Precipitate flotation separation system of rubidium and cesium in aqueous solution and application thereof

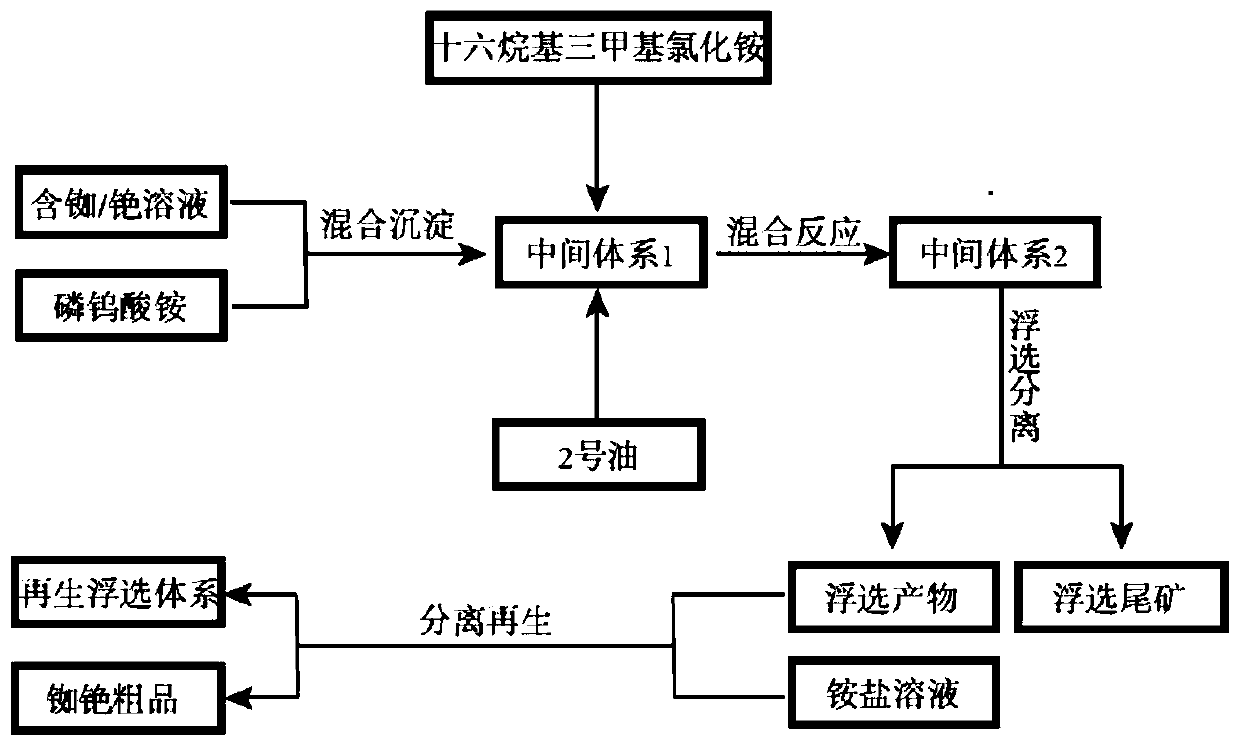

An aqueous solution and flotation technology, which is applied in the precipitation flotation system, the removal of cesium, and the field of rubidium in radioactive waste liquid, can solve the problems of rubidium and cesium precipitates that are difficult to recycle and reuse, the preparation process of composite materials is complicated, and it is difficult to extract and separate. , achieving fast solid-liquid separation rate, thorough solid-liquid separation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] First to 500mL Cs + Add 0.5mmol of ammonium phosphotungstate to 1mmol / L CsCl solution, stir for 60 minutes, add 0.01g of cetyltrimethylammonium chloride, 0.1mL of No. 2 oil, stir for 30 minutes, place in flotation Flotation separation is carried out in the tank, the flotation foam is collected, and the Cs in the flotation substrate is + Concentration (the calculated removal rate is 95.6%).

[0061] During the regeneration process, add the foam collected by flotation into 100mL 2mol / L ammonium chloride and stir for 2 hours, and then separate by air flotation. The flotation foam is the regenerated flotation system and can be used in the next flotation separation solution rubidium, cesium. The flotation tail liquid is a mixed solution of cesium chloride and ammonium chloride.

Embodiment 2

[0063] First add 500mL Rb + Add 0.5mmol of ammonium phosphotungstate to the 1mmol / L RbCl solution, stir for 45 minutes, then add 0.01g of cetyltrimethylammonium chloride, 0.1mL of No. 2 oil, stir for 30 minutes, place in flotation Carry out flotation separation in the tank, collect the flotation foam, and carry out the Rb in the flotation substrate + Concentration (the calculated removal rate is 93.5%).

[0064] During the regeneration process, add the foam collected by flotation into 100mL 3mol / L ammonium nitrate and stir for 2 hours, and then separate by air flotation. ,cesium. The flotation tail liquid is a mixed solution of rubidium chloride and ammonium nitrate.

Embodiment 3

[0066] First to 500mL Cs + Add 0.3mmol of ammonium phosphotungstate to the 1mmol / L CsCl solution, stir for 35 minutes, then add 0.015g of cetyltrimethylammonium chloride, 0.1mL of No. 2 oil, stir for 30 minutes, place in flotation Flotation separation is carried out in the tank, the flotation foam is collected, and the Cs in the flotation substrate is + Concentration (the calculated removal rate is 96.3%).

[0067] The regeneration steps are basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com