Low-smoke flame-retardant cable and preparation method thereof

A low-smoke, flame-retardant, and cable technology, which is applied in the field of wire and cable, can solve problems such as poor cable application effects, and achieve the effects of reducing polluting smoke, good environmental protection, and reducing the generation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

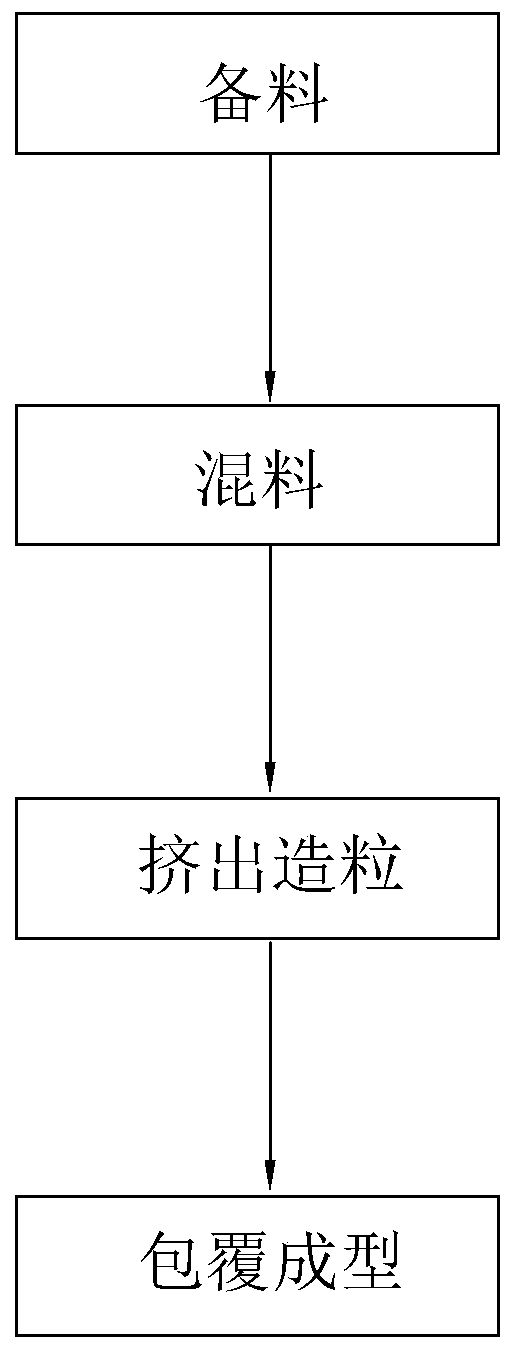

[0043] Example 1: A low-smoke flame-retardant cable, including cable wires and cable materials, the components of the cable materials and their corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

[0044] Step 1, preparing materials, weighing the raw materials of corresponding parts by weight according to the formula;

[0045] Step 2, mixing materials, mix PVC resin material, ammonium phosphomolybdate, calcium carbonate, hydrotalcite powder, dibutyl hydroxytoluene, tricresyl phosphate, carbon forming agent, dibasic lead phosphite, and color masterbatch evenly , heated up to 65°C and stirred for 45min to obtain a mixture;

[0046] Step 3, extrusion granulation, put the mixture into a twin-screw extruder and extrude granulation. The temperature of the extruder is set to: 175°C in the first zone, 185°C in the second zone, 195°C in the third zone, and the rotation speed is 50r / min. Obtain low-smoke flame-retardant cable materials;

[...

Embodiment 2-8

[0049] Embodiment 2-8: A low-smoke flame-retardant cable, including cable conductors and cable materials. The difference from Embodiment 1 is that the components of the cable materials and their corresponding weight parts are shown in Table 1.

[0050] Each component and parts by weight thereof in table 1 embodiment 1-8

[0051]

Embodiment 9

[0052] Embodiment 9: A low-smoke flame-retardant cable. The difference from Embodiment 1 is that in step 2, 5 parts by weight of dibasic lead phosphite is replaced by dibasic lead sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com