Lens optical coating surface treatment process and lens obtained by process

An optical coating and surface treatment technology, used in the field of glasses, can solve the problems of friction resistance, drop angle value drop, surface color shedding, etc., and achieve the effect of strong anti-aging ability, small change in surface properties, and increased service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

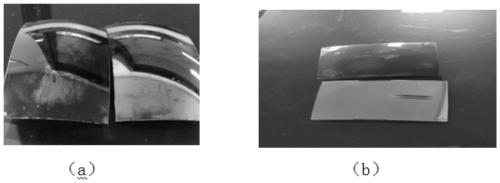

[0096] Step 1), performing plasma bombardment on the surface of the lens to activate the substrate, and for the glass lens, the water drop angle value is lower than 15° after plasma bombardment;

[0097] Step 2), prepare the coating material, adopt ion-assisted plating, and adjust the thickness of the film layer according to different color requirements (made by TFC simulation);

[0098] Step 3), anti-evaporation evaporation waterproof film;

[0099] Step 4), the electron gun evaporates AF;

[0100] Step 5), stand still.

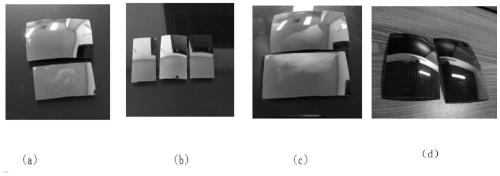

[0101] Figure 5 It is a comparison chart of lenses treated by the process of Example 1 after soaking in seawater for different times.

[0102]

[0103] The advantage data of embodiment 1 relative comparative example 1-4:

[0104] 1. The overall initial water drop angle value is about 2° higher. This method evaporates AF, and the evaporation is more complete. The thickness of the film layer will be thicker than the above method, and there will be no l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com