Hemispherical glass outer surface film coating device and method

A glass outer surface, coating device technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of increasing the manufacturing cost, the film thickness cannot be guaranteed to be uniform and stable, etc., so as to reduce the coating cost , Solve the effect of the more complicated coating method and simplify the method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

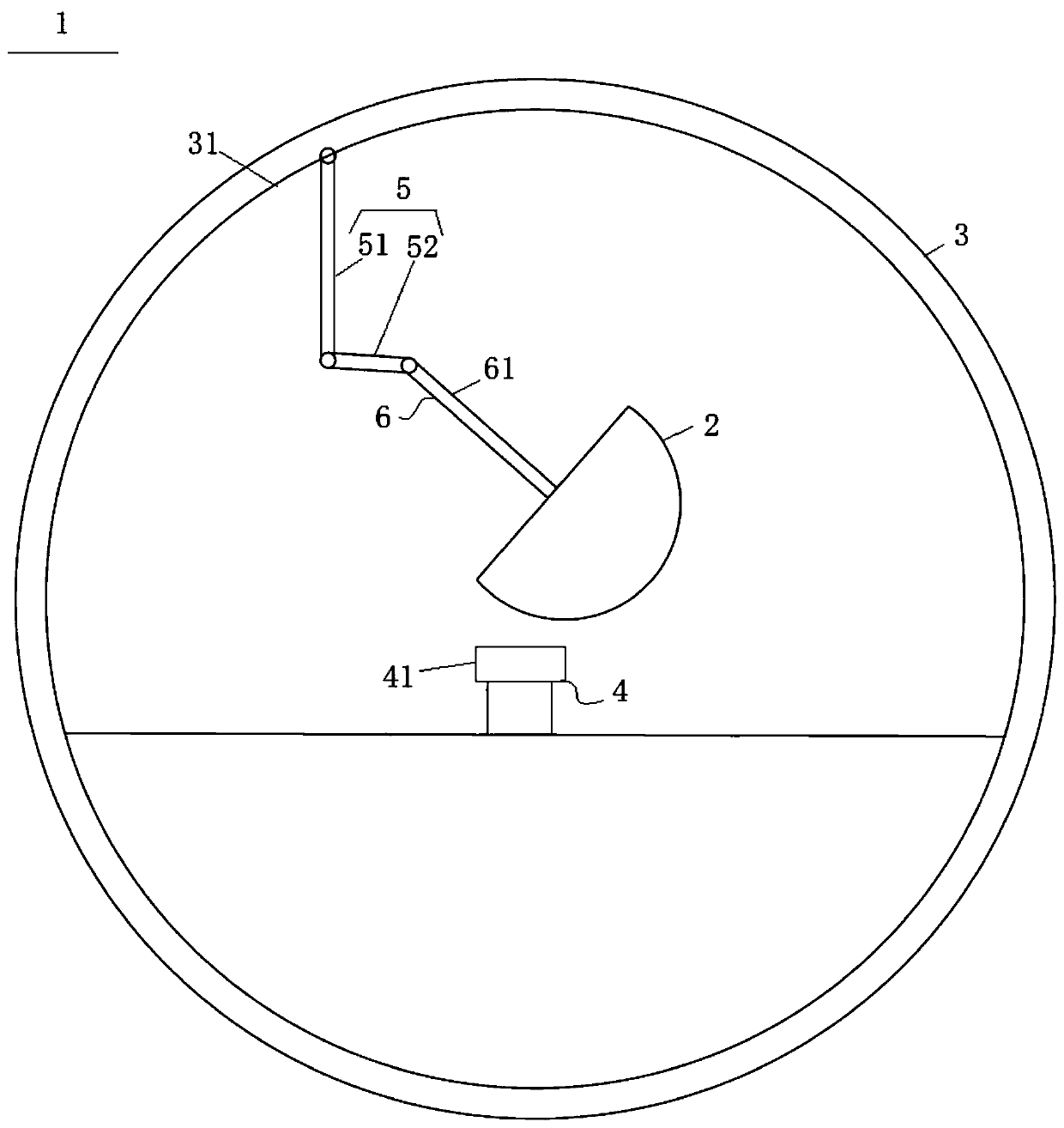

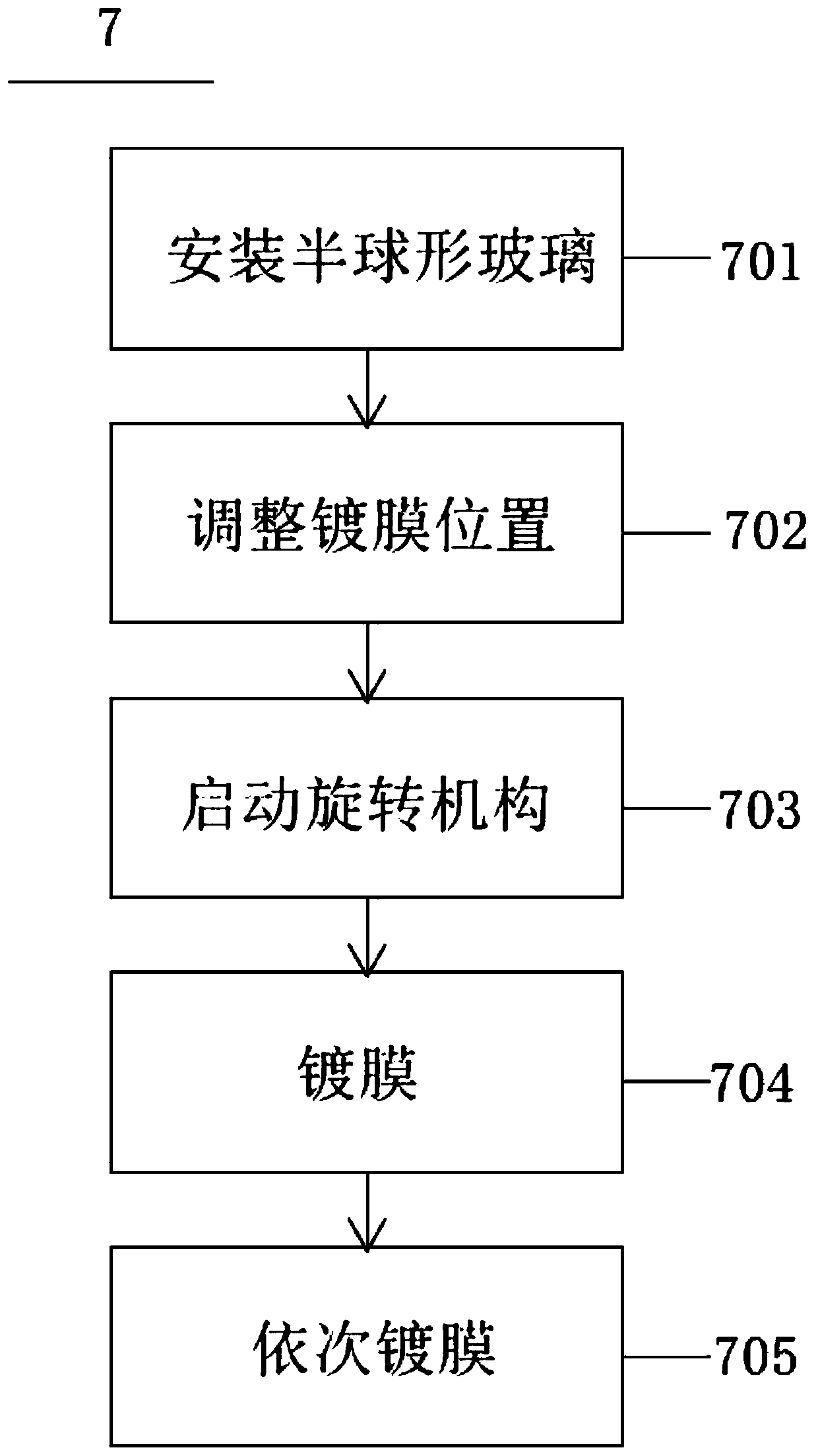

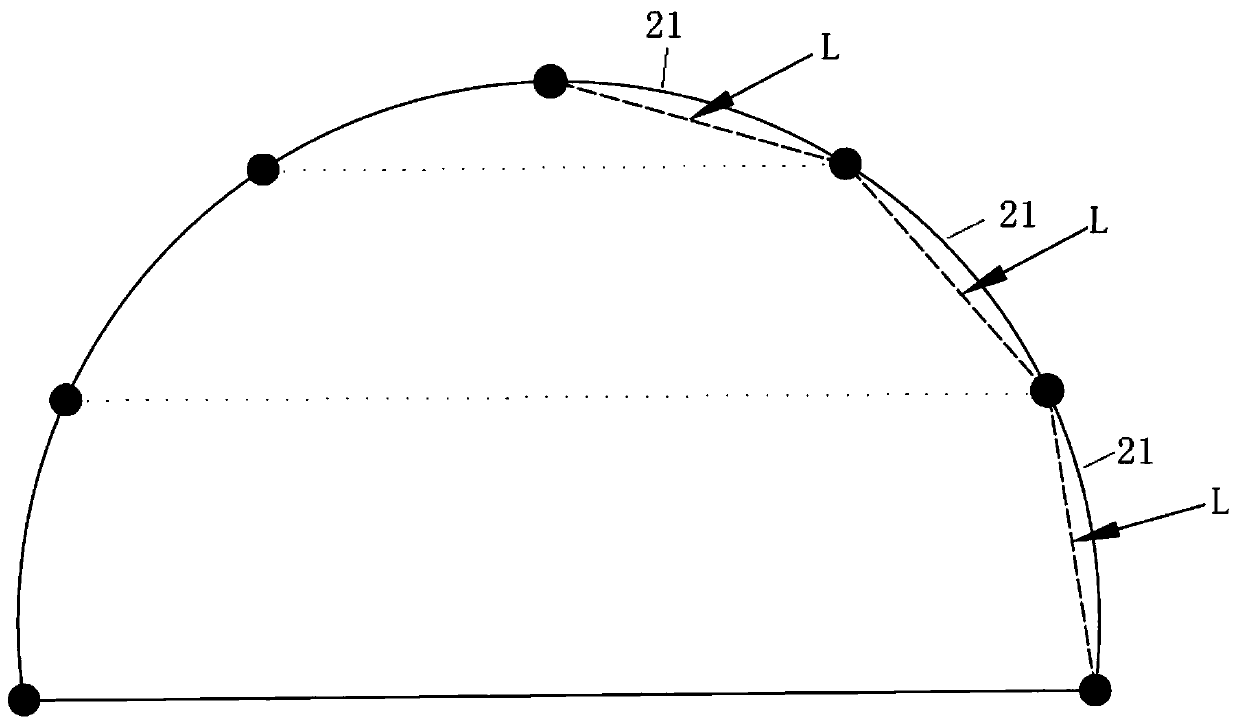

[0041] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic structural view of a hemispherical glass outer surface coating device 1 according to an embodiment of the present invention. The outer surface coating device 1 of the hemispherical glass is used to divide the hemispherical glass 2 into a plurality of toroidal surfaces 21, and perform the coating process in sequence. The outer surface coating device 1 of the hemispherical glass 2 includes a coating cavity 3, a coating mechanism 4, an adjustable Fixed mechanism 5 and rotating mechanism 6, wherein:

[0042] The coating chamber 3 is mainly used to provide a vacuum coating space for the coating process of the hemispherical glass 2. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com