Lithium-ion battery ternary material coated with metal oxide on surface and preparation method thereof

A lithium-ion battery and surface coating technology, applied in the field of lithium-ion batteries, can solve the problems of electrolyte reaction, voltage platform reduction, difficulty in ensuring uniformity of precipitation, etc., and achieve the effect of uniform coating and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, weigh the percentage by weight to be 0.5% (that is, 0.5% wt ) of polyacrylamide aqueous solution 5L as a dispersant solution. 36.84g of Al(NO 3 ) 3 9H 2 O was added to the above-mentioned dissolved dispersant solution to fully disperse evenly. Step 2, the cathode material Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Add to the solution obtained in step 1 and stir for 3 hours. Step 3, adding potassium hydroxide solution, adjusting the pH value of the solution in step 2 to between 9-10, then filtering, drying the obtained solid at 120°C to obtain a positive electrode material coated with aluminum hydroxide; step 4, adding The positive electrode material coated with aluminum hydroxide was heated at 450°C for 2 hours to convert the hydroxide into an oxide, and finally a positive electrode material sample coated with aluminum oxide was obtained.

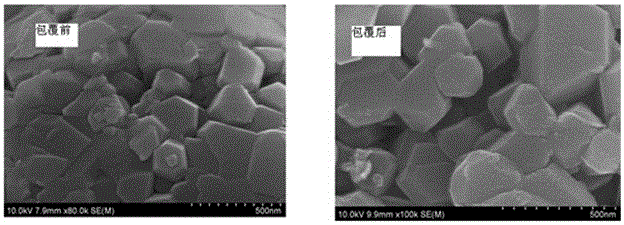

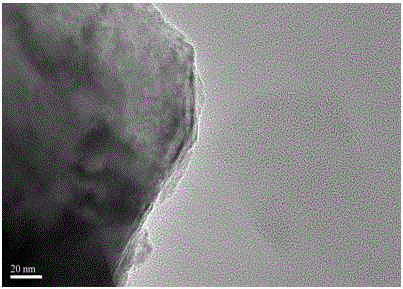

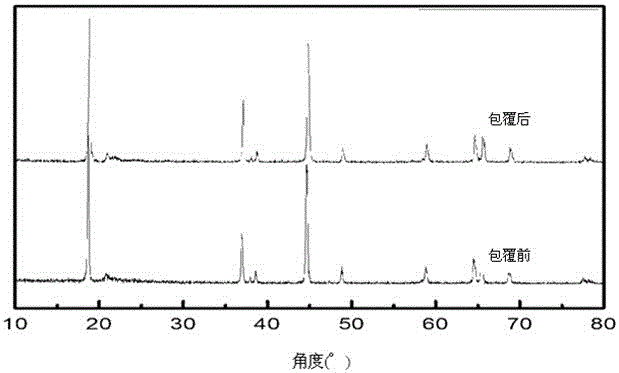

[0038] The Li[Li obtained by this embodiment 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Scanning electron microscope (SEM...

Embodiment 2

[0043] Step 1, weigh the percentage by weight to be 0.25% (i.e. 0.25% wt ) of polyacrylamide aqueous solution 6L as a dispersant solution. 36.84g of Al(NO 3 ) 3 9H 2 O was added to the above-mentioned dissolved dispersant solution to fully disperse evenly. Step 2, the cathode material Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Add to the solution obtained in step 1 and stir for 3 hours. Step 3, adding potassium hydroxide solution, adjusting the pH value of the solution to 8, then filtering, and drying the obtained solid at 120° C. to obtain a positive electrode material coated with aluminum hydroxide. Step 4: heat-treat the positive electrode material coated with aluminum hydroxide at a temperature of 550° C. for 2 hours to convert the hydroxide into an oxide, and finally obtain a positive electrode material sample coated with aluminum oxide on the surface.

Embodiment 3

[0045] Step 1, weigh the percentage by weight to be 0.5% (that is, 0.5% wt ) of polyacrylamide aqueous solution 5L as a dispersant solution. 55.26g of Al(NO 3 ) 3 9H 2 O was added to the above-mentioned dissolved dispersant solution to fully disperse evenly. Step 2, the cathode material Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 Add to the solution obtained in step 1 and stir for 6 hours. Step 3, adding potassium hydroxide solution, adjusting the pH value of the solution to 8.5, then filtering, and drying the obtained solid at 120° C. to obtain a positive electrode material coated with aluminum hydroxide. Step 4: heat-treat the positive electrode material coated with aluminum hydroxide at a temperature of 450°C for 3 hours to convert the hydroxide into an oxide, and finally obtain a positive electrode material sample coated with aluminum oxide on the surface.

[0046] The material cycle performance curve before and after coating is as follows: Figure 5 As shown, charg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com