Preparation method of chlorine-resistant pollution-resistant polyamide reverse osmosis membrane

A technology of reverse osmosis membrane and polyamide membrane, applied in the field of preparation of reverse osmosis membrane, can solve the problems of poor chlorine resistance and pollution resistance, and achieve the effect of enhancing chlorine resistance and excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

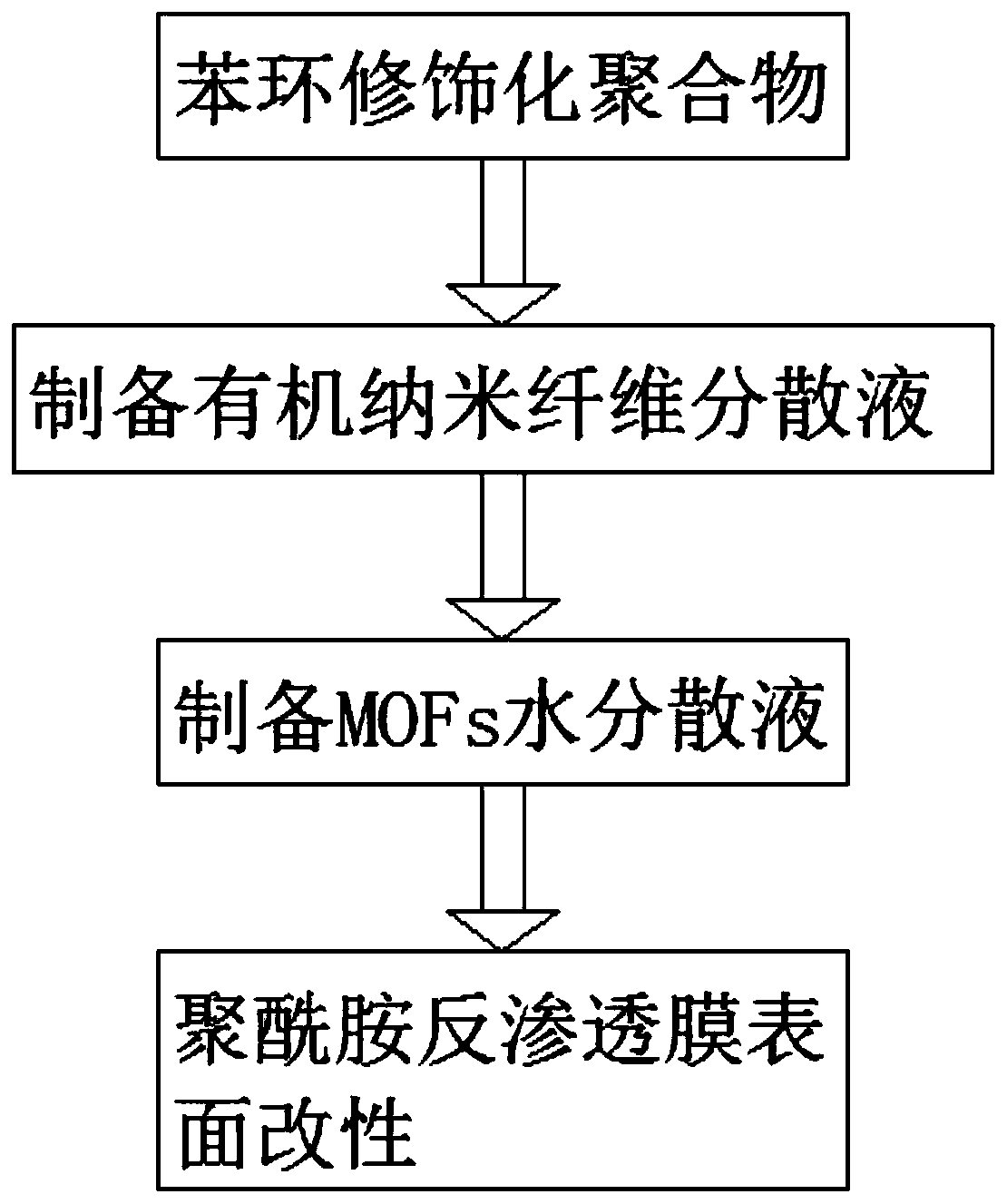

[0034] refer to figure 1 , a preparation method of a chlorine-resistant and pollution-resistant polyamide reverse osmosis membrane, comprising the following steps;

[0035] Step 1: benzene ring modified polymer, the specific steps are as follows;

[0036] A, use 4-methyldiphenylamine and 1,3,5-triformyl chloride cyclohexane to carry out interfacial polymerization preparation, obtain the polyamide membrane with reverse osmosis, polyamide membrane is in the sodium chloride feeding liquid concentration of 1500ppm and The rejection rate can reach 97.5% under the operating pressure of 1.5MPa, and the flux is 52 liters per square meter per hour;

[0037] B. Introduce sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com