Electrostatic spinning gel battery diaphragm, preparation method and application thereof

An electrospinning, gel battery technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as deficiencies, achieve high oxidation limit, improve safety and stability, and high ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

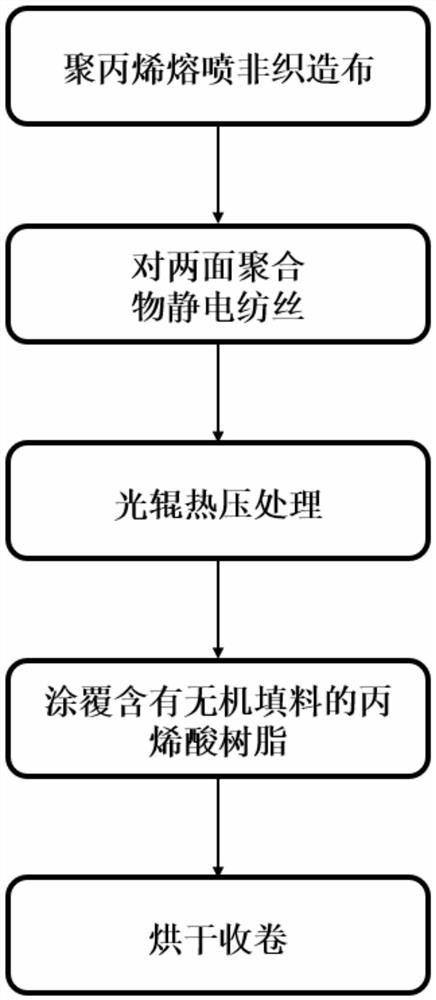

Method used

Image

Examples

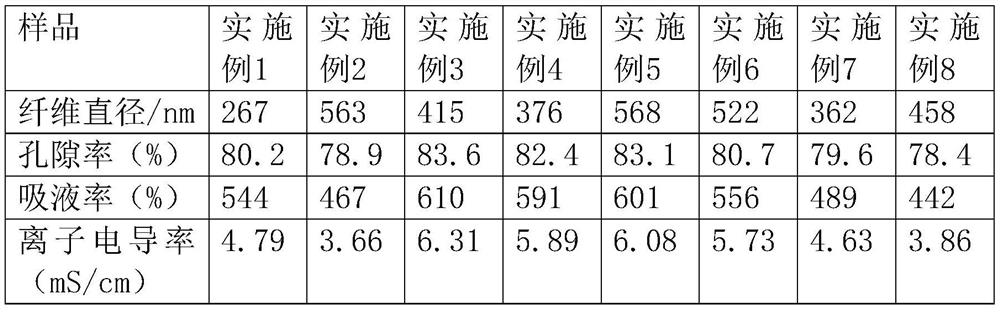

Embodiment 1

[0026] At room temperature, polyvinylidene fluoride powder and polyacrylonitrile were blended and dissolved in a mixed solution with acetone: N,N-dimethylformamide molar ratio of 3:1 to prepare a solution with a mass fraction of 8 wt%. , wherein the mass content of polyvinylidene fluoride is 30%, polyacrylonitrile is 70%; 50 ℃ water bath stirring for 24h, to obtain a uniform spinning solution; under the voltage of 20kV, the polypropylene melt-blown nonwoven fabric is used as the receiving substrate , the receiving distance is 10cm, and its double-sided electrospinning is obtained by blending polymer composite film, which is hot-pressed by a smooth roller at 125°C, and then the heat-treated composite diaphragm is put into a coating machine to coat with 10wt% alumina Silicone-modified acrylic emulsion, the solid content of the silicone-modified acrylic emulsion is 10%, the coating speed is 2m / min, and finally placed in an oven for 6 hours at 60°C to obtain an electrospun gel batt...

Embodiment 2

[0028] At room temperature, polyvinylidene fluoride powder and polyacrylonitrile were blended and dissolved in a mixed solution of acetone: N,N-dimethylformamide molar ratio of 3:1 to obtain a solution with a mass fraction of 14 wt%. , wherein the mass content of polyvinylidene fluoride is 40%, polyacrylonitrile is 60%; 50 ℃ water bath stirring for 24h, to obtain a uniform spinning solution; under the voltage of 20kV, the polypropylene melt-blown non-woven fabric is used as the receiving substrate , the receiving distance is 20cm, and its double-sided electrospinning is obtained by blending polymer composite membrane, which is hot-pressed by a smooth roller at 125°C, and then the heat-treated composite membrane is put into a coating machine to coat with 10wt% carbon dioxide Silicone silicone-modified acrylic emulsion, the solid content of the silicone-modified acrylic emulsion is 40%, the coating speed is 1.5m / min, and finally placed in an oven at 60°C for 6 hours to obtain an ...

Embodiment 3

[0030] At room temperature, polyvinylidene fluoride powder and polyacrylonitrile were blended and dissolved in a mixed solution of acetone: N,N-dimethylformamide molar ratio of 3:1 to obtain a solution with a mass fraction of 12 wt%. , wherein the mass content of polyvinylidene fluoride is 35%, polyacrylonitrile is 65%; 50 ℃ water bath stirring for 24h, to obtain a uniform spinning solution; under the voltage of 20kV, the polypropylene melt-blown nonwoven fabric is used as the receiving substrate , the receiving distance is 15cm, and its double-sided electrospinning is obtained by blending polymer composite film, which is hot-pressed by a smooth roller at 125°C, and then the heat-treated composite diaphragm is put into a coating machine to coat with 10wt% alumina Silicone-modified acrylic emulsion, the solid content of the silicone-modified acrylic emulsion is 10%, the coating speed is 2m / min, and finally placed in an oven for 6 hours at 60°C to obtain an electrospun gel batter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com