Patents

Literature

53results about How to "Coating method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

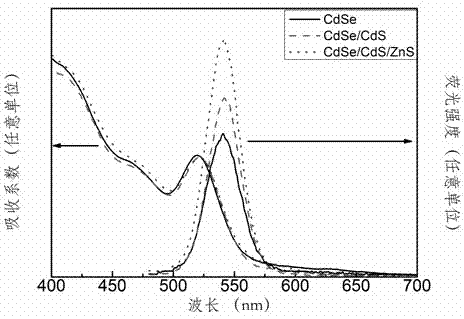

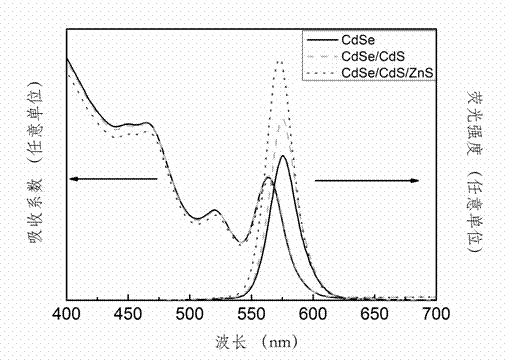

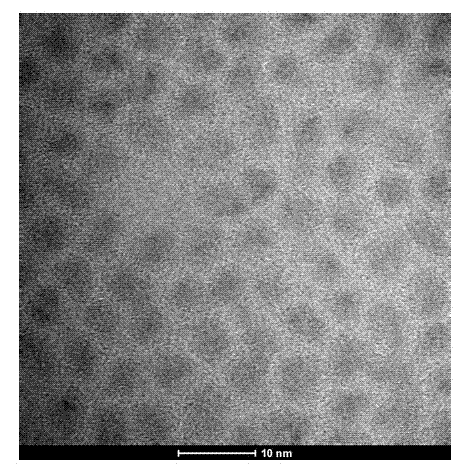

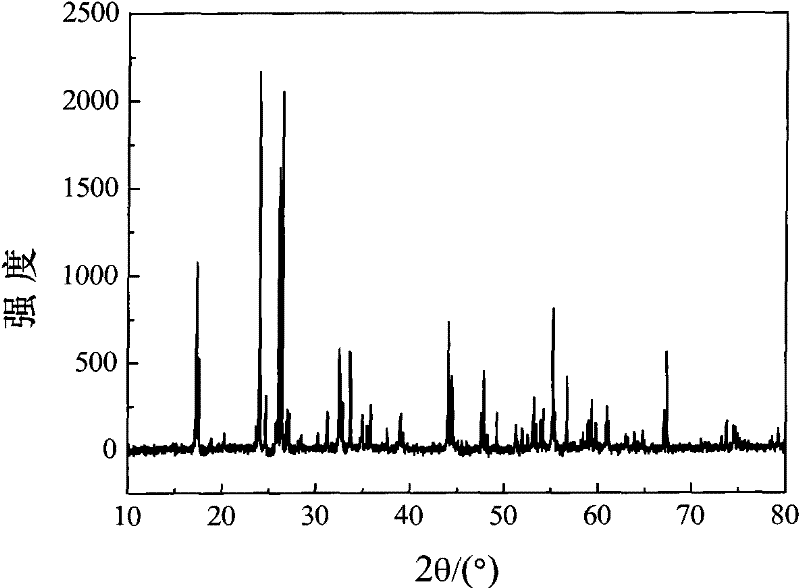

Synthetic method for preparing CdSe/CdS/ZnS core-shell structure quantum dots by acid assistance

InactiveCN104498039ASmall emission wavelength effectCoating method is simpleLuminescent compositionsOrganic acidParaffin oils

The invention discloses a synthetic method for preparing CdSe / CdS / ZnS core-shell structure quantum dots by acid assistance. The synthetic method comprises the following steps: synthesizing a CdSe core quantum dot solution in a paraffin oleic acid system, using cadmium oleate as a precursor of a shell layer CdS, using a sulfur source dissolved in liquid paraffin as a precursor of the shell layers CdS and ZnS, using a zinc source dissolved in the liquid paraffin as a precursor of the shell layer ZnS, adding an organic acid in a precursor of S, and dripping the organic acid into the core quantum dot solution, wherein the organic acid reinforces the activity of the precursors of the shell layers, reduces the surface ligands of the core quantum dot, promotes the growth of the CdS shell layer on the surface of the CdSe core quantum dot and achieves epitaxial coating; dripping the precursor of Zn to wrap the ZnS shell layer to obtain a CdSe / CdS / ZnS core-shell structure quantum dot solution. The synthetic method disclosed by the invention has the advantages that the CdSe / CdS / ZnS core-shell structure quantum dots can be synthesized in the atmosphere under a non-phosphor system, the raw materials are cheap, the reaction temperature is low, the growth of the shell layers is fast, the operation is simple and mass production is suitable.

Owner:HUBEI UNIV

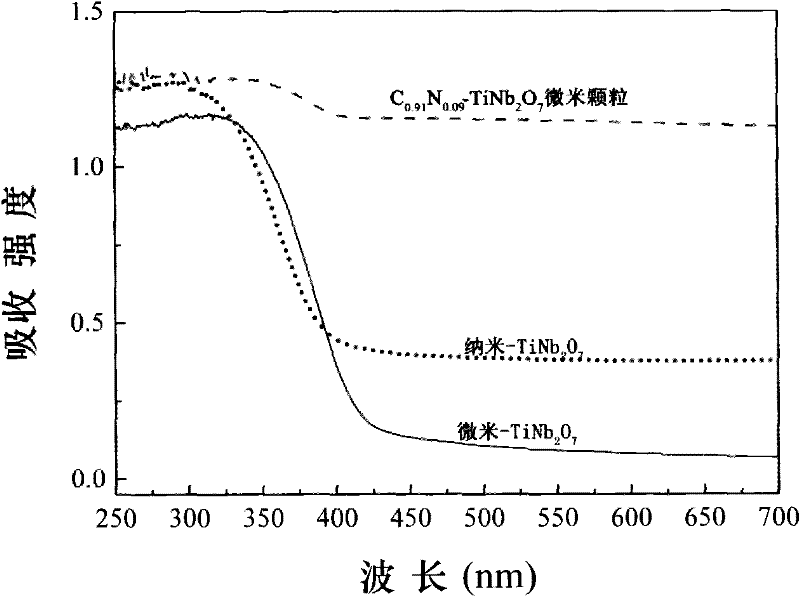

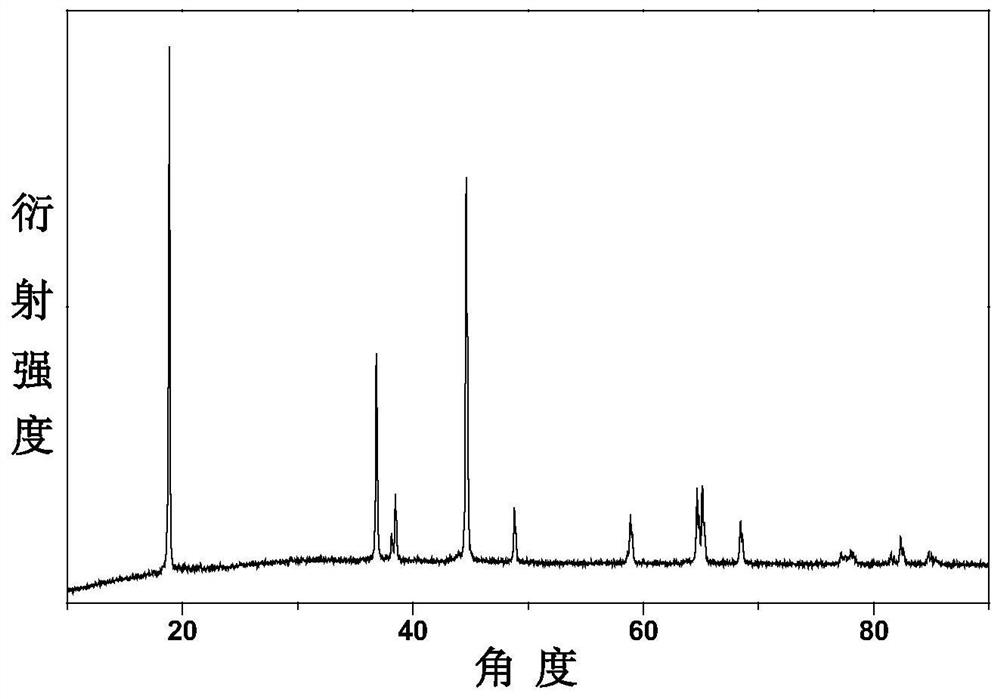

Titanium niobate composite material, preparation method thereof, and cathode and battery containing the same

ActiveCN102479950AImprove cycle performanceFacilitated DiffusionCell electrodesLi-accumulatorsHigh rateTitanium

The invention relates to a titanium niobate composite material, a preparation method thereof, and a cathode and a battery containing the composite material. The titanium niobate composite material is represented as BxCyNz-LaTibMcNbdOe, wherein BxCyNz represents a compound containing boron carbon or carbon nitrogen or boron carbon nitrogen; L represents Li or Na, preferably Li; M is one element selected from Al, B, V, Cr, Mn, Fe, Co, Ni, Ce, Y, Zr, Mo, La, Ta, N and P; x, y, z, a, b, c, d and e represent mole percentages, x is no less than 0 and less than 1, y is larger than 0 and less than 1, z is no less than 0 and less than 1, a is no less than 0 and no larger than 0.2, b is larger than 0.8 and no larger than 1.1, c is no less than 0 and less than 0.2, d is larger than 1.95 and no larger than 2.1, e is no less than 6.8 and no larger than 7, and x and y are not 0 at the same time. The composite material disclosed herein and used as a cathode material of a lithium ion battery has the advantages of high coulombic efficiency, high ionic and electric conductance, good cycling performance of high-rate charge and discharge, high safety, no pollution, and low price.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

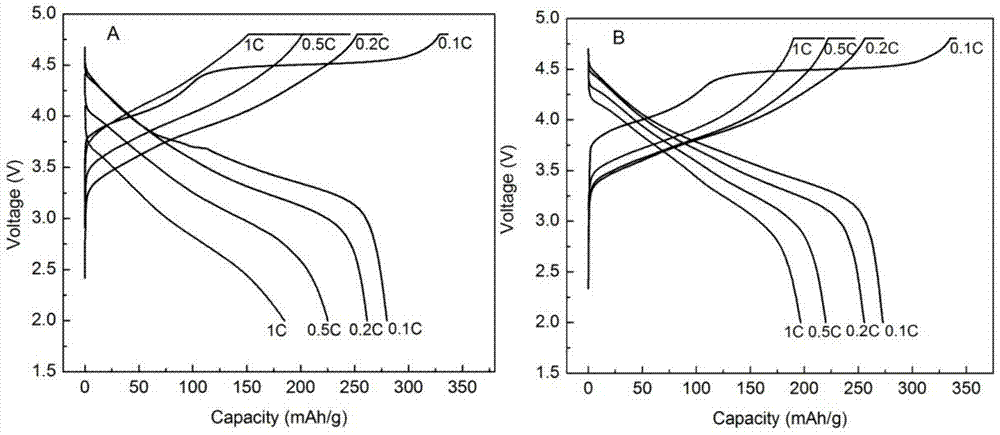

Aluminum cladding method of high-safety lithium ion battery anode material

InactiveCN102364723AImprove cycle performanceImprove securityCell electrodesHigh temperature storageElectrical battery

The invention relates to a manufacturing method of a lithium ion battery anode material, in particular to an aluminum cladding method of a high-safety lithium ion battery anode material. The method comprises the following steps of: a, manufacturing a non-cladded anode material by adopting a conventional method; b, preparing a cladding solution, wherein the cladding solution is aluminum salt sol formed by mutually dissolving an aluminum source and a cosolvent, and the weight concentration of the aluminum salt in the sol is 15-30 percent; c, performing a cladding process: adding the non-cladded anode material to cladding-phase methanol or ethanol or acetone, stirring and mixing, and then adding an aluminum salt sol cladding solution, wherein the molar ratio Al / M of the element Al to the central element M of the anode material is 0.002-0.05; and d, heating and drying for 1-6h at 70-100 DEG C under the vacuumizing condition to form a finished product. According to the aluminum cladding method disclosed by the invention, the high-temperature storage safety and the cycle stability of the lithium ion anode material under high charging cutoff voltage can be ensured.

Owner:JIANGSU KING LITHIUM CELL

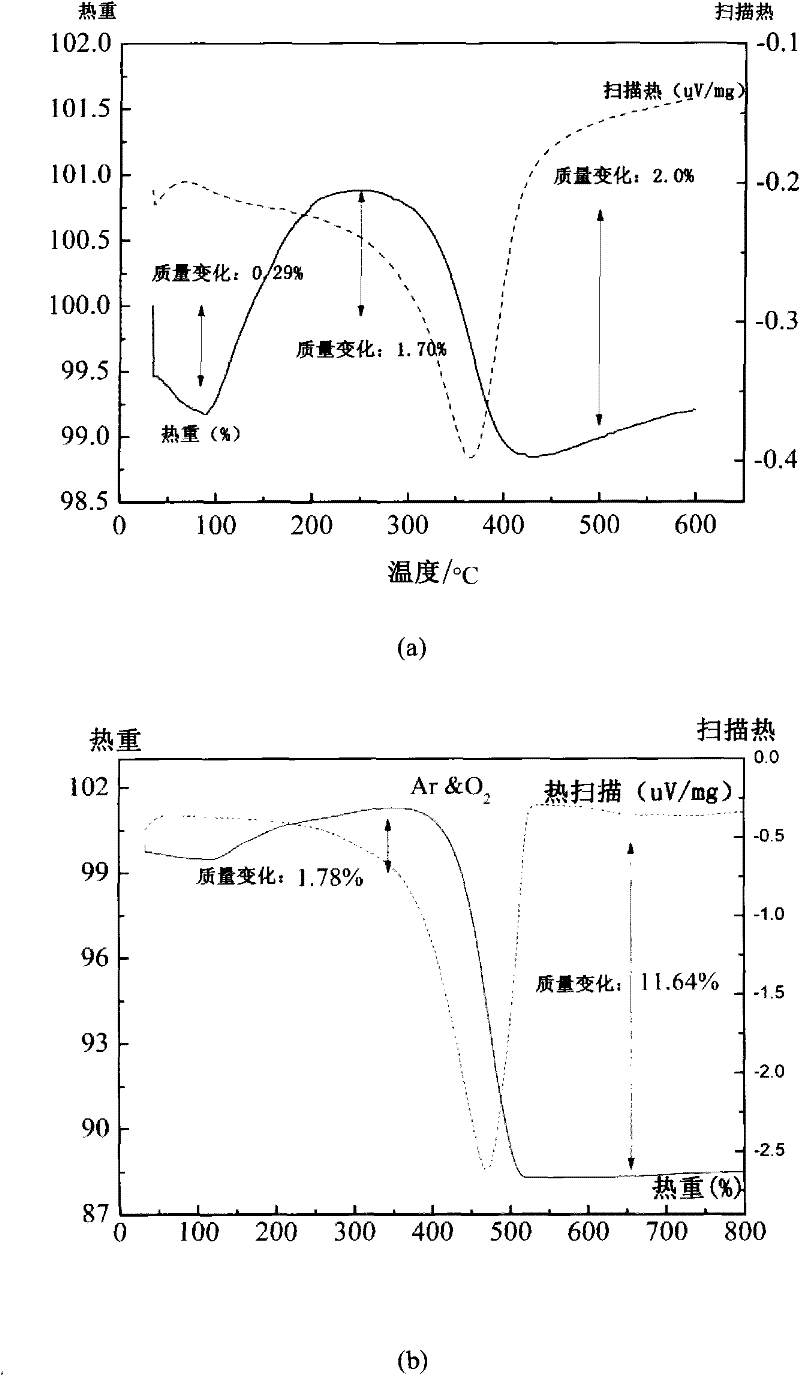

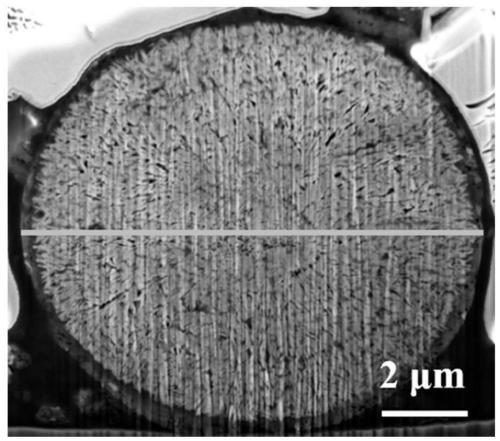

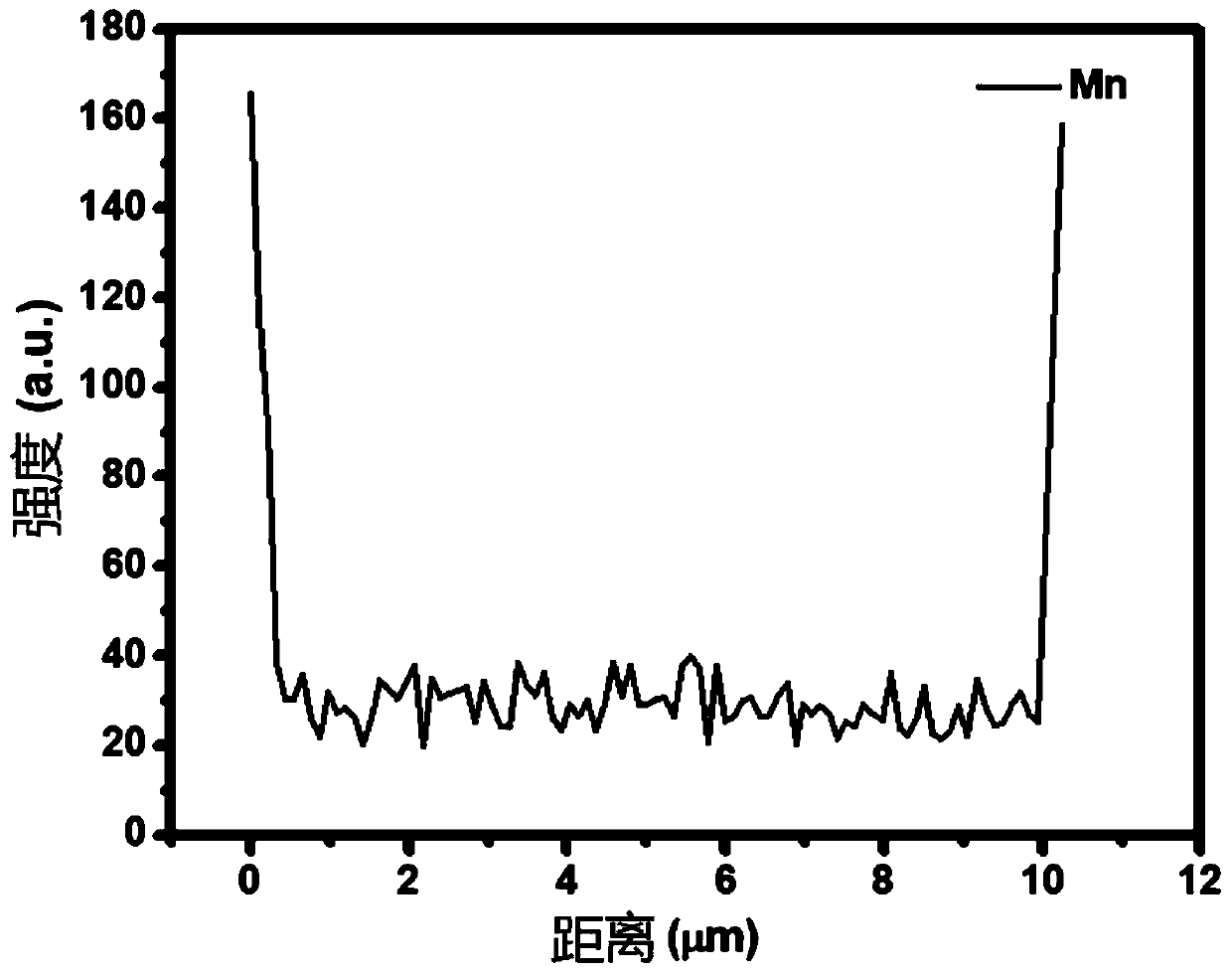

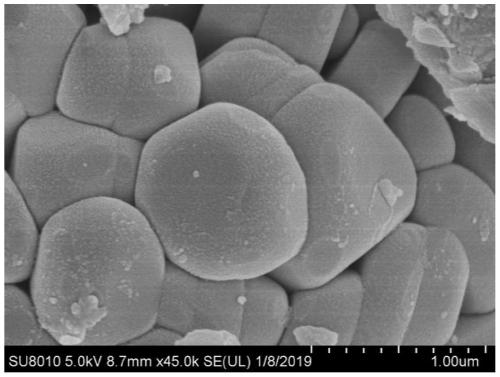

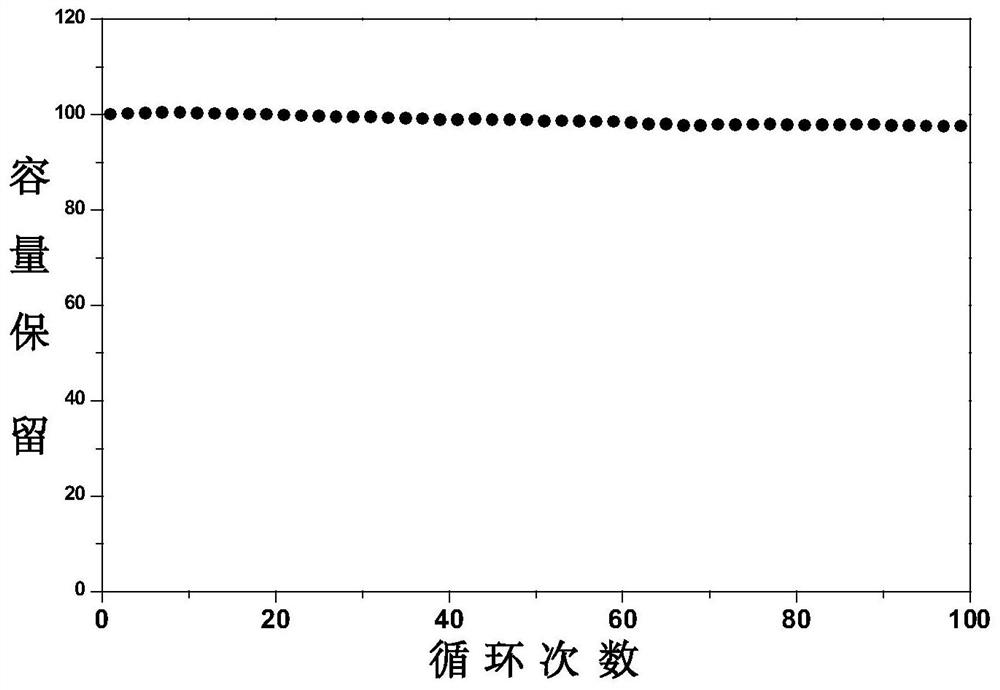

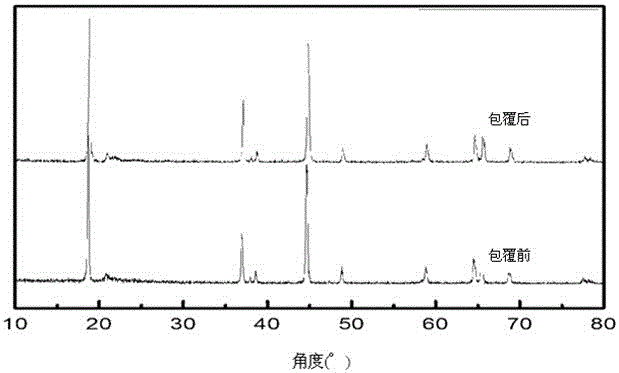

Modification method of high-nickel ternary anode material of lithium ion battery

InactiveCN111477867ACoating method is simpleReduce difficultySecondary cellsPositive electrodesManganeseLithium-ion battery

The invention discloses a modification method of a high-nickel ternary anode material of a lithium ion battery. The method comprises the following steps: a, mixing an original precursor of the high-nickel ternary material with a lithium source, and presintering to prepare a lithiated precursor; b, preparing manganese / aluminum oxide nanoparticles by using a sol-gel method; c, uniformly coating thesurface of the lithiation precursor of the high-nickel ternary material with manganese / aluminum oxide nanoparticles; and d, preparing the manganese / aluminum element doped high-nickel ternary materialthrough high-temperature calcination. According to the lithiation precursor route provided by the invention, the breakage of the precursor in the nanoparticle coating process can be greatly reduced, and the uniform coating of the manganese / aluminum oxide nanoparticles on the lithiation precursor is realized. By regulating and controlling the crystal microstructure of the manganese / aluminum doped high-nickel ternary material, cracks of the ternary material microspheres in the charge-discharge cycle process of the battery can be greatly reduced, so that the high-nickel ternary material shows excellent cycle stability.

Owner:SUZHOU UNIV

High-performance nanofiltration composite membrane containing polymer coating layer

InactiveCN110496533AHigh retention rateControl Separation PerformanceReverse osmosisPolymer sciencePoly ether ether ketone

The invention relates to a preparation method of a high-performance nanofiltration composite membrane containing a polymer coating layer. The preparation method comprises following steps: a polymer coating layer is introduced onto the surface of a porous supporting membrane; solvent volatilization treatment is carried out; interface polymerization is carried out on the supporting material containing the polymer coating layer, wherein the monomers adopted in interface polymerization are polyamines and poly acyl chlorides; after interface polymerization reaction, heat crosslinking treatment is carried out; or before introduction of the polymer coating layer, interface polymerization reaction is carried out on the surface of the porous supporting membrane. The adopted porous supporting material is prepared from a polymer material such as polysulfones, polyethersulfones, polyether ether ketones, polycarbonates, polyvinylidene fluoride, polyacrylonitrile, polyethylene, polypropylene, or inorganic porous materials such as alumina and titanium dioxide ceramic materials. The preparation method is capable of avoiding the seesaw effect of permeability and interception performance of nanofiltration and reverse osmosis membranes, and obtaining the nanofiltration membrane high in permeability and retention rate. The preparation method is low in cost, and simple in operation, and great meaning in the field of membrane material wide applications and circular economy is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

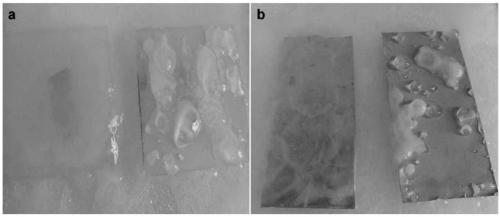

Process for producing aluminum surface super hydrophobic thin film

InactiveCN101096771ADense growthTightly boundElectrolytic organic material coatingWater solubleAluminium

The invention discloses a super dewatering film preparing method on the Al surface, which comprises the following steps: formulating the organic coating film with the electrolysis solution by selecting 0.5-5mmol / l water-soluble triazoxide organic compound salt and 0.25-5mol / l basic supporting electrolysis salt; regarding the roughening and cleaning aluminium surface as the working electrode and putting in the electrolysis solution; proceeding with the organic coating with tri electrode method (the coating temperature is 5-25Deg. C, the current density is 0.5-10A / m2, the coating time is 30s-50min); preparing a layer dense super dewatering film with super dewatering function characteristic and binding the organic film with aluminium basis surface tightly by the conjugated linkage. The invention can be used for the large-area super dewatering modifying property on the aluminum surface, in particular to the specially-shaped and complicated parts. The method is provided with the simple operation, the easy industrialization characteristic.

Owner:SOUTH CHINA UNIV OF TECH

Anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for surface of silicon rubber material and preparation method thereof

ActiveCN110204650AHigh densityHigh reactivitySurgeryPharmaceutical containersPhosphatePolymer chemistry

The invention provides an anticoagulation, antibacterial, anti-adhesion, anti-anti-inflammation and lubricating copolymer coating material for the surface of a silicon rubber material and a preparation method thereof. The material is a high molecular copolymer formed by polyelectrolyte and active ester; the polyelectrolyte is a zwitter-ion polyelectrolyte which is generated by polymerizing phosphate ammonium or carboxyl ammonia or sulphur ammonia zwitter-ion monomers. The monomers and active ester monomers of the prepared polyelectrolyte are directly mixed and polymerized, or a homopolymer ofone of the two monomers is prepared at first, the homopolymer is adopted as a chain transfer agent, and the other monomer is adopted as a polymer monomer to obtain the copolymer. The prepared copolymer coating can be bonded on the surface of silicon rubber through the single coating technology to form the stable polymer coating; the number and density of microorganisms and bacteria attached to thesurface of the modified silicon rubber material are remarkably decreased, and the anticoagulation, antibacterial, anti-adhesion and anti-anti-inflammation performance can be remarkably improved; thesurface of the silicon rubber is high in hydrophilicity, the friction coefficient is remarkably lowered, and the lubricating performance can be obviously enhanced.

Owner:NANJING NORMAL UNIVERSITY

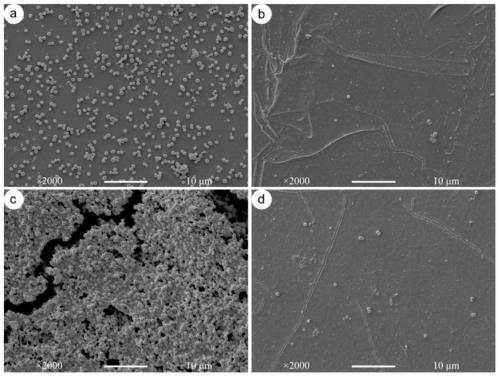

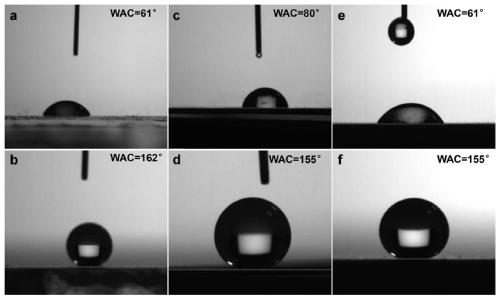

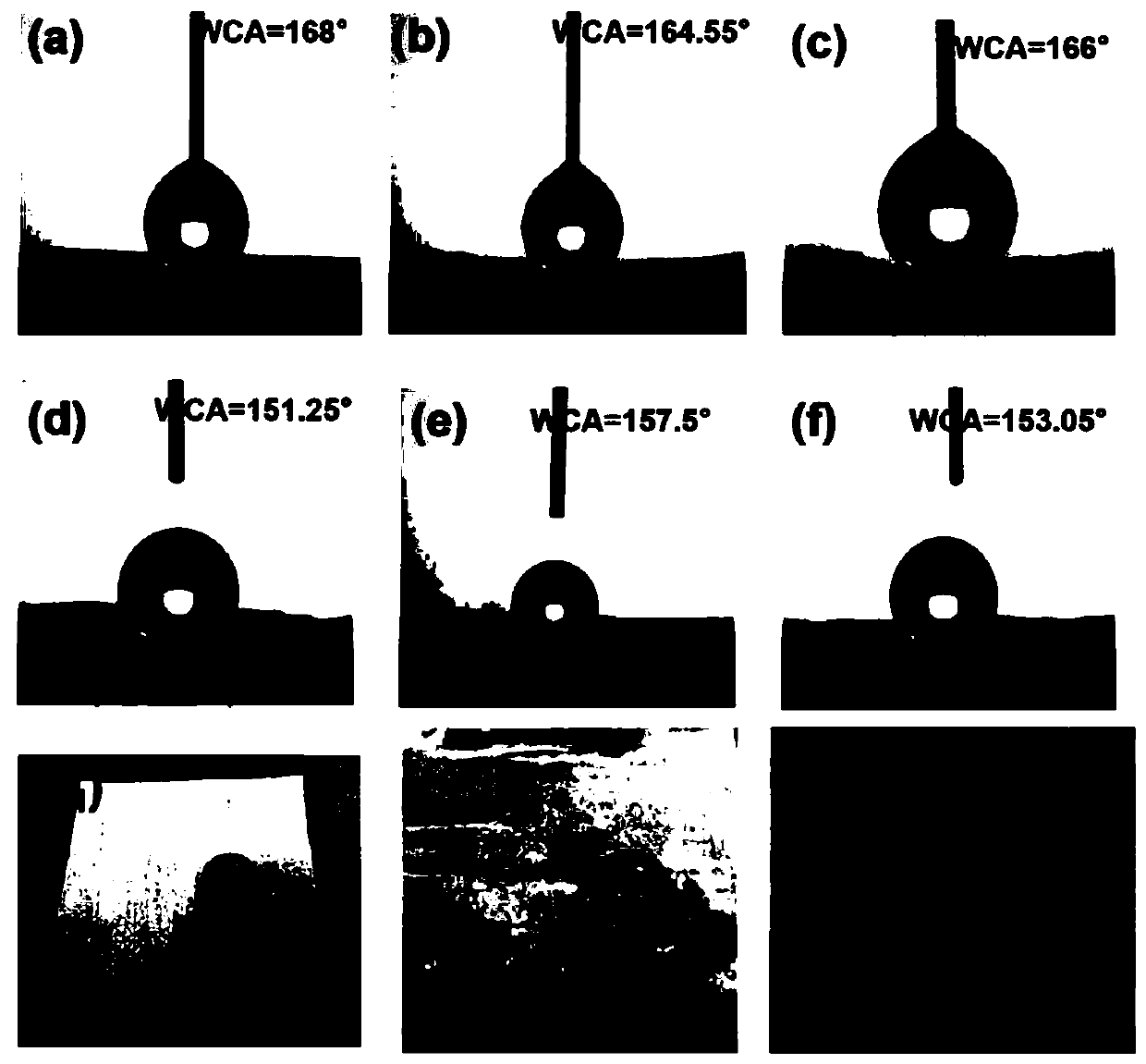

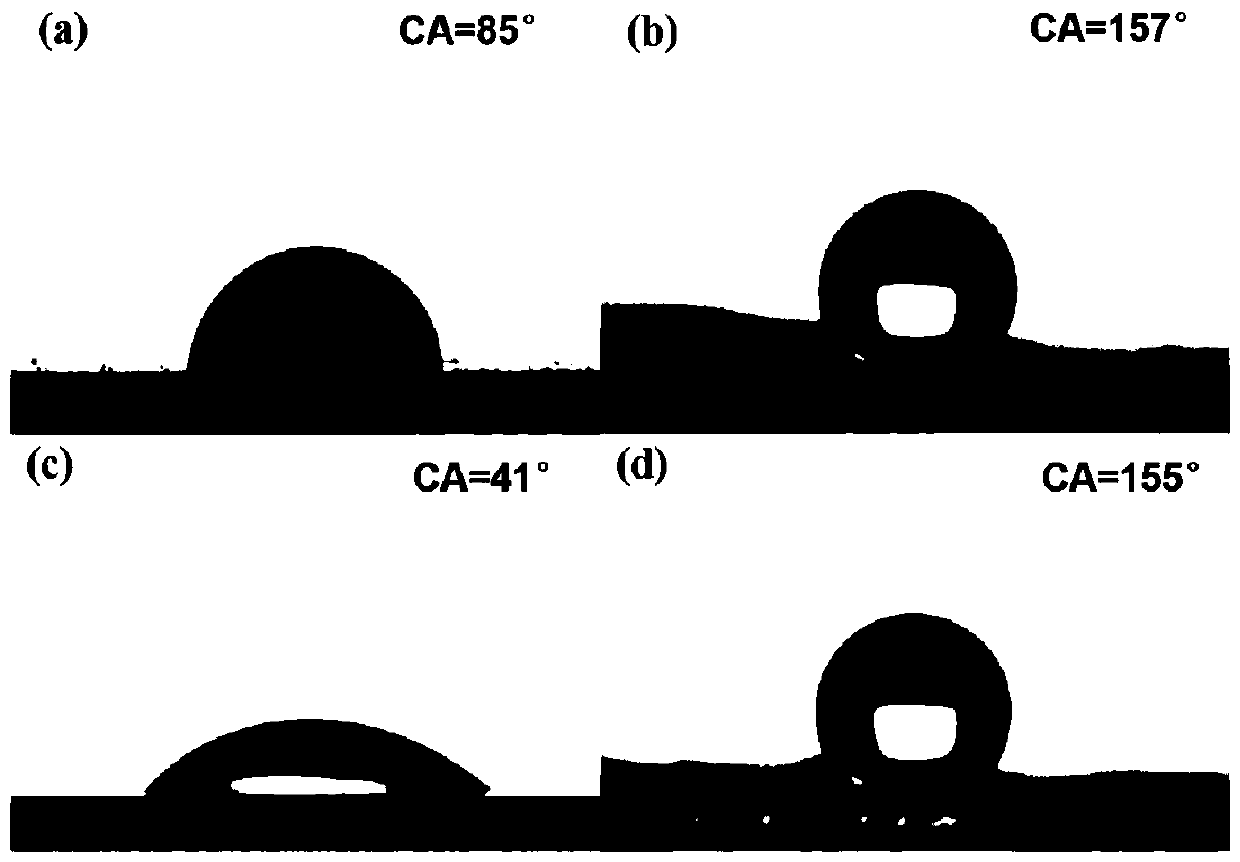

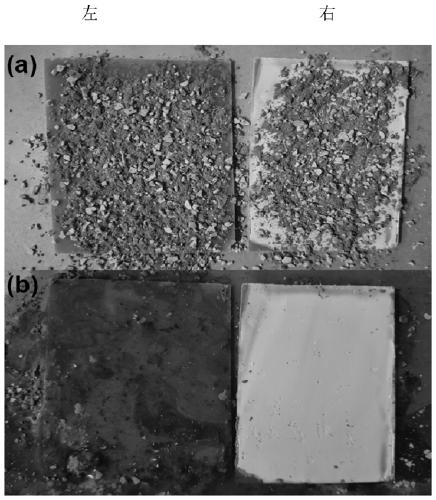

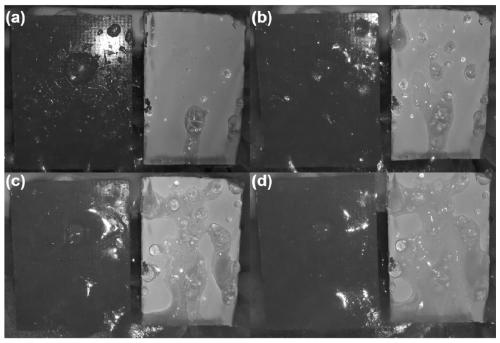

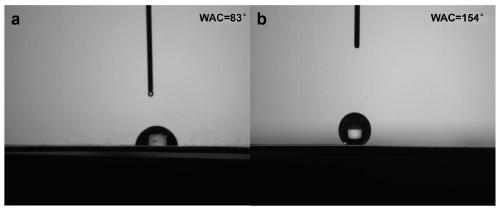

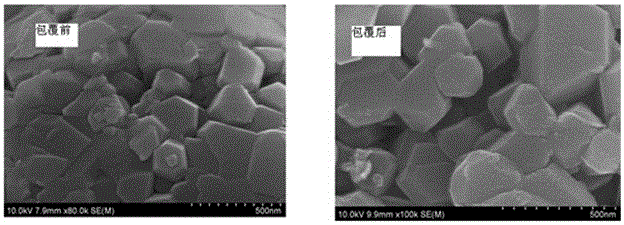

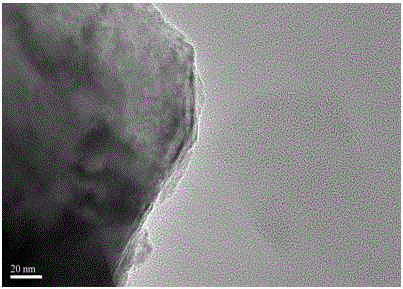

TiO2 composite hydrophobic icephobic coating and preparation method thereof

ActiveCN109535782ACoating method is simpleReduce manufacturing costAntifouling/underwater paintsPaints with biocidesWater contactRolling angle

The invention relates to a nano-material and a method for preparing a coating, particularly a method for preparing a titanium dioxide composite coating mainly by a hydrothermal method and a sol-gel method so as to form a superhydrophobic film. The superhydrophobic film prepared has the characteristics of a large static water contact angle, a small rolling angle and a wide application matrix range,the static water contact angle on a glass substrate can reach 162 degrees, and the rolling angle is less than 1 degree. This coating has a self-cleaning effect like a lotus leaf structure, and in addition, the film can provide good anti-icing and anti-corrosion effects.

Owner:CHINA THREE GORGES UNIV

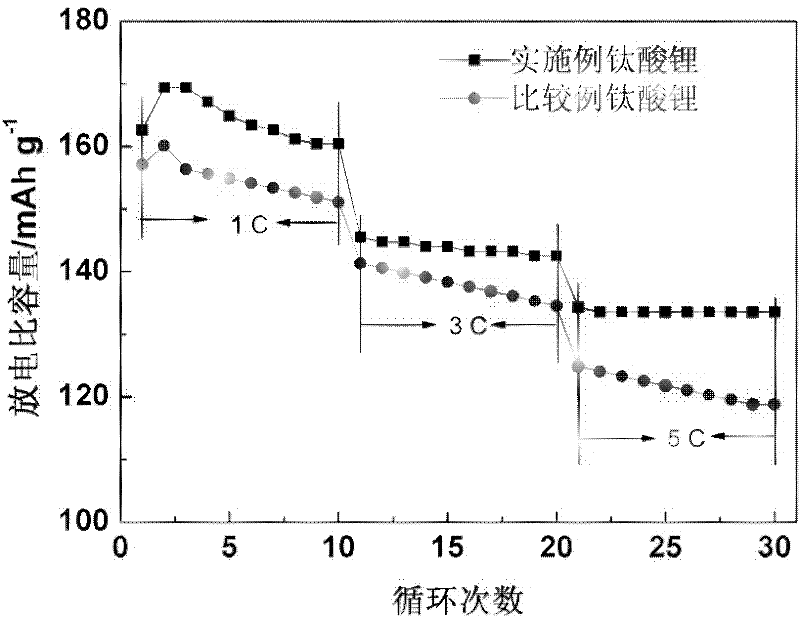

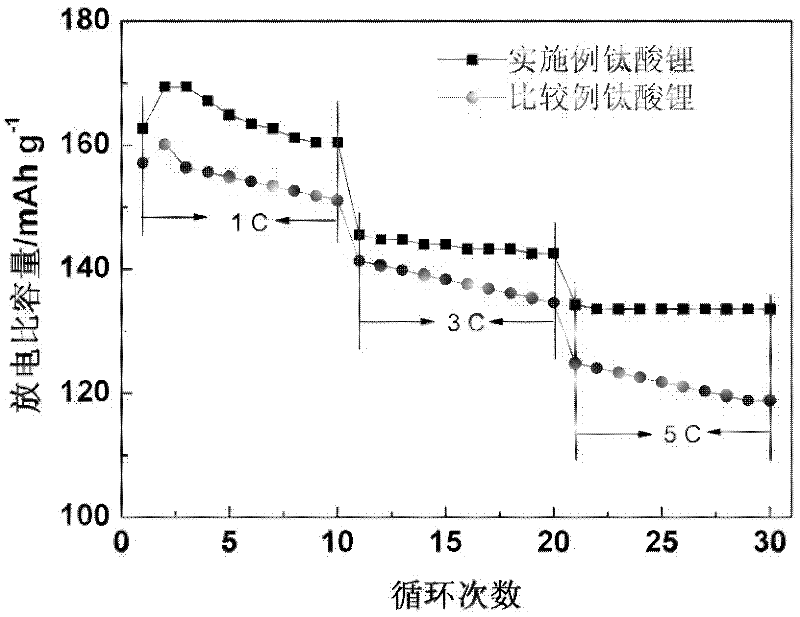

Composite material Li3V2(PO4)3/Li4Ti5O12 and preparation method thereof

InactiveCN102315449ALarge capacity lossReduce contact areaCell electrodesHigh potentialSide reaction

The invention relates to the technical field of materials of electrodes of a lithium ion battery, and especially relates to a composite material Li3V2(PO4)3 / Li4Ti5O12 and a preparation method thereof. According to the invention, Li4Ti5O12 is coated on monoclinic Li3V2(PO4)3 with mechanical ball milling combined with heat treatment, wherein spinel type Li4Ti5O12 has a stabile structure, a coating Li4Ti5O12 not only can provide a mechanical support for monoclinic Li3V2(PO4)3, but also can be used as a protective layer to reduce the contact area of an active substance and an electrolyte, thereby reducing the generation of side reactions and improving electrochemial performances of Li3V2(PO4)3 at a high potential. In comparison with monoclinic Li3V2(PO4)3 which is not coated with Li4Ti5O12, the material prepared in the present invention exhibits excellent multiplying power and cycle performances, and a coating process in the invention is simple.

Owner:MCNAIR TECH

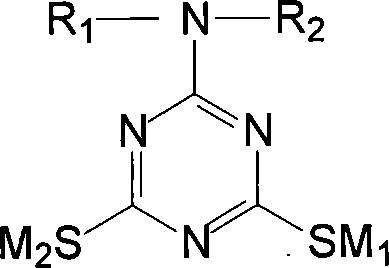

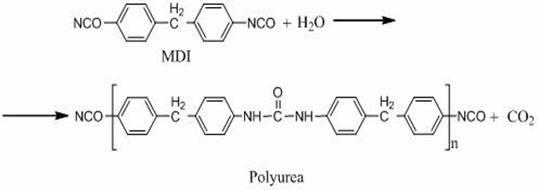

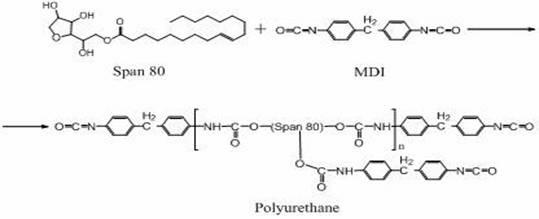

Method for preparing microcapsule coated ammonium polyphosphate

InactiveCN101972620AExpansion of the field of flame retardant modificationImprove flame retardant performanceMicroballoon preparationPigment treatment with macromolecular organic compoundsAmmonium polyphosphateIsocyanate

The invention belongs to the technical field of materials, and in particular relates to a method for preparing microcapsule coated ammonium polyphosphate (MCAPP). The method comprises the following steps of: uniformly dispersing APP containing water or not containing water in an organic solvent by utilizing a mixed dispersing agent; adding diisocyanate substances and a catalyst, and performing polymerization with hydroxy on the dispersing agent; and washing with water and the organic solvent, filtering, and drying to obtain the microcapsulated APP. Compared with APP, the microcapsule coated ammonium polyphosphate has the advantages of obviously improving water resistance and obviously improving a moisture absorption agglomeration phenomenon; and the MCAPP has good compatibility with a polymer substrate and good dispersability in the polymer substrate, so the excellent flame retardancy of the APP is fully achieved. The method successfully solves the problem that the flame retardancy of an inorganic flame retardant in the polymer substrate cannot be last, and realizes the expansion of the field of polymer flame retardancy modification.

Owner:TONGJI UNIV

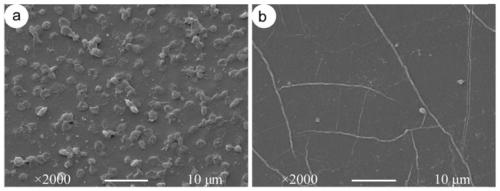

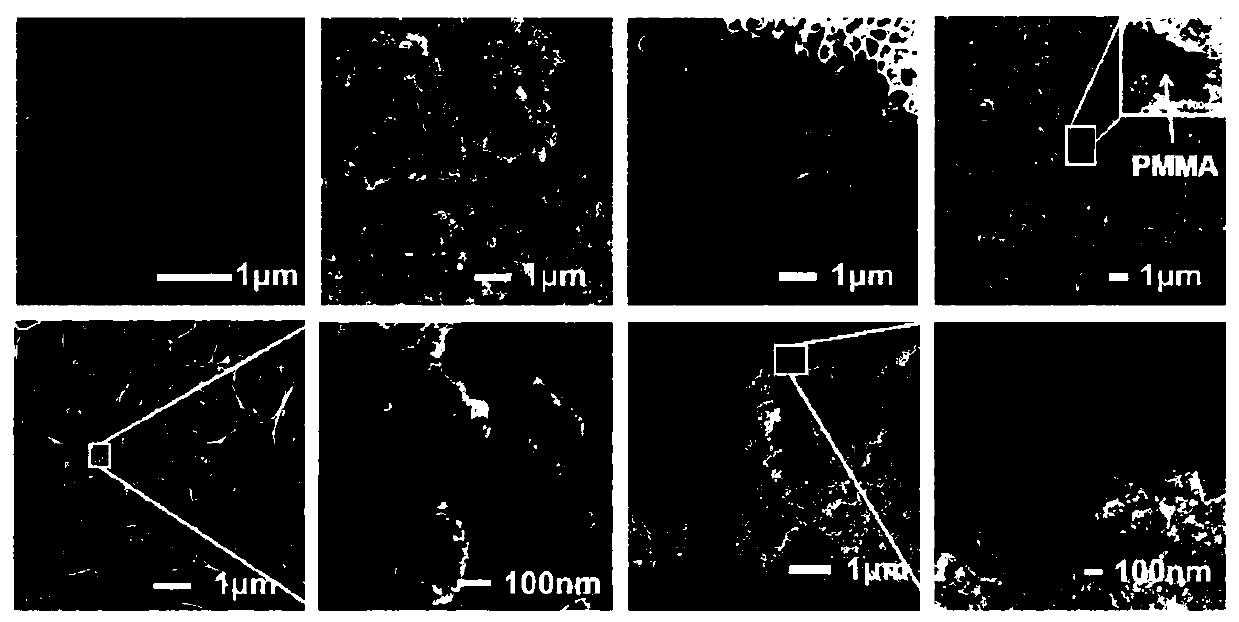

Preparation method for abrasion-resistant super-hydrophobic coating

ActiveCN110681552AImprove wear resistanceAnti-icing effectPretreated surfacesSpecial surfacesPolymer scienceNitrocellulose

The invention provides a preparation method for an abrasion-resistant super-hydrophobic coating. The preparation method comprises the following steps that acrylates copolymer and BYK-333 are mixed jointly and stirred uniformly, then a blended solution of ethyl acetate and butyl acetate is added, and adipic acid / neopentyl glycol / trimellitic anhydride copolymer, acetyl tributyl citrate, and epoxy resin are sequentially added after stirring is carried out for a moment, nitrocellulose is added to obtain a solution A; and an aluminum sheet is placed on a spin coater, a nano silicon dioxide particlesolution is immediately coated in a spinning mode after spin coating is completed, and then drying is carried out to obtain the abrasion-resistant super-hydrophobic coating. Hydrophobic modified silicon dioxide insets in the surface or an inner hole of PMMA, so that a white abrasion-resistant coating with a static WCA of 168 degrees + / -0.9 degrees and a rolling angle of less than 1 degree is obtained. The abrasion-resistant super-hydrophobic coating has the advantages of good self-cleaning effect, anti-icing and acid-alkali-resistant properties and capable of being applied to different substrates, and the above advantages provides a certain reference value for the industrial market requirement that super-hydrophobic materials has a certain mechanical stability and environmental adaptability.

Owner:CHINA THREE GORGES UNIV

Urea formaldehyde photochromic microcapsule and preparation method thereof

InactiveCN108380146AAvoid interactionImprove fatigue resistanceTenebresent compositionsMicroballoon preparationIn situ polymerizationColor changes

The invention discloses a urea formaldehyde photochromic microcapsule and a preparation method thereof. The preparation method comprises the following steps: first step, polymerizing urea and formaldehyde to generate a urea formaldehyde prepolymer; and second step, by in-situ polymerization, polymerizing the prepolymer on a water-oil interface to wrap a photochromic compound to form the urea formaldehyde photochromic microcapsule. By the in-situ polymerization, a photochromic compound is used as a core material, and urea formaldehyde resin is used as a wall material to prepare the urea formaldehyde photochromic microcapsule. The method is simple to operate, the chemical resistance of the photochromic material can be improved remarkably, the color performance is improved, the color changinglife is prolonged, the reversible color changing times are increased, and the urea formaldehyde photochromic microcapsule can be used for anti-fake, military camouflage, photoelectric information storage materials, intelligent textiles and other industries.

Owner:JIANGNAN UNIV

Antiviral emulsion composition, coating and preparation method thereof

ActiveCN111333862AReduce surface viral activityAvoid uneven loadAntifouling/underwater paintsPaints with biocidesPhosphonium saltPolyvinyl alcohol

The invention provides an antiviral water-based matrix emulsion composition and an antiviral coating containing the same. The emulsion composition is composed of an inorganic metal nanocomposite dispersion liquid with photocatalytic antiviral activity, a water-based high-molecular polymer emulsion containing a high-content quaternary phosphonium salt unit, and an optional polyvinyl alcohol auxiliary agent. The water-based matrix emulsion or the coating thereof can be used for surface coating treatment of textile articles, plastic products, glass products, leather, wooden products and other objects, so that the virus activity on the surfaces of the objects is reduced or inactivated in a short time, and the effects of inhibiting viruses and blocking propagation are achieved.

Owner:LONGHAI ZHENGUYUAN ADHESIVE CO LTD

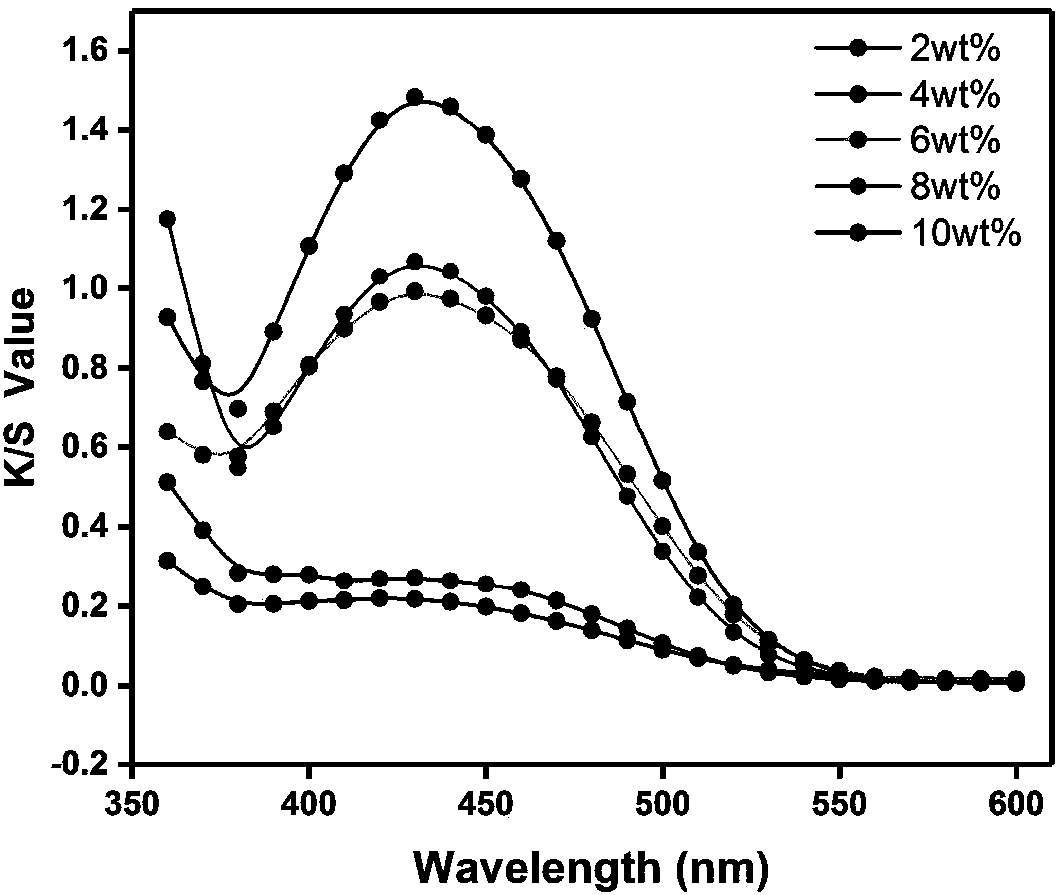

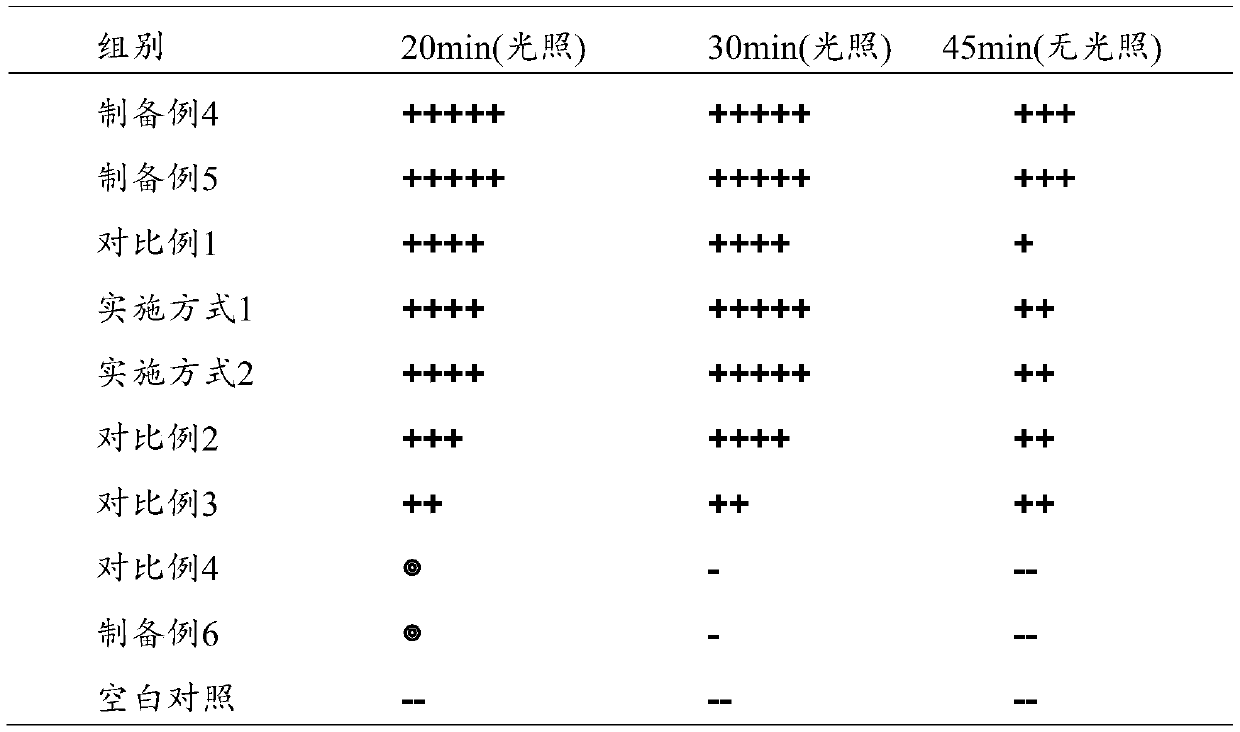

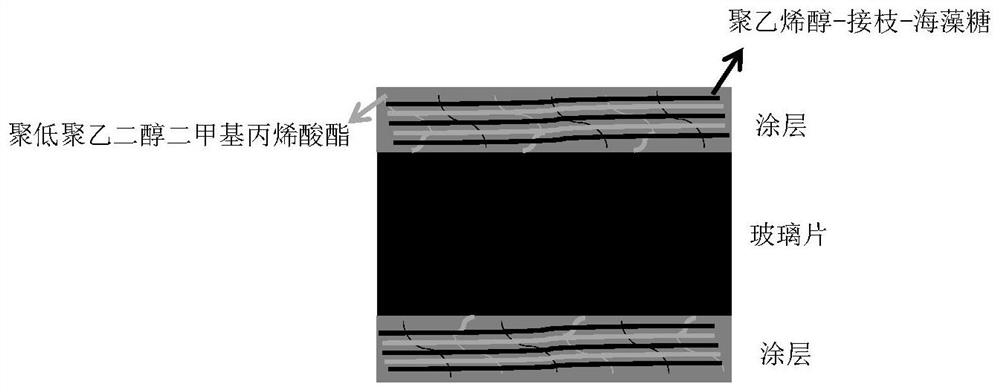

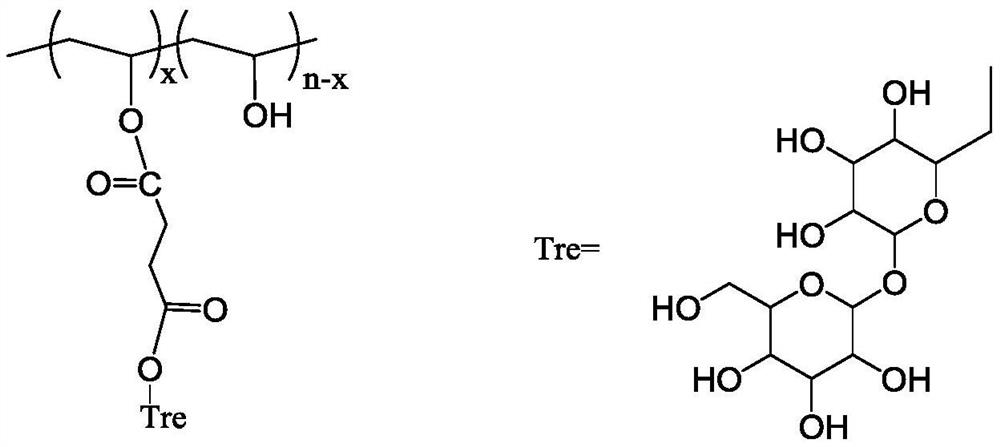

Trehalose modified polyvinyl alcohol anti-fog and anti-frost coating and preparation method thereof

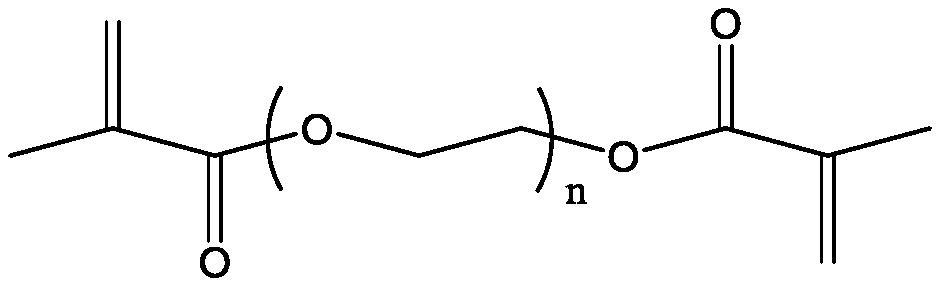

ActiveCN113004730AGood anti-fogFast curingOther chemical processesCoatingsMethacrylatePolyvinyl alcohol

The invention relates to a trehalose modified polyvinyl alcohol anti-fog and anti-frost coating and a preparation method thereof. The coating is prepared from polyvinyl alcohol-grafted-trehalose, low polyethylene glycol dimethacrylate, benzoin dimethyl ether and deionized water; the materials are uniformly mixed and coated on a transparent glass sheet, and the mixture is irradiated and cured by ultraviolet light to form the hydrophilic graft polymer semi-interpenetrating network coating. According to the prepared anti-fog and anti-frost coating, the light transmittance can be kept at 89-90% in the anti-fog process, the anti-frost time can be prolonged by 9-31 min, and the light transmittance value of the glass sheet coated with the coating on the two sides at the wave band of 400-800 nm is calculated by using a visible spectrophotometer. Good anti-fog and anti-frost performance is realized. The preparation method is simple and convenient and mild in reaction, and has great application potential in the field of fog and frost prevention.

Owner:TIANJIN UNIV

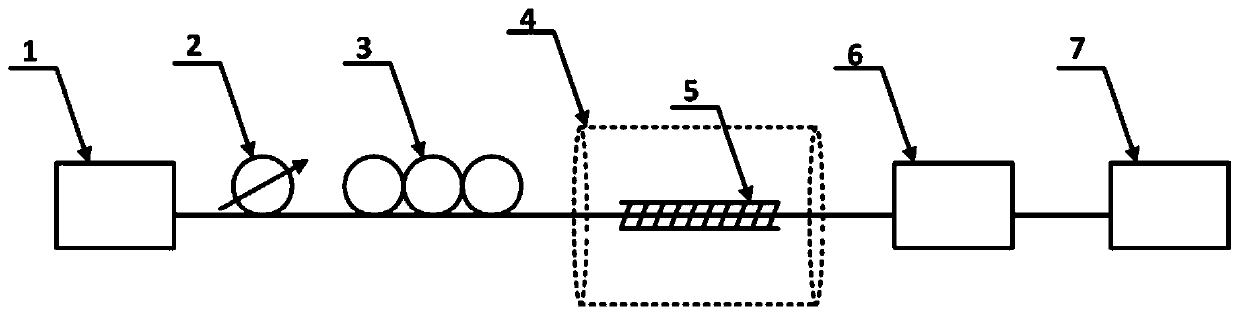

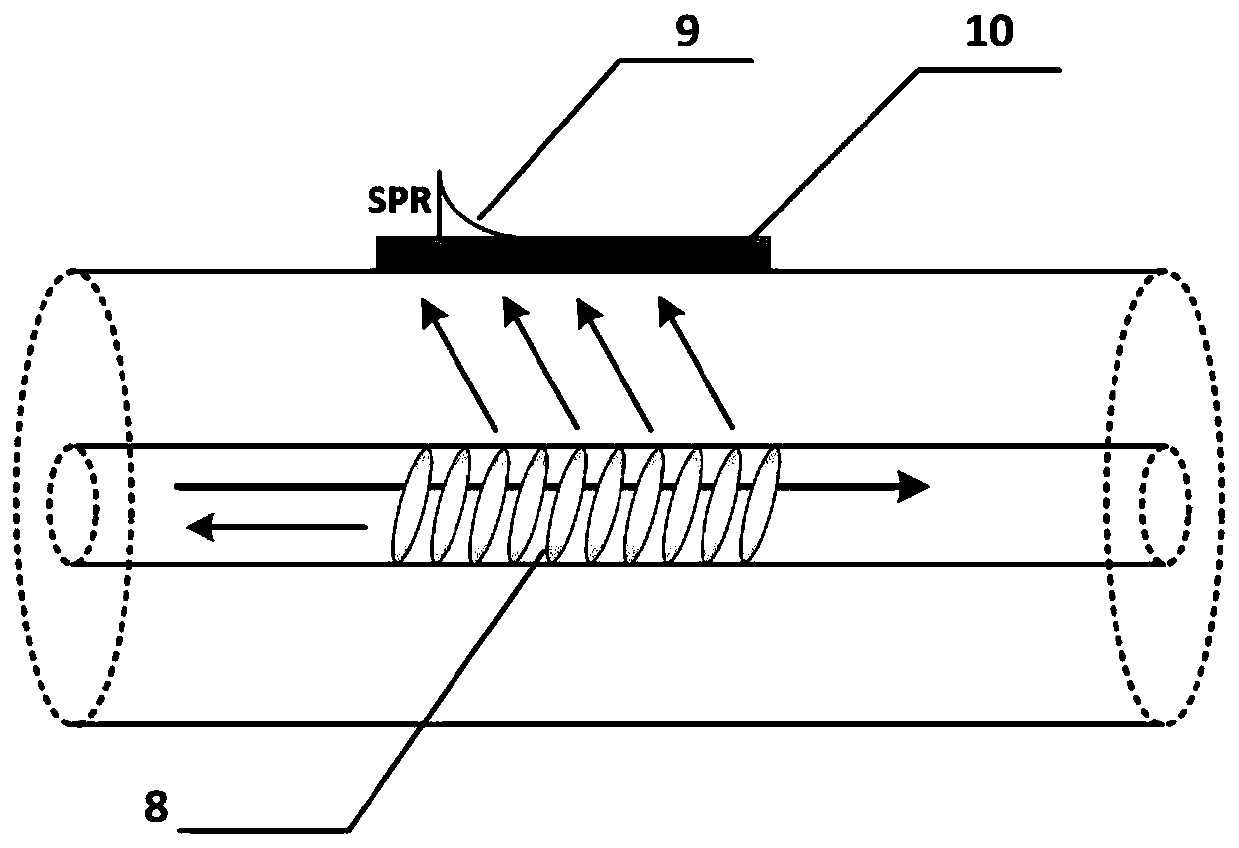

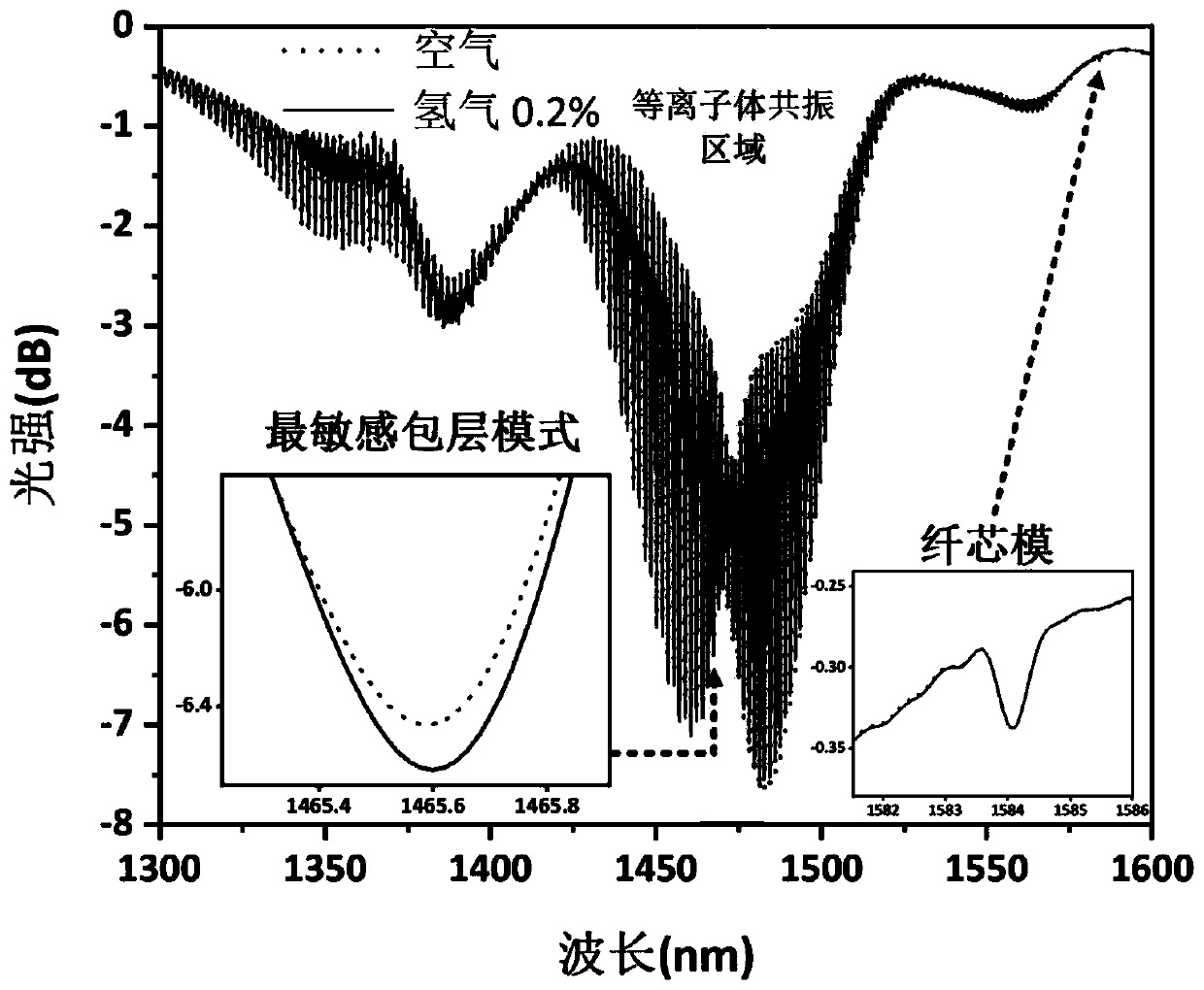

Plasma resonance tilted fiber Bragg grating hydrogen sensor, detection system and method

InactiveCN110261351ARealize high-precision measurementPlated evenlyMaterial analysis by optical meansGratingPhotovoltaic detectors

The invention discloses a plasma resonance tilted fiber Bragg grating hydrogen sensor, a plasma resonance tilted fiber Bragg grating hydrogen detection system and a plasma resonance tilted fiber Bragg grating hydrogen method. The system comprises a light source, a polarizer, a polarization controller, a plasma resonance tilted fiber Bragg grating hydrogen sensor, a photoelectric detector, an oscilloscope and a gas storage container; the light source, the polarizer, the polarization controller, the hydrogen sensor, the photoelectric detector and the oscilloscope are sequentially connected with one another; the hydrogen sensor is arranged in the gas storage container when hydrogen is measured; the hydrogen sensor comprises an optical fiber engraved with a tilted fiber Bragg grating; the tilt angle of the tilted fiber Bragg grating is smaller than or equal to 45 degrees; the outer surface of the cladding layer of the optical fiber is plated with a nano-scale palladium film; plasma resonance waves on the surface of the palladium film are excited through the tilted fiber Bragg grating plated with the palladium film, so that specific recognition is carried out on the hydrogen; and the high-precision measurement of the static concentration and dynamic concentration change of the hydrogen is further realized.

Owner:JINAN UNIVERSITY

Method for covering plastic film on surface of wood or plastic special-shaped substrate

InactiveCN101249740AAchieve full coverageFix damageLaminationLamination apparatusEngineeringPlastic film

The invention discloses a method for coating a plastic film on the surface of woody or plastic deformed basis material, which relates to a method for coating a plastic film. The method solves the problems that the prior method for coating a plastic film influences the exterior quality of a product, the cost of the paint spraying on the surface of the woody basis material is high, and the noxious substance volatilized from the paint is easy to pollute the environment. The inventice method has the following steps that: firstly, plastic heat shrinking material is made into a cylindrical film; secondly, vacuum suction plastic is sprayed on the surface of the woody or the plastic profile basis material; thirdly, the cylindrical film made of the plastic heat shrinking material in the step one is covered on the outer surface of the gummed woody or the gummed plastic profile basis material prepared in the step two; fourthly, the woody or the plastic profile basis material processed through the step three is put into a vacuum sucking and coating machine to perform the contraction and the vacuum sucking and coating, and then the woody or the plastic profile basis material with the plastic film covered on the surface is obtained. The surface of the woody or the plastic profile basis material covered in the invention has no seam, the coating method is simple, and the production cost and the production cycle are reduced.

Owner:施永志

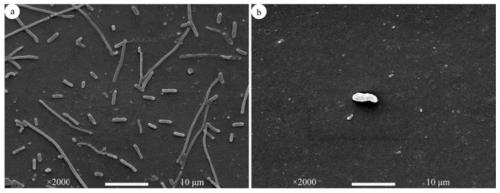

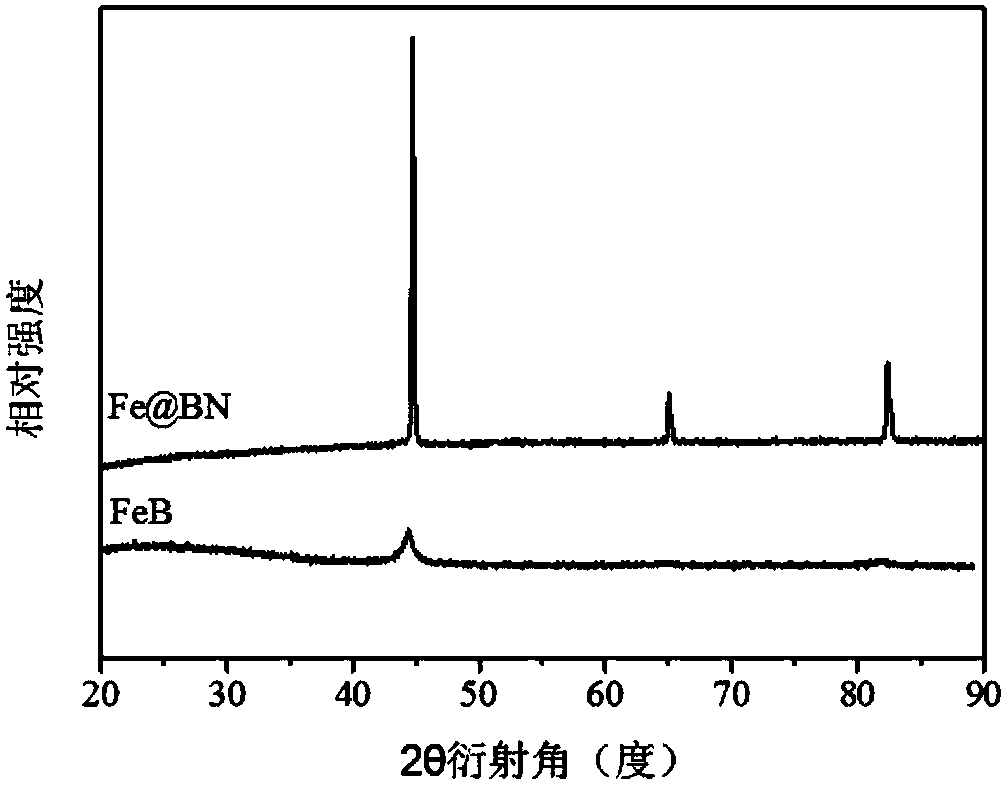

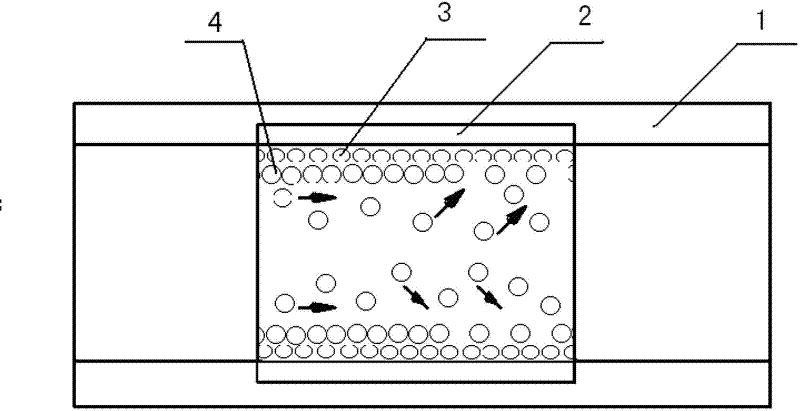

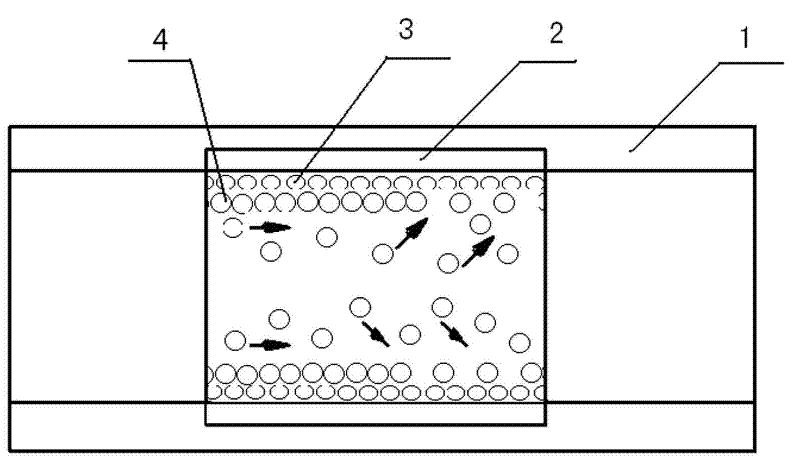

Supporting or non-supporting type transition metal @h-BN core-shell nanostructure preparation method

ActiveCN108500285AWide variety of sourcesLow priceMaterial nanotechnologyTransportation and packagingHexagonal boron nitrideAlloy

The invention discloses a supporting or non-supporting type transition metal @h-BN core-shell nanostructure preparation method. According to the preparation method, transition metal salt serves as a precursor, KBH4 or NaBH4 serves as a reducing agent, reduction of metal ions is carried out in a solution system, and an amorphous alloy nanostructure (TMB) comprising transition metal (TM) and boron (B) element is obtained; and the TMB structure is heated to 500 DEG C-850 DEG C under the nitrogenous atmosphere, the temperature is kept for 1 h-3 h, cooling is carried out to the room temperature inthe inert gas atmosphere, and the core-shell nanostructure with a metal core and h-BN shell layer is obtained. The preparation method is simple and convenient in preparing process, the raw material price is low, the process repeatability is good, operation is safe and reliable, macro-quantity preparation can be achieved, and amplification production is easy. The prepared raw material structure isunique, and important application to the processes of catalysis, energy resources and the like is achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for high-temperature-resistant enteric coating for micro-dropping pills

ActiveCN110251478AImprove heat resistanceEasy to operatePharmaceutical non-active ingredientsMicrocapsulesSilicone ElastomersSilicon dioxide

The invention relates to the biomedical technical field, and discloses a process for a high-temperature-resistant enteric coating for micro-dropping pills. The high-temperature-resistant enteric coating comprises the following components in parts by weight: 50-55 parts of a methacrylic acid copolymer, 10-15 parts of hydroxypropyl methyl cellulose succinate, 3-7 parts of a silicone elastomer, 1-5 parts of triethyl citrate and 3-5 parts of nanosilicon dioxide. The high-temperature-resistant enteric coating has good stability and heat resistance in a gastric acid environment and high drug release efficiency in an intestinal fluid environment. The process for the high-temperature-resistant enteric coating for the micro-dropping pills is convenient to operate, and the prepared dropping pill preparation has smooth surface, bacterial resistance and no adhesion and is convenient to store and transport.

Owner:ZHEJIANG WECOME MEDICINE IND

Method for plating thin film on inner wall of slender pipeline

InactiveCN102337520AImprove uniformityCoating method is simpleChemical vapor deposition coatingSulfideFluoride

The invention discloses a method for plating a thin film on an inner wall of a slender pipeline, belonging to the technical field of vacuum film plating. The method comprises the steps of: putting a pipeline to be plated with a film in a reaction chamber, alternatively introducing a gaseous phase precursor to a reactor in a pulse form, wherein the first precursor reaches to the inside of the pipeline and is chemically adsorbed on the inner wall of the pipeline to form a single adsorption layer; introducing a second precursor to react with the first precursor so as to generate a thin film with a single atom layer on the inner wall of the pipeline; cleaning the reactor through inert gas between every two precursor pulses, and repeating the adsorption and reaction processes to generate the thin film layer by layer. The method is used for plating the thin film on the inner wall of the slender pipeline in a gas adsorption and reaction combination manner to solve the problem that the thin film cannot be plated on the inner wall of the slender pipeline in a vacuum film plating method currently; and the method can be used for plating such thin film materials as metal, oxide, nitride, sulfide and fluoride, and the like so as to meet different demands.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

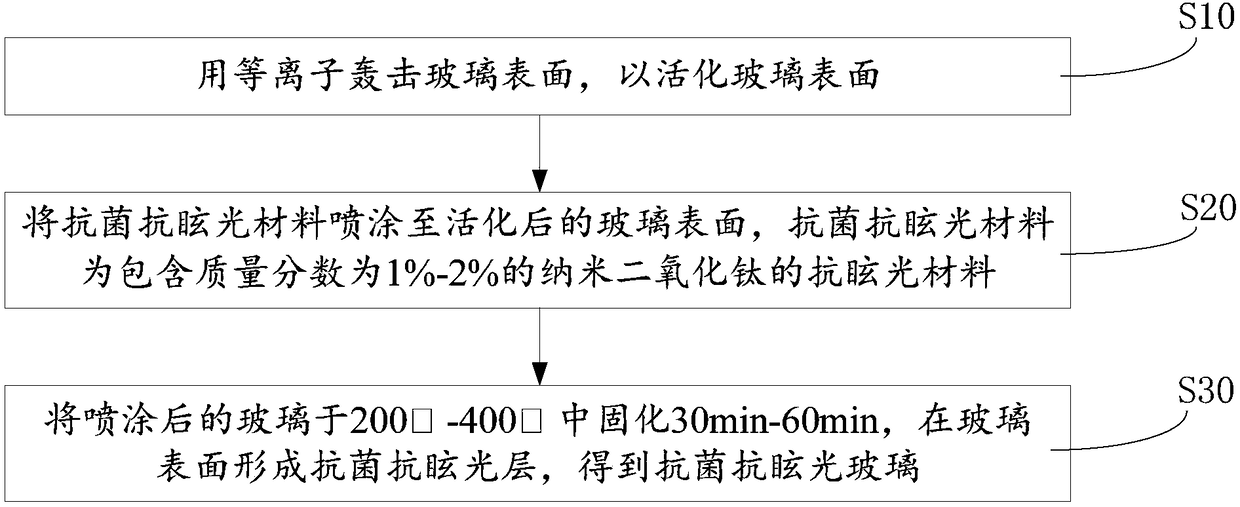

Antibacterial anti-glare glass and preparation method thereof

An antibacterial anti-glare glass includes glass and an antibacterial anti-glare layer coating the surface of the glass. The antibacterial anti-glare layer includes an anti-glare material comprising 1-2 mass% of nano TiO2. In the antibacterial anti-glare glass, the glass is coated with the antibacterial anti-glare layer formed by the anti-glare material comprising nano TiO2, wherein the TiO2 is harmless to human body and can be activated to perform a reaction under a weak ultraviolet light, thus killing bacteria. The glass has effects of sterilization, antifouling, deodorization and self-cleaning; meanwhile, the antibacterial anti-glare glass has excellent anti-glare effect. The invention also provides a preparation method for the antibacterial anti-glare glass by the steps of: bombardingsurface of the glass by plasma to activate the surface, and spray-coating the activated surface of the glass with the antibacterial anti-glare material; then curing the coating to form the antibacterial anti-glare glass. The preparation method is simple in operation, is high in yield and is environment-friendly.

Owner:HENAN ZHUOJIN PHOTOELECTRIC TECH CO LTD

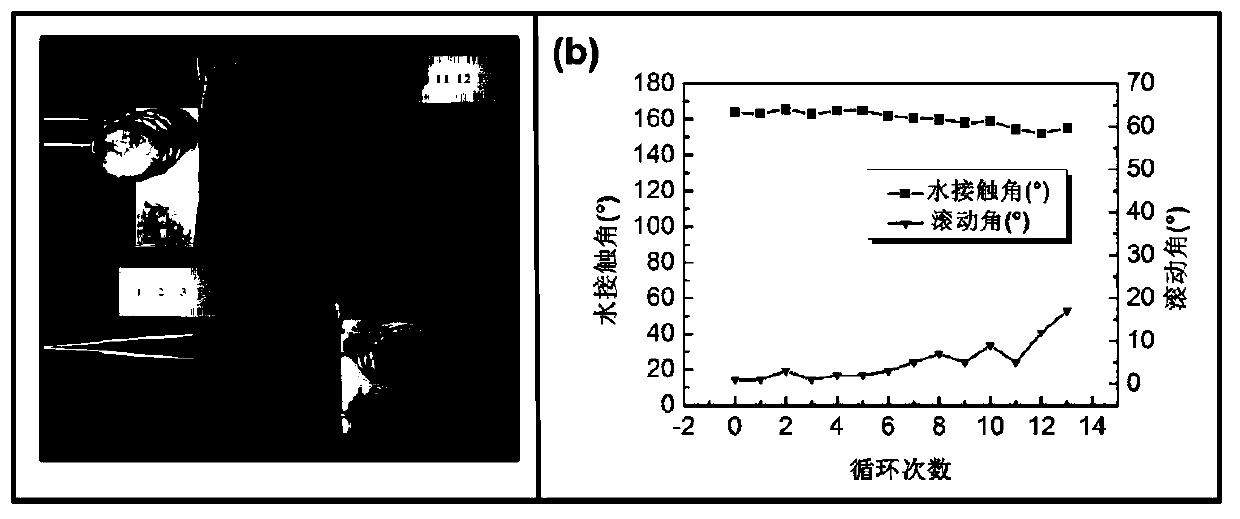

Method for preparing anti-icing self-repaired coating

ActiveCN110396308ACoating method is simpleLow cost of preparationAntifouling/underwater paintsPaints with biocidesIonEmulsion

The invention relates to a method for preparing a nano porous coating. The method comprises the following steps: mixing and stirring micron-order calcium carbonate particles, nano-grade silicon dioxide particles, polydimethylsiloxane and ethyl acetate so as to obtain an emulsion for later use; soaking a substrate into the emulsion, taking out the substrate after 10-20 minutes of soaking, and performing drying, namely drying the substrate with the coating for 50-80 minutes at 120-150 DEG C; and soaking the dried sample into diluted hydrochloric acid for 5-10 minutes, washing the dried sample with deionized water, and performing drying for 0.5-1.5 hours at 120-160 DEG C, so as to obtain an anti-icing self-repaired coating. A double-rough composite coating of a lotus leaf structure is prepared by mainly using a physical mixing and chemical corrosion methods, and the coating has good super-hydrophobicity under a low temperature condition, and thus has an anti-icing capability. The super-hydrophobicity coating prepared by using the method not only has good super-hydrophobicity and anti-icing capabilities, but also has a self repairing capability and acid-alkali resistance. The coating is low in preparation method cost, convenient to operate and wide in application substrate.

Owner:CHINA THREE GORGES UNIV

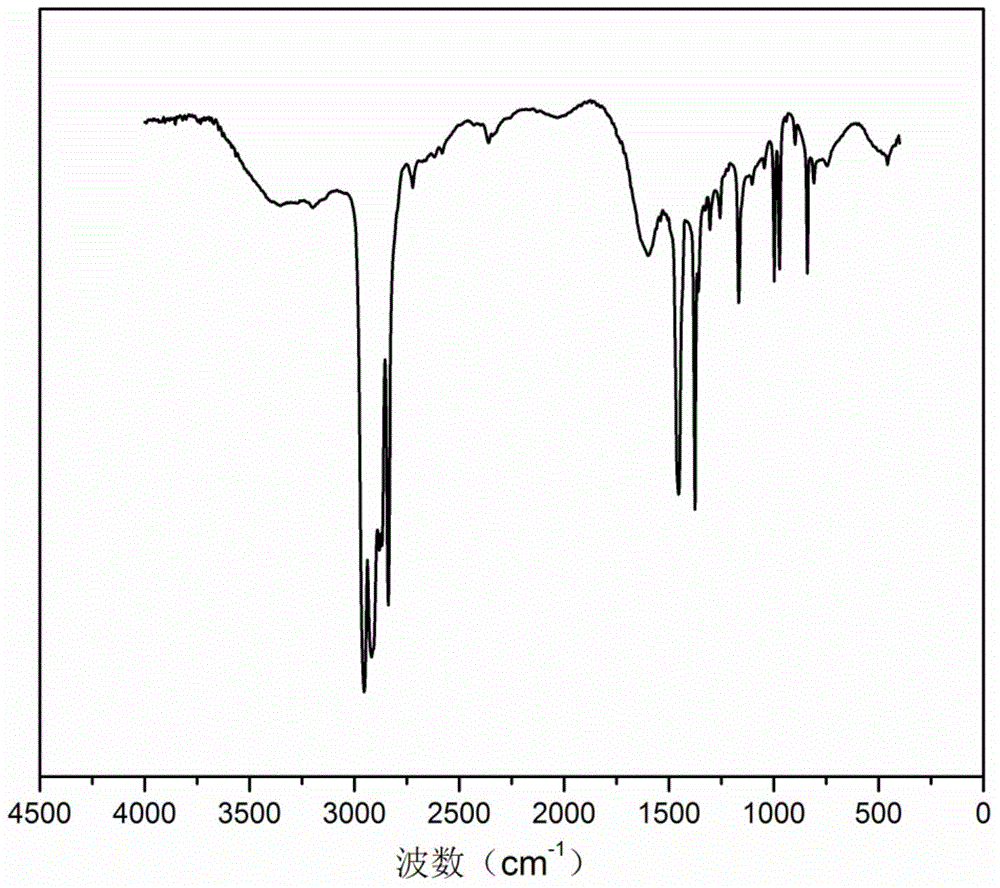

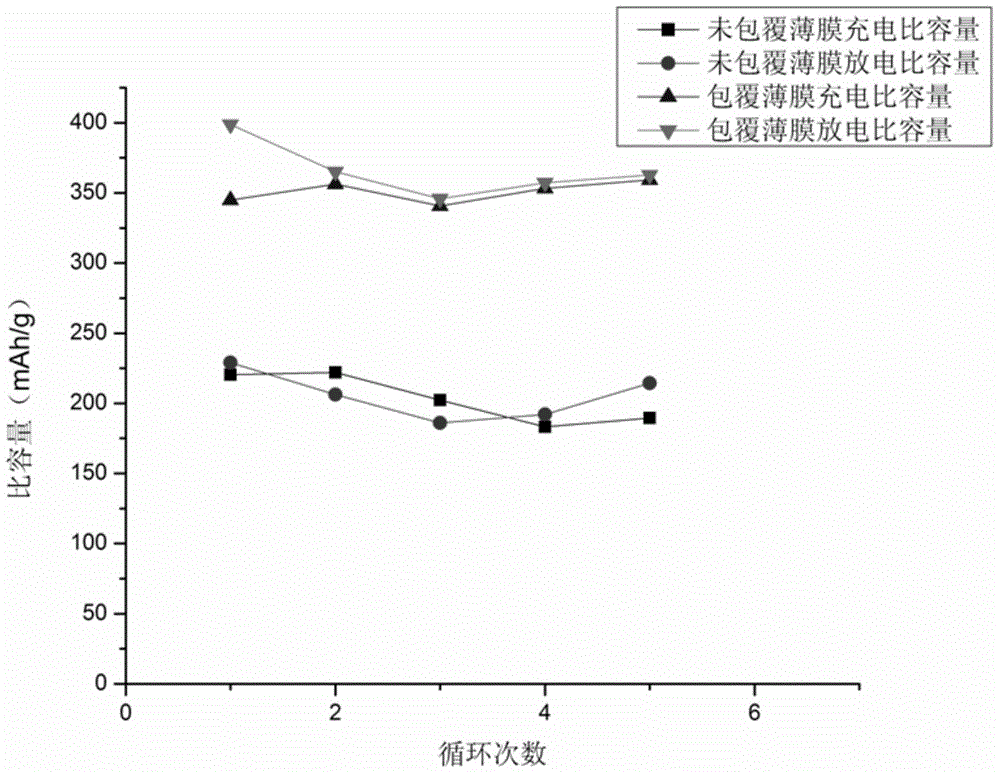

Core-shell composite positive electrode material coated with mixed polymer, its preparation method and application in lithium ion battery

ActiveCN107706377BLower internal resistanceGood physical compatibilityCell electrodesSecondary cellsSolid state electrolytePolyethylene oxide

The invention discloses a mixed polymer-coated core-shell composite positive electrode material, a preparation method thereof and application in a lithium ion battery. The composite positive electrodematerial comprises a positive active material core and a mixed polymer shell, wherein the mixed polymer shell is coated on a surface of the core and comprises a mixture of a conductive polymer and anorganic solid polymer. The method comprises the steps of 1) mixing polyethylene oxide and lithium hexafluorophosphate, and performing ball-milling to obtain a mixture A; 2) mixing the positive activematerial and a coupling agent, and performing dry ball-milling to obtain a mixture B; and 3) mixing the mixture A, the mixture B and the conductive polymer, and performing dry ball-milling and calcination to obtain the core-shell composite positive electrode material. The coating layer of the composite positive electrode material can be compatible with electron conductivity and lithium ion conductivity of the material, the internal resistance of the electrode material is effectively reduced, moreover, two materials in the coating layer are high in compatibility, and the coating uniformity isimproved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of surface coating method of positive electrode material of lithium ion battery

ActiveCN105322176BImproved magnification performanceImprove cycle performanceCell electrodesSecondary cellsCarbon coatingMagnesium salt

The invention discloses a surface coating method of a cathode material for a lithium-ion battery. The method comprises the following steps: adding the cathode material for the lithium-ion battery to a magnesium salt solution, simultaneously adding a certain amount of lithium compound, carrying out ultrasound for 30-180 minutes, stirring the solution at 50-80 DEG C until dry, and putting the sample into a drying oven at 80 DEG C for drying; slowly heating the dried sample to 110-130 DEG C in a tube furnace, maintaining the temperature for 1-2 hours, heating the sample to 500-600 DEG C at the speed of 2 DEG C / min, maintaining the temperature for 2 hours, and introducing an oxidizing atmosphere to the tube furnace in the overall process; and burning the sample in the tube furnace. According to the cathode material for the lithium-ion battery, oxide coating is combined with carbon coating; and the amount of the oxide can be reduced, so that reduction of the conductivity caused by the oxide coating is well improved; meanwhile, reduction of the tap density caused by traditional carbon coating can also be improved; and the rate capability and the cycle performance of the material are improved. The carbon coating is carried out on the cathode material for the lithium-ion battery by a catalysis method; the coated carbon is uniform and controlled in thickness; and meanwhile, reduction of the cathode material caused by coated carbon can be reduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

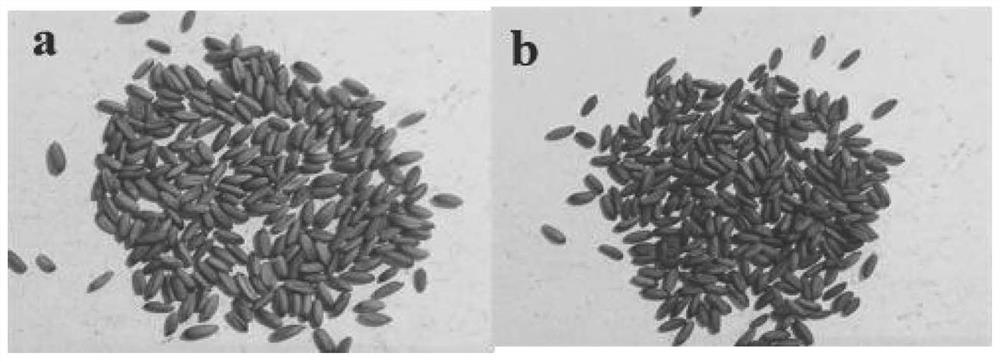

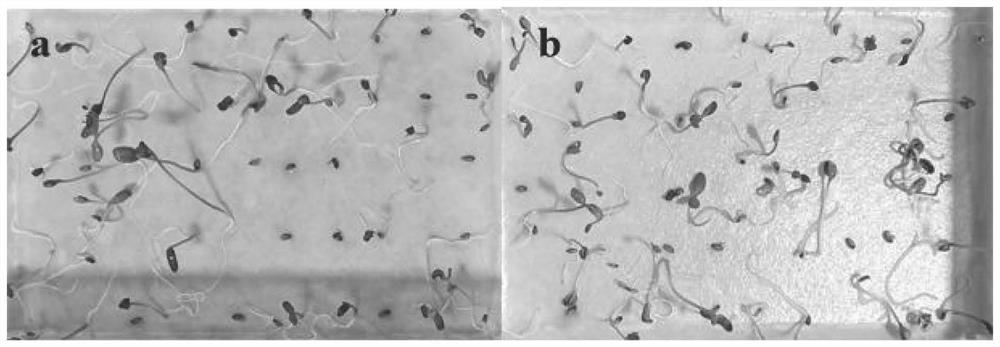

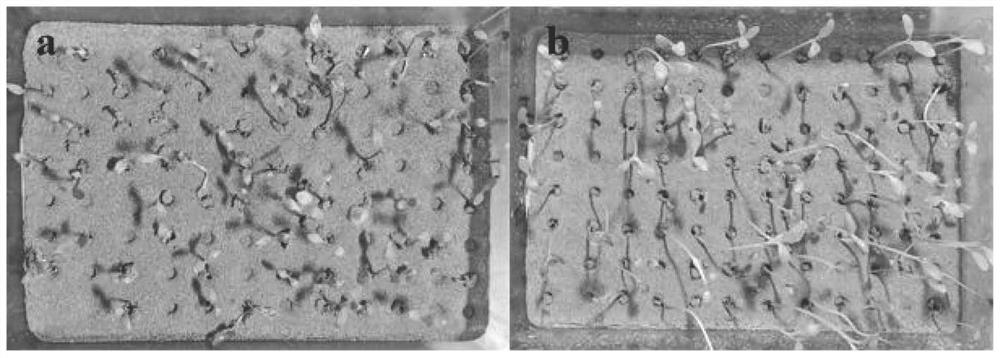

Isatis root seed coating agent as well as coating method and application thereof

InactiveCN113331202ASimple ingredientsEasy to prepareBiocidePlant growth regulatorsCelluloseMedicinal herbs

The invention relates to an isatis root seed coating agent as well as a coating method and application thereof. The isatis root seed coating agent is prepared from the following raw material components in percentage by mass: 0.28 to 0.56 percent of ipconazole, 0.23 to 0.45 percent of metalaxyl, 3.6 percent of thiamethoxam, 2.0 percent of pesticide emulsifier 700, 0.2 percent of xanthan gum, 0.2 percent of sodium carboxymethyl cellulose, 4 percent of ethylene glycol and the balance of purified water. The coating method comprises the steps of S1, preparing an isatis root seed coating agent; and S2, uniformly stirring the isatis root seed coating agent and the isatis root seeds, and airing to complete isatis root seed coating. The isatis root seed coating agent can be used for solving pathogenic bacteria carried by isatis root seeds, diseases and insect pests in the seedling stage and the like, and meanwhile, the root biomass of isatis root is increased, so that the germination rate of the seeds and the quality of medicinal materials are improved.

Owner:CHINA TRADITIONAL CHINESE MEDICINE +1

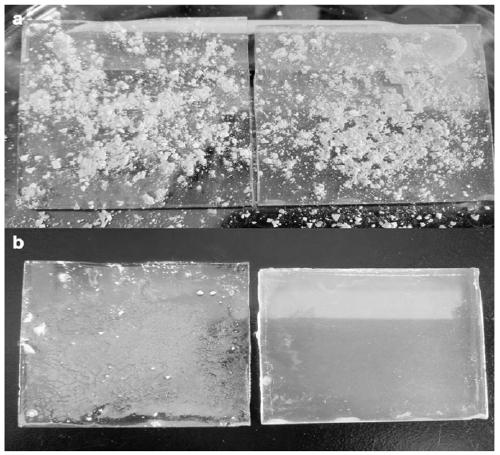

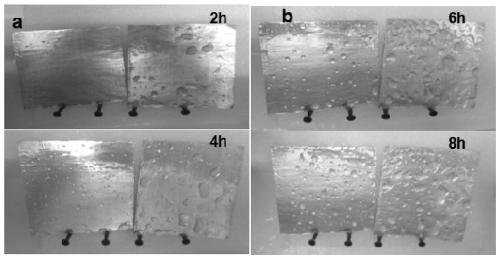

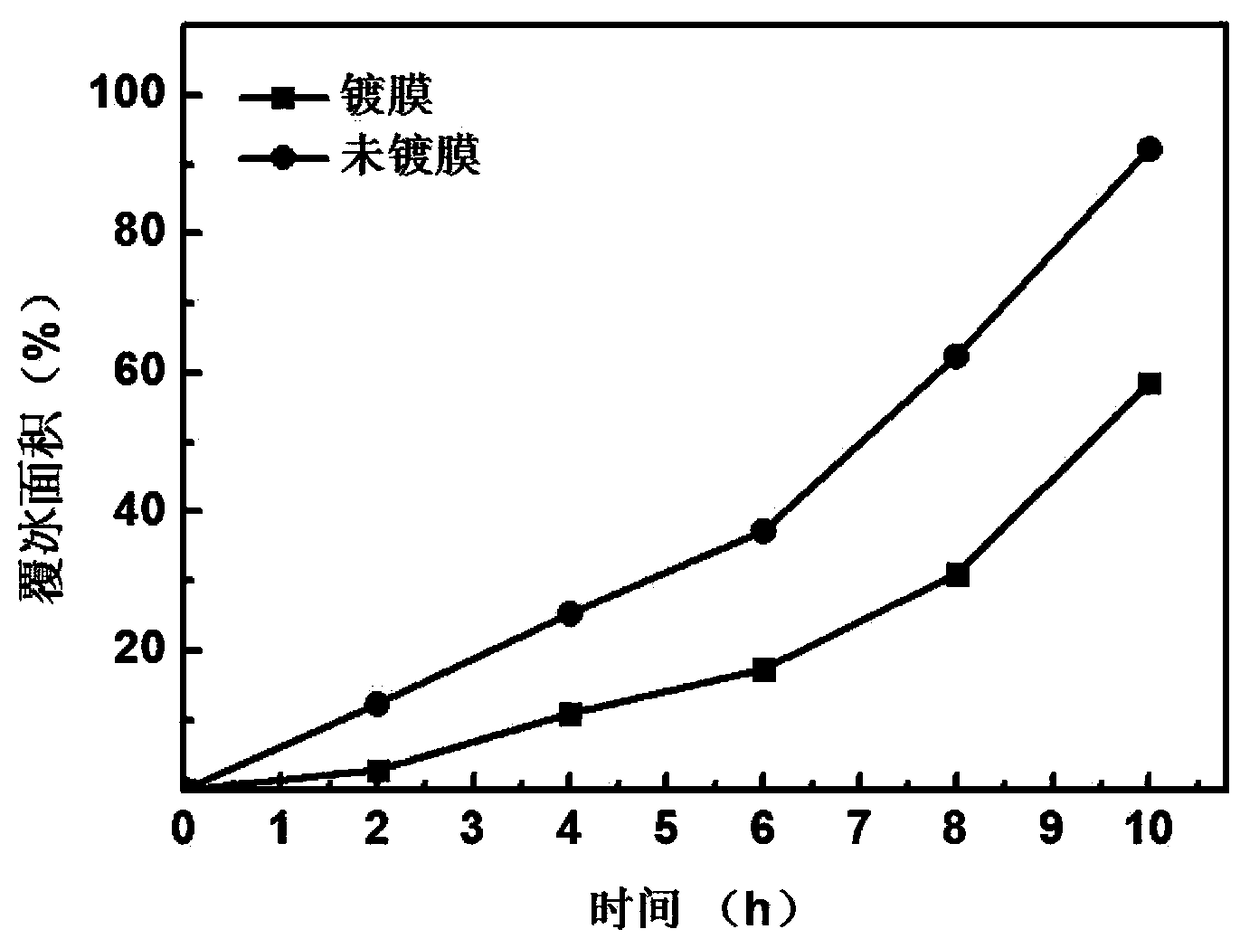

Preparation method of aluminum-based power transmission line with anti-icing coating layer

InactiveCN109504220ACoating method is simpleReduce manufacturing costAntifouling/underwater paintsPaints with biocidesTransmission lineEngineering

The invention relates to a nanometer coating material, and provides a preparation method of an aluminum-based power transmission line with an anti-icing coating layer. The anti-icing coating layer prepared by a hydrolysis method has a static water contact angle greater than 150 degrees; after the anti-icing coating layer is applied to an aluminum sheet, the icing time can be obviously delayed, andthe icing area can be reduced; when the common aluminum sheet is completely covered with ice after 10 h, the icing area of the coating layer is only 60%; after being abraded, the coating layer stillhas certain anti-icing property; after the anti-icing coating layer is applied to the aluminum wire, the ice removal ability is obviously reduced.

Owner:CHINA THREE GORGES UNIV

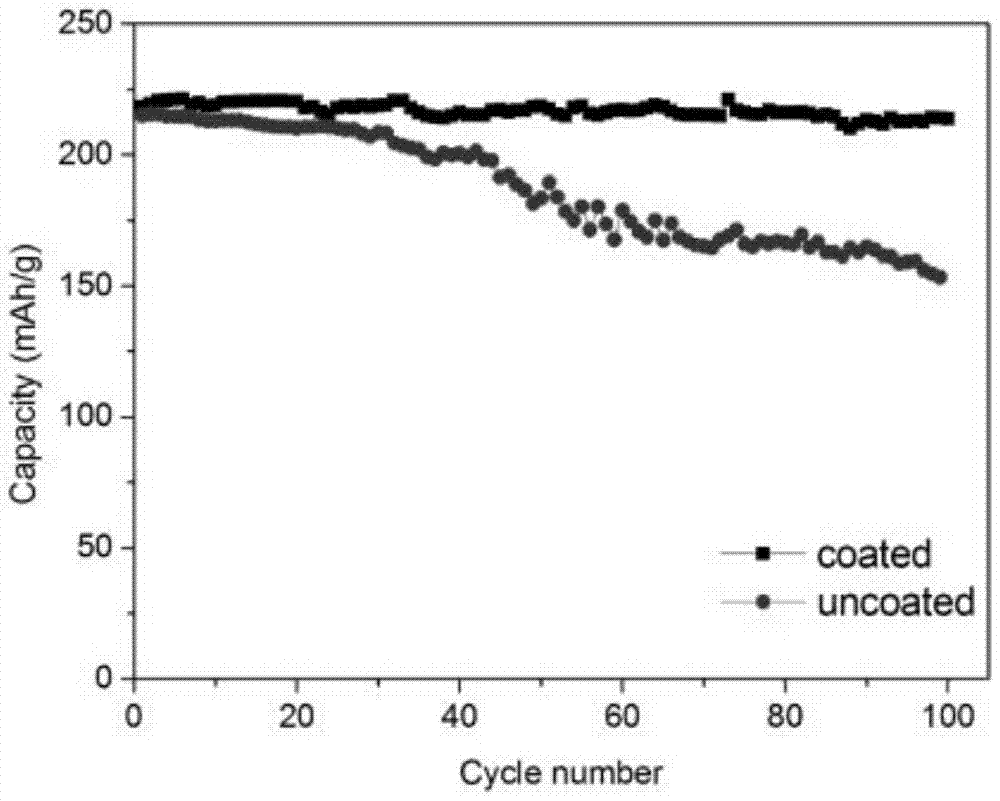

Lithium-ion battery ternary material coated with metal oxide on surface and preparation method thereof

ActiveCN104393277BAct as a flocculantCoated evenlyMaterial nanotechnologyCell electrodesElectrical batteryLithium-ion battery

The invention discloses a ternary cathode material coated with metal oxide on the surface and used for a lithium ion battery, and a preparation method for the ternary cathode material. The preparation method comprises the following steps: step 1, adding soluble metal salt to a dispersant solution to enable the salt to be sufficiently dispersed evenly; step 2, adding a cathode material in a solution obtained in the step 1 for stirring for 1-5 h; step 3, adding an aqueous solution of an alkali metal hydroxide to a solution obtained in the step 2, adjusting the pH value of the solution to be 7-12, and carrying out filtering and drying to obtain a cathode material coated with metal oxide on the surface; step 4, performing heat treatment on the cathode material coated with metal oxide on the surface at the temperature of 400-700 DEG C to obtain the ternary cathode material coated with metal oxide on the surface. According to the preparation method for the ternary cathode material coated with metal oxide on the surface and used for the lithium ion battery, the method is simple, polyacrylamide is introduced as a dispersing agent and a flocculating agent, so that uniform coating of the ternary cathode material is realized, industrial production is facilitated, and the performance of the modified ternary cathode material is greatly improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Convenient and cheap universal cladding technology

InactiveCN104979514ACoating method is simpleRaw materials are cheap and easy to getCell component detailsAlloyPhenol

The invention relates to a convenient and cheap universal cladding technology and particularly relates to a convenient and cheap cladding technology using phenols and derivatives thereof as well as common amino acid. According to the cladding technology, a polymer which is formed by phenols and derivatives thereof as well as common amino acid in a solution plays a good role in good adhesion effect, through simple immersing and stirring, uniform cladding layers are formed on the surfaces of the different substrates such as alloy, inorganic materials and organic polymers.

Owner:SHANDONG UNIV

Coating method of woven artificial blood vessel and artificial blood vessel

ActiveCN114159624AGood biocompatibilityIncrease elasticityStentsPharmaceutical delivery mechanismBiocompatibilityBiomedical engineering

The invention belongs to the technical field of medical instruments, and particularly relates to a coating method of a woven artificial blood vessel and the woven artificial blood vessel. According to the method, a step-by-step coating mode is adopted, the braided tube blank is firstly coated, and the coating is performed under the flat state of the tube blank, so that the contact surface tension of the coating solution and the artificial blood vessel is consistent, the uniformity of the coating is solved, and meanwhile, the water permeation amount of the artificial blood vessel is also effectively reduced; according to the artificial blood vessel and the preparation method thereof, the artificial blood vessel prepared by the method is uniform in coating, small in overall water permeation amount and good in biocompatibility, good elasticity and compliance of the artificial blood vessel are maintained, and the artificial blood vessel has the advantages of being simple in process, convenient to operate, low in cost and good in application prospect. The prepared artificial blood vessel is stored after sterilization, does not need to be pre-coagulated before implantation, and can be directly used for clinical transplantation after being soaked in normal saline.

Owner:山东欣脉通生物科技有限公司 +2

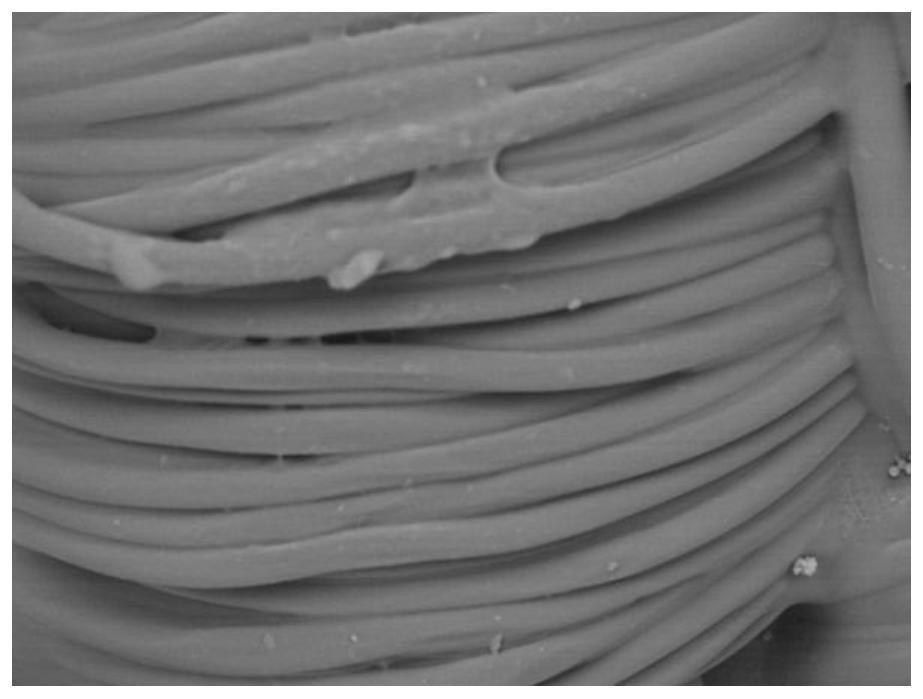

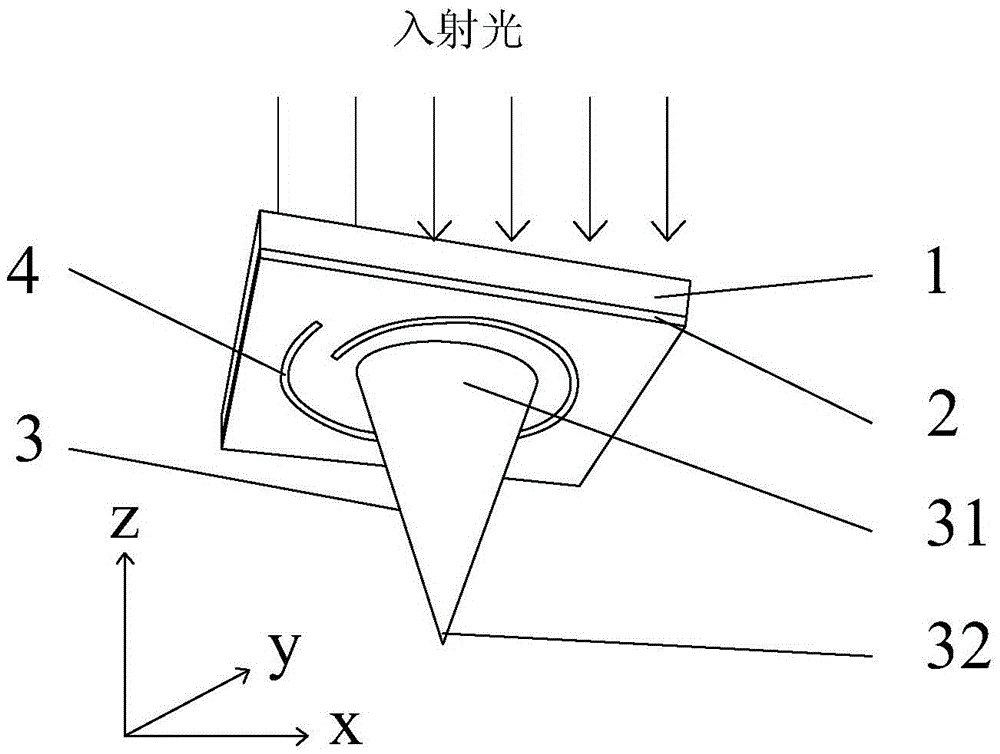

A surface plasmon-enhanced needle tip and a needle-tip enhancement method

ActiveCN103837709BEnhancement effect is goodImprove signal-to-noise ratioScanning probe microscopyOptical elementsSignal-to-noise ratio (imaging)Image resolution

The invention relates to a surface plasmon polariton enhancement needlepoint which comprises a transparent substrate (1) used for incidence of light, a metal film (2) arranged on one side of the transparent substrate and provided with a slit of a spiral structure, and a metal needlepoint body (3) which comprises a pointed portion and a root portion of the metal needlepoint body, wherein the root portion is connected with the metal film and located in the center of the spiral structure. The needlepoint enhancement effect of the enhancement needlepoint is good, needlepoints of three orders of magnitude can be enhanced, the resolution ratio of 0.03lambda0 can be achieved, the enhancement depth reaches 50 nm, the signal-to-noise ratio and sensitivity are greatly improved, operation is convenient and easy to achieve, large-area needlepoint arrays are easy to form, and the scanning speed is improved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

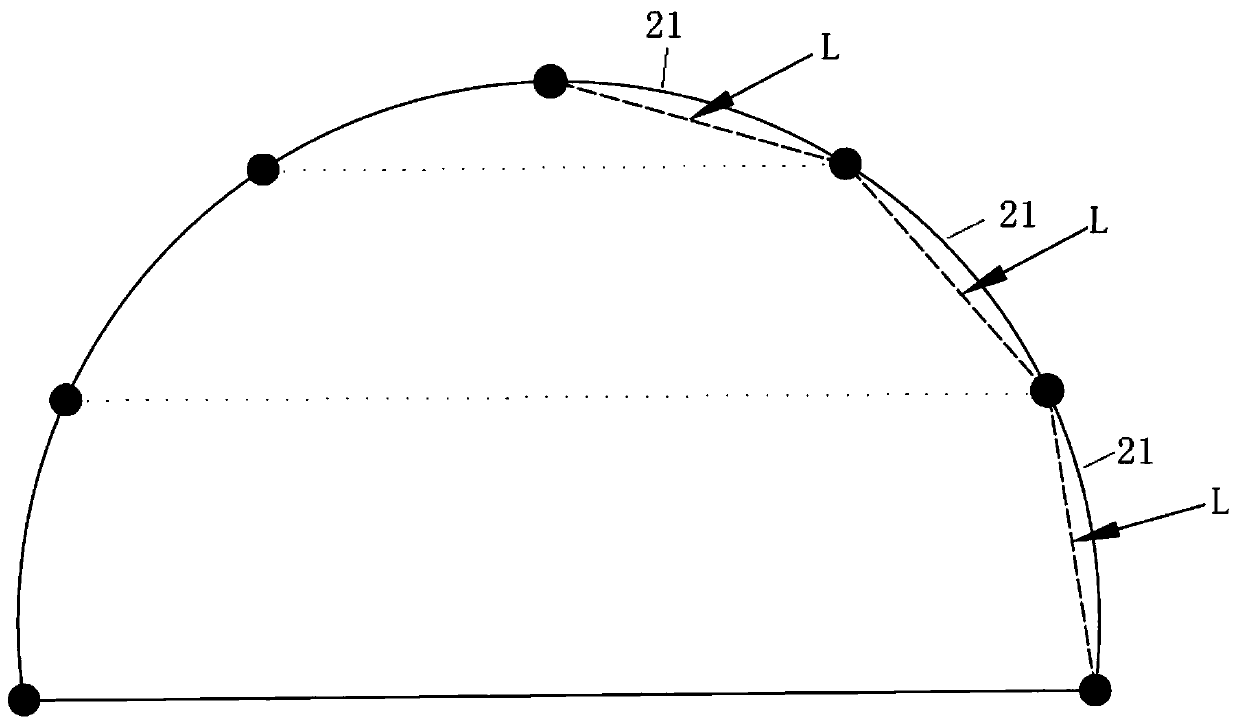

Hemispherical glass outer surface film coating device and method

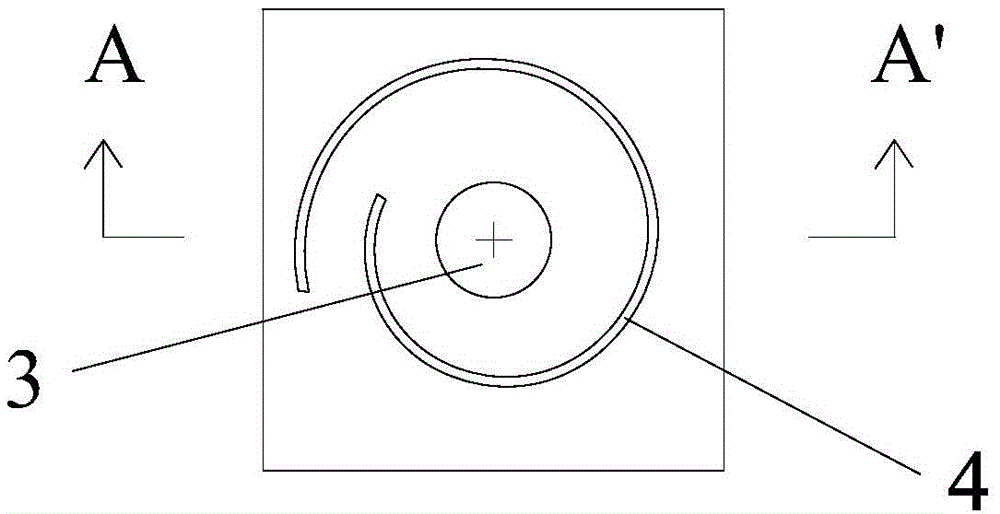

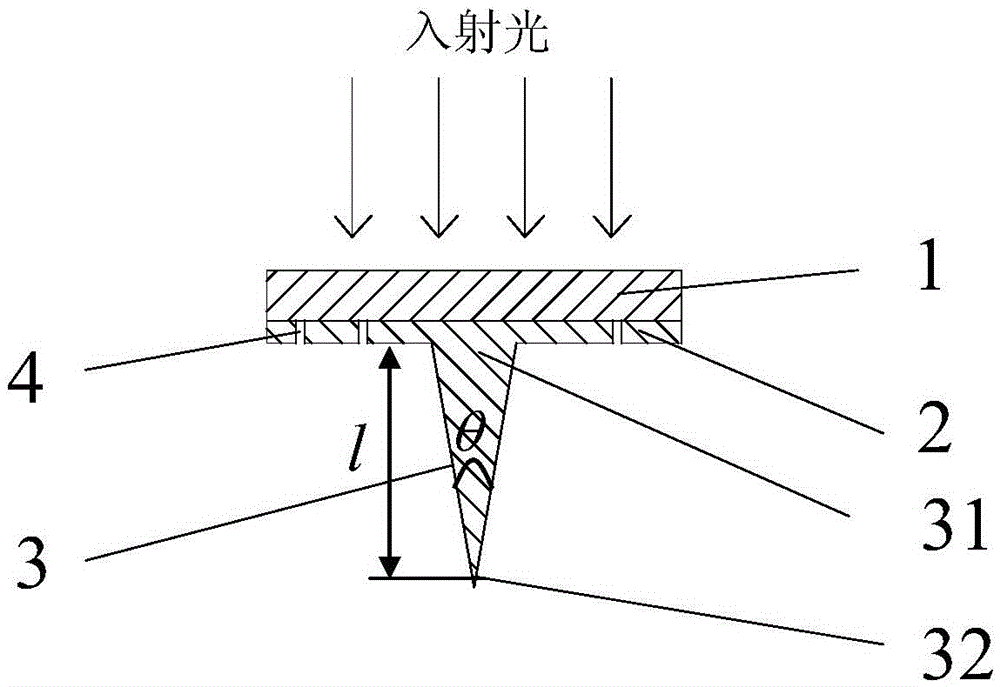

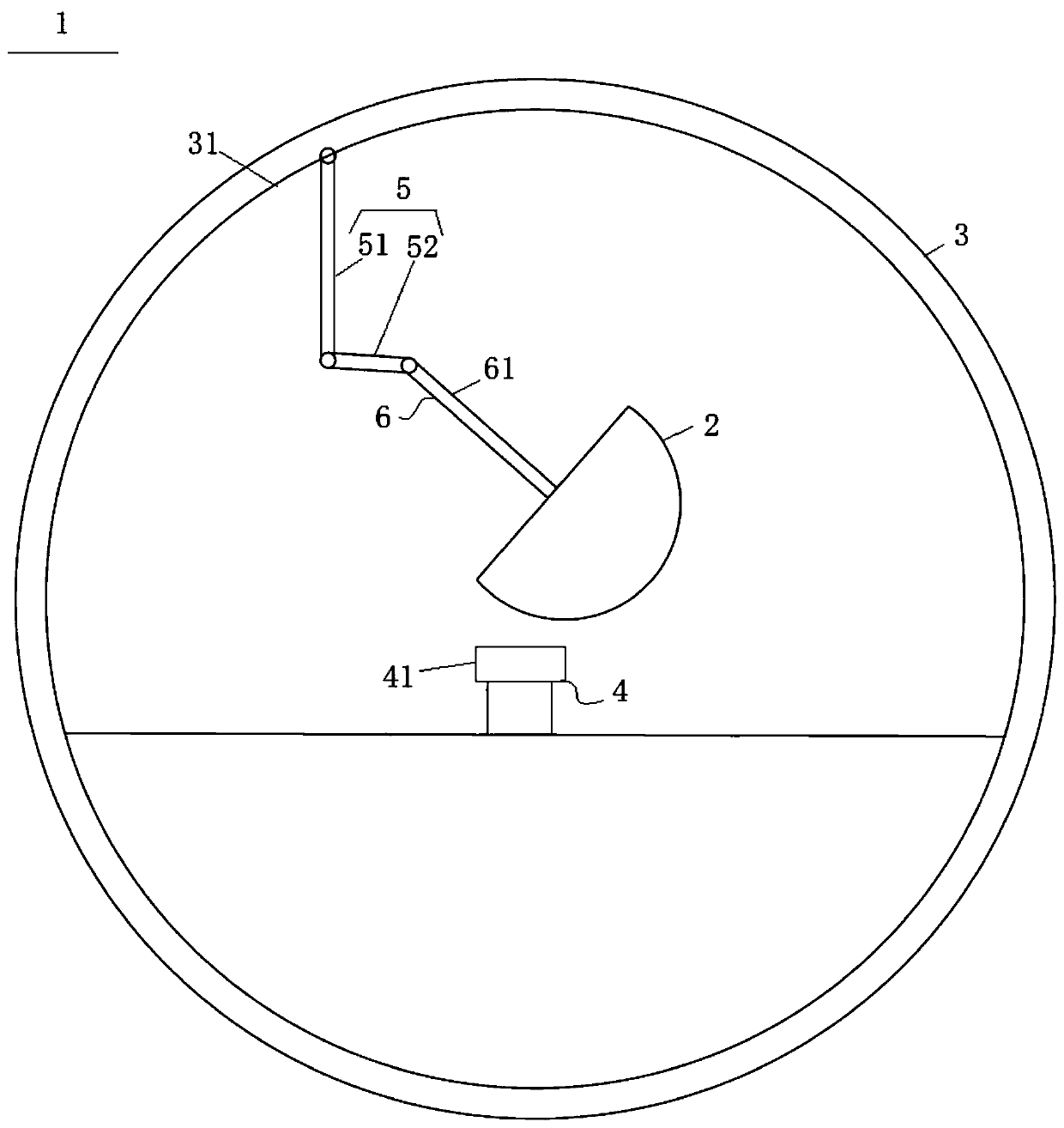

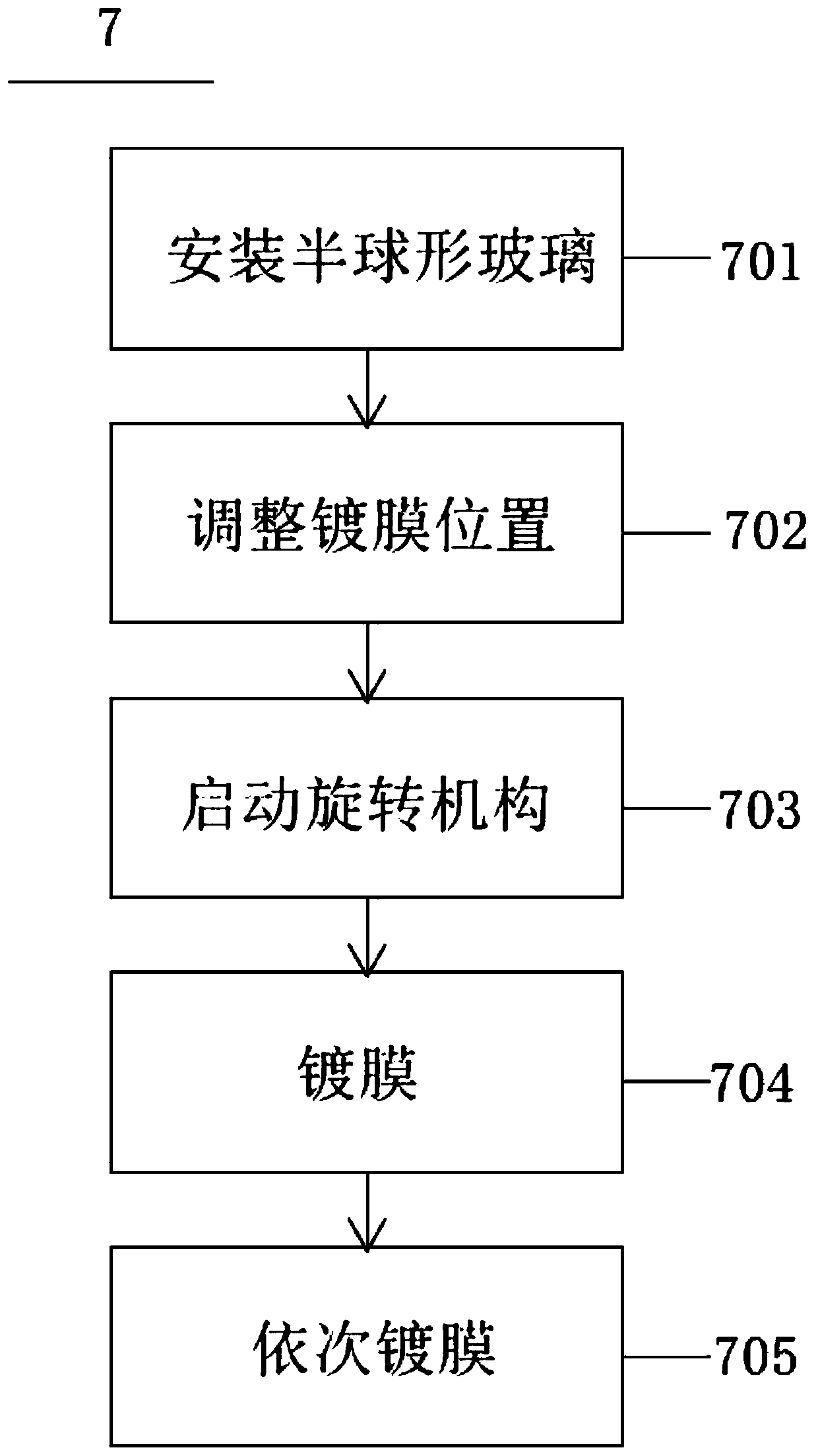

PendingCN110760812AThe method steps are simpleCoating method is simpleVacuum evaporation coatingSputtering coatingFilm-coated tabletMaterials science

The invention relates to a hemispherical glass outer surface film coating device and method. The hemispherical glass outer surface film coating device comprises a film coating cavity, a film coating mechanism, an adjustable fixing mechanism and a rotating mechanism. The film coating mechanism is arranged in the film coating cavity and used for conducting the film coating technology on multiple circular ring surfaces in sequence. The adjustable fixing mechanism is arranged on the film coating cavity, and the position of the adjustable fixing mechanism can be adjusted according to the film coating position of a piece of hemispherical glass. The rotating mechanism is connected with the adjustable fixing mechanism in a pivot joint mode and can be driven by the adjustable fixing mechanism to adjust the position of the rotating mechanism. The rotating mechanism is used for achieving the process that when the film coating technology is conducted, the rotating mechanism is connected with the hemispherical glass, drives the hemispherical glass to rotate, controls the multiple circular ring surfaces to face the film coating mechanism in sequence by rotating around the pivot joint end of therotating mechanism, and conducts the film coating technology on the multiple circular ring surfaces in sequence. According to the hemispherical glass outer surface film coating device and method, thehemispherical glass is divided into the multiple circular ring surfaces, the multiple circular ring surfaces are subjected to the film coating technology in sequence, and therefore the whole film coating process can be accomplished only through one cathode.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com