Convenient and cheap universal cladding technology

A coating and cheap technology, applied in the field of materials, can solve the problems of restricting practical application and high price of dopamine, and achieve the effects of wide application, improved electrochemical performance, and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

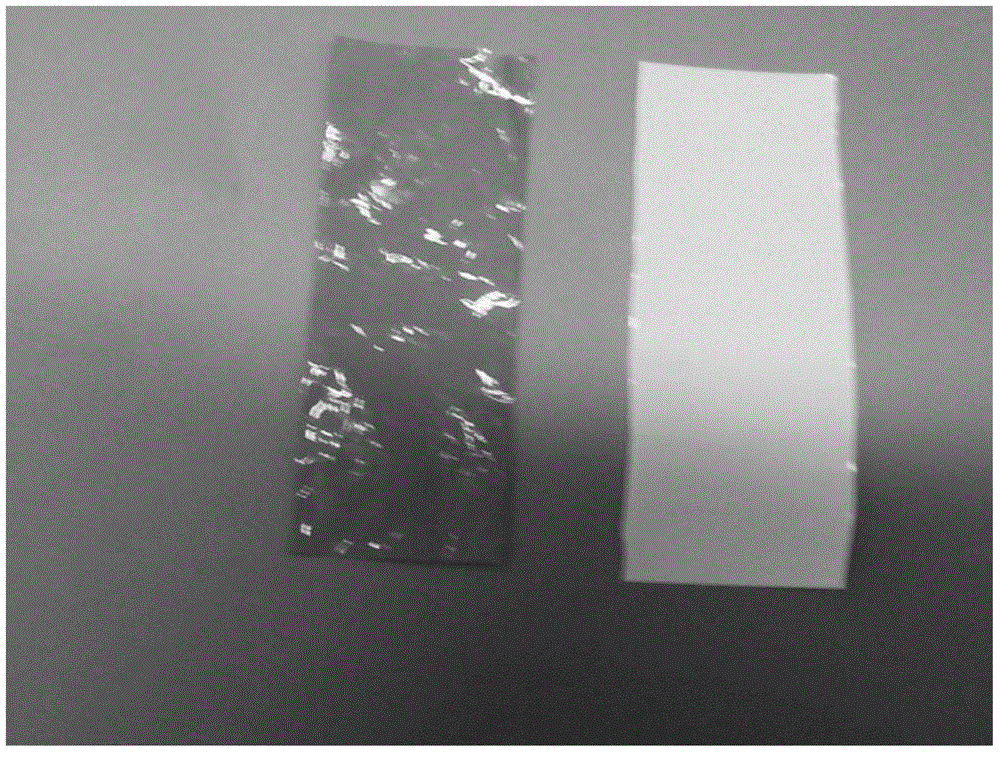

[0023] In this embodiment, catechol and lysine are used as raw materials to coat polyethylene film.

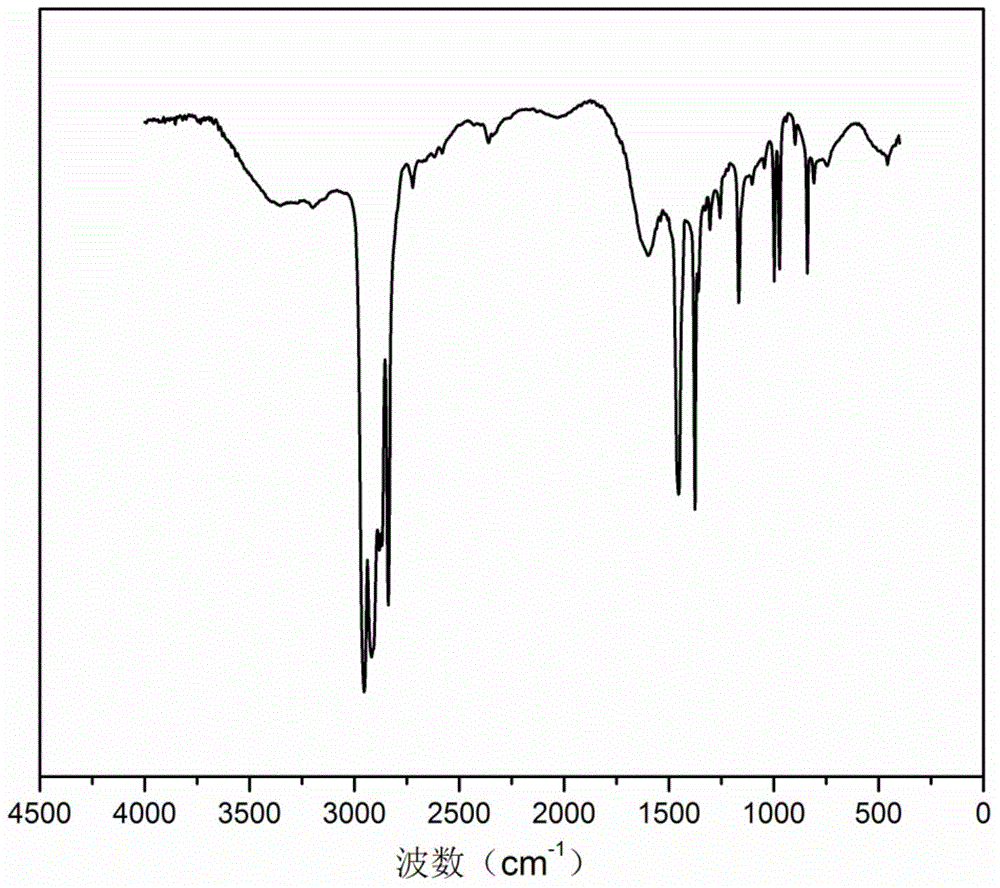

[0024] Prepare 150ml of mixed solvent of water and ethanol (volume ratio water / ethanol=1 / 2), add catechol and lysine each 0.01mol, stir and make it dissolve. Immerse the polyethylene film in the prepared mixed solution, take it out after stirring for 5 days, rinse it with water, and then air dry it. Obviously, the surface of the polyethylene film is covered with a layer of earth-gray coating material. The result is as figure 1 shown. It shows that this kind of coating method has excellent coating performance on polymers. figure 2 It is the infrared spectrum of the coated polyethylene film, in which there are absorption peaks of C-H unsaturated bonds near 2900cm-1, and the sharp absorption peaks at 1500 and 650-900 can be attributed to the C=C stretching vibration and benzene ring in the benzene ring. The out-of-plane bending vibration of C-H on the ring indicates that the...

Embodiment 2

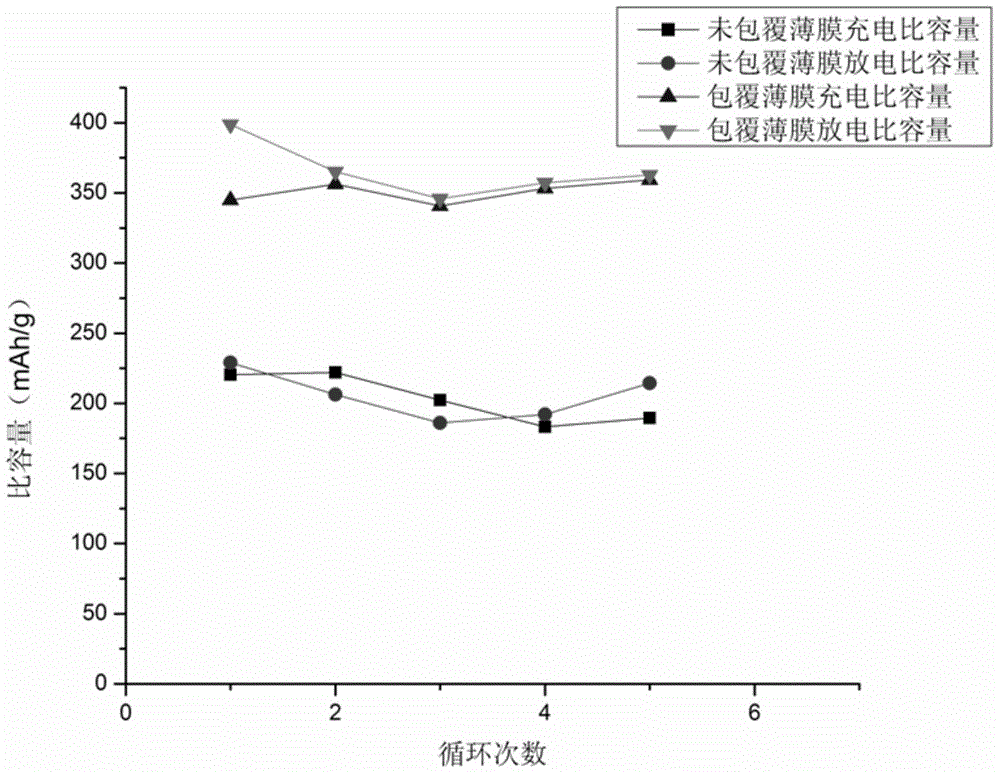

[0026] The polyethylene film coated in Example 1 was used as a battery separator and assembled into a battery to improve battery performance.

[0027] The lithium sheet is used as the negative electrode, and the graphite used in the factory is used as the positive electrode. The coated polyethylene film and the uncoated polyethylene film are respectively used as battery separators to assemble a button battery, and the battery charge and discharge specific capacity performance test is carried out. By comparison, after the diaphragm is coated, the charge-discharge specific capacity of the battery increases from about 220mAh / g to about 340mAh / g, and the charge-discharge specific capacity of the battery increases by as much as half. The results are as follows image 3 shown. It shows that the coating of the separator by the polymer of catechol and lysine can be used to improve the battery separator and increase the charge-discharge specific capacity of the battery.

Embodiment 3

[0029] The polyethylene film coated in Example 1 was used as a battery separator and assembled into a battery, and the internal resistance of the battery was reduced by increasing the wettability of the separator.

[0030] Lithium iron phosphate is used as the positive electrode, silicon wafer is used as the negative electrode, polyethylene film and uncoated polyethylene film are used as battery separators respectively, and the battery is assembled for impedance performance testing. The results show that the battery impedance drops from about 430 ohms to about 220 ohms, such as Figure 4 shown. That is, the coating of the polymer of catechol and lysine can improve the wettability of the battery separator, thereby reducing the internal resistance of the battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com