Coating method of woven artificial blood vessel and artificial blood vessel

An artificial blood vessel and coating technology, which is applied in the field of medical devices, can solve the problems of uneven inner and outer surfaces of artificial blood vessels, expensive imported artificial blood vessels, and difficulty in uniform coating, so as to shorten the waiting time for surgery, protect elasticity and compliance , good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

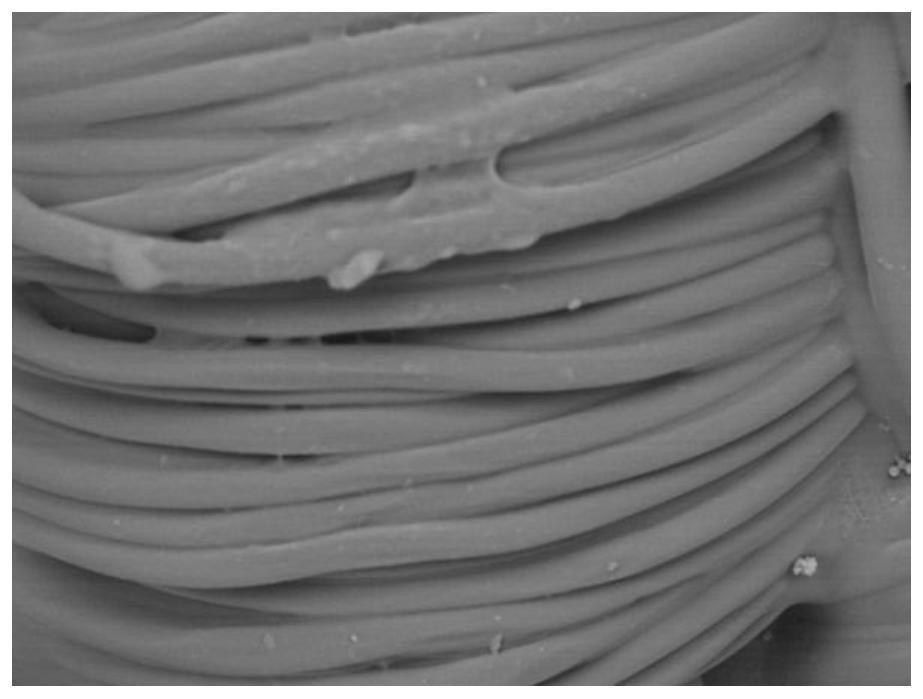

[0038] 8mm diameter artificial vascular coating.

[0039] First, degrease the braided artificial blood vessels, refining agent 3g / L, NaHCO 3 5g / L, liquor ratio 1:10, 90℃, treatment for 30min. Wash with deionized water three times, then bake at 60°C for 20 minutes.

[0040] Then, the degreased braided blank tube is coated with a 5% mass fraction and a bio-grade polyurethane solution as an active ingredient. Pad coating is adopted, the pressure is 2Bar, the vehicle speed is 2m / min, and hot air drying is adopted, the drying temperature is 50°C, and the drying time is 1h.

[0041] After the braided blank tube is coated, texture is carried out. The blank tube after texture is made of albumin as the active ingredient, and ultrapure water is used as the solvent to prepare a solution with a concentration of 5%. Conduct chemical cross-linking with 0.05% acetaldehyde, and then put it into a vacuum drying oven for drying at a temperature of 45° C. and a drying time of 6 hours to obta...

Embodiment 2

[0046] 18mm diameter artificial vascular coating.

[0047] First, degrease the braided artificial blood vessels, refining agent 5g / L, NaHCO 3 9g / L, liquor ratio 1:10, 90℃, treatment for 30min. Wash with deionized water 4 times, then bake at 60°C for 30 minutes.

[0048] Then, the degreased braided blank tube is coated with a polyester solution with a mass fraction of 8% and an active ingredient of biological grade. Pad coating is adopted, the pressure is 2.5Bar, the vehicle speed is 2.5m / min, and hot air drying is adopted, the drying temperature is 60°C, and the drying time is 1h.

[0049] After the braided blank tube is coated, patterning is carried out. The blank tube after patterning uses grade heparin as the active ingredient, and uses ultrapure water as the solvent to prepare a solution with a concentration of 8%. Perform chemical cross-linking for 1% formaldehyde, and then put it into a vacuum drying oven for drying at a temperature of 35° C. and a drying time of 8 h...

Embodiment 3

[0052] 28mm diameter artificial vascular coating.

[0053] First, degrease the braided artificial blood vessels, refining agent 5g / L, NaHCO 3 10g / L, liquor ratio 1:10, 90℃, treatment for 30min. Wash with deionized water 3 times, then bake at 60°C for 40min.

[0054] Then, the degreased braided blank tube is coated with a 10% mass fraction and a bio-grade polyurethane solution as an active ingredient. Pad coating is adopted, the pressure is 3.0Bar, the vehicle speed is 3m / min, and hot air drying is adopted, the drying temperature is 50°C, and the drying time is 1h.

[0055] After coating the woven blank tube, it is textured. The textured blank tube uses biological grade silk fibroin as the active ingredient, and uses ultra-pure water as the solvent to prepare a solution with a concentration of 6%, and coats it by pouring the coating. Then use glutaraldehyde at a concentration of 0.1% for chemical cross-linking, and then put it into a vacuum drying oven for drying at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com