Intelligent temperature control vanadium dioxide composite film with enhanced infrared regulation capacity and preparation method thereof

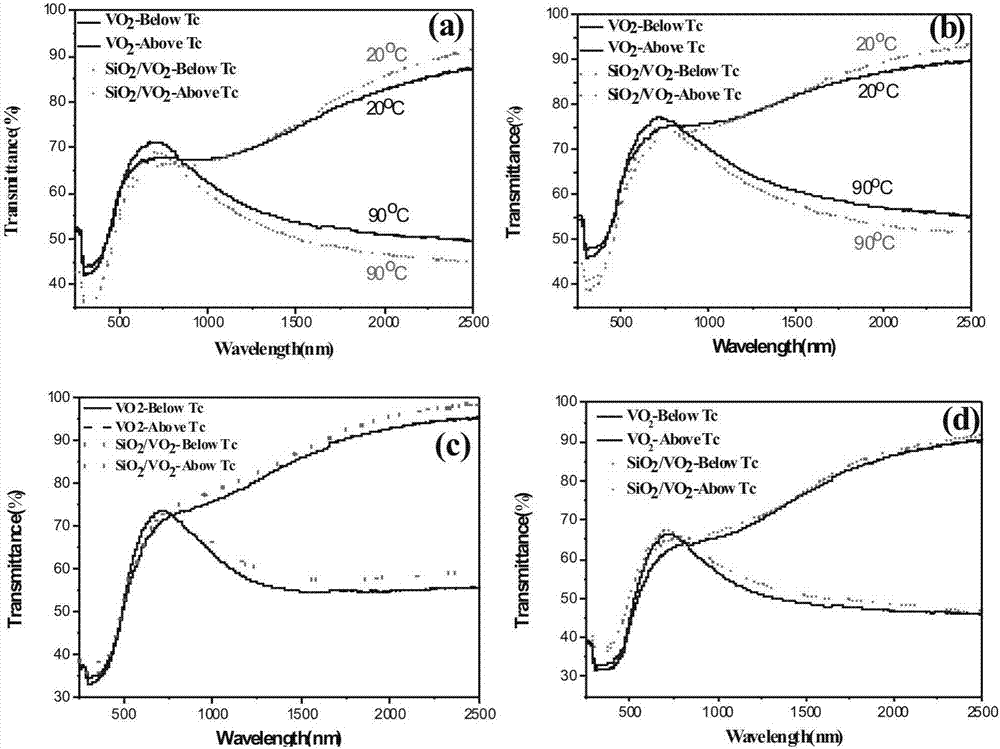

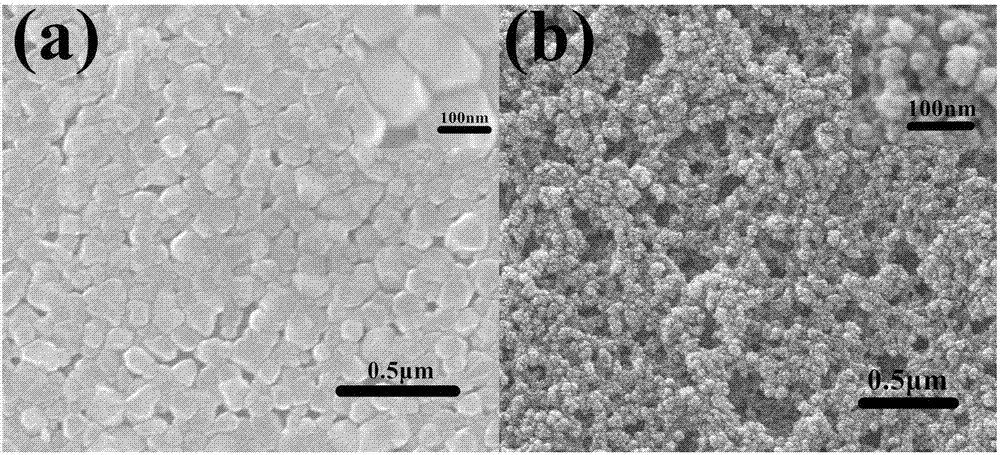

A technology of vanadium dioxide film and adjustment ability, applied in the field of intelligent temperature control vanadium dioxide composite film and its preparation, can solve the problems of low transmittance of visible light and no improvement of adjustment ability in near-infrared light region, and achieve enhanced infrared adjustment Ability and solar regulation ability, excellent optical switching characteristics, excellent superhydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

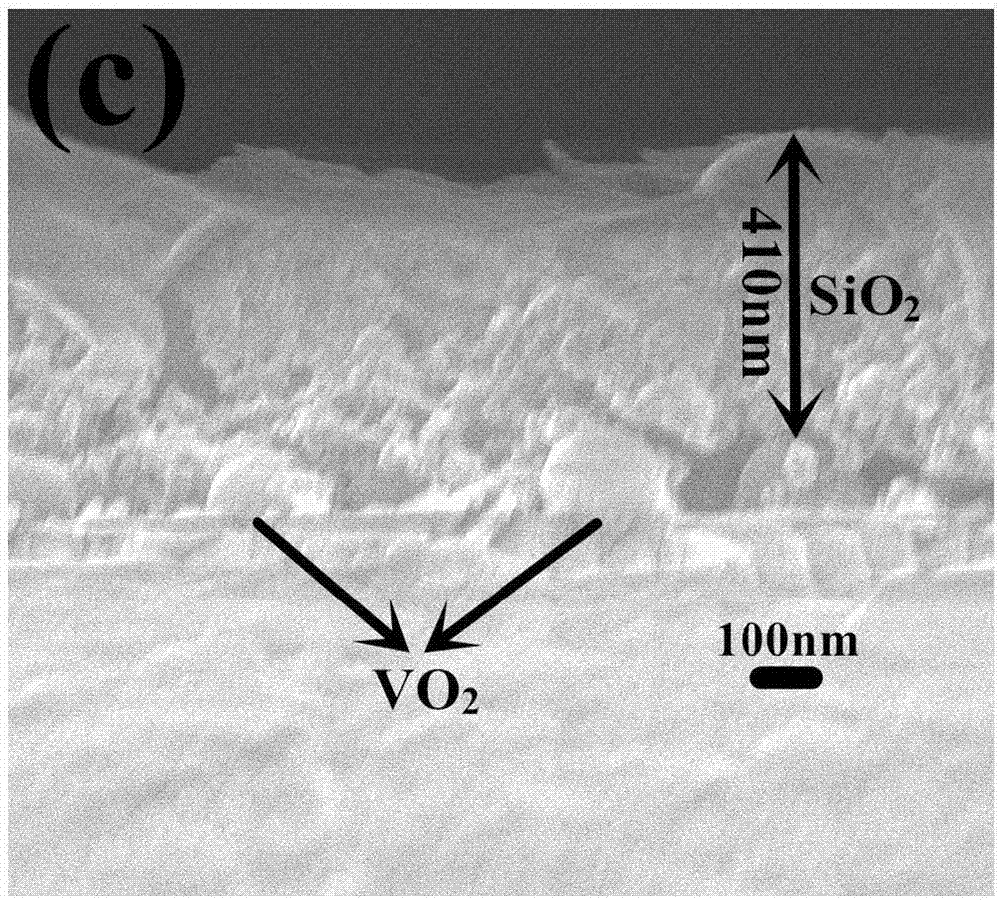

Method used

Image

Examples

Embodiment 1

[0035]A method for preparing an intelligent temperature-controlled vanadium dioxide composite thin film with enhanced infrared light adjustment capability, the specific steps are as follows:

[0036] 1) Take 1g of vanadyl acetylacetonate and 30ml of methanol in a beaker, place it on a magnetic stirrer and stir evenly, then add 0.2g of PVP, 0.5ml (11.2mol / L) of hydrochloric acid solution in sequence (at this time the system pH=3), Then continue to stir for 24 hours, let it stand for aging for 48 hours, and obtain a uniform dark blue precursor solution without precipitation;

[0037] 2) Drop the precursor solution obtained in step 1) on the surface of the quartz glass rotating in the homogenizer, spin-coat at a slow speed of 800r / min for 9s, and a high speed of 2500r / min for 30s, and dry it in argon after vacuum drying. Annealing at 650 °C for 1 h in the atmosphere and tubular muffle furnace to obtain VO 2 film;

[0038] 3) Take 1.08g of methyltrimethoxysilane, 0.5ml (0.001mol...

Embodiment 2

[0045] A method for preparing an intelligent temperature-controlled vanadium dioxide composite thin film with enhanced infrared light adjustment capability, the specific steps are as follows:

[0046] 1) Take 1g of vanadyl acetylacetonate and 30ml of methanol in a beaker, place it on a magnetic stirrer and stir evenly, then add 0.4g of PVP and 1ml (11.2mol / L) oxalic acid solution in sequence (at this time, the system pH=2), and continue Stir for 48 hours, stand for aging for 96 hours, and obtain a uniform dark blue precursor solution without precipitation;

[0047] 2) Drop the precursor solution on the surface of the quartz glass rotating in the homogenizer, spin-coat at a slow speed of 800r / min for 9s, and a high speed of 2500r / min for 30s, and dry it in a vacuum. Annealing at 500°C for 3 hours in a muffle furnace yields VO 2 film;

[0048] 3) Take 1.08g of methyltrimethoxysilane, 0.5ml (0.001mol / L) of oxalic acid, and 8.72g of methanol in a 25ml beaker (at this time, the p...

Embodiment 3

[0052] A method for preparing an intelligent temperature-controlled vanadium dioxide composite thin film with enhanced infrared light adjustment capability, the specific steps are as follows:

[0053] 1) Take 1g of vanadyl acetylacetonate and 30ml of methanol in a beaker, put it on a magnetic stirrer and stir evenly, then add 0.4g of PVP, 0.5ml (11.2mol / L) of hydrochloric acid solution in sequence (at this time the system pH=2), Stir continuously for 24 hours, and stand for aging for 48 hours to obtain a uniform dark blue precursor solution without precipitation;

[0054] 2) Drop the precursor solution on the surface of the quartz glass rotating in the homogenizer, spin-coat at a slow speed of 800r / min for 9s, and a high speed of 2500r / min for 30s, and dry it in a vacuum. Anneal at 500℃ for 1.5h in muffle furnace to get VO 2 film;

[0055] 3) Take 0.54g of methyltrimethoxysilane, 0.64g of hexamethyldisilazane, 0.5ml (0.001mol / L) of oxalic acid, and 8.72g of methanol in a 25m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com