Flocculant suitable for papermaking wastewater treatment and use method thereof

A technology for papermaking wastewater and flocculant, which is applied in the process of wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc. Cost, reduction in usage, and effect of increasing the number of charges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

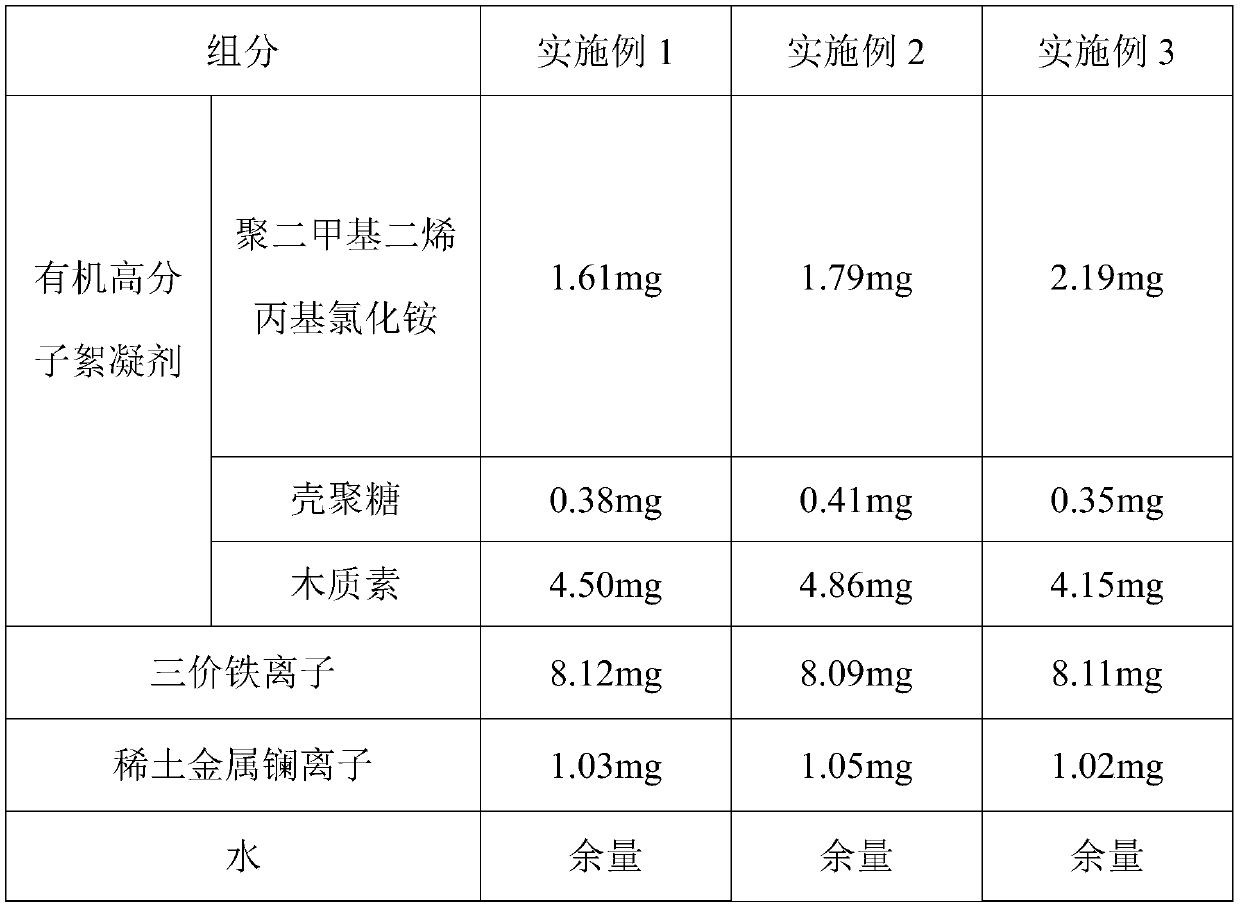

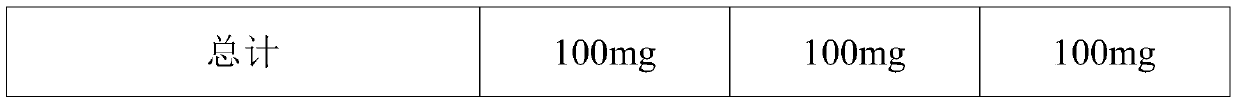

[0024] A flocculant suitable for papermaking wastewater treatment, comprising the following components by mass percentage: organic polymer flocculant 5.8%-7.4%, ferric ion 6.2%-10.5%, lanthanide rare earth metal ion 0.3%-1.8% % and water 78%-88%.

[0025] The organic polymer flocculants include cationic organic polymer flocculants.

[0026] The organic macromolecule flocculant includes polydimethyl diallyl ammonium chloride, chitosan and lignin, and the lignin is large-aperture spherical lignin with a particle size of 0.2-1.2mm.

[0027] The dosage ratio of the polydimethyldiallylammonium chloride, chitosan and lignin is (4-7):(0.8-2):(5-15).

[0028] The ferric ions are derived from ferric sulfate solution or ferric chloride solution.

[0029] A method for using the above-mentioned flocculant suitable for papermaking wastewater treatment, comprising the following steps:

[0030] (1), adding the described flocculant suitable for papermaking wastewater treatment in waste wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com