Trehalose modified polyvinyl alcohol anti-fog and anti-frost coating and preparation method thereof

A technology of polyvinyl alcohol and trehalose, applied in coatings, chemical instruments and methods, and other chemical processes, can solve problems such as poor stability of composite systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

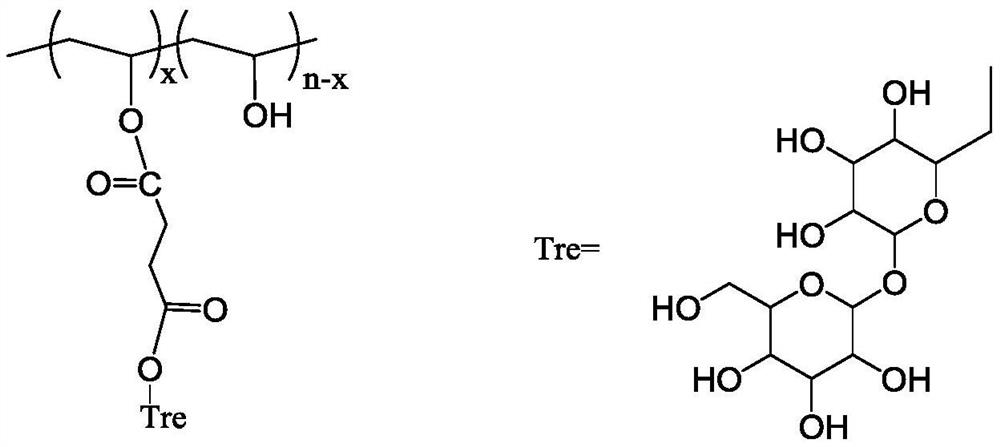

[0037] (1) Synthesis of polyvinyl alcohol-graft-trehalose:

[0038] 2.45g carboxylated trehalose, 0.3g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 0.13g 4-dimethylaminopyridine were dissolved in 10mL deionized water, and 110 mL of 10 mg / mL polyvinyl alcohol solution was added to the reaction bottle, and reacted at room temperature for 1 day. After the reaction, a dialysis bag was used for dialysis treatment for 1 day, and then the white flocculent solid sample was collected by lyophilization.

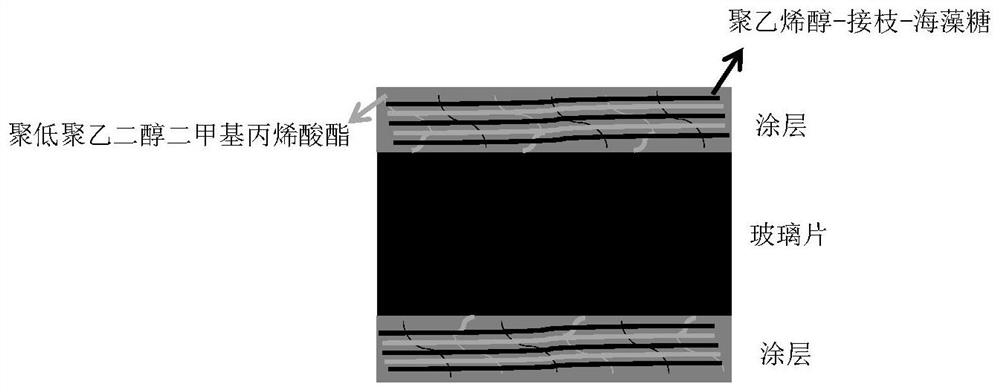

[0039] (2) Preparation of anti-fog / anti-frost coating containing polyvinyl alcohol-graft-trehalose:

[0040] Polyvinyl alcohol-graft-trehalose: 1%;

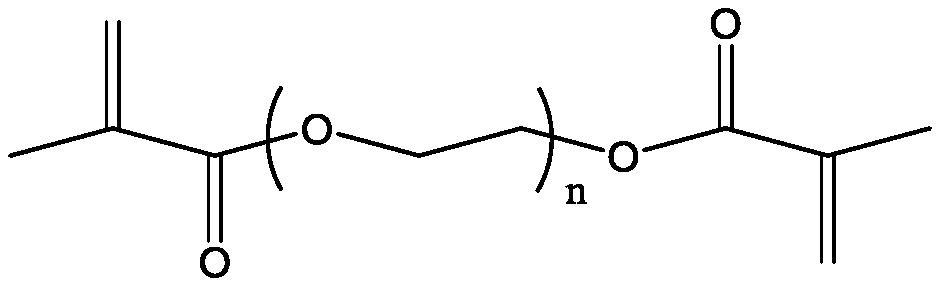

[0041] Oligoethylene glycol dimethacrylate: 0.1%;

[0042] Benzoin dimethyl ether: 0.05%;

[0043] Deionized water: 98.85%.

[0044] Both sides of the glass sheet were treated with plasma for 2 min each, and then immersed in a toluene solution of 1% (3-mercaptopropyl) trimethoxysilane for 1 h, and then soaked in toluen...

Embodiment 2

[0049] (1) Synthesis of polyvinyl alcohol-graft-trehalose:

[0050] 4.91g carboxylated trehalose, 0.6g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 0.26g 4-dimethylaminopyridine were dissolved in 10mL deionized water, and 55mL of 20mg / mL polyvinyl alcohol solution was added to the reaction bottle and reacted at room temperature for 1 day. After the reaction was completed, a dialysis bag was used for dialysis treatment for 1 day, and then the white flocculent solid sample was collected by lyophilization.

[0051] (2) Preparation of anti-fog / anti-frost coating containing polyvinyl alcohol-graft-trehalose:

[0052] Polyvinyl alcohol-graft-trehalose: 2%;

[0053] Oligoethylene glycol dimethacrylate: 0.2%;

[0054] Benzoin dimethyl ether: 0.1%;

[0055] Deionized water: 97.7%.

[0056] Both sides of the glass sheet were treated with plasma for 2 min respectively, and then immersed in 2% (3-mercaptopropyl) trimethoxysilane in toluene solution for 1.5 h, and then ...

Embodiment 3

[0061] (1) Synthesis of polyvinyl alcohol-graft-trehalose:

[0062] 7.36g carboxylated trehalose, 0.9g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 0.39g 4-dimethylaminopyridine were dissolved in 10mL deionized water, and 22.5mL of 40mg / mL polyvinyl alcohol solution was added to the reaction bottle, and reacted at room temperature for 2 days. After the reaction, a dialysis bag was used for dialysis treatment for 2 days, and then the white flocculent solid sample was collected by lyophilization.

[0063] (2) Preparation of anti-fog / anti-frost coating containing polyvinyl alcohol-graft-trehalose:

[0064] Polyvinyl alcohol-graft-trehalose: 5%;

[0065] Oligoethylene glycol dimethacrylate: 0.5%;

[0066] Benzoin dimethyl ether: 0.25%;

[0067] Deionized water: 94.25%.

[0068] Both sides of the glass sheet were treated with plasma for 3 minutes respectively, and then immersed in 3% (3-mercaptopropyl) trimethoxysilane in toluene solution for 2 hours, and then r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com