Neutralization treatment method of acid solution in lead-acid storage battery disassembling process

A technology of lead-acid batteries and lead-acid batteries, which can be used in the fields of neutralization water/sewage treatment, chemical instruments and methods, battery recycling, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment is a method for neutralizing acid solution during dismantling of a lead-acid battery, comprising the following steps:

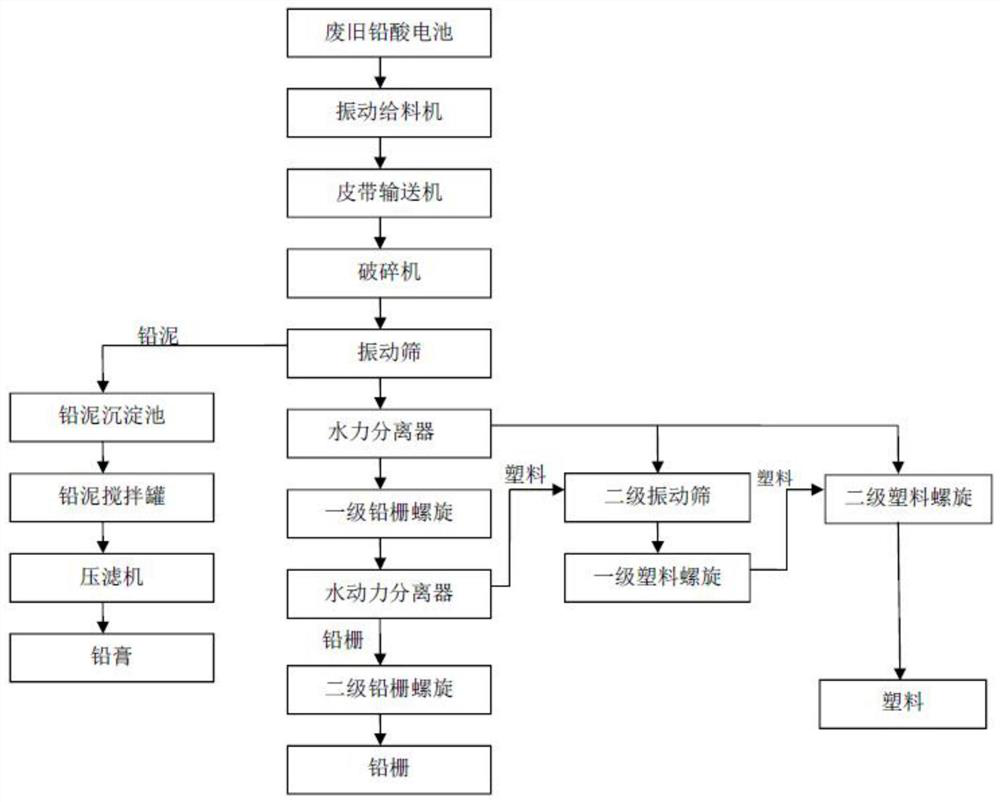

[0035] Step 1: Disassemble the recovered waste lead-acid batteries through the automatic waste lead-acid battery crushing and sorting system, sort out the lead sludge through mechanical crushing, and then use a hydraulic separator and a hydrodynamic separator to separate the lead grid and plastic ;

[0036] Step 2: Transport the acid produced in the process of separating the lead grid and plastic by hydraulic separation technology to the dismantling sewage treatment system, and then put calcium hydroxide into the acid, and the calcium hydroxide and the acid are neutralized.

[0037] The fully automatic waste lead-acid battery crushing and sorting system includes a vibrating feeder, a belt conveyor, a crusher, a vibrating screen, a lead mud sedimentation tank, a lead mud mixing tank, a filter press, a hydraulic separator, and a first-sta...

experiment example 1

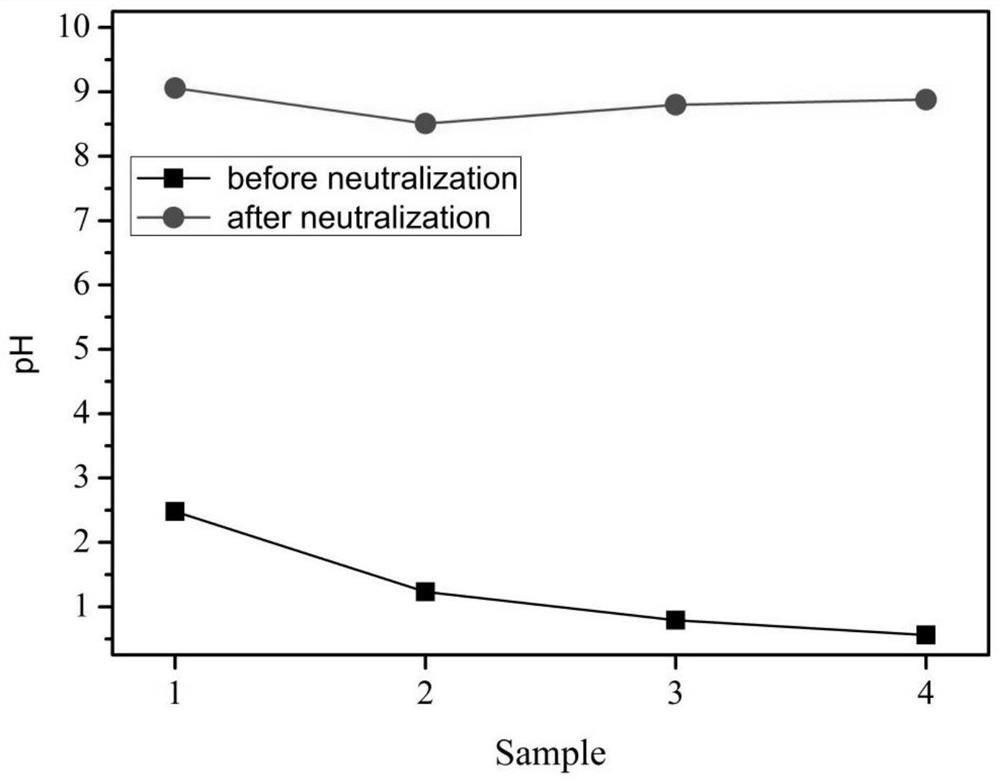

[0047] Calcium hydroxide dosage test: Sampling the acid liquid produced in the automatic waste lead-acid battery crushing and sorting system, respectively sampling 300ml of acid liquid produced by the battery processing capacity of 1000 tons, 2000 tons, 3000 tons and 4000 tons, respectively In 4 beakers and marked as 1, 2, 3, 4 respectively, then add calcium hydroxide powder into the beakers and stir evenly until the pH value of each water sample is adjusted to 8.5±1, then the treated water The samples were left to stand for 6 hours, and the supernatants in 4 beakers were extracted with 100ml syringes for detection.

[0048] Result analysis:

[0049] see figure 2 As shown, it can be seen from the figure that with the increase of battery processing capacity, the acid content in the acid solution gradually increases, and the pH value gradually decreases. When the battery is processed to 3000 tons, the pH value of the acid solution is already less than 1. After neutralization...

experiment example 2

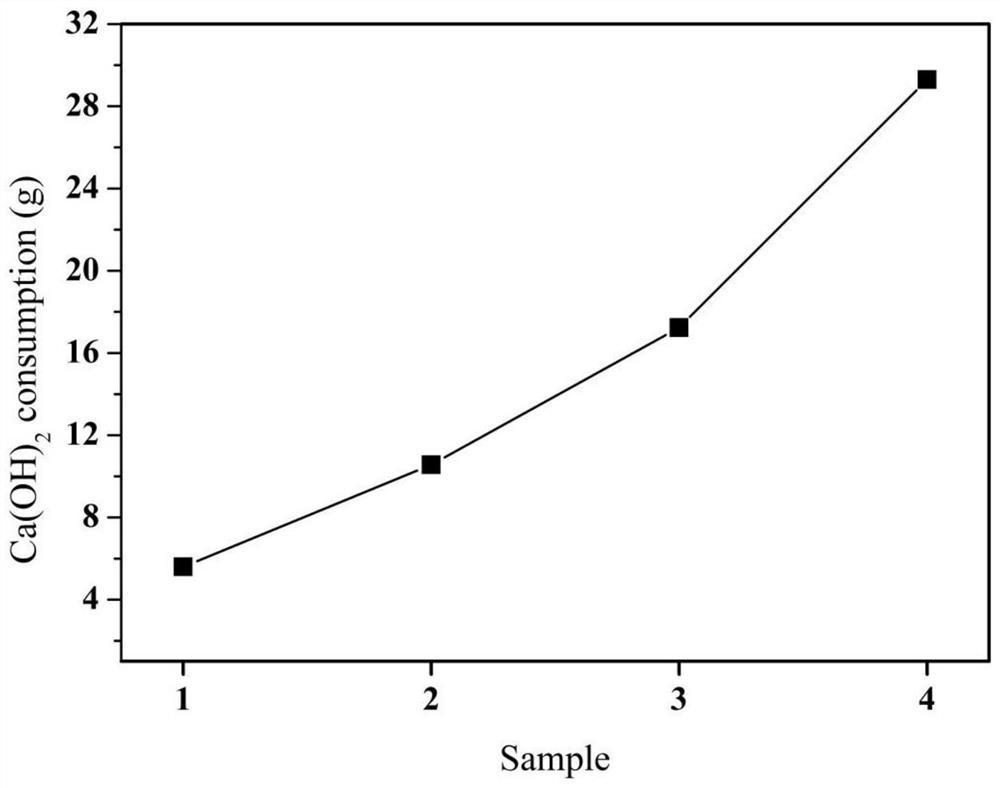

[0052] Acid content test: use the calibrated 0.1mol / l NaOH solution to calibrate the water samples in the 4 beakers, and convert the sulfuric acid content in the water samples.

[0053] Result analysis:

[0054] see Figure 4 As shown, it can be seen from the figure that with the increase of battery processing capacity, the sulfuric acid content in the acid solution gradually increases, and basically has a linear relationship with the battery processing capacity. When the processing capacity of the lead-acid battery reaches 4000 tons, The sulfuric acid content in the acid solution has reached about 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com