Method for preparing sanitizer and liquid ammonium-potassium compound fertilizer from sheep manure

A compound fertilizer and fungicide technology, applied in botany equipment and methods, disinfectants, fungicides, etc., can solve the problems of sheep manure pollution, unreasonable utilization, etc., achieve good sterilization effect, realize waste utilization, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

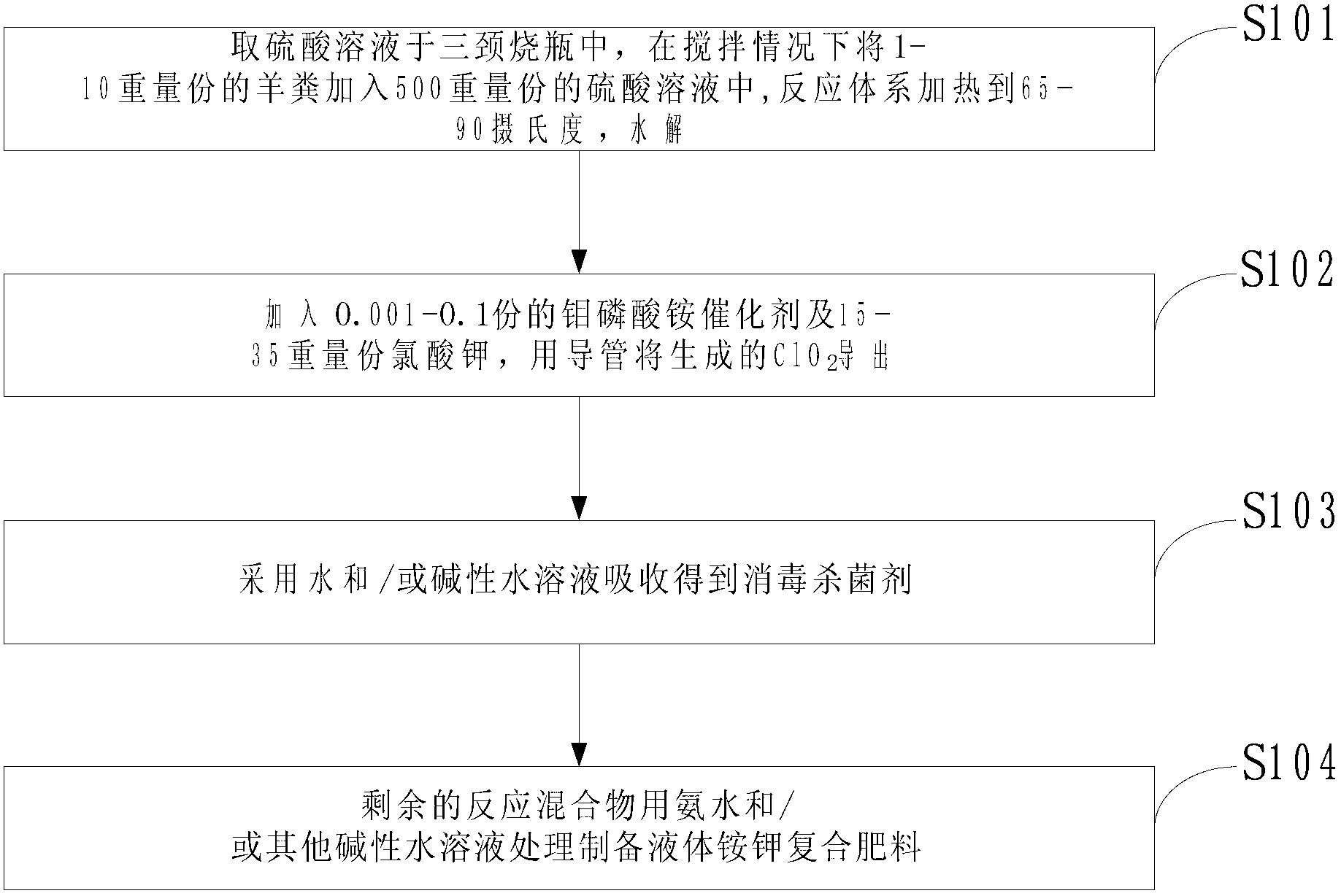

Method used

Image

Examples

Embodiment 1

[0038] Take 100ml of sulfuric acid solution in a three-necked flask, add 0.3001g of dry sheep manure sample while stirring, stir and dissolve, heat the reaction system to 80 degrees Celsius, hydrolyze for about 30 minutes, add 0.0031g of ammonium molybdophosphate catalyst and 2.5010g potassium chlorate, reaction system sulfuric acid concentration is 5moL / L, with the ClO that generates 2 Derived, using five-stage absorption (the first four stages are ice water, the fifth stage is sodium carbonate solution with a mass fraction equal to 0.05), the total reaction time is about 100min, until chlorine dioxide is no longer produced, use the five-step iodometric method Determination of the content and purity of chlorine dioxide, based on the percentage of chlorine converted into chlorine dioxide in potassium chlorate, the yield of chlorine dioxide is 44.35%, and the purity is 97.56%. After the reaction, the residual liquid is adjusted to pH with ammonia water and potassium hydroxide ,...

Embodiment 2

[0040] Take 100ml of sulfuric acid solution in a three-necked flask, add 0.4002g of sheep manure sample while stirring, stir and dissolve, heat the reaction system to 80 degrees Celsius, after hydrolysis for a period of time, add 0.0032g of ammonium molybdophosphate catalyst and 2.5003 g potassium chlorate, the reaction system sulfuric acid concentration is 5moL / L, the ClO that generates 2 Derived, using five-level absorption (the first four levels are ice water, the fifth level is sodium carbonate solution with a mass fraction equal to 0.05), the reaction time is about 100 minutes, and until chlorine dioxide is no longer produced, it is measured with sodium thiosulfate solution The content of chlorine dioxide, the chlorine dioxide yield rate is 60.35%, and the purity is 97.24%;

Embodiment 3

[0042] Take 100ml of sulfuric acid solution in a three-necked flask, add 0.5001g of sheep manure sample while stirring, stir and dissolve, heat the reaction system to 80 degrees Celsius, after hydrolysis for a period of time, add 0.0031g of ammonium molybdophosphate catalyst and 2.5001 g potassium chlorate, the reaction system sulfuric acid concentration is 5moL / L, the ClO that generates 2 Derived, using five-level absorption (the first four levels are ice water, the fifth level is sodium carbonate solution with a mass fraction equal to 0.05), the reaction time is about 100 minutes, and until chlorine dioxide is no longer produced, it is measured with sodium thiosulfate solution The content of chlorine dioxide, the chlorine dioxide yield rate is 73.60%, and the purity is 98.82%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com