A surface plasmon-enhanced needle tip and a needle-tip enhancement method

A surface plasmon, needle tip technology, applied in optical components, scanning probe technology, scanning probe microscopy, etc., can solve the problems of difficulty in forming a fast scanning array structure, difficulty, and long needle tip length, and achieve easy formation of large The effect of area tip arrays, increased scanning speed, improved signal-to-noise ratio and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

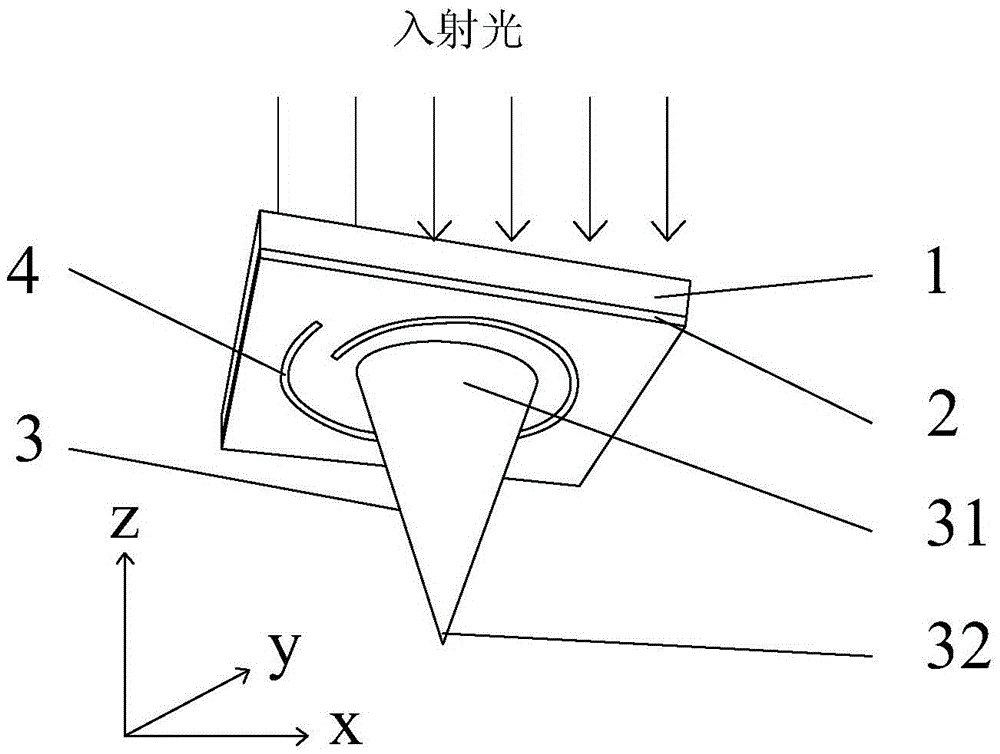

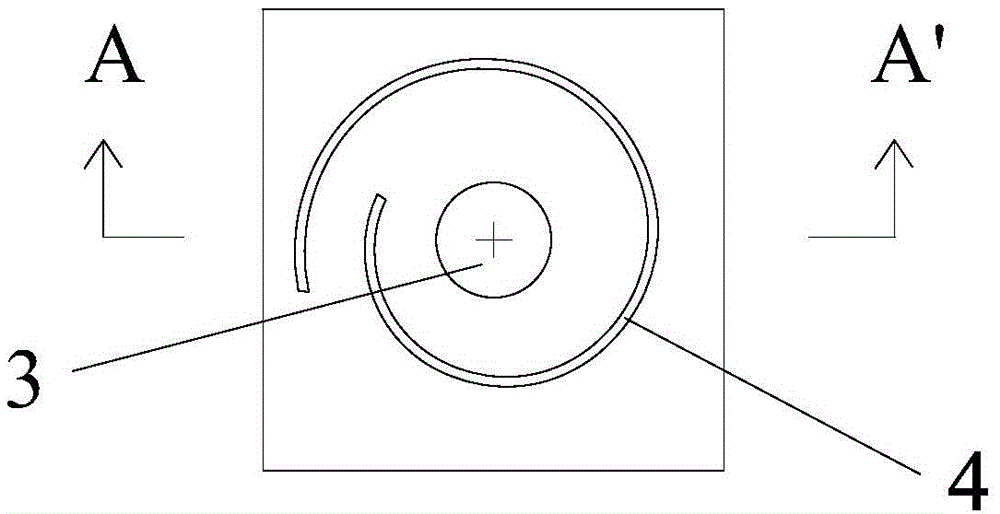

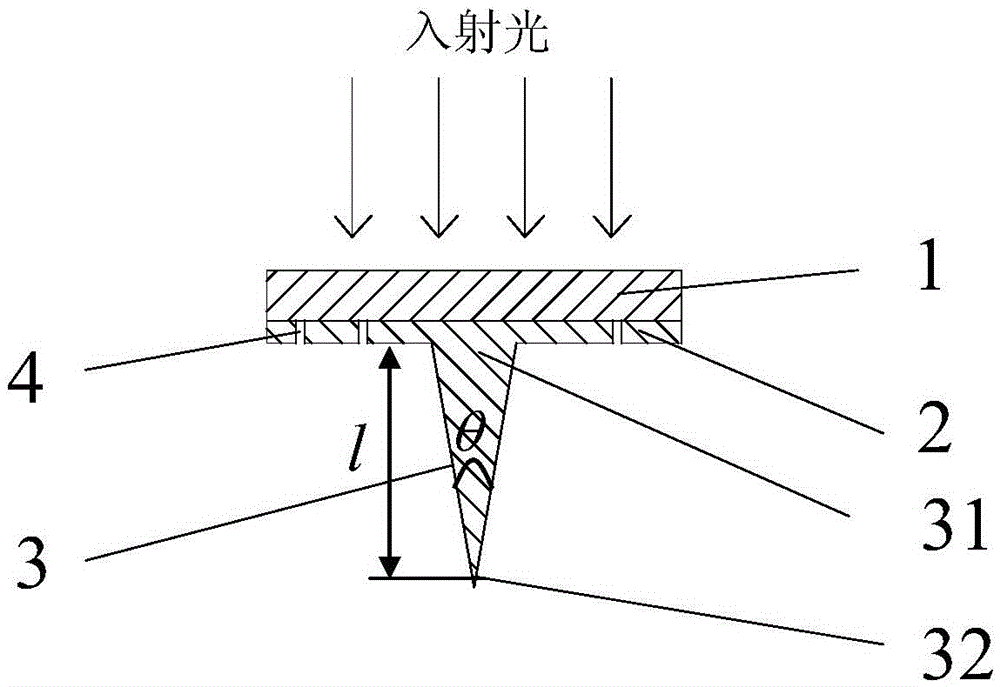

[0081] Embodiment 1 provides a surface plasmon enhanced needle tip, Figure 1a Schematic diagram illustrating the three-dimensional structure of the enhanced needle tip with the illumination direction of the incident light ( Figure 1a A schematic diagram of the three-dimensional structure of the enhanced needle tip provided in Example 1); Figure 1b Schematic illustration of a slit that enhances the helical structure machined on the tip structure ( Figure 1b Bottom view of the enhanced needle tip provided for Example 1); Figure 1c Schematic diagram illustrating the hierarchical structure of the enhanced tip structure ( Figure 1c The front cross-sectional view of the enhanced needle tip provided for Example 1);

[0082] Such as Figure 1a , Figure 1b , Figure 1c It can be seen that the surface plasmon-enhanced tip provided in this embodiment includes a transparent substrate 1, a metal film 2 fabricated on one side of the transparent substrate 1, and a metal tip 3 conne...

Embodiment 2

[0101] Embodiment 2 provides a surface plasmon-enhanced needle tip. The difference from Embodiment 1 is that the slit of the helical structure processed on the metal film is right-handed (rotating clockwise), and the slit of the helical structure The slit width is 50nm, the number of turns is 10, the minimum length (inner radius) between the first turn of the helical structure and the center of the helix is 550nm, and the pitch is 360nm.

Embodiment 3

[0102] Embodiment 3 provides a surface plasmon-enhanced needle tip. The difference from Embodiment 1 is that the slit width of the slit of the helical structure processed on the metal film is 400 nm, and the number of turns is 1. The first slit of the helical structure The minimum length (inner radius) of one turn from the center of the helix is 10 μm, and the helix pitch is 740 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com