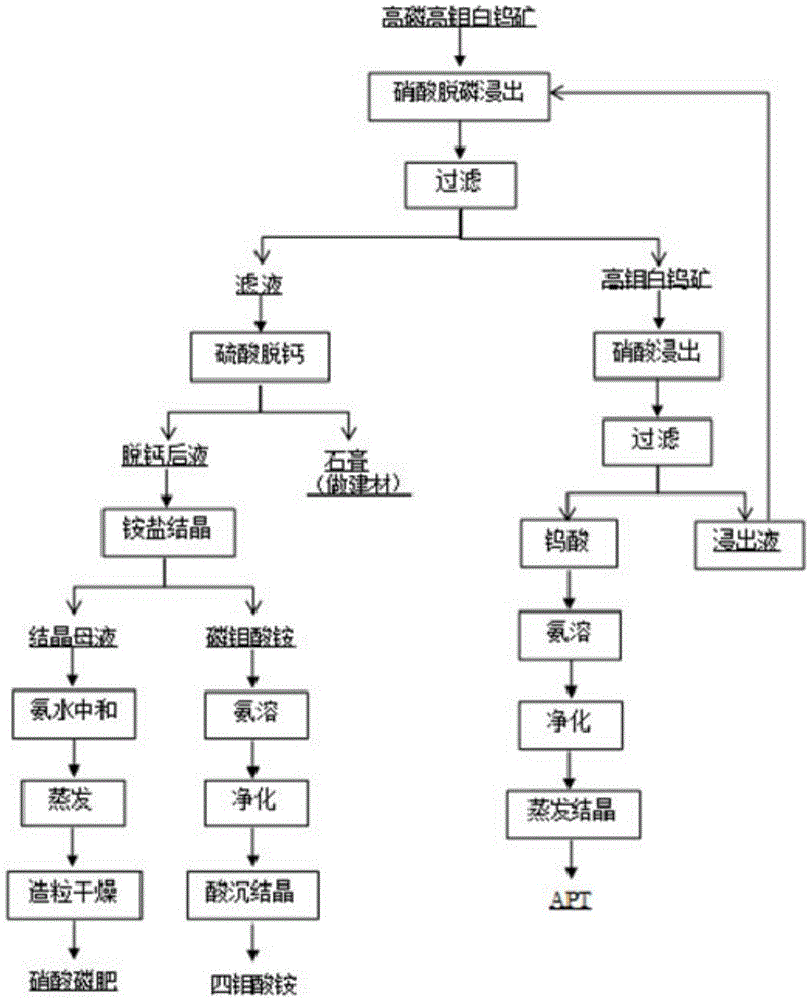

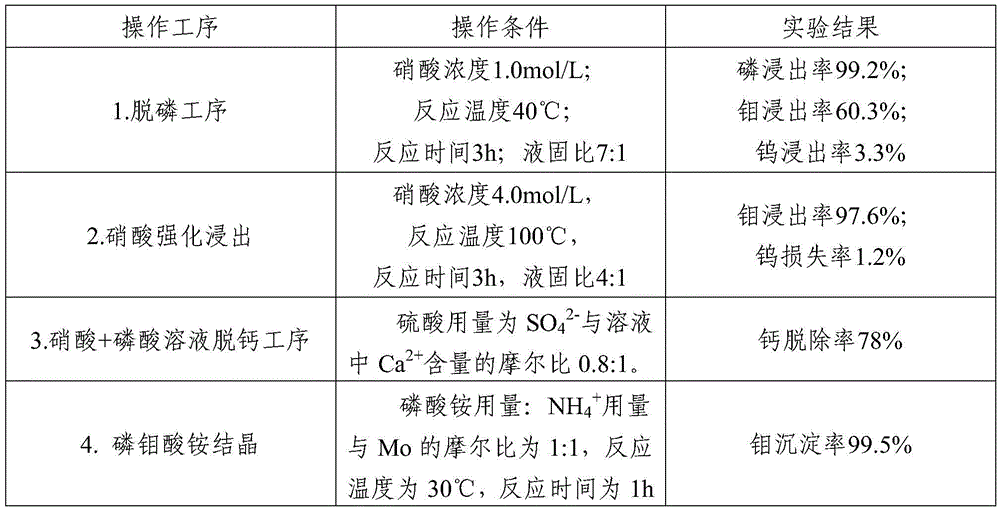

[0037] See figure 1 , The grade of the treated high-phosphorus and high-molybdenum scheelite is P 2 O 5 12.4%, WO 3 29.7%, Mo2.8%, specific operating conditions and results are shown in Table 1. The obtained tungstic acid adopts the technical route of ammonia dissolution-purification and removal-evaporation crystallization to prepare APT to recover tungsten; to obtain ammonium phosphomolybdate crystals, the technical route of preparing ammonium tetramolybdate by ammonia dissolution-purification and removal-acid precipitation crystallization to recover molybdenum ; The obtained contains nitric acid, phosphoric acid and NH 4 + The ammonium phosphomolybdate crystallization mother liquor adopts the technical route of ammonia water neutralization-vacuum evaporation-granulation drying to prepare nitrophosphate fertilizer to recover phosphorus.

[0038] Table 1: Operating conditions and experimental results of Example 1

[0039]

Embodiment 2

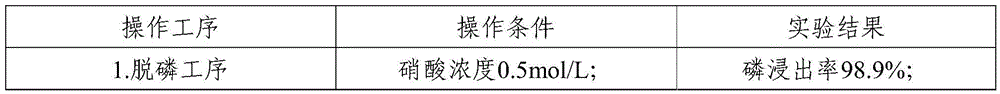

[0041] See figure 1 , The grade of the processed high-phosphorus and high-molybdenum scheelite is P 2 O 5 12.4%, WO 3 29.7%, Mo2.8%, specific operating conditions and results are shown in Table 2. The obtained tungstic acid adopts the technical route of ammonia dissolution-purification and removal-evaporation crystallization to prepare APT to recover tungsten; to obtain ammonium phosphomolybdate crystals, the technical route of preparing ammonium tetramolybdate by ammonia dissolution-purification and removal-acid precipitation crystallization to recover molybdenum ; The obtained contains nitric acid, phosphoric acid and NH 4 + The ammonium phosphomolybdate crystallization mother liquor adopts the technical route of ammonia water neutralization-vacuum evaporation-granulation drying to prepare nitrophosphate fertilizer to recover phosphorus.

[0042] Table 2: Operating conditions and experimental results of Example 2

[0043]

[0044]

Embodiment 3

[0046] See figure 1 , The grade of the processed high-phosphorus and high-molybdenum scheelite is P 2 O 5 16.2%, WO 3 20.3%, Mo3.1%, specific operating conditions and results are shown in Table 3. The obtained tungstic acid adopts the technical route of ammonia dissolution-purification and removal-evaporation crystallization to prepare APT to recover tungsten; to obtain ammonium phosphomolybdate crystals, the technical route of preparing ammonium tetramolybdate by ammonia dissolution-purification and removal-acid precipitation crystallization to recover molybdenum ; The obtained contains nitric acid, phosphoric acid and NH 4 + The ammonium phosphomolybdate crystallization mother liquor adopts the technical route of ammonia water neutralization-vacuum evaporation-granulation drying to prepare nitrophosphate fertilizer to recover phosphorus.

[0047] Table 3: Operating conditions and experimental results of Example 3

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com