Oil well acidification process and device for increasing oil-gas well yield

A technology for acidizing oil wells and oil and gas wells, which is applied in wellbore/well components, drilling compositions, chemical instruments and methods, etc., and can solve problems such as long construction period, corrosion of production equipment such as downhole pipe strings, and acid pollution , to achieve the effect of solving oil layer blockage, convenient construction and reducing acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

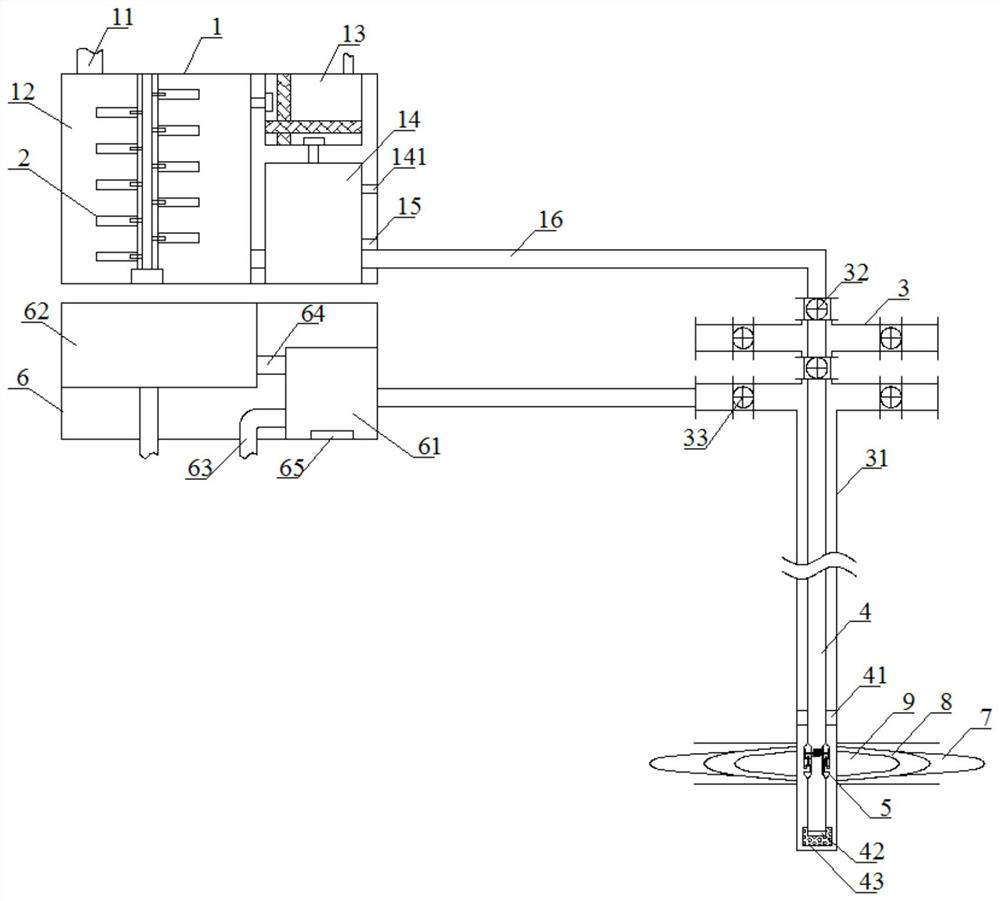

[0045] Such as figure 1 Shown, a kind of oil well acidizing process for improving oil and gas well production comprises the following steps:

[0046] S1 Acidizing Pretreatment: Pull out the production string in the test well with a body length of 1387m, run it into the well cleaning string, and perform a positive flushing and a backwashing. It is injected into the casing and returned. Backwashing is to inject the flushing fluid from the casing and return to the flushing string. The volume of the flushing fluid is 12m 3 , the mass ratio of the components of the well flushing fluid is surfactant: fluid loss control agent: octylphenol polyoxyethylene ether: water = 4:2:3:91, and the well flushing string is pulled out after the well flushing is completed;

[0047] S2 note pre-acid solution 7: such as Figure 10 As shown, the acidizing string 4 with a packer 41 is lowered. The packer 41 is a commercially available Y241-115 packer. The device 41 is sealed, and the pre-acid liquid...

Embodiment 2

[0061] This embodiment is basically the same as Embodiment 1, except that the injection speeds of the pre-acid solution 7, the reaction acid solution 8, and the neutralizing agent 9 are different, specifically:

[0062] Note pre-acid solution 7: injection speed is 0.35m 3 / min;

[0063] Injection reaction acid solution 8: the injection speed is 0.55m 3 / min;

[0064] Note neutralizer 9: injection speed is 0.2m 3 / min.

Embodiment 3

[0066] This embodiment is basically the same as Embodiment 1, except that the injection speeds of the pre-acid solution 7, the reaction acid solution 8, and the neutralizing agent 9 are different, specifically:

[0067] Note the pre-acid solution 7: the injection speed is 0.5m 3 / min;

[0068] Injection reaction acid solution 8: injection speed is 0.7m 3 / min;

[0069] Note neutralizer 9: injection speed is 0.3m 3 / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com