TiO2 composite hydrophobic icephobic coating and preparation method thereof

A coating, hydrophobic technology, applied in coatings, anti-fouling/underwater coatings, anti-corrosion coatings, etc., can solve the problems of loss of manpower, financial resources, and the inability to achieve the effect of anti-icing, and achieve extended icing time, preparation Low cost and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

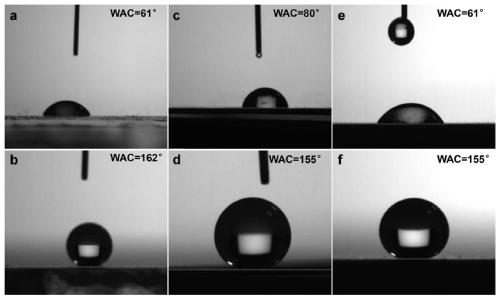

[0025] Self-cleaning of glass substrates

[0026] (1) Preparation of TiO 2 Colloid: A solution (take 17ml n-tetrabutyl titanate, mix 4.035g diethanolamine and 57.5ml absolute ethanol in a beaker, and stir in a magnetic stirrer for half an hour.) B solution (0.9ml deionized water, 25ml anhydrous water ethanol mixed with 0.045g urea). Add solution B to solution A dropwise, and stir at room temperature for 24 hours.

[0027] (2) TiO 2 Preparation of slurry: 8 g of isopropyl titanate, 8 g of dodecylamine, and 360 ml of absolute ethanol were mixed and stirred uniformly as a precursor solution. Dissolve 8g of urea in 120ml of deionized water, add the urea solution dropwise to the precursor solution and stir vigorously, and stir magnetically for 12 hours after the addition to prepare TiO 2 colloid. Take 360ml TiO 2 The colloid was put into the reactor and grown by hydrothermal treatment at 200°C for 12 hours, and the TiO grown by hydrothermal 2 Wash with absolute ethanol and c...

Embodiment 2

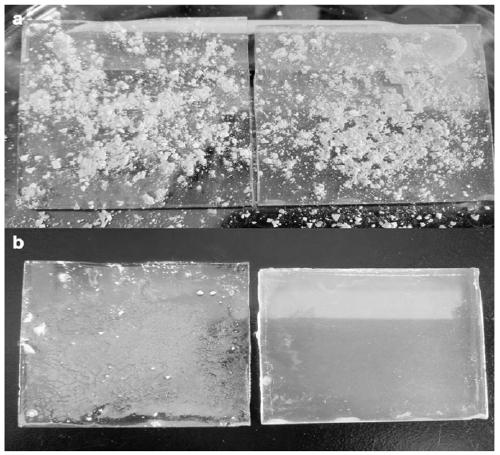

[0035] Anti-icing of aluminum sheet and glass substrate

[0036] (1) Preparation of TiO 2 Colloid: Solution A (take 15ml n-tetrabutyl titanate, mix 4g diethanolamine and 48ml absolute ethanol in a beaker, and stir in a magnetic stirrer for half an hour.) B solution (0.9ml deionized water, 25ml absolute ethanol and 0.045g urea). Add solution B to solution A dropwise, and stir at room temperature for 24 hours.

[0037] (2) TiO 2 Preparation of slurry: 8 g of isopropyl titanate, 8 g of dodecylamine, and 360 ml of absolute ethanol were mixed and stirred uniformly as a precursor solution. Dissolve 8g of urea in 120ml of deionized water, add the urea solution dropwise to the precursor solution and stir vigorously, and stir magnetically for 12 hours after the addition to prepare TiO 2 colloid. Take 360ml TiO 2 The colloid was put into the reactor and grown by hydrothermal treatment at 230°C for 12 hours, and the TiO grown by hydrothermal 2 Wash with absolute ethanol and centri...

Embodiment 3

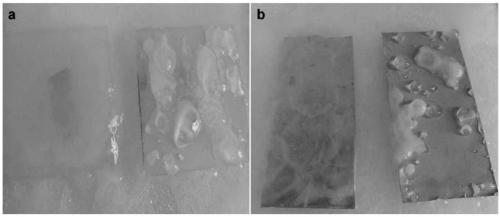

[0044] Anti-corrosion of iron substrate

[0045] (1) TiO 2 Thin film: Dip the cleaned iron sheet into TiO 2 Sol (TiO in embodiment 2 2 Coating a layer of TiO on the surface of the iron sheet by the pulling method in the sol) 2 The film was dried in an oven at 70°C for 30 minutes and then put in a muffle furnace at 480°C for 40 minutes;

[0046] (2) TiO 2 Slurry coating: After the iron sheet in (1) is cooled to room temperature, scrape a layer of TiO on the surface of the coated iron sheet 2 The slurry was dried in an oven at 60°C for 20 minutes and then placed in a muffle furnace at 450°C for 1 hour;

[0047] (3) Hydrophobic modification: Spray the hydrophobic solution on the sample of (2) with a watering can, let it stand at room temperature for 10 minutes, and then put it in an oven at 140°C to dry for 2 hours;

[0048] (4) Immerse the iron sheet treated in step (3) and the untreated iron sheet in a 10% NaCl solution. After a period of time, comparing the corrosion co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com