Dimethylpolysiloxane composite membrane and preparation method and application thereof

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of polydimethylsiloxane composite membrane and its preparation, can solve the problems of low organic solvent separation factor and poor separation performance, and achieve Improve the separation factor of ethanol/water, improve the separation factor, and simplify the effect of membrane making process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

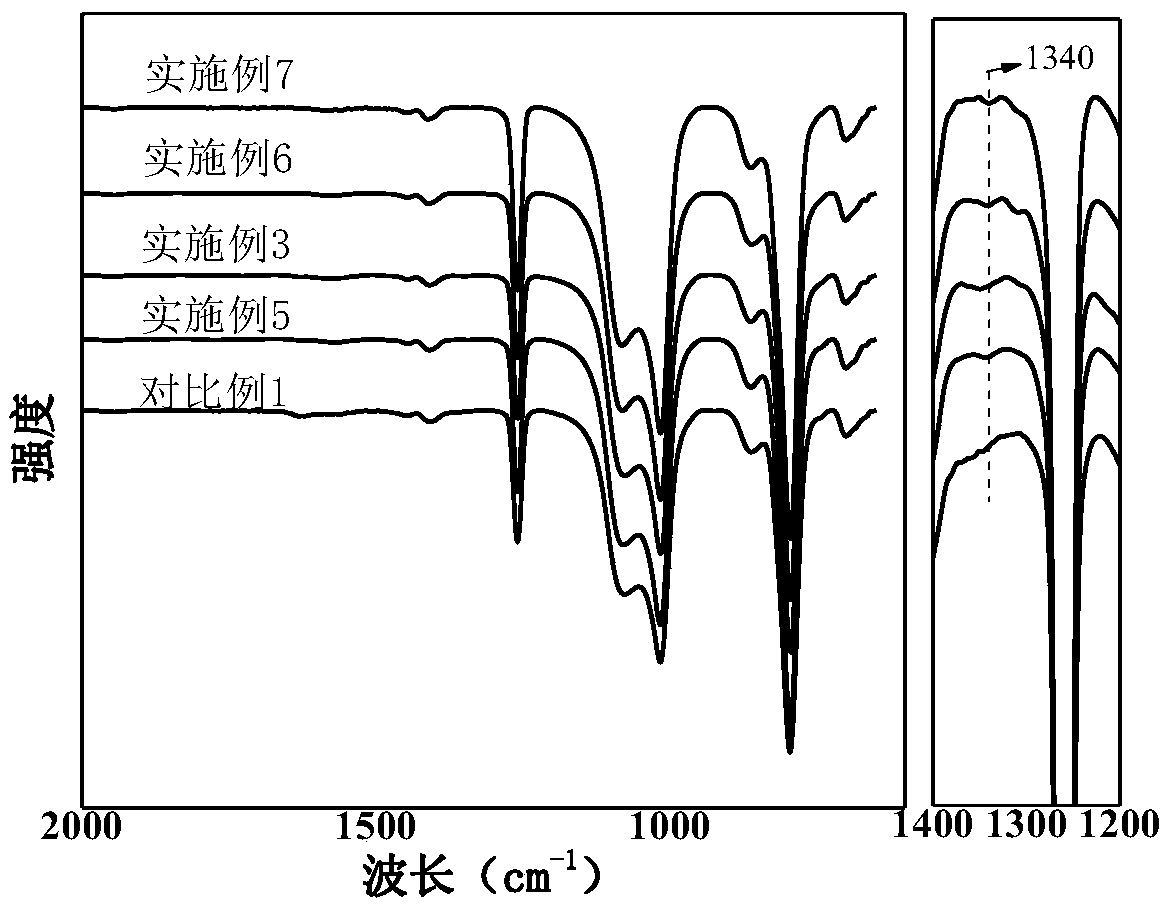

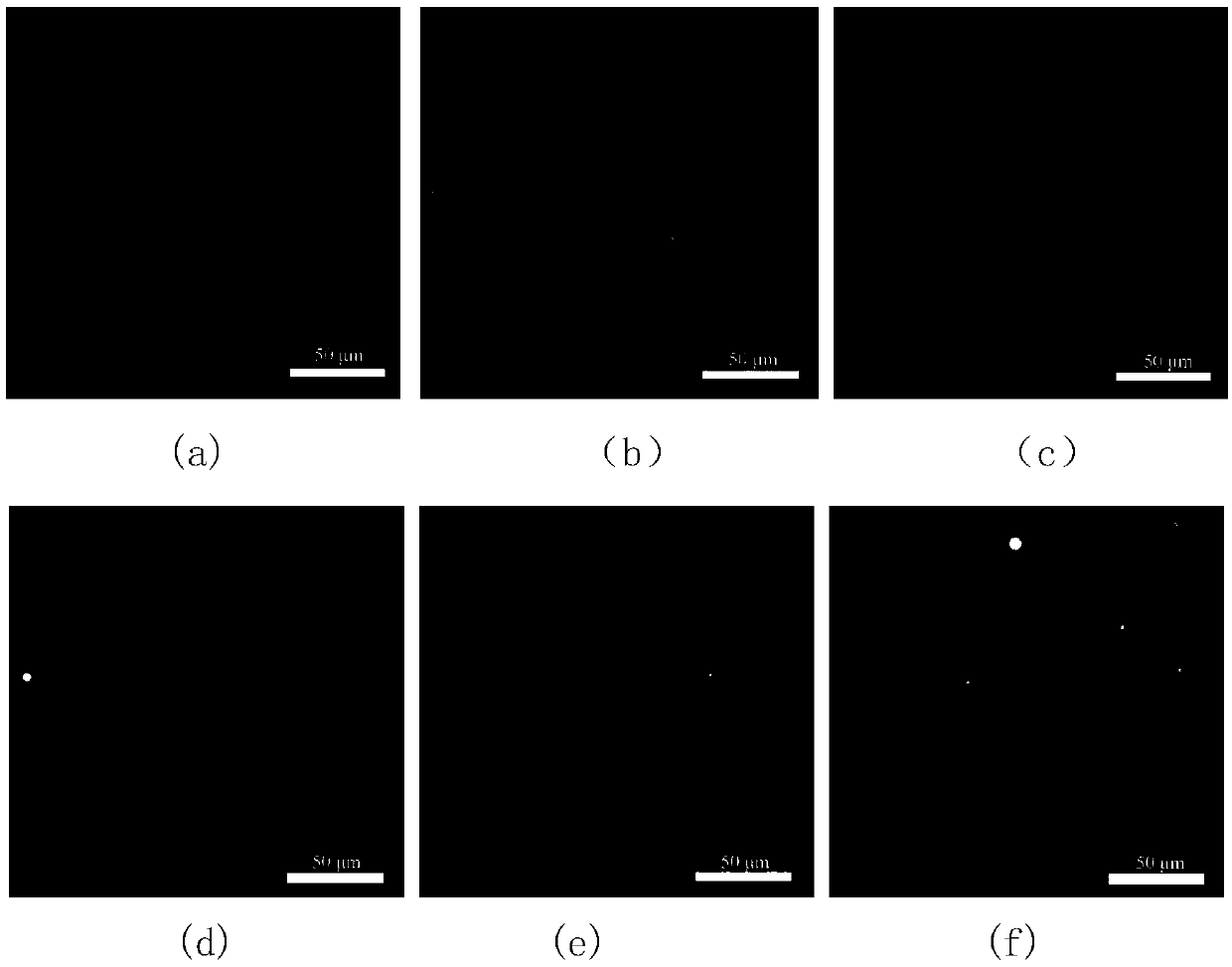

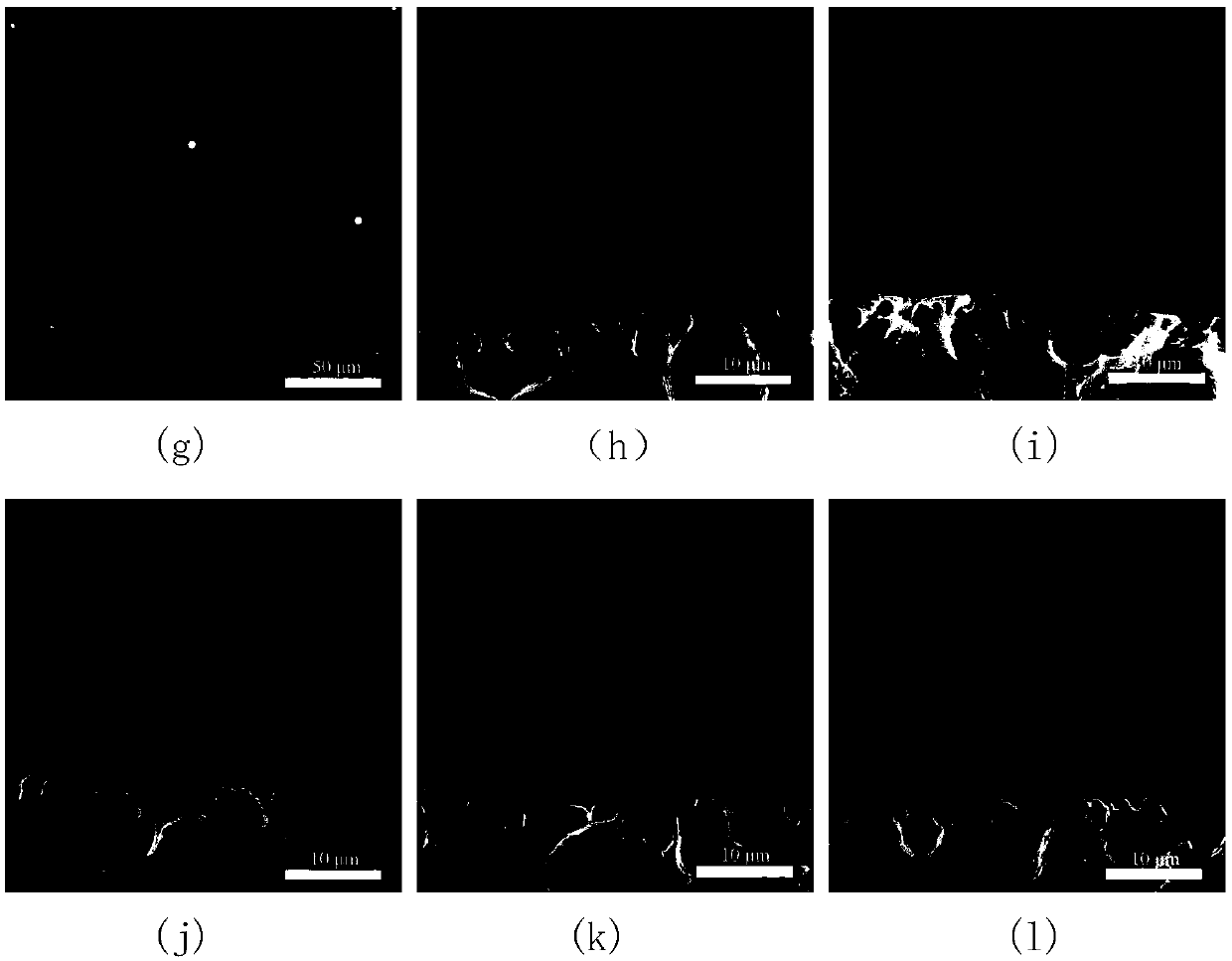

[0045] (1) Prepare ZIF-8@GO and polydimethylsiloxane tetrahydrofuran mixed solution, the mass fraction of ZIF-8@GO and polydimethylsiloxane in the mixed solution is 20wt%, first 0.005g The ZIF-8@GO hybrid material containing 20mg GO content was added to 4.5ml tetrahydrofuran solution, stirred ultrasonically for 12h to make it uniformly dispersed, then added 0.995g polydimethylsiloxane, and continued ultrasonically stirred for 12h to obtain For a uniform mixed solution, the mass of ZIF-8@GO accounts for 0.5wt% of the mass of polydimethylsiloxane.

[0046] (2) Add crosslinking agent and catalyst to ZIF-8@GO and polydimethylsiloxane tetrahydrofuran mixed solution, polydimethylsiloxane: crosslinking agent: catalyst mass ratio 50:8:1, room temperature Stir at a lower temperature, and wait for the viscosity of the solution to increase, scrape-coat it on the polyvinylidene fluoride / non-woven microfiltration membrane to solidify and form a film. The crosslinking agent is one or more ...

Embodiment 2

[0048] The experimental operation was the same as in Example 1, except that in step (1), the content of GO in ZIF-8@GO was 30 mg.

Embodiment 3

[0050] The experimental operation was the same as that in Example 1, except that in step (1), the content of GO in ZIF-8@GO was 40 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com