Method for covering plastic film on surface of wood or plastic special-shaped substrate

A technology of substrate surface and plastic film, applied in the field of coating plastic film, can solve the problems of long construction time, difficult comprehensive coating, environmental pollution, etc., achieve high gloss and color, simple coating method, and solve pollution problems. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

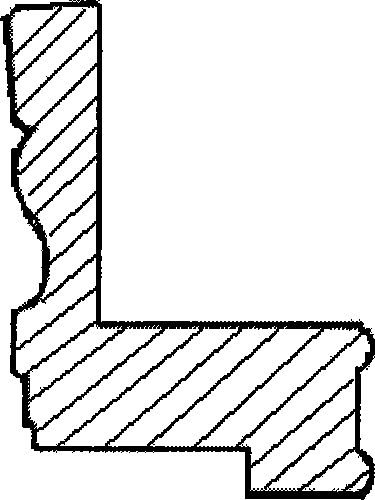

Image

Examples

specific Embodiment approach 1

[0012] Specific embodiment one: the steps of this embodiment method are as follows:

[0013] Step 1. Select a plastic heat-shrinkable material, and make the plastic heat-shrinkable material into a cylindrical film, the heat shrinkage rate of the plastic heat-shrinkable material is 10-50%, and the thickness of the plastic heat-shrinkable material cylindrical film is 0.01mm-3mm;

[0014] Step 2. Spray a layer of oil-based or water-based vacuum-absorbing plastic on the surface of the wooden or plastic shaped substrate;

[0015] Step 3, putting the plastic heat-shrinkable cylindrical film prepared in step 1 on the outer surface of the wooden (artificial board) or plastic special-shaped substrate sprayed with oily or water-based vacuum plastic in step 2;

[0016] Step 4. Put the wooden (artificial panel) or plastic special-shaped substrate with the plastic heat-shrinkable tubular film in the step 3 into the vacuum suction coating machine, and vacuum the inside of the vacuum suction...

specific Embodiment approach 2

[0017] Embodiment 2: The plastic heat-shrinkable material in step 1 of this embodiment adopts materials such as PVC, PET, PEPOF or CPVC. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the plastic heat-shrinkable material in step 1 is PVC, and the heat shrinkage rate is 40%, and the thickness of the PVC plastic heat-shrinkable material tubular film is 1mm. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com