Patents

Literature

33results about How to "Quick and efficient preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

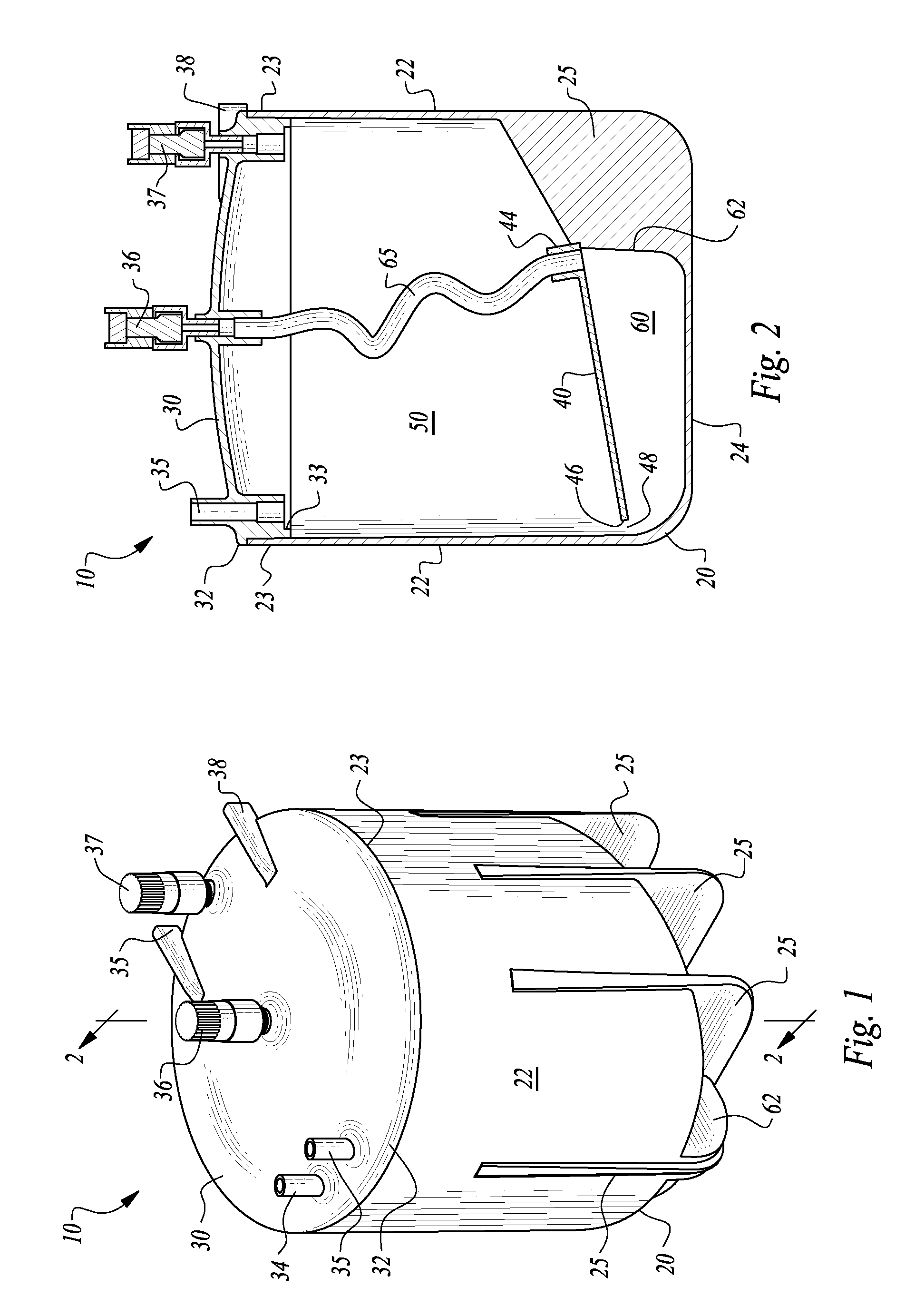

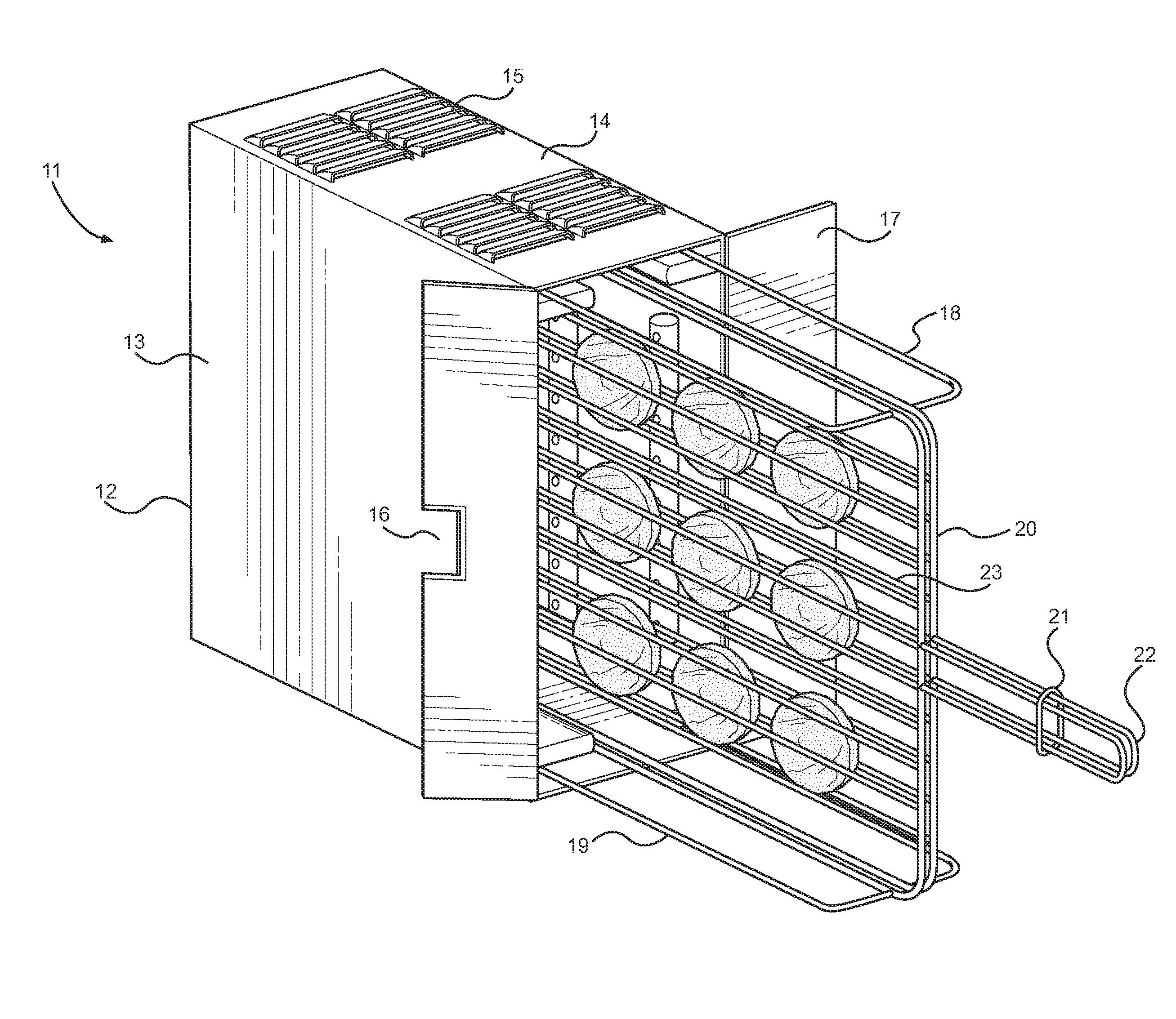

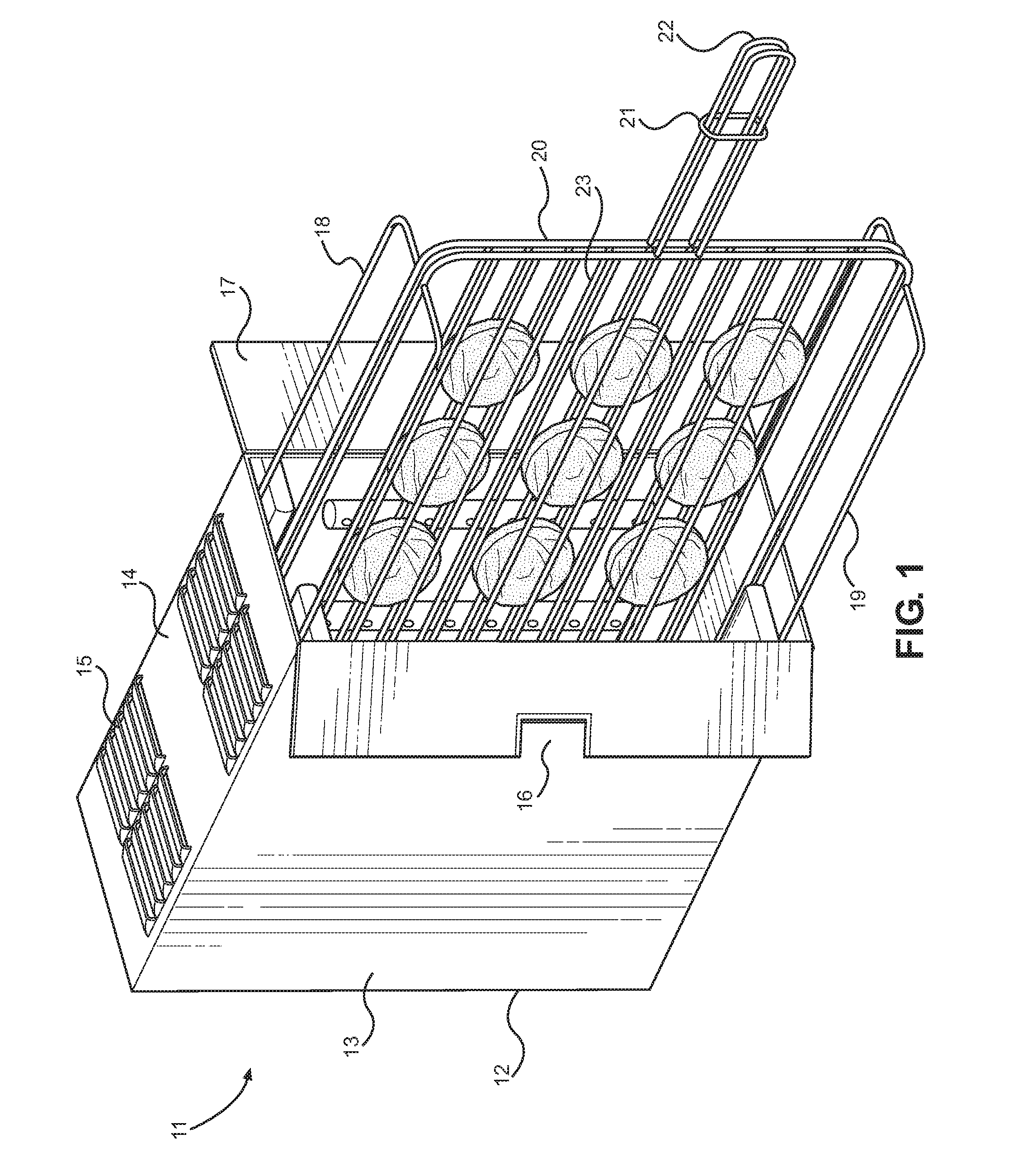

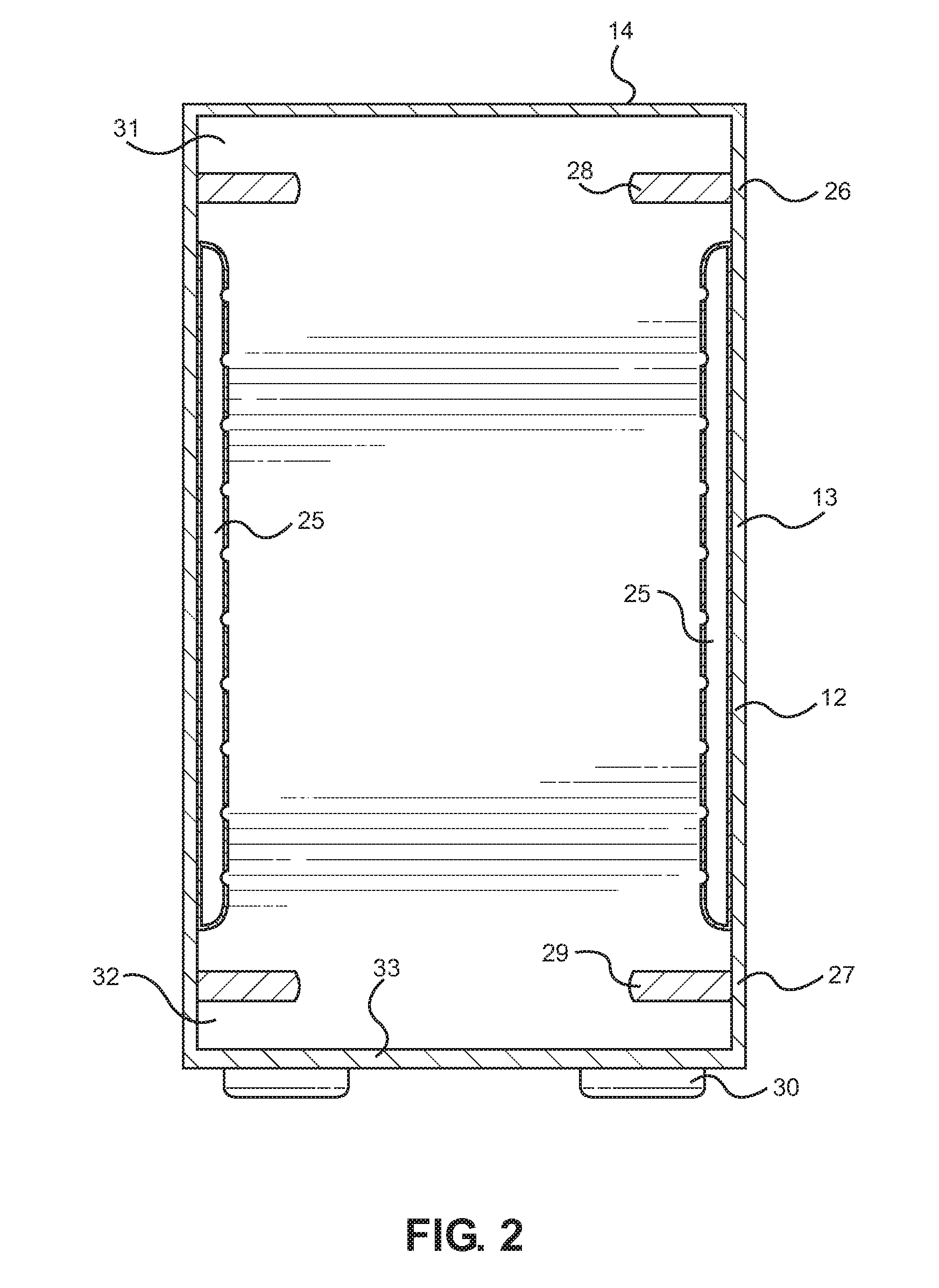

Multi-modal vehicle implemented food preparation, cooking, and distribution systems and methods

InactiveUS20190050952A1Quick and efficient preparationRoad vehicles traffic controlWorkshop/display transportationDelivery vehicleDistribution system

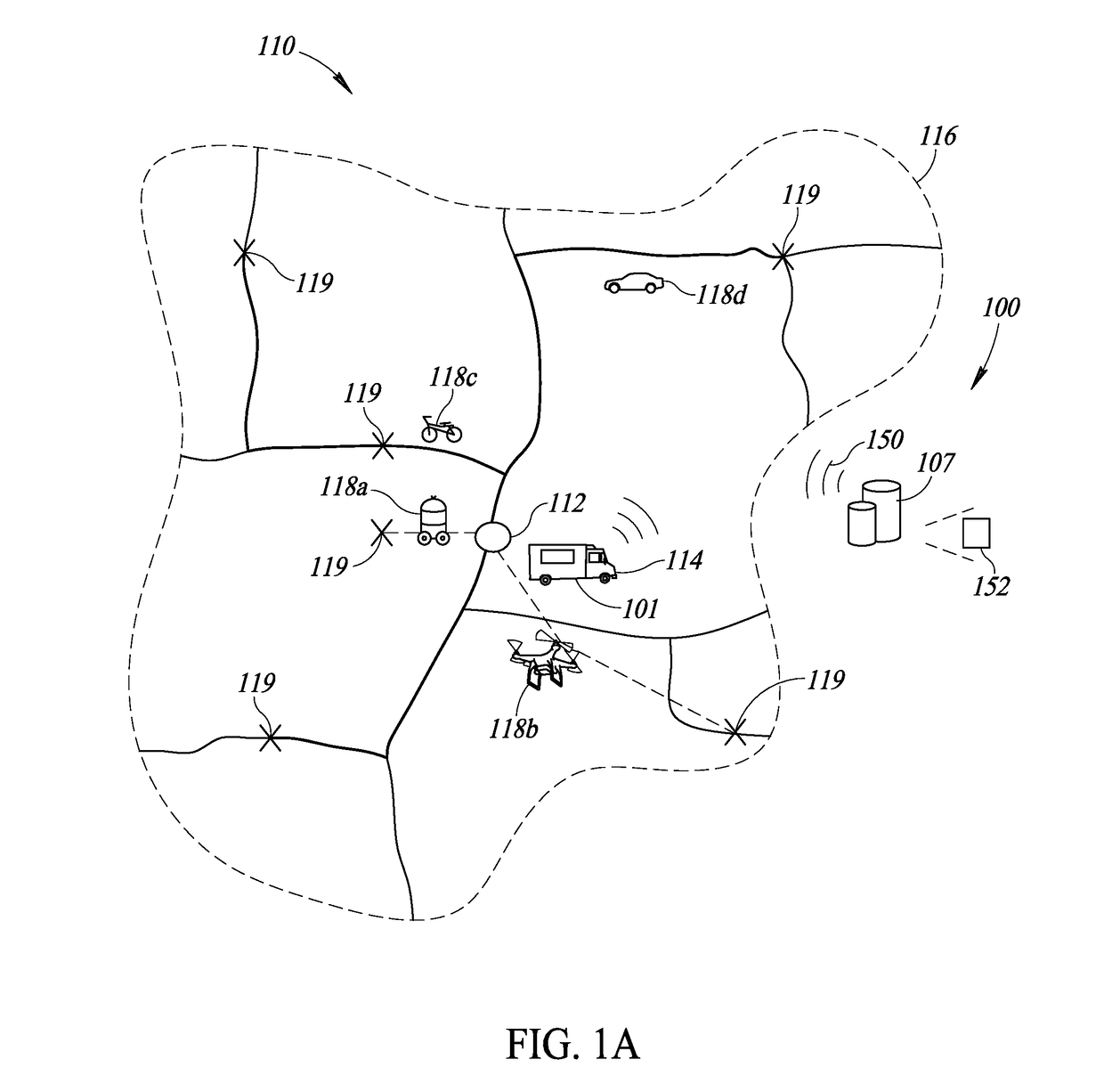

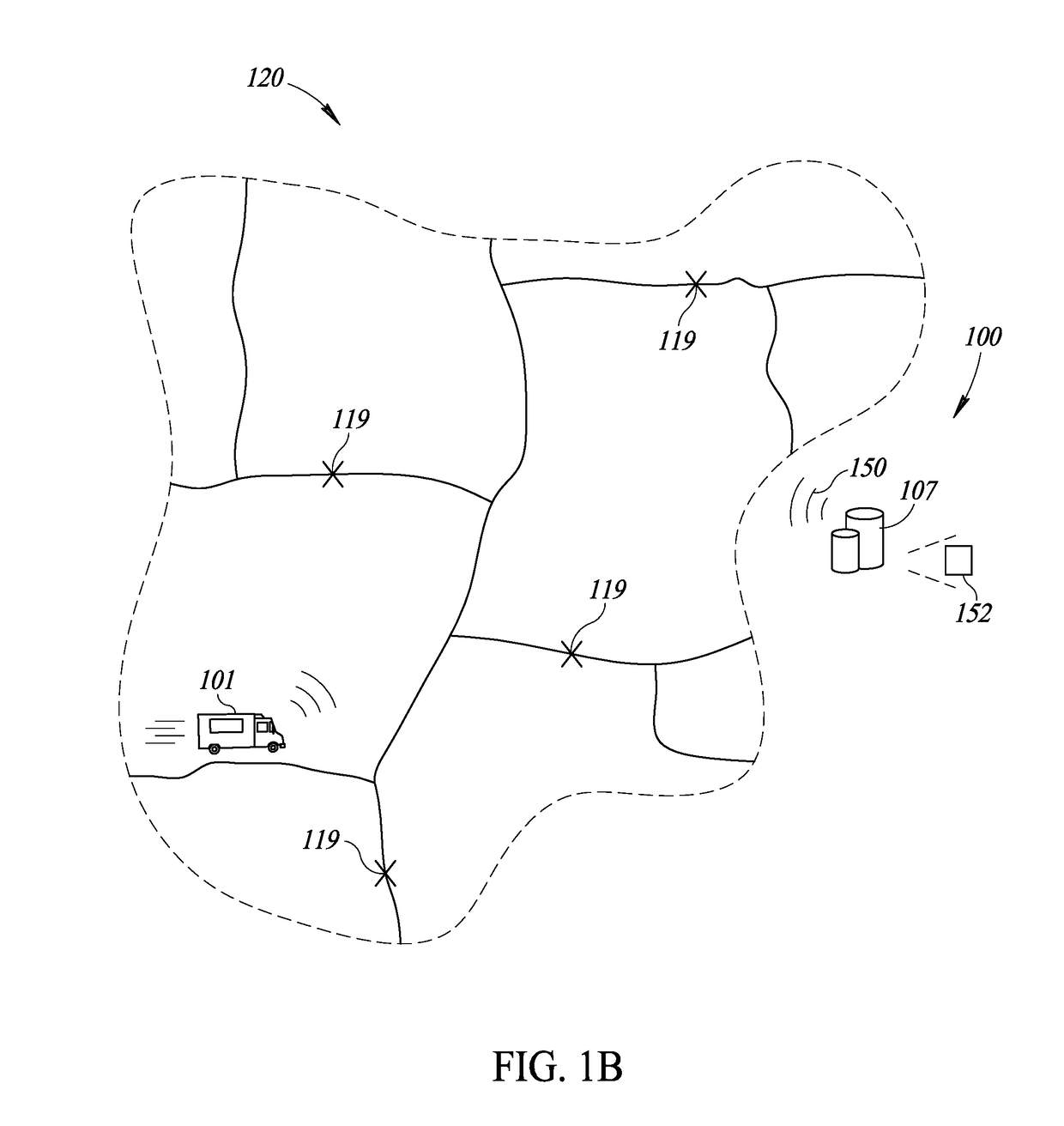

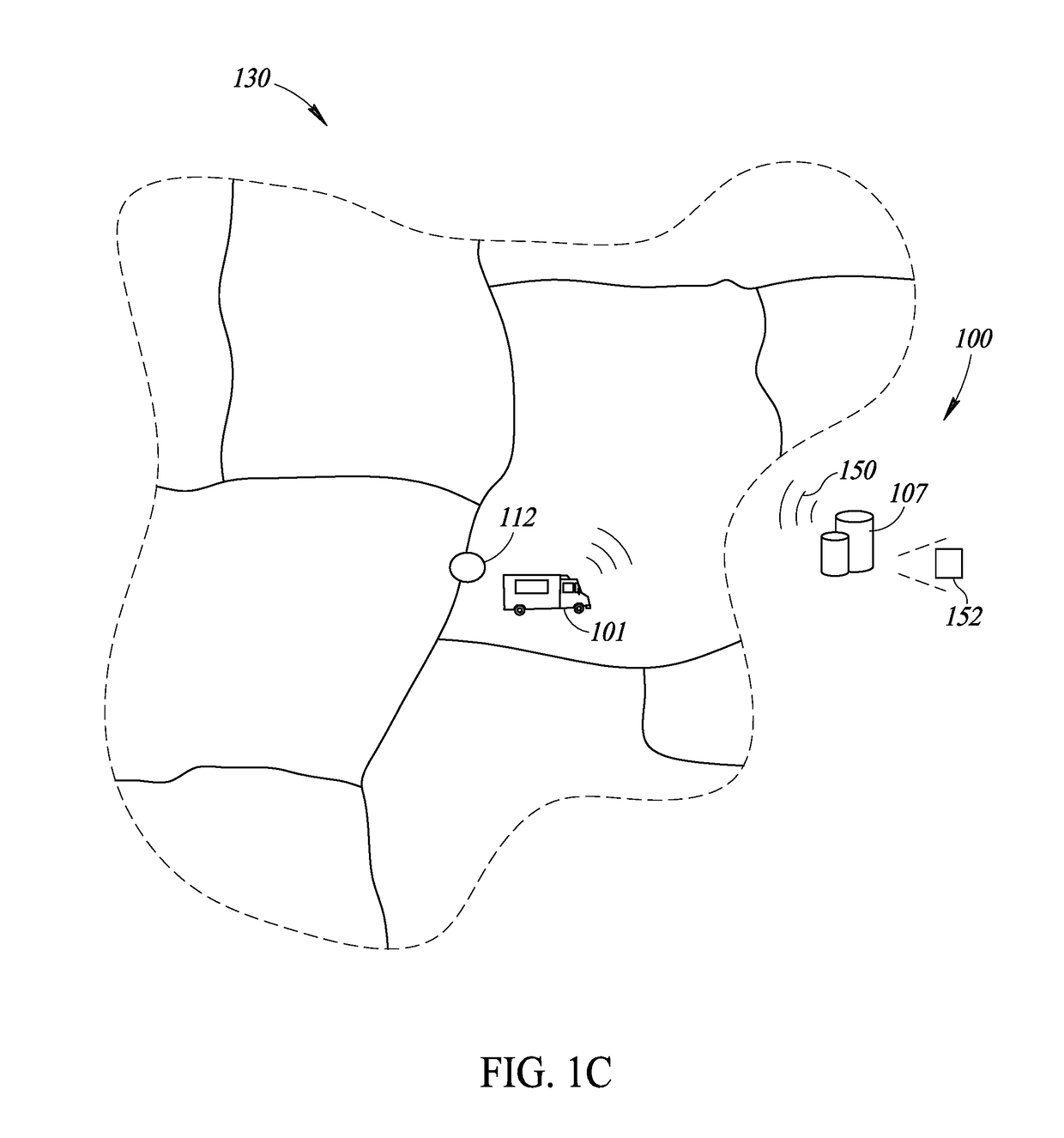

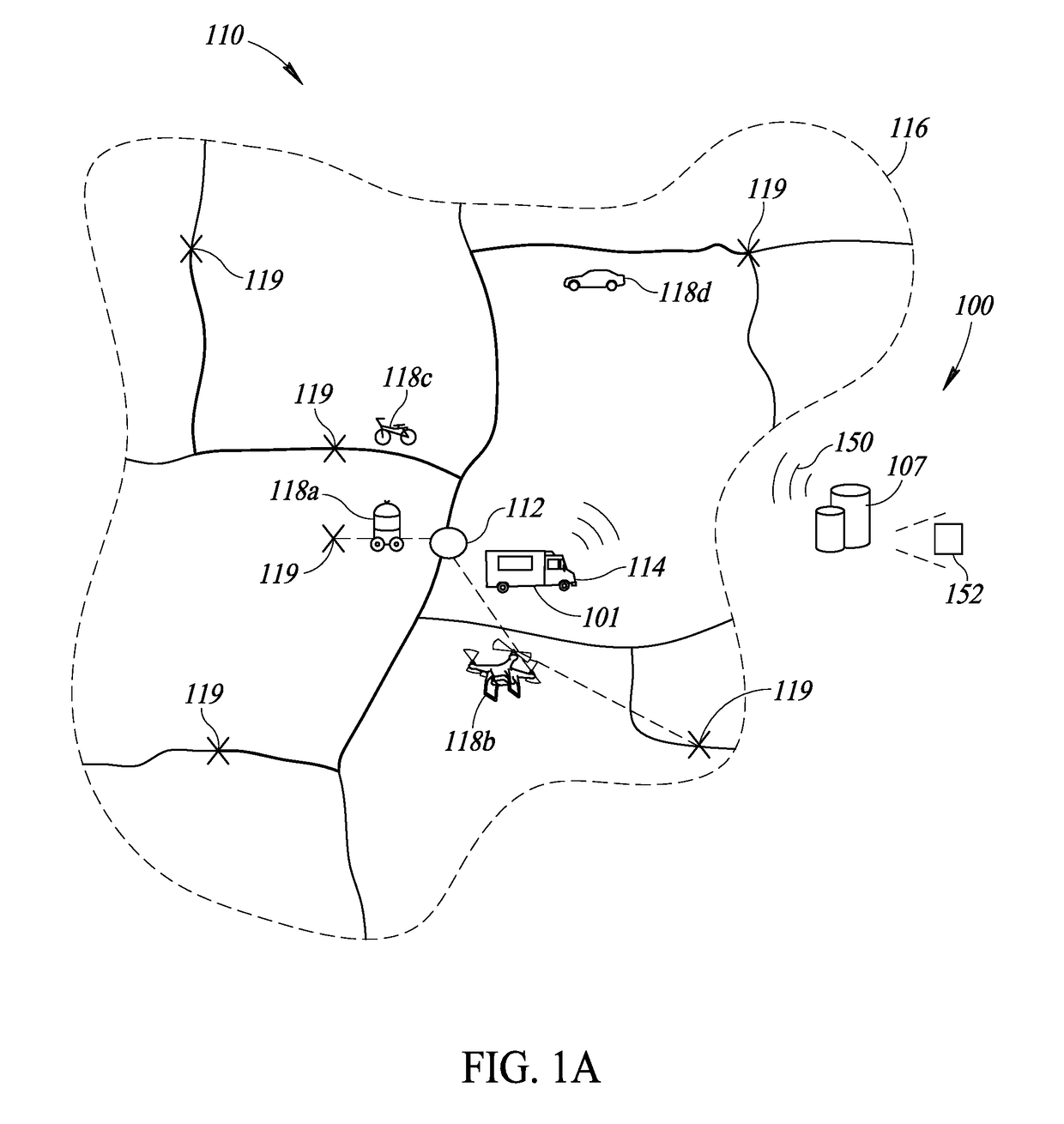

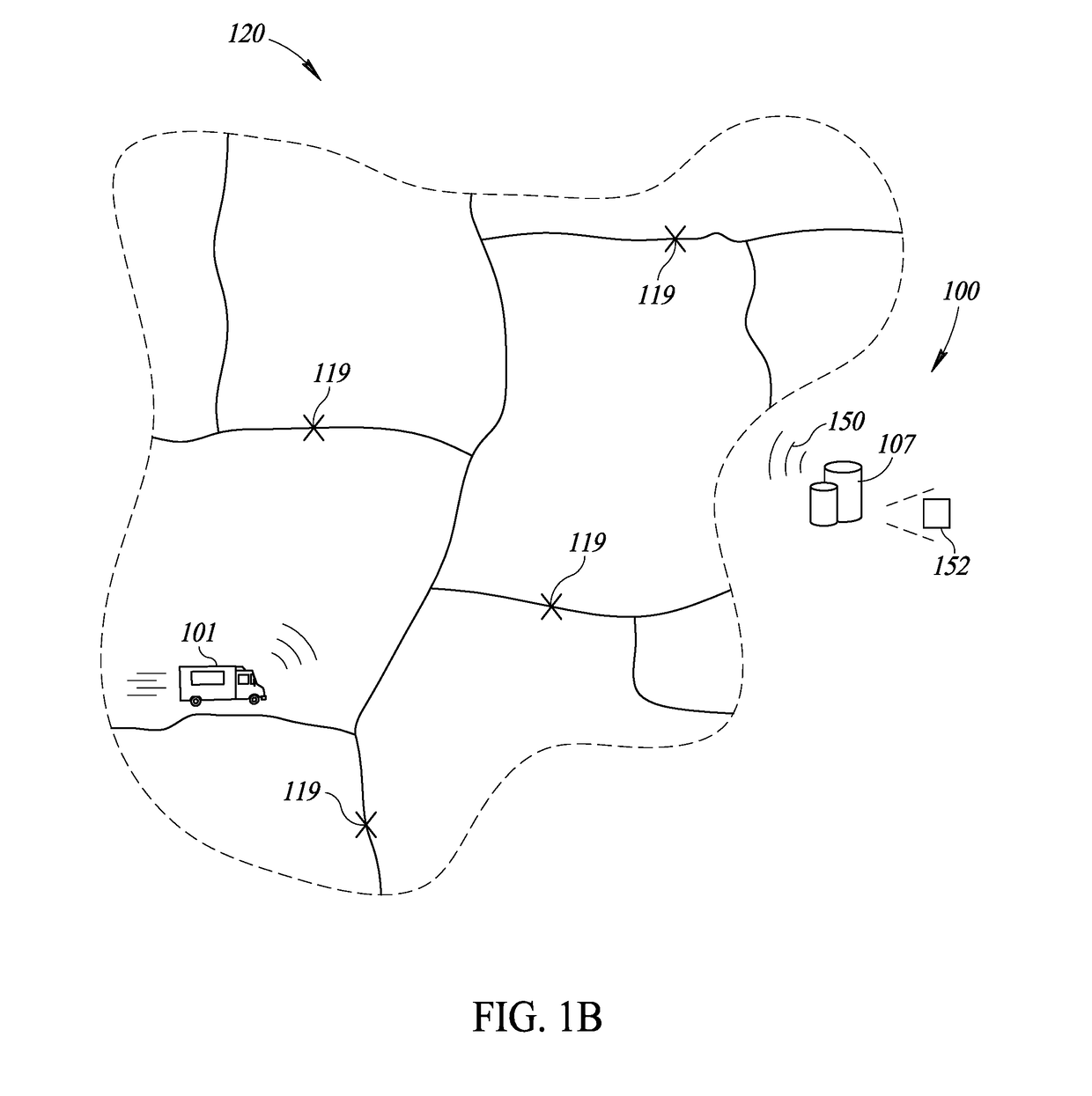

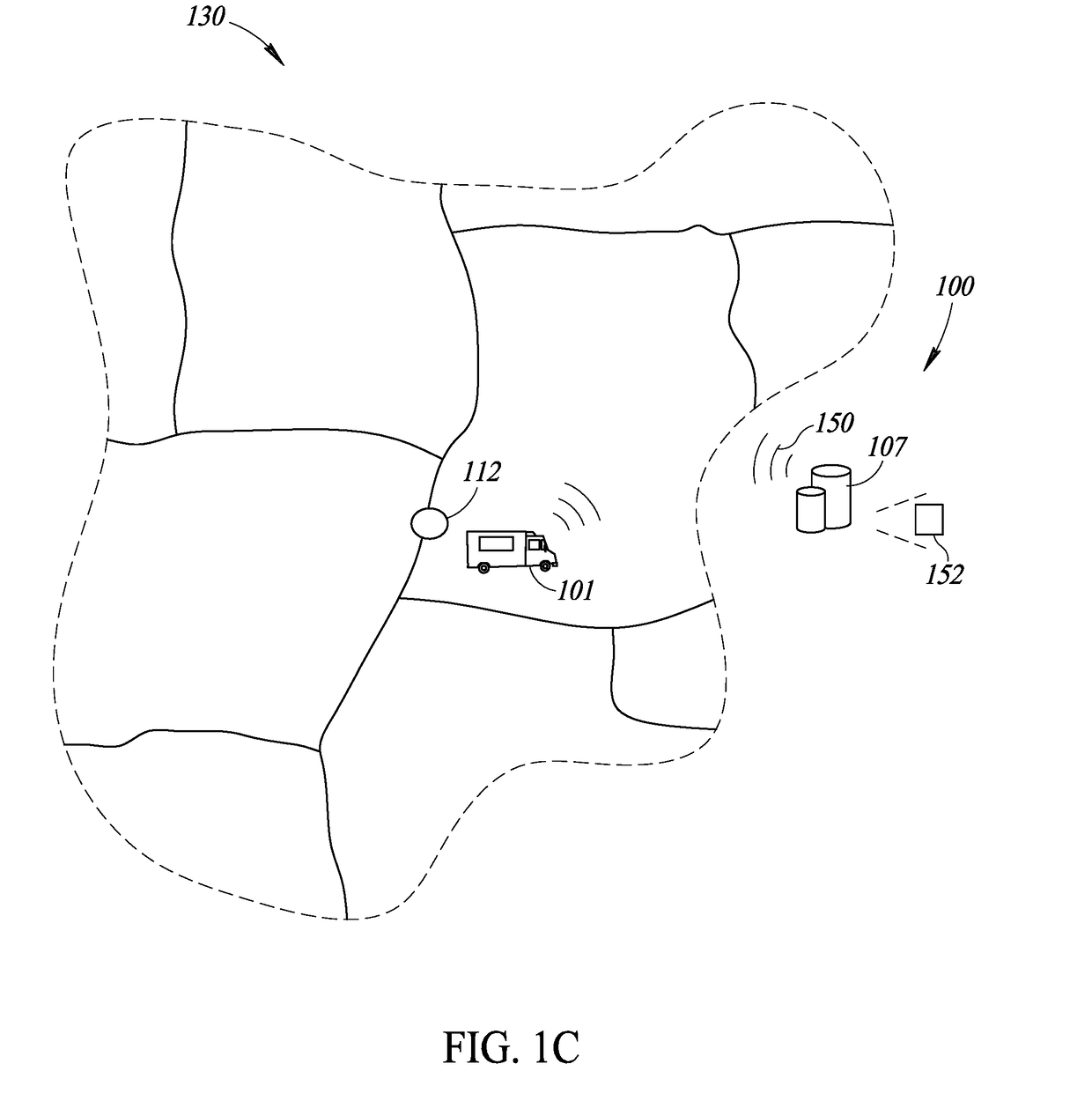

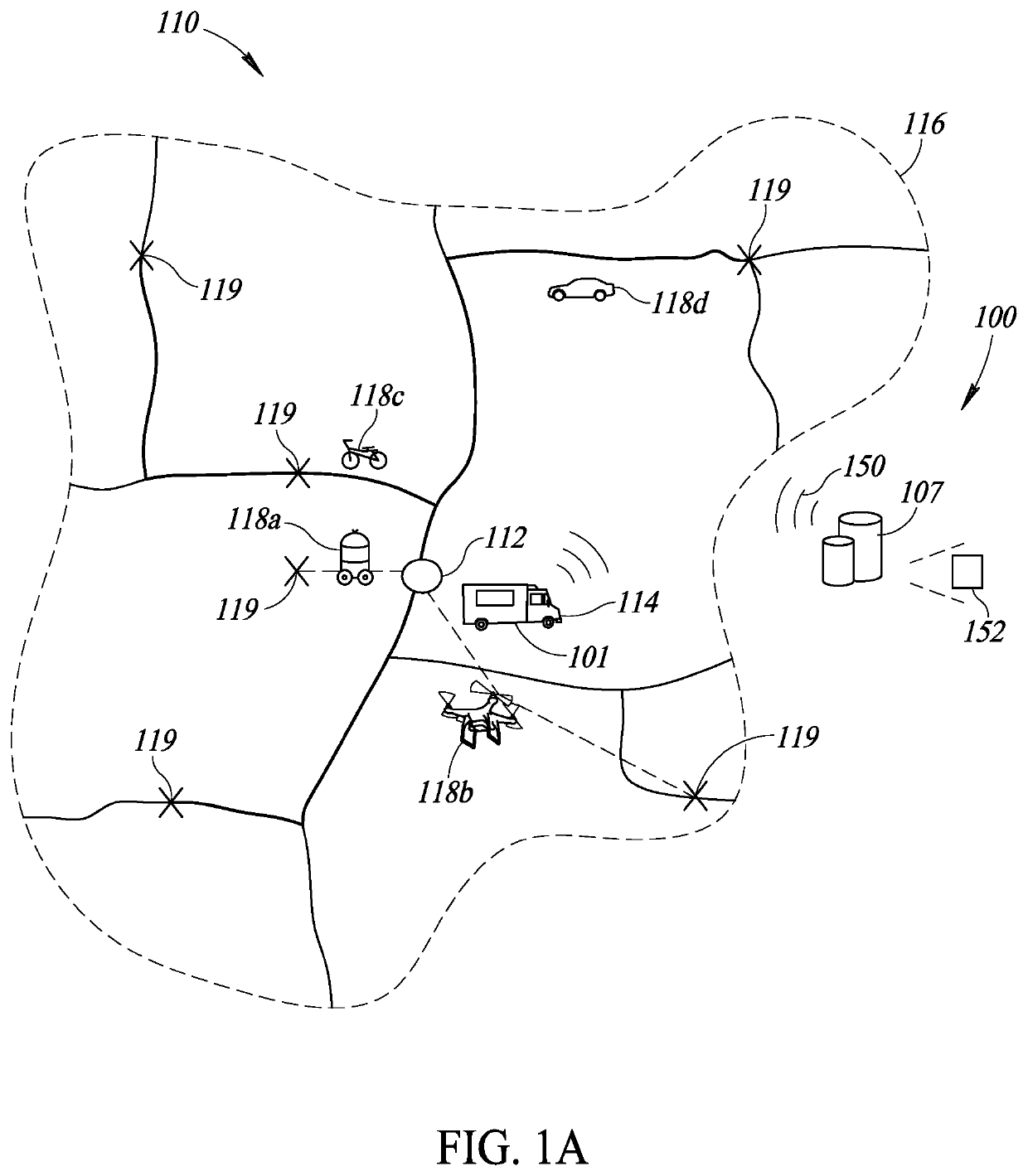

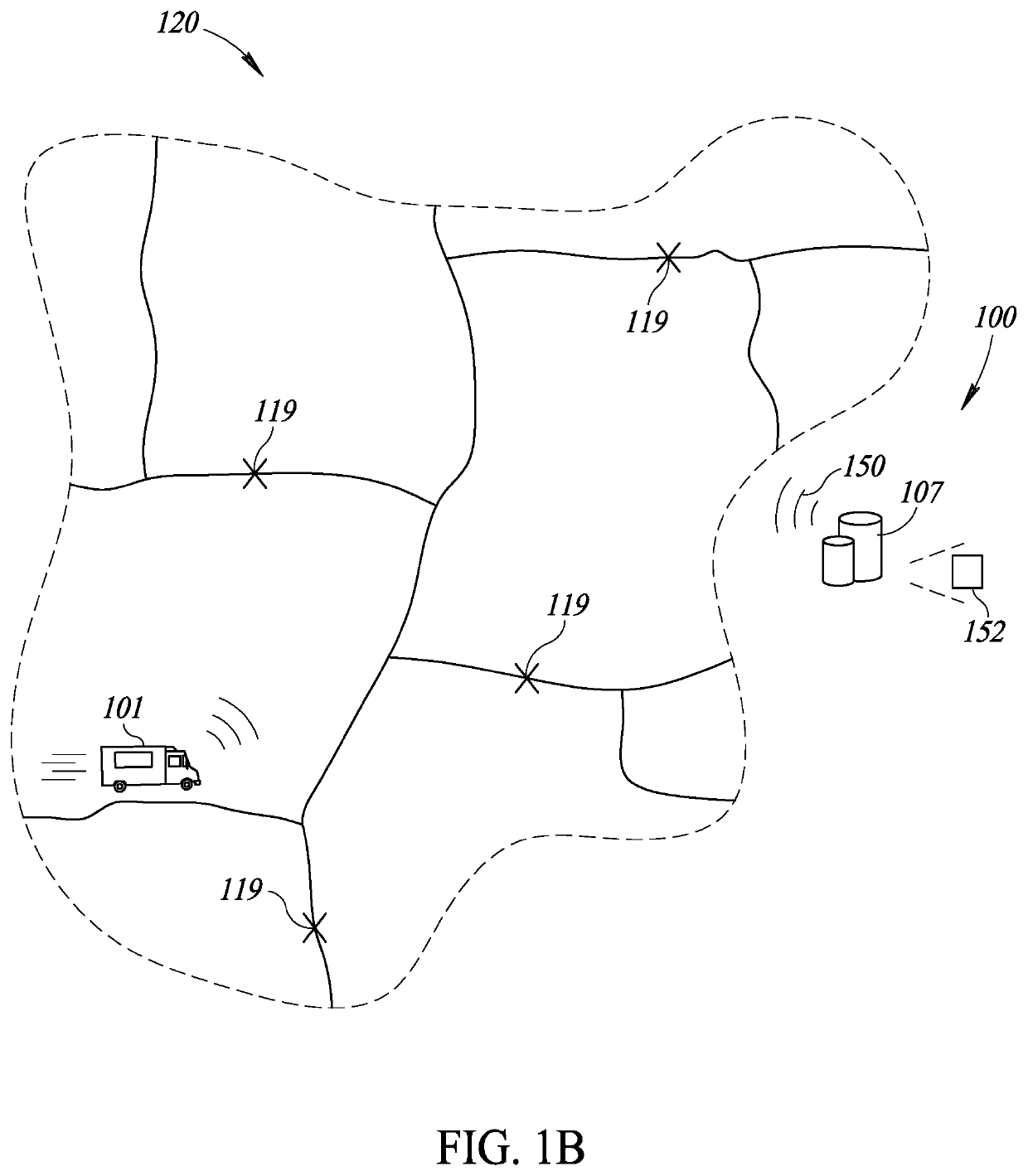

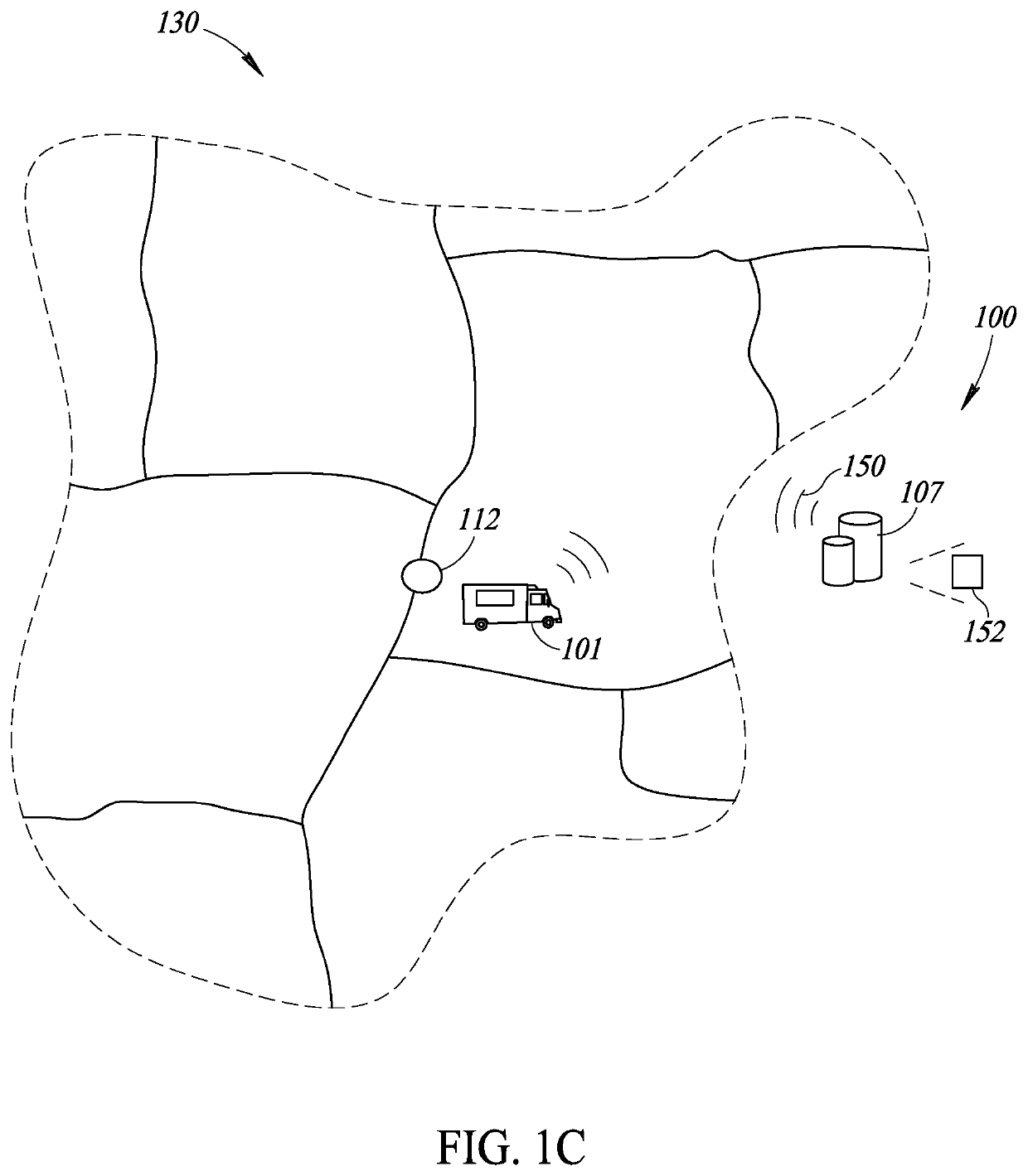

Vehicles, components, and methods are disclosed for preparing hot food during delivery or at a remote location. A multi-modal food distribution system may operate in one or more various modes, including a constellation mode, a cook enroute mode, and a pop-up kitchen mode, to deliver hot, prepared food to customers. The vehicles in the system may be configurable to change between each of the different modes depending upon information received by the system. The system may in the constellation mode include additional delivery vehicles that retrieve food from a vehicle that serves as a hub. The additional delivery vehicles may deliver the food to the delivery destination. In the cook enroute mode, the vehicle may prepare and cook food enroute to a delivery destination. In a pop-up kitchen mode, the vehicle may prepare food for pick up by customers.

Owner:ZUME INC

Multi-modal vehicle implemented food preparation, cooking, and distribution systems and methods

InactiveUS20190050951A1Quick and efficient preparationRoad vehicles traffic controlWorkshop/display transportationDelivery vehicleDistribution system

Vehicles, components, and methods are disclosed for preparing hot food during delivery or at a remote location. A multi-modal food distribution system may operate in one or more various modes, including a constellation mode, a cook enroute mode, and a pop-up kitchen mode, to deliver hot, prepared food to customers. The vehicles in the system may be configurable to change between each of the different modes depending upon information received by the system. The system may in the constellation mode include additional delivery vehicles that retrieve food from a vehicle that serves as a hub. The additional delivery vehicles may deliver the food to the delivery destination. In the cook enroute mode, the vehicle may prepare and cook food enroute to a delivery destination. In a pop-up kitchen mode, the vehicle may prepare food for pick up by customers.

Owner:ZUME INC

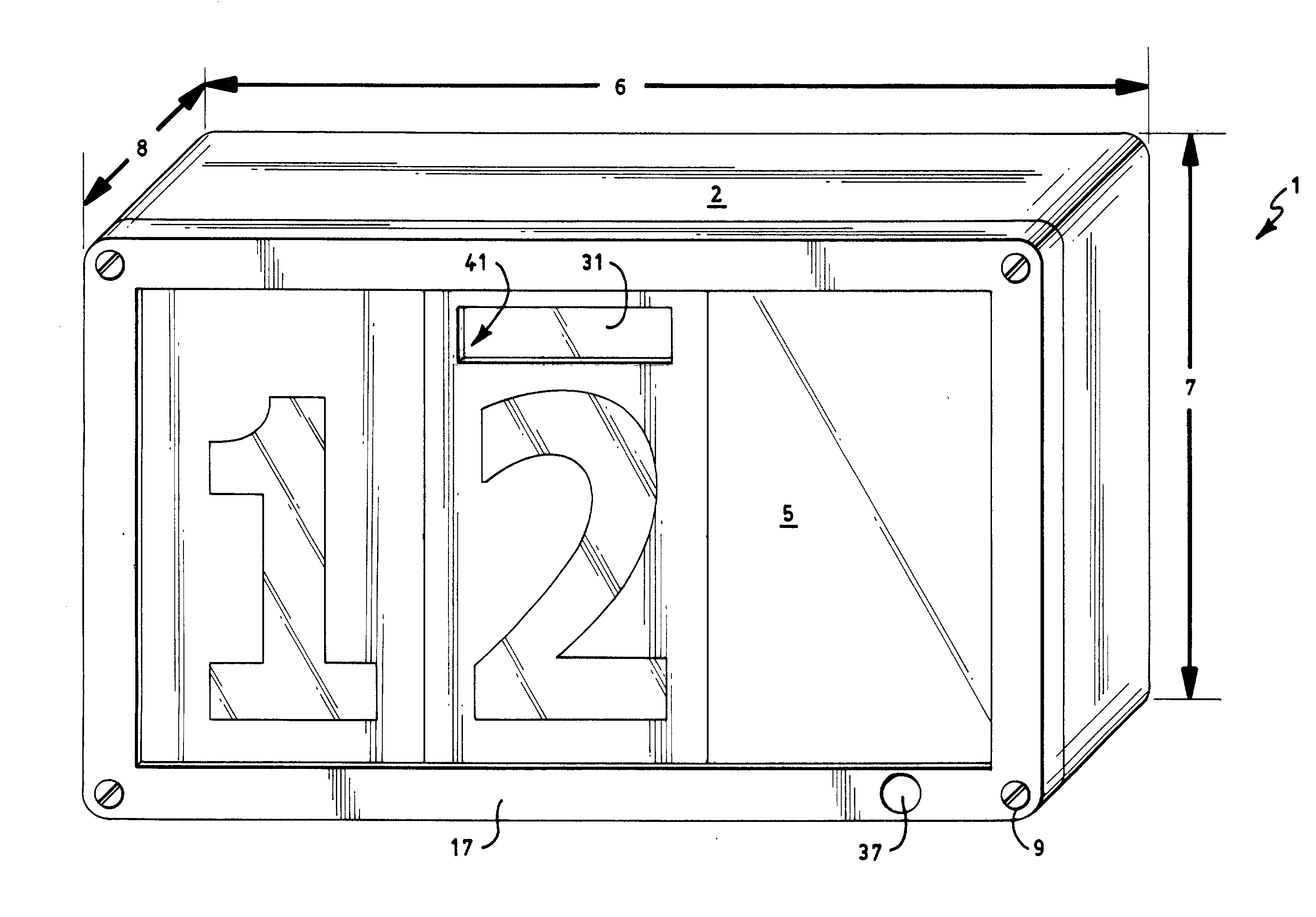

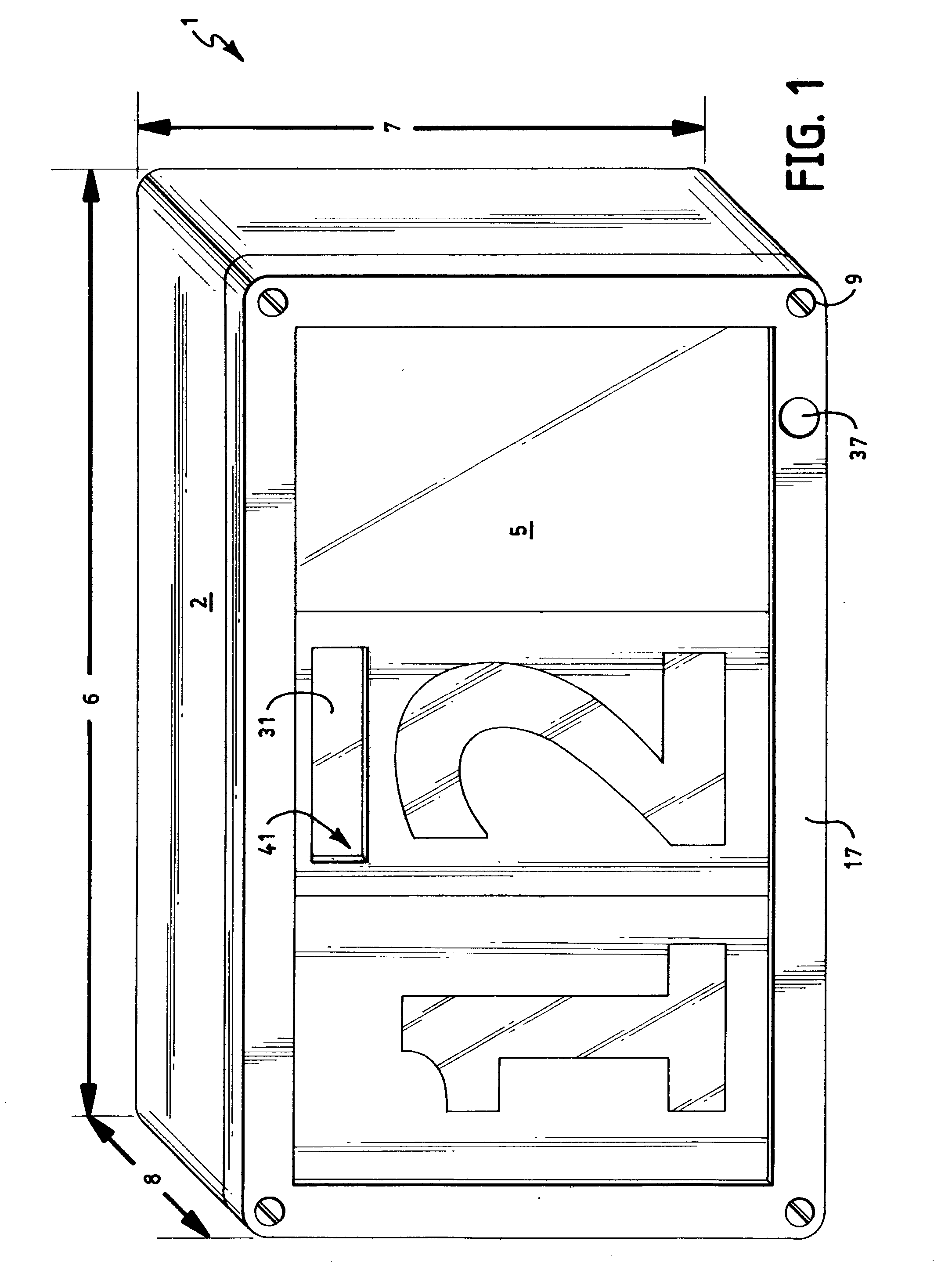

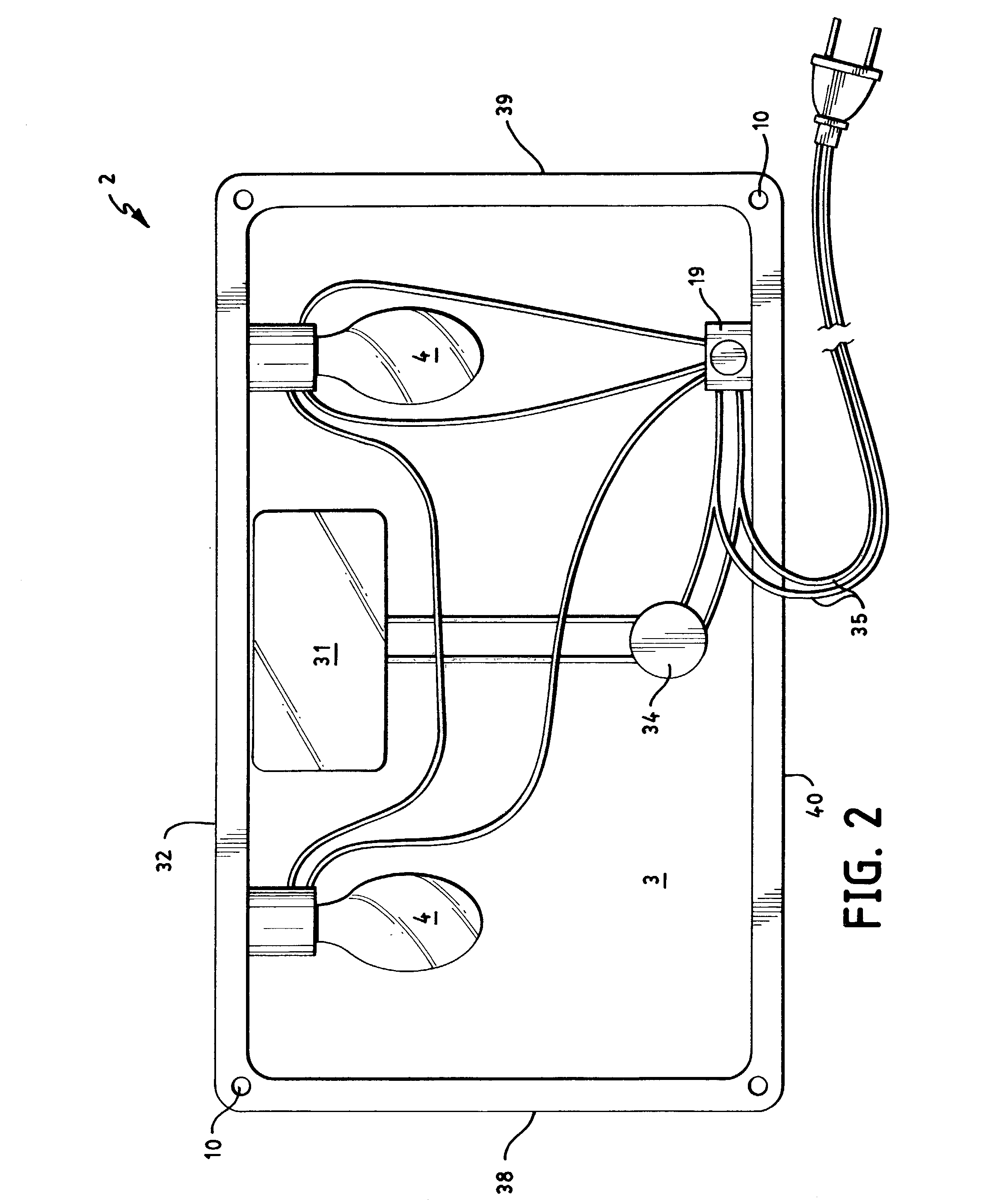

Customizable back lighted sign

InactiveUS20030121191A1Quick and efficient preparationObstruct passageIlluminated signsEngineeringLettering

A customizable back lighted sign comprising a hollow box-like body having an open side, an illumination source mounted within the body and electrically connected to a power source, a removable cover plate and lens mounted on the body and covering the open side, and thin sheet-like material having visible thereupon data such as numbers and letters and opaque background against which the data is highly visible, the thin sheet-like material being attached to the lens, the data being highly contrasted against the background while at the same time permitting the passage therethrough of light produced by the illumination source from within the box-like body.

Owner:DEJARNETTE JEFFREY M +1

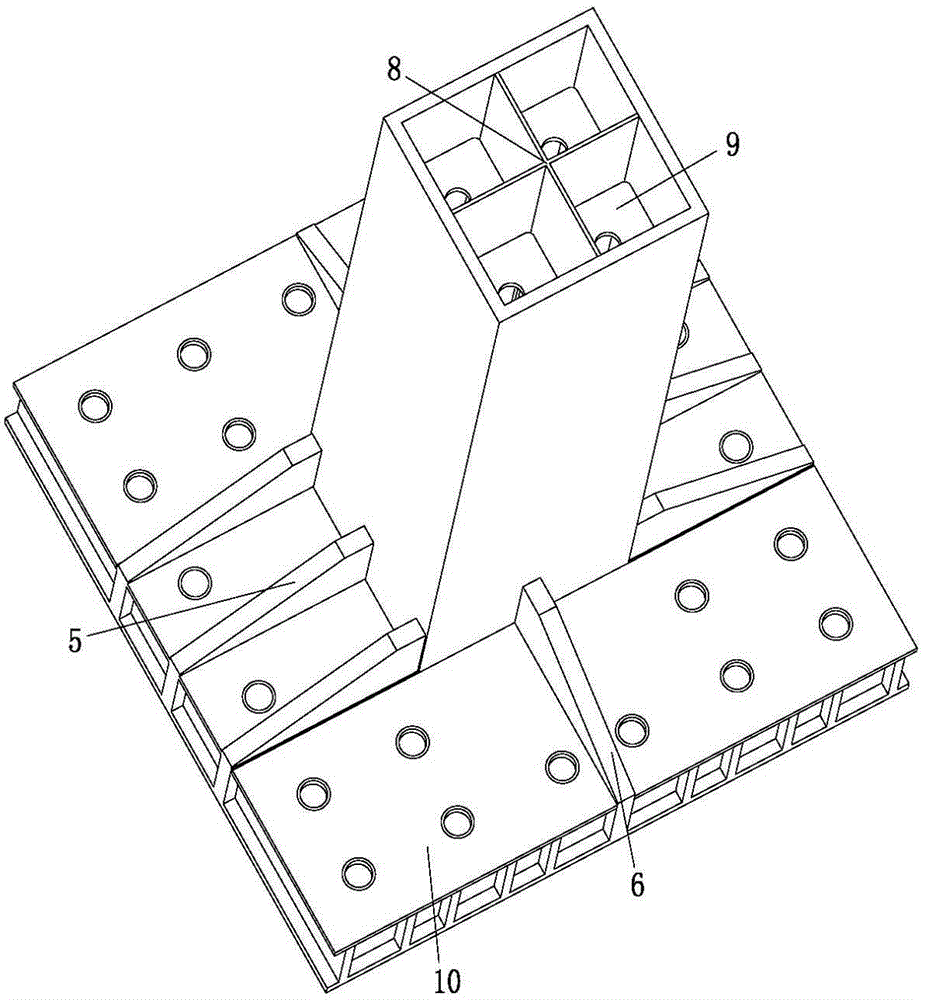

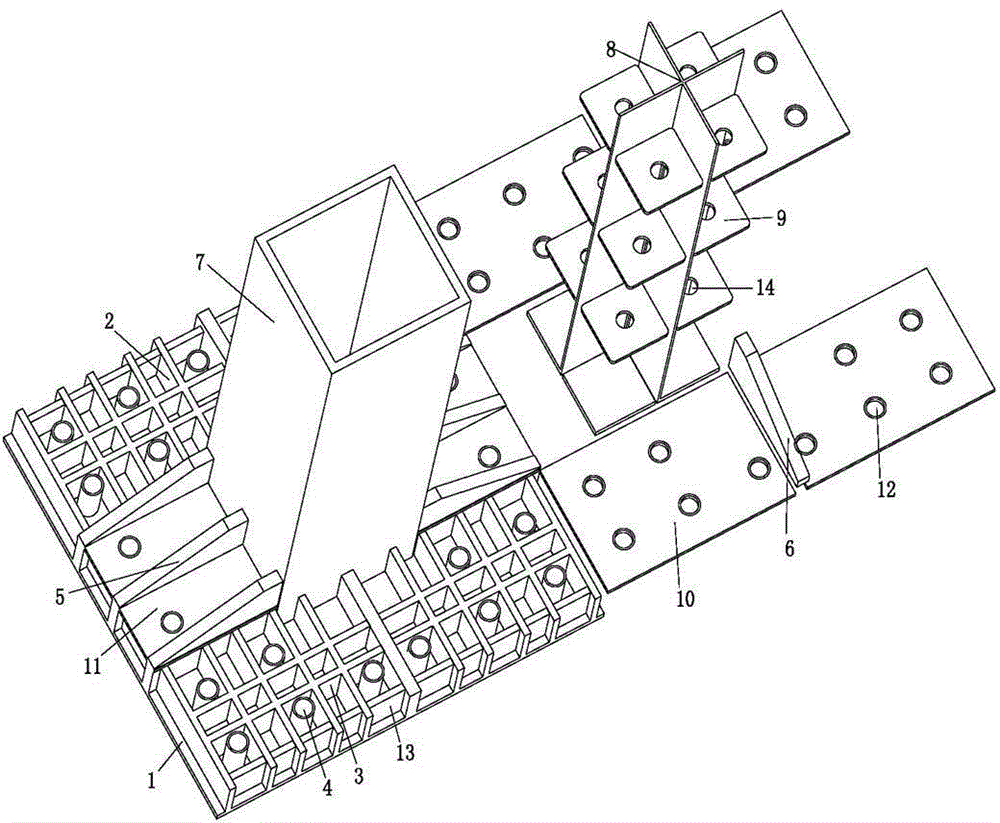

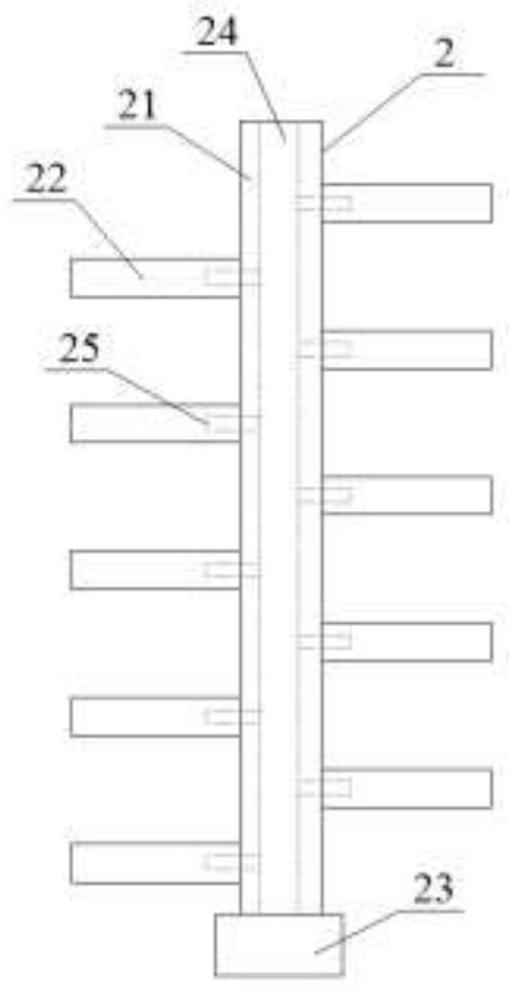

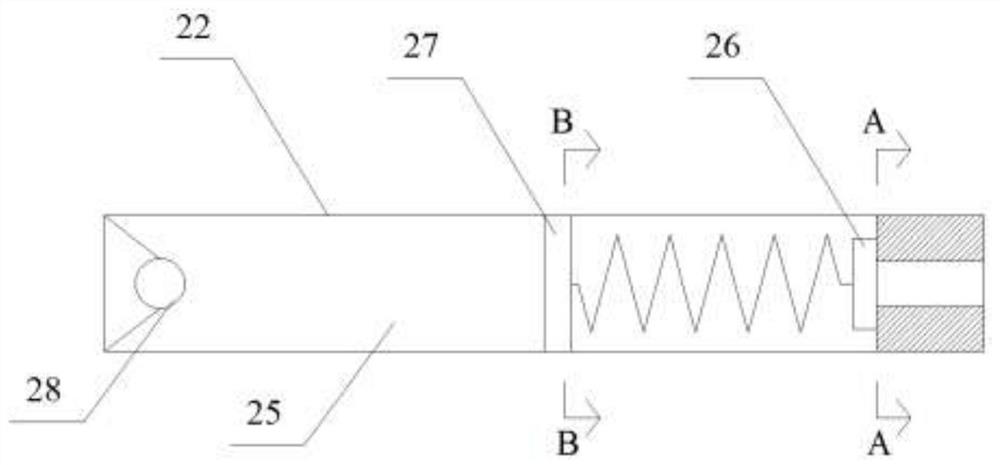

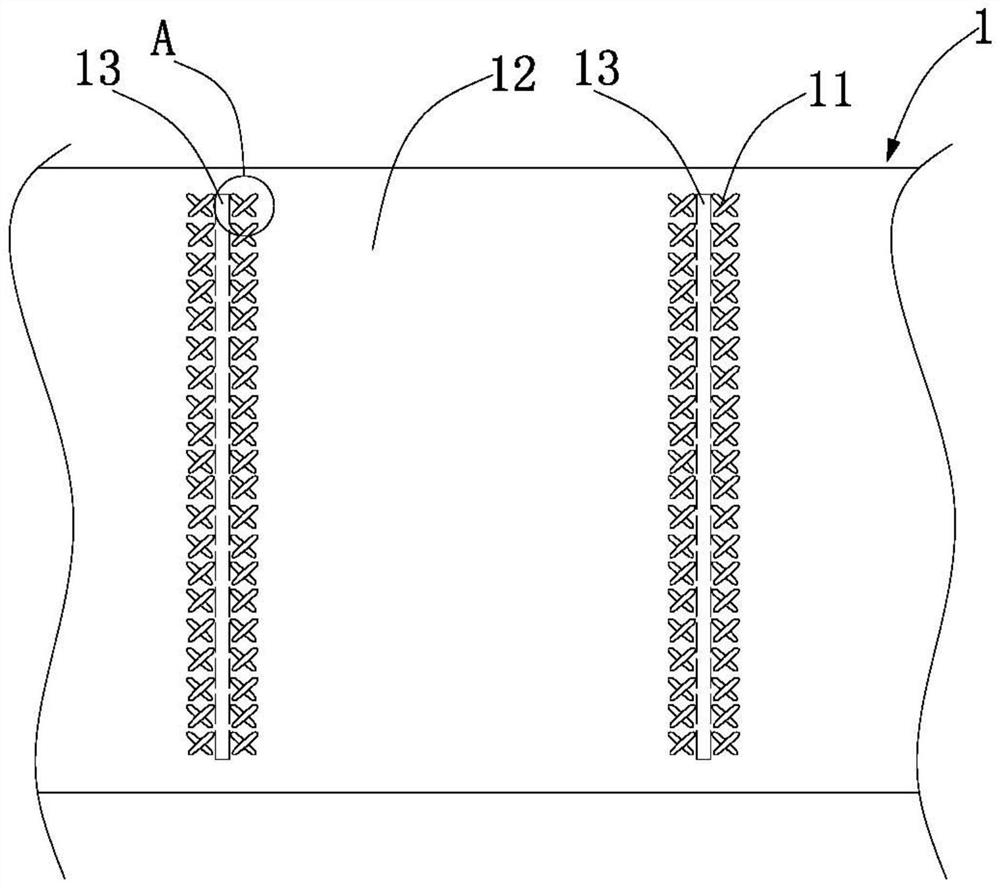

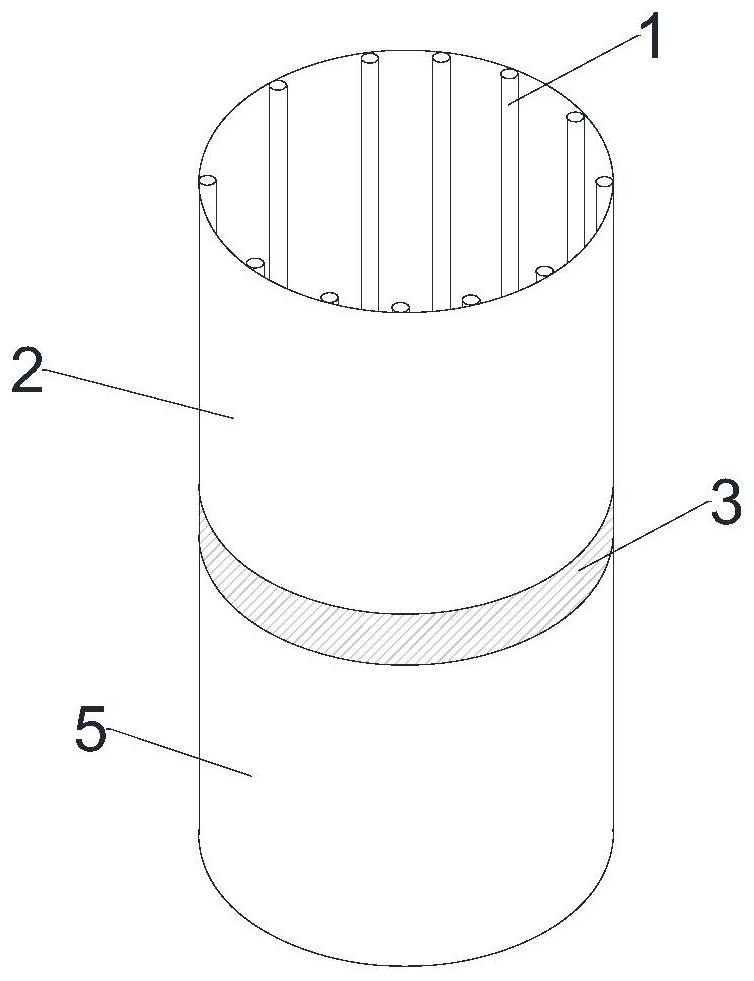

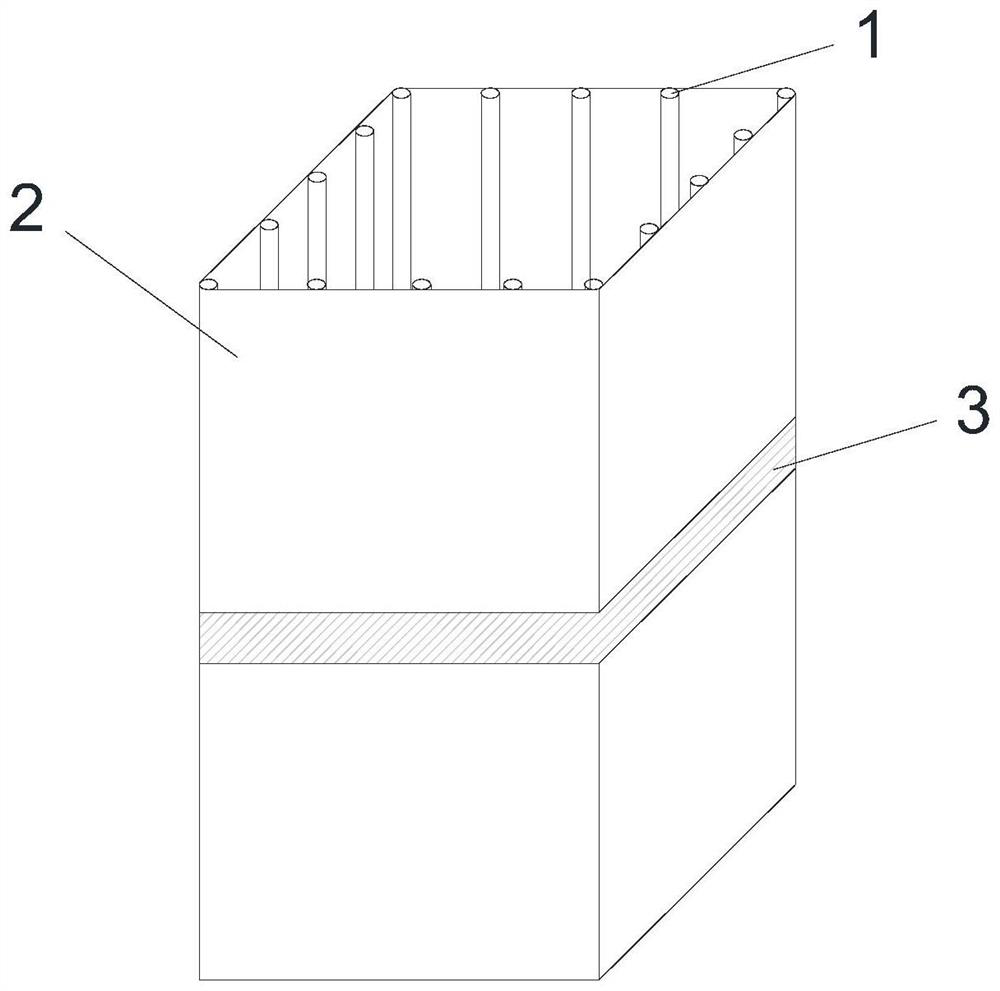

Large-cross-section box column and processing technology thereof

ActiveCN104695624AImprove bearing capacityQuick and efficient preparationStrutsPillarsStructural engineeringThermal treatment

The invention relates to the technical field of building structures, and particularly relates to a large-cross-section box column and a processing technology thereof. An auxiliary stiffening plate, a small stiffening plate and a positioning pin are connected between a bottom plate and a cover plate; a main stiffening plate and an upper cover stiffening plate are connected with the side surface of the box column; the main stiffening plate is connected with the bottom plate and the cover plate; a cross column and an inner partition plate are connected with the inside of the box column; and the structures are gradually connected into a whole through part preparation, welding of an H-shaped girder, welding of the box column, welding of a base and thermal treatment after welding. The product is efficient and fast to prepare, so that the large-cross-section box column is high in bearing capacity and high in stability.

Owner:HUAXING STEEL STRUCTURE

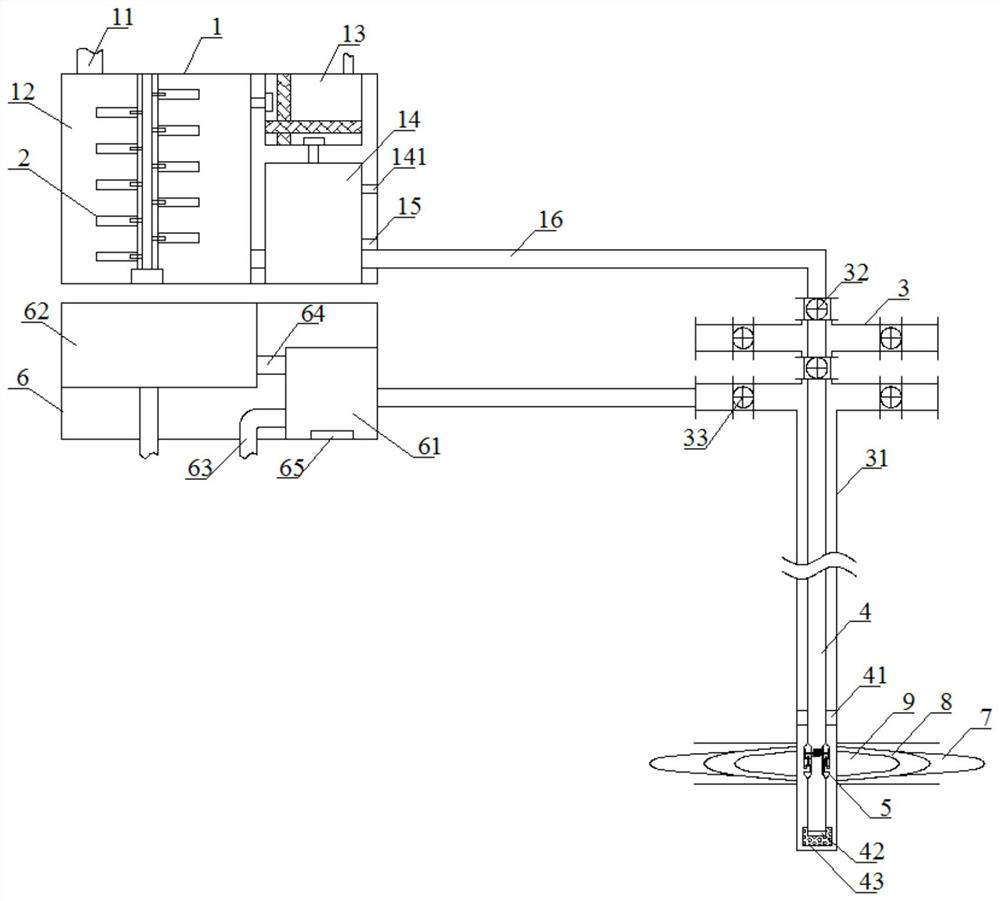

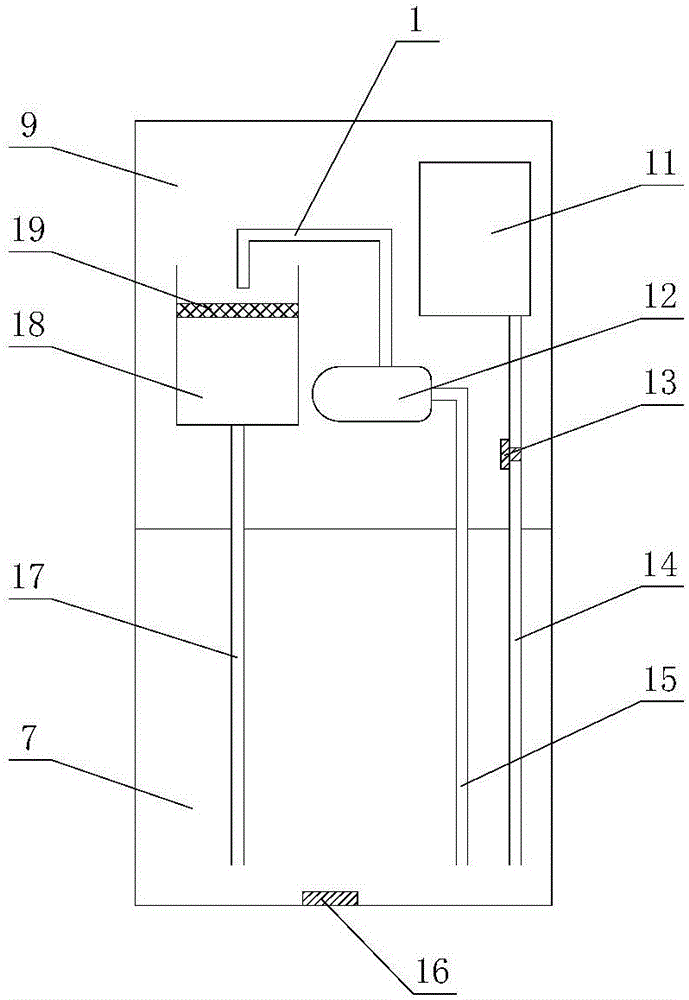

Oil well acidification process and device for increasing oil-gas well yield

ActiveCN112523737AReduce acid contentAvoid cloggingFluid removalDrilling compositionLiquid tankPre treatment

The invention discloses an oil well acidification process and device for increasing oil-gas well yield. The oil well acidification device comprises an acid liquid tank and a waste liquid tank, whereina stirring tank is arranged in the acid liquid tank, a stirring device is arranged in the stirring tank, an acidification pipe column penetrates through a wellhead device and then extends into the bottom of a casing pipe, a nozzle is arranged at the bottom of the acidification pipe column, and pulse supercharging devices are arranged on the two sides of the acidification pipe column above the nozzle; and the waste liquid tank is connected with a liquid outlet of the wellhead device. The acidification process comprises the following steps that S1, acidification pretreatment is conducted; S2, preposed acid liquid is injected; S3, reaction acid liquid is injected; and S4, a neutralizer is injected in a pulse pressurization mode, so that the acid liquid enters an oil layer in a fluctuation mode, the swept area is enlarged, the injection effect of the acid liquid is effectively enhanced, residual acid liquid is neutralized in sections at the bottom of a well, the content of the acid liquidin flowback fluid is reduced, components of preposed acid liquid, reaction acid liquid and the neutralizer are optimized, the problem of oil layer blockage can be effectively solved, and the purposeof increasing the yield is achieved.

Owner:西安石油大油气科技有限公司

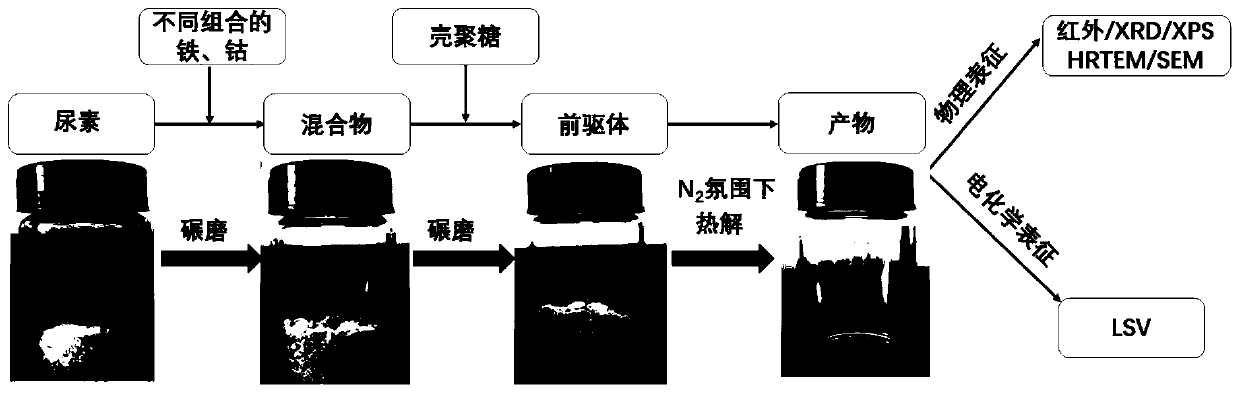

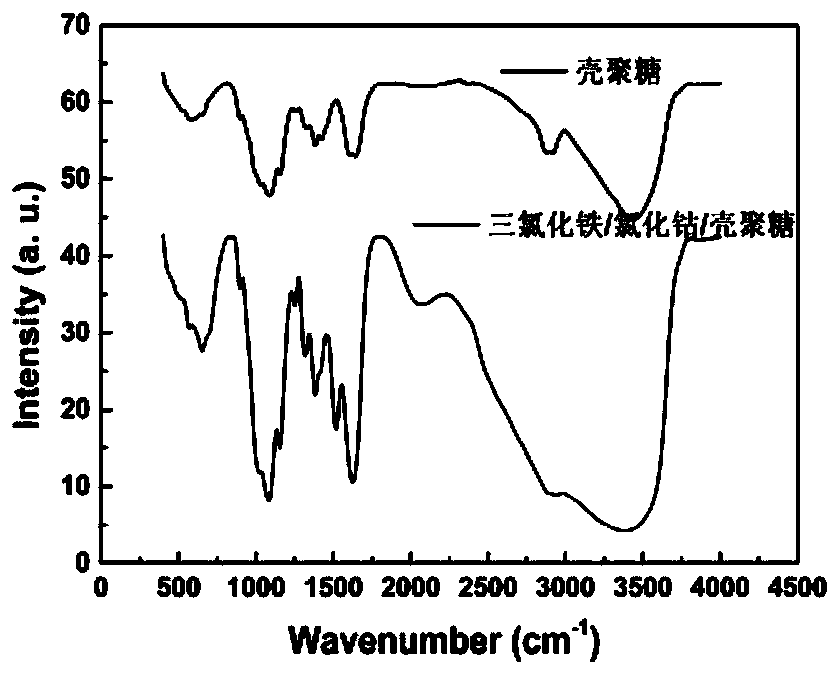

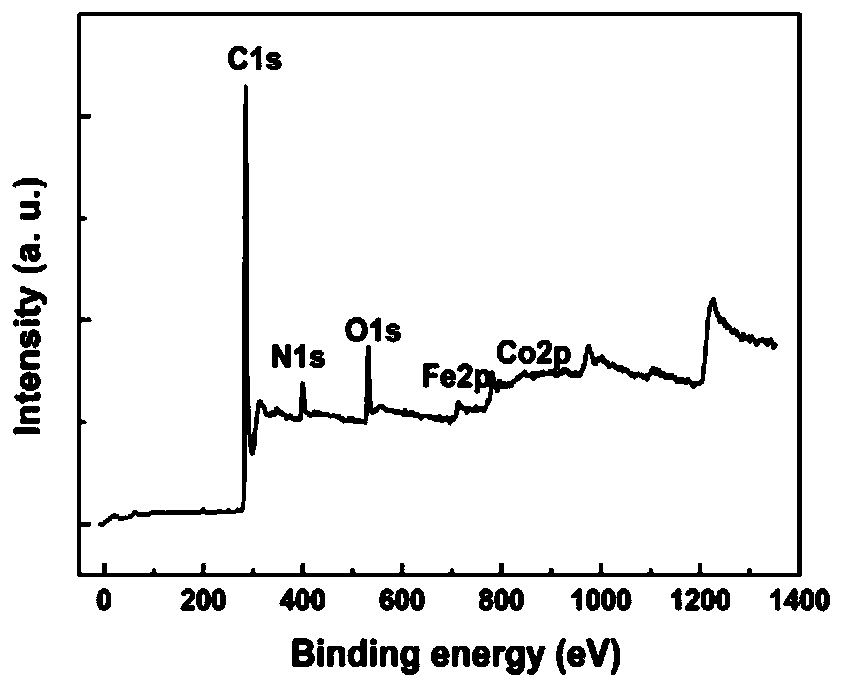

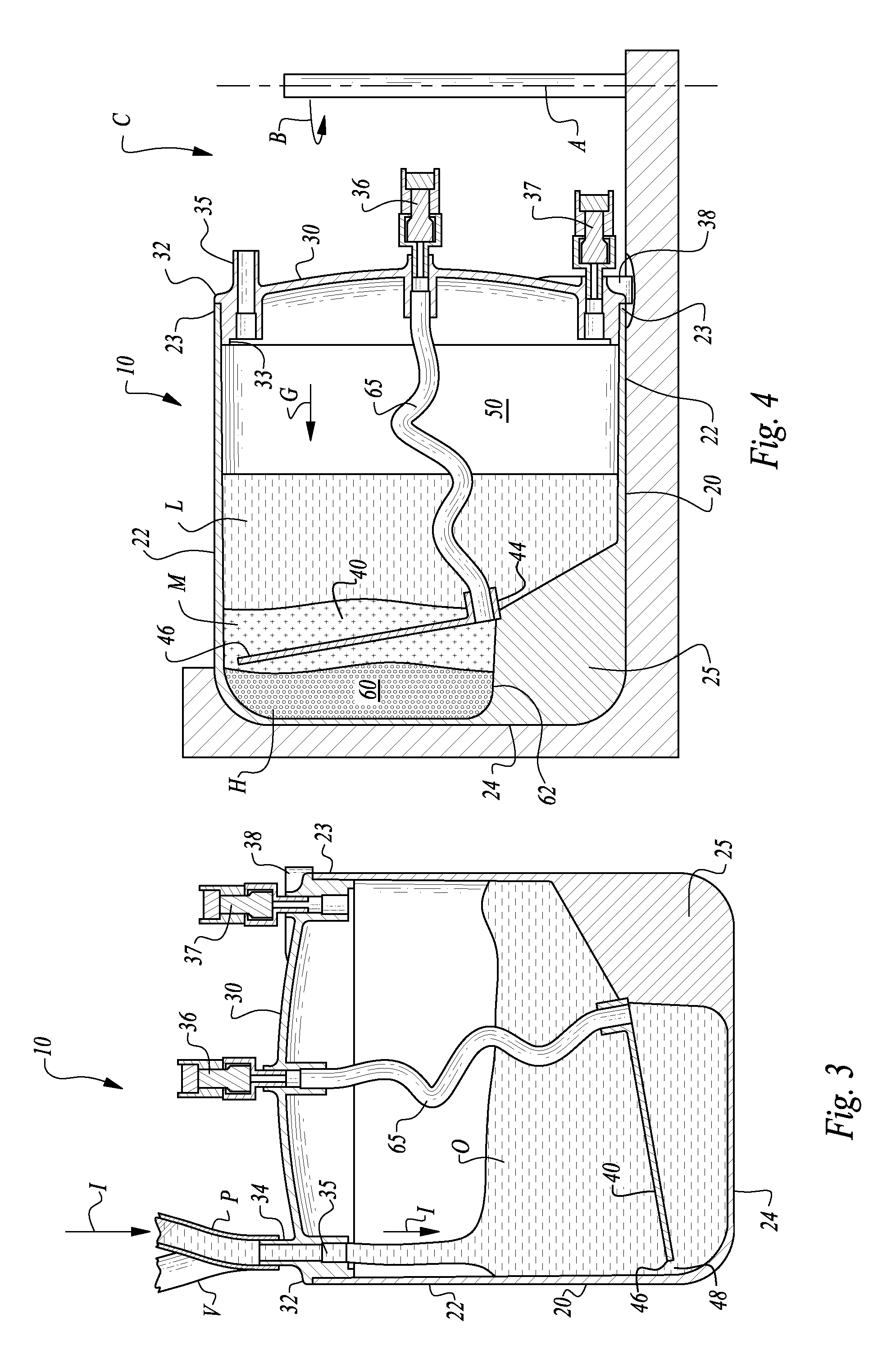

Preparation method of three-dimensional carbon network loaded FeCo difunctional oxygen catalyst

ActiveCN110756188AQuick and efficient preparationPreparation of environmental protectionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsElectro catalystPtru catalyst

The invention belongs to the technical field of electrochemical catalyst material synthesis and particularly discloses a preparation method of a three-dimensional carbon network loaded FeCo difunctional oxygen catalyst. According to the method, a three-dimensional carbon netlike structure is constructed according to the property that chitosan is chelated with ferric chloride and cobalt chloride; NH<3> and CN gases (C<2>N<2+>, C<3>N<2+> and C<3>N<3+>) which are generated during urea decomposition in the pyrolysis process are utilized to etch carbon nanosheets generated by the chitosan in situ so as to further prepare N-doped carbon nanosheets; and Fe and Co catalyze urea under a high temperature to form carbon nano tubes, and the carbon nano tubes wrap FeCo alloy to crosslink into a three-dimensional carbon netlike structure which serves as the efficient difunctional oxygen electrocatalyst. Through the method, no solvent is involved, no auxiliary needs to be added, no template is involved, and only a simple pyrolysis mode after physical grinding is needed; and the method is simple in process route, environmentally friendly and low in cost, and the obtained product has a good difunctional oxygen electrocatalytic effect and shows extremely high application value.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

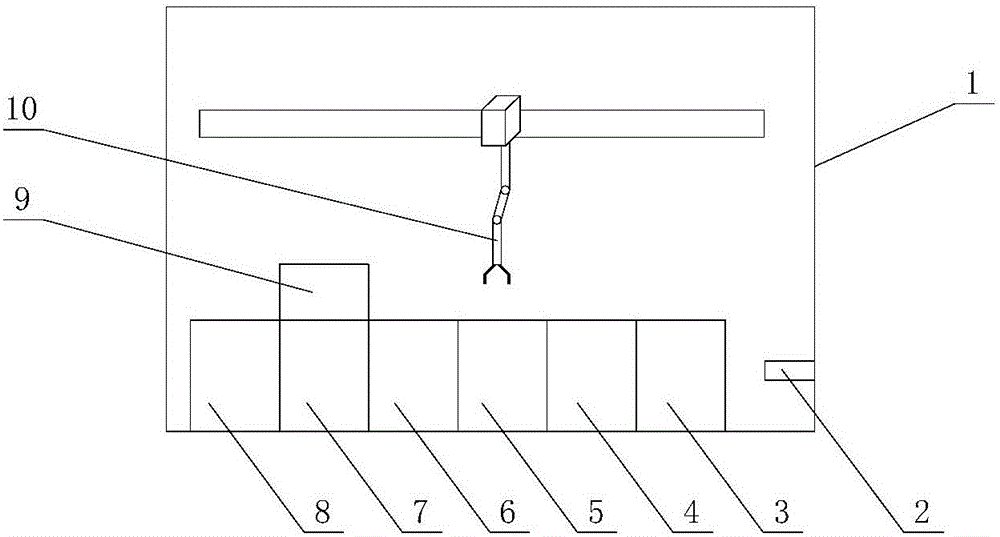

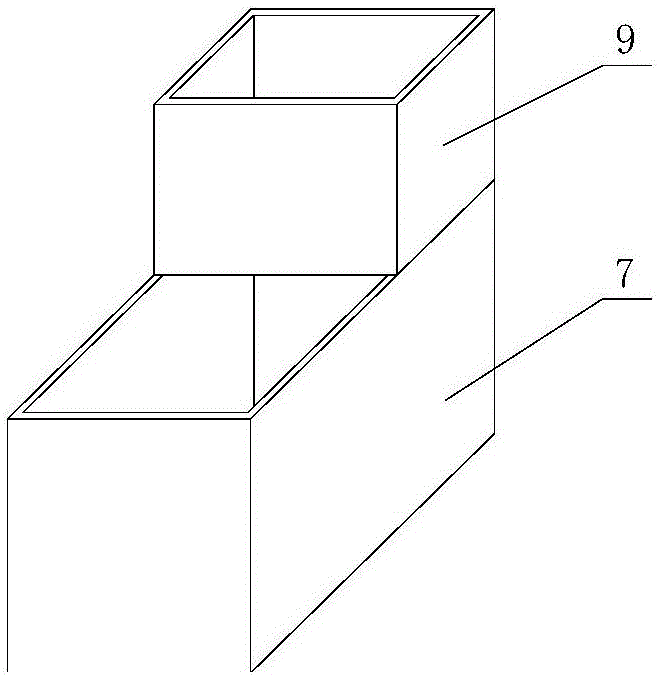

Full-automatic PCB (printed circuit board) making system and method based on Internet of Things

PendingCN106550545AQuick and efficient preparationPrinted circuit manufactureControl signalEngineering

The invention relates to a full-automatic PCB (printed circuit board) making system and method based on Internet of Things. The system is characterized by comprising a shell, a PCB laser printer, an etching trench, a rinsing trench device, a polishing trench device, a multi-joint manipulator and a control module, wherein the etching trench, the rinsing trench device, the polishing trench device and the multi-joint manipulator are arranged on the shell; the PCB laser printer is used for printing a PCB; the control module generates a control signal and sends the control signal to the multi-joint manipulator; the multi-joint manipulator is used for grabbing an external PCB, and placing the circuit board in the etching trench, the rinsing trench device or the polishing trench device. Through the interaction of the PCB laser printer, the etching trench, the rinsing trench device, the polishing trench device, the multi-joint manipulator and the control module disclosed by the invention, a complete PCB is manufactured; the manufacturing process is efficient and fast and can be used for small-scale production in schools or laboratories.

Owner:HUBEI UNIV OF EDUCATION

Multi-modal vehicle implemented food preparation, cooking, and distribution systems and methods

InactiveUS20200175467A1Quick and efficient preparationRoad vehicles traffic controlWorkshop/display transportationDelivery vehicleDistribution system

Vehicles, components, and methods are disclosed for preparing hot food during delivery or at a remote location. A multi-modal food distribution system may operate in one or more various modes, including a constellation mode, a cook enroute mode, and a pop-up kitchen mode, to deliver hot, prepared food to customers. The vehicles in the system may be configurable to change between each of the different modes depending upon information received by the system. The system may in the constellation mode include additional delivery vehicles that retrieve food from a vehicle that serves as a hub. The additional delivery vehicles may deliver the food to the delivery destination. In the cook enroute mode, the vehicle may prepare and cook food enroute to a delivery destination. In a pop-up kitchen mode, the vehicle may prepare food for pick up by customers.

Owner:ZUME INC

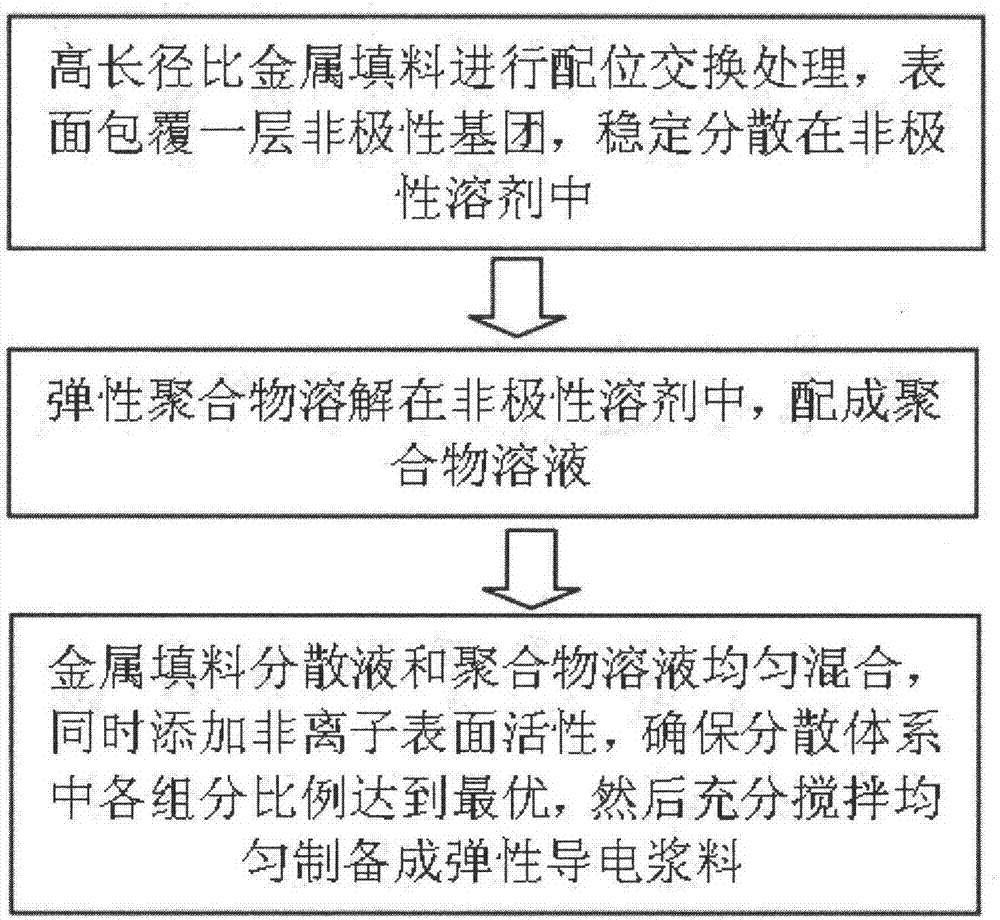

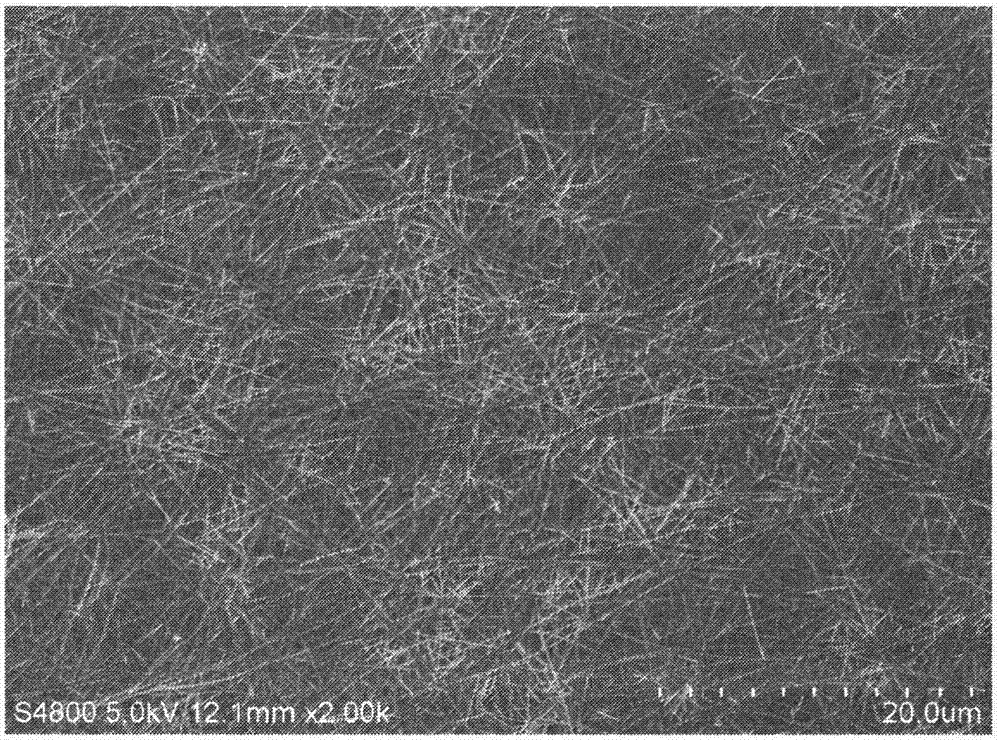

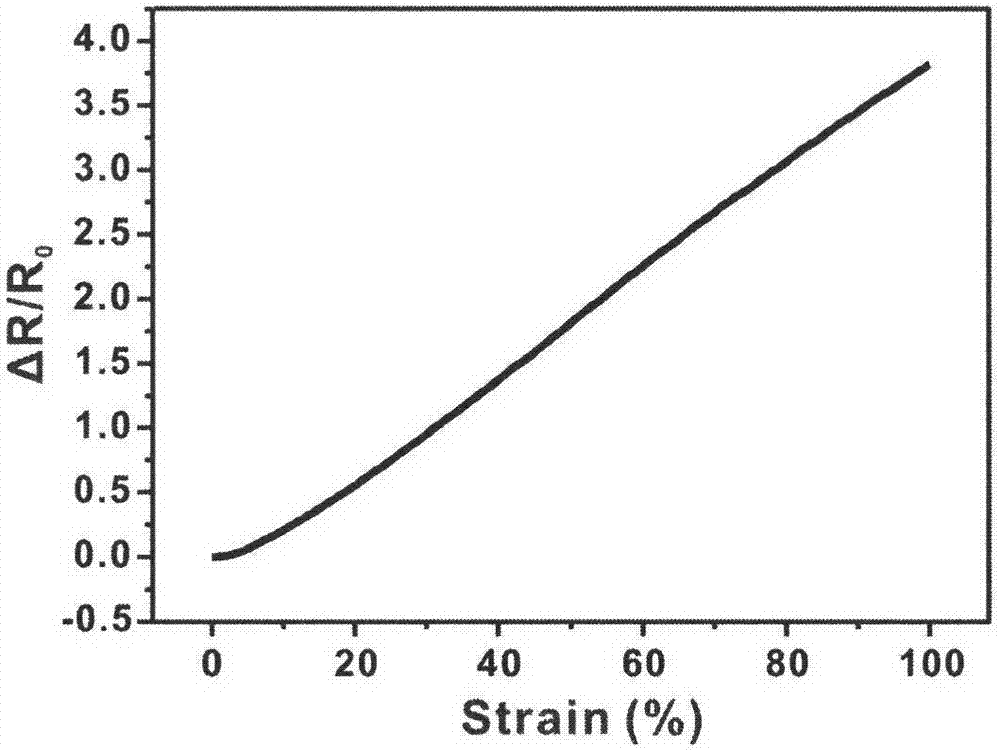

Preparation method of elastic conductive paste

ActiveCN107316707AHigh tensile electrical stabilityImprove initial conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteConductive polymer

The invention relates to the technical field of flexible electronics, in particular to a preparation method of elastic conductive paste. The elastic conductive paste prepared by the method of the elastic conductive paste can be used for printing and processing. The problems solved by the preparation method of the elastic conductive paste are as follows: (1) uniformly mixing of conductive filler with high length-diameter ratio and an elastic polymer is solved, so that a uniform conductive network structure is formed in the elastic paste, and high stretching electrical stability is achieved; and (2) by adding a surfactant, the solvent evaporation and phase separation process during the drying process of the paste is facilitated, more conductive filer is generated on a surface of a paste system, so that the initial conductivity is improved. The preparation method of the elastic conductive paste is reasonable in structural design, high-efficiency and rapid preparation is achieved, and the preparation method is suitable for promotion and application.

Owner:袁伟

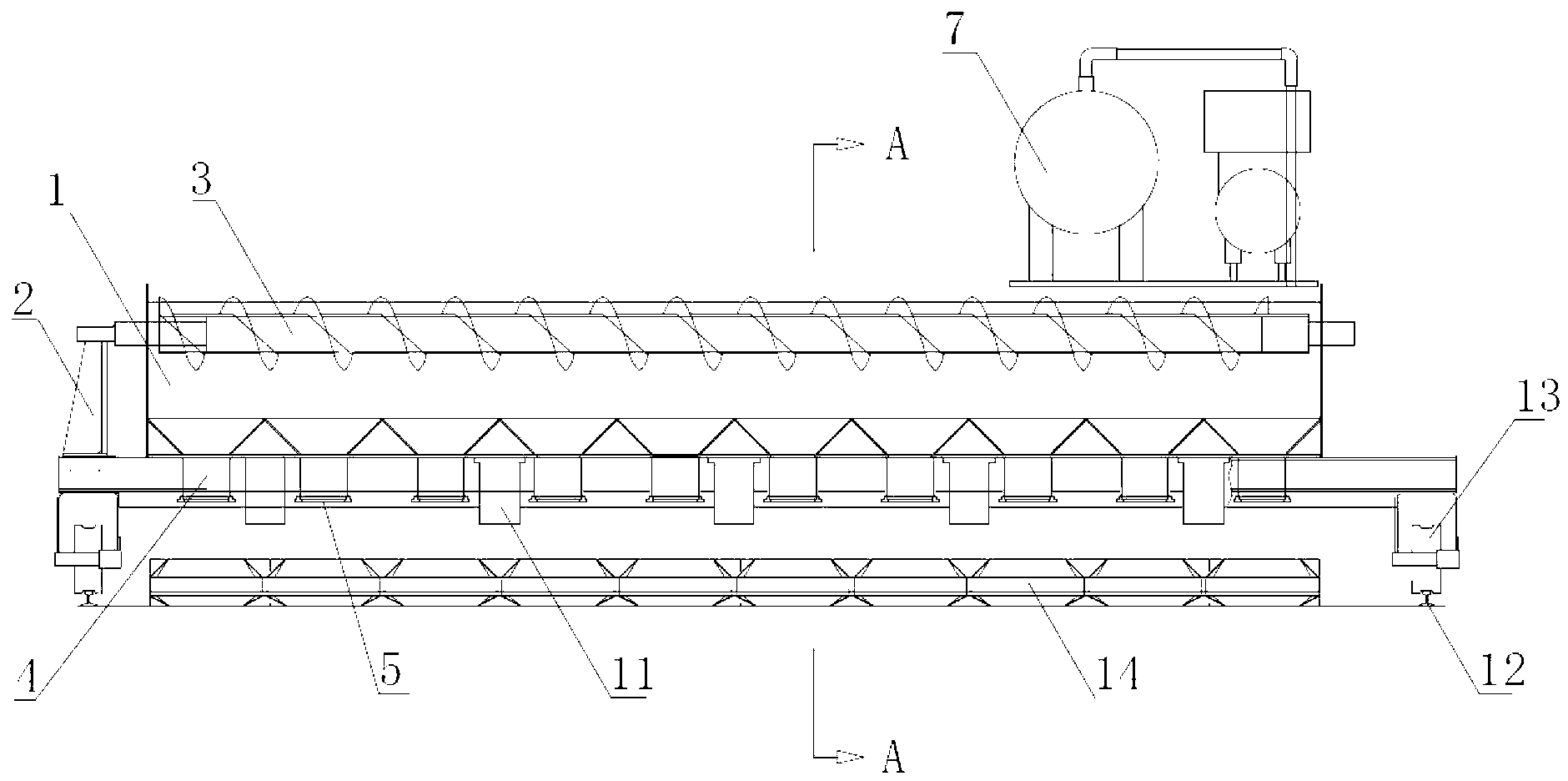

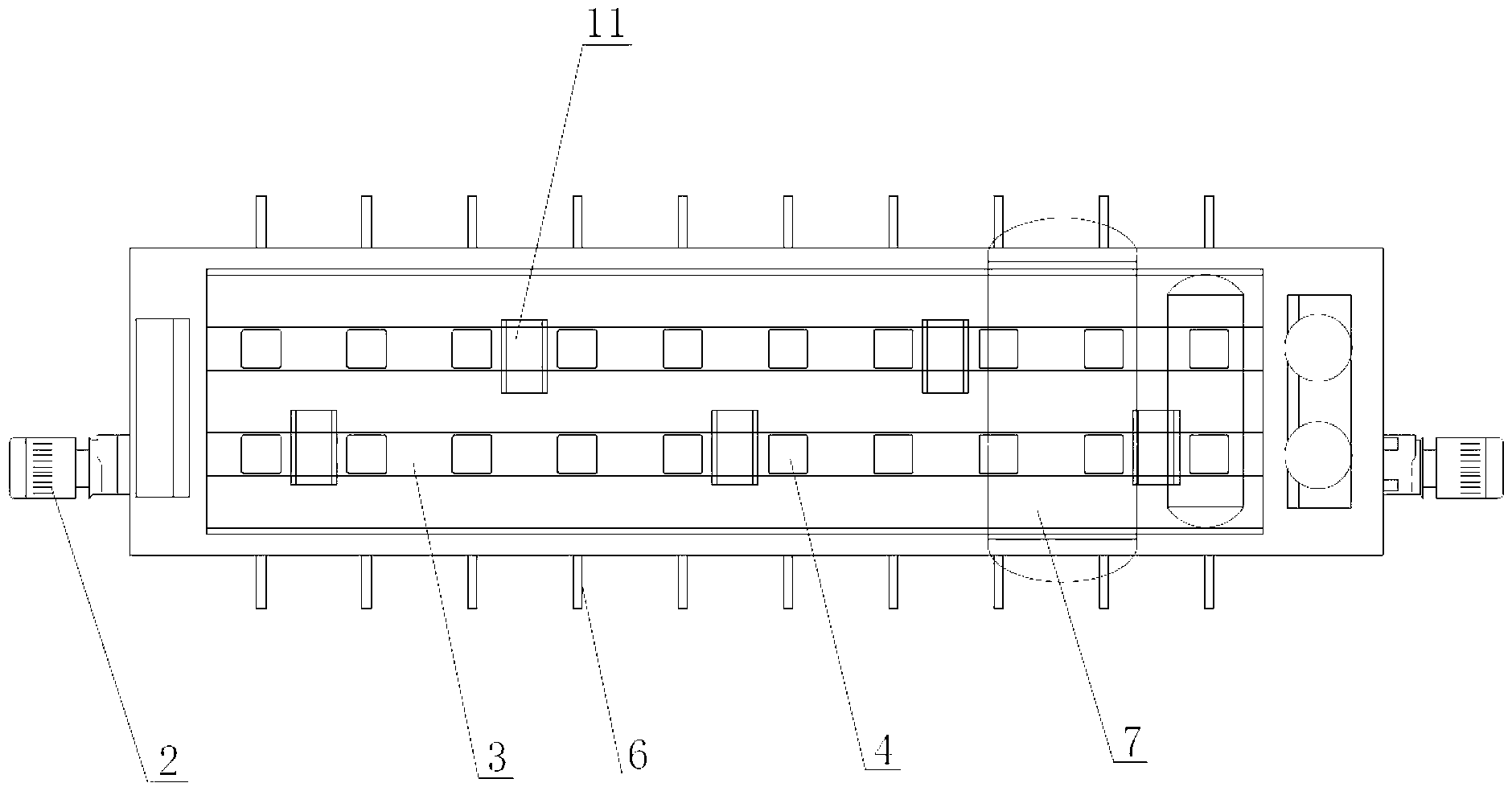

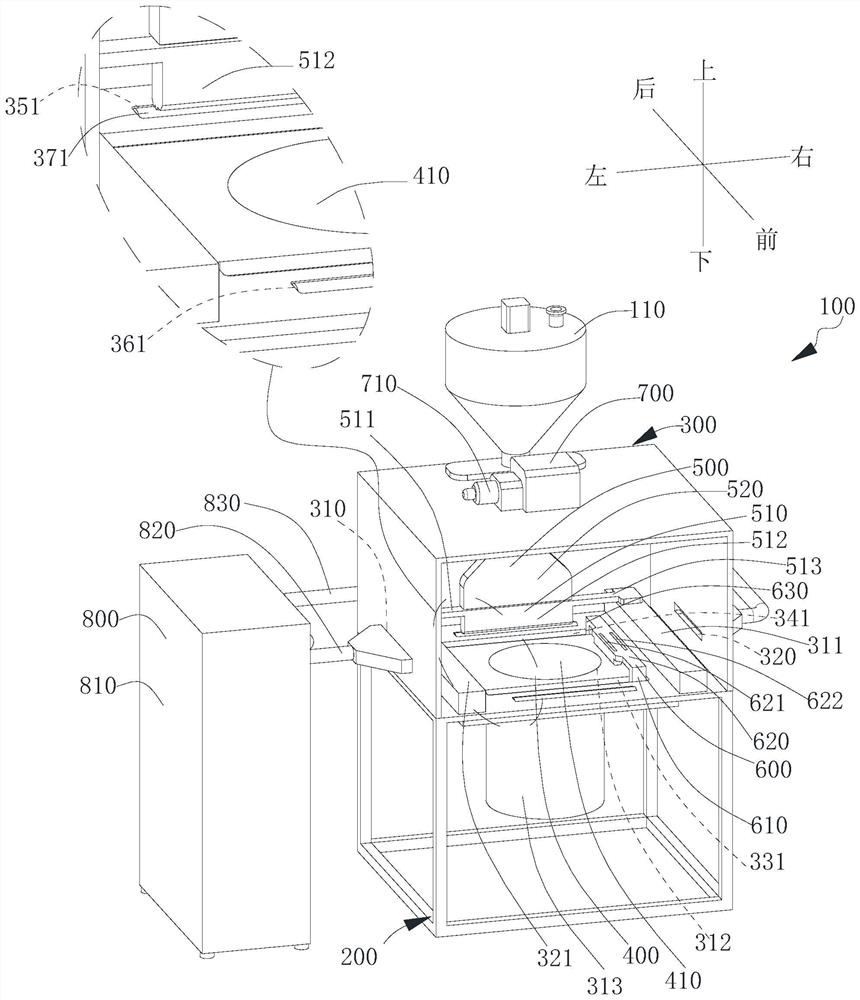

Automatic mortar distributor for prefabricating interlocking blocks

InactiveCN103182734AImprove the efficiency of scale prefabricationImprove prefabrication mechanizationFeeding arrangmentsControl systemAir compressor

The invention relates to an automatic mortar distributor for prefabricating interlocking blocks. The automatic mortar distributor comprises a hopper; spiral conveying devices driven by a driving device are arranged in the hopper; discharge ports are formed below the hopper and are provided with mortar feeding gates which can be opened and closed and controlled through a pneumatic control system; the pneumatic control system comprises an air cylinder and an air compressor, wherein the air cylinder is connected to the gates, the air compressor is connected with the air cylinder, and the air cylinder and the air compressor are connected with an electric control system which is capable of adjusting the mortar feeding time and positions to realize the purpose of quantitatively distributing mortar in fixed points; the discharge ports are positioned in a plurality of rows, and each row includes a plurality of discharge ports; and the spiral conveying devices are arranged on the discharge ports in each row. By virtue of the automatic mortar distributor, the massive prefabricating efficiency of the interlocking blocks can be obviously improved, the degrees of mechanization and automation in prefabrication of the interlocking blocks can be improved, and the cost of equipment in an interlocking block prefabricating site and the amount of construction workers can be greatly reduced.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

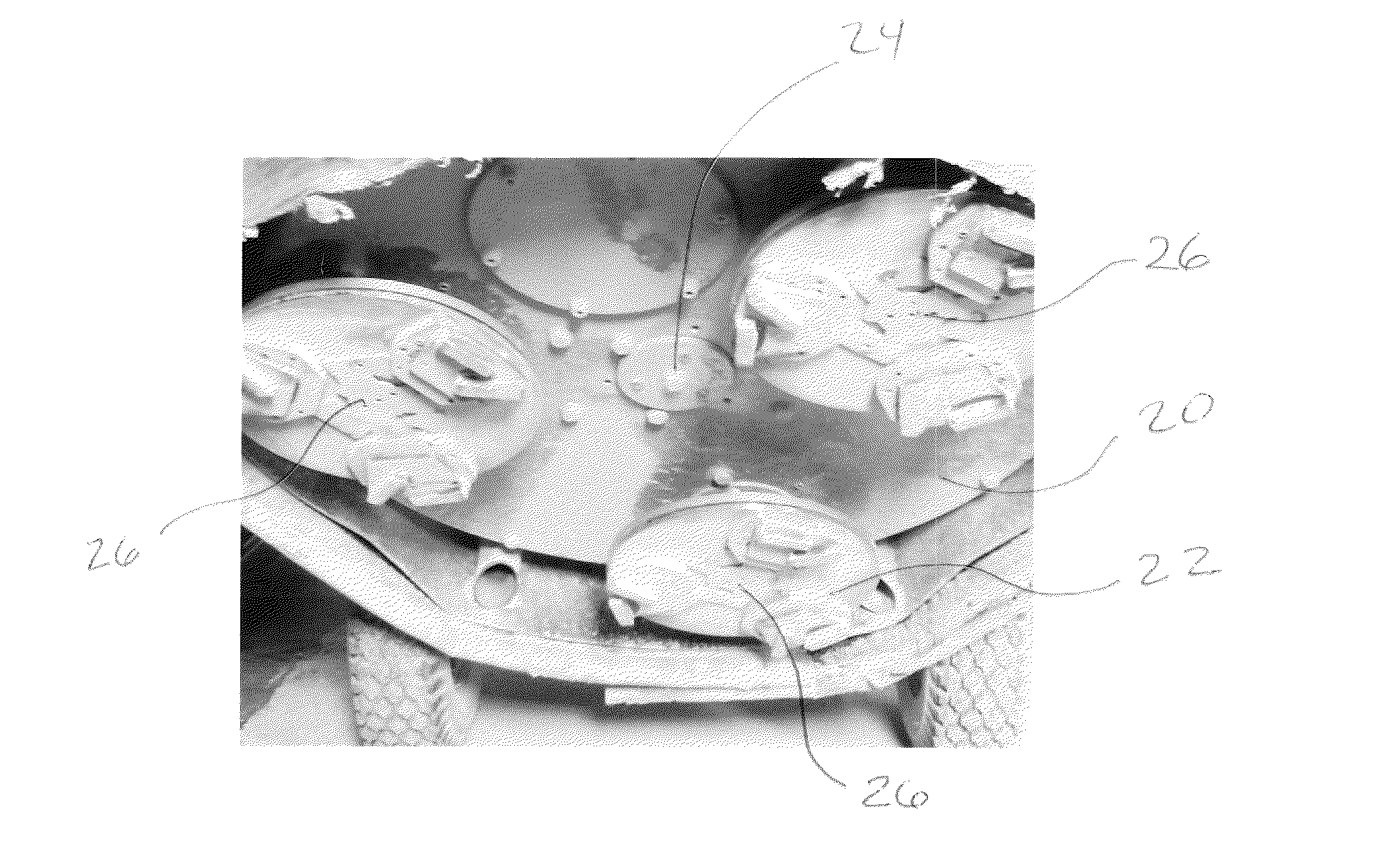

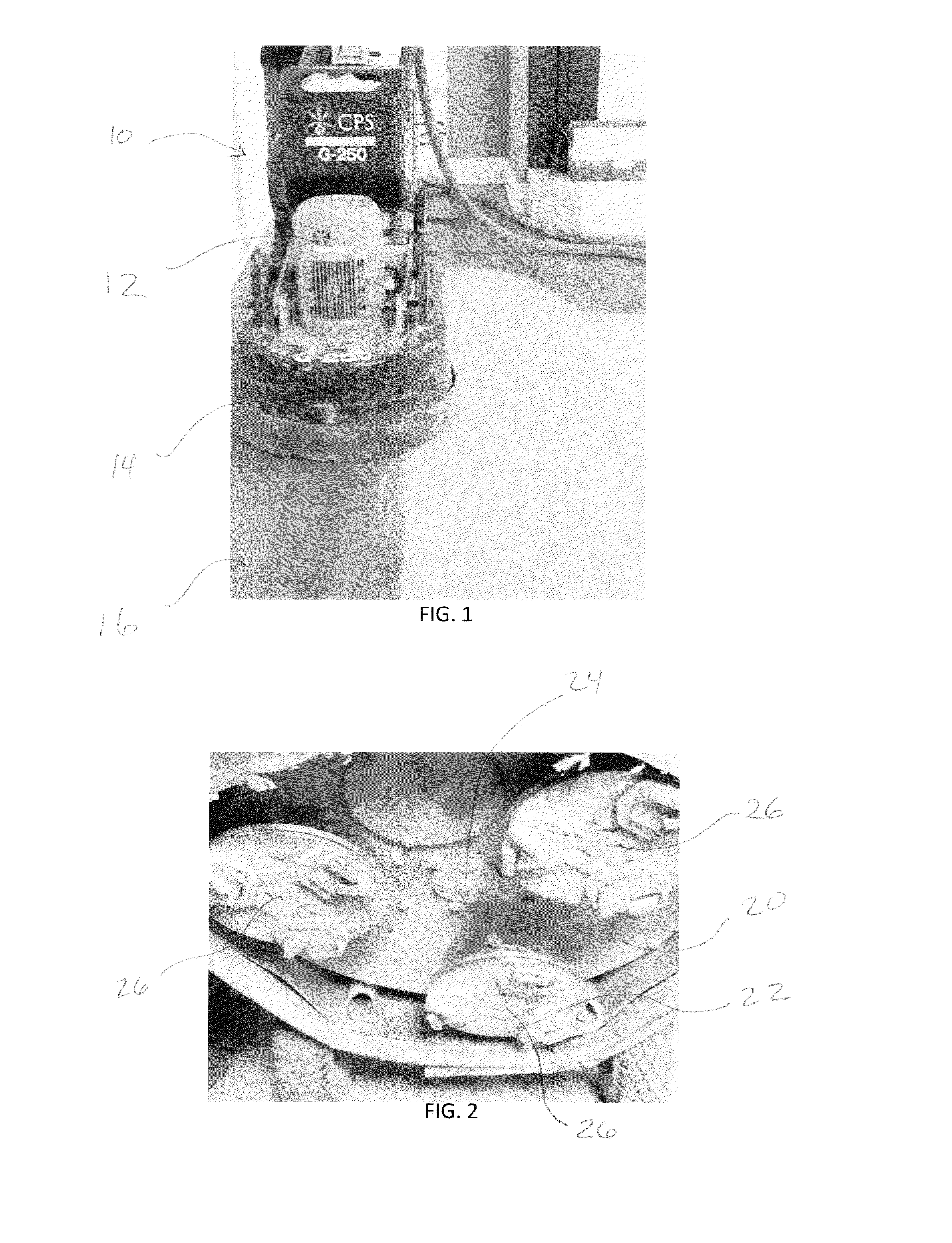

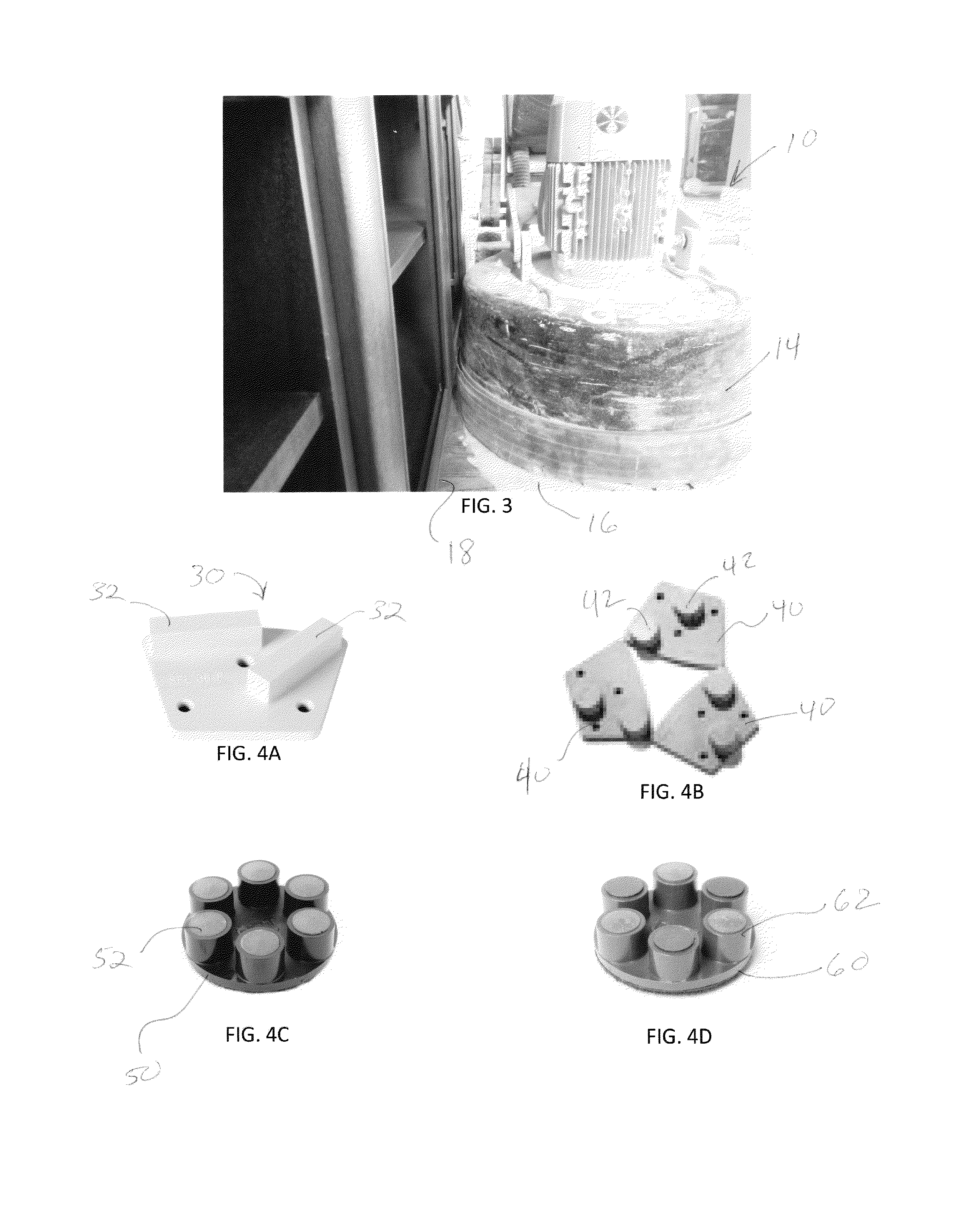

Systems and Methods for Stripping and/or Finishing Wood Surfaces

InactiveUS20140154955A1Accomplished quickly and efficientlyQuick and efficient preparationRevolution surface grinding machinesAbrasion apparatusPulp and paper industryMetal

Owner:MRKVICKA ANTHONY C

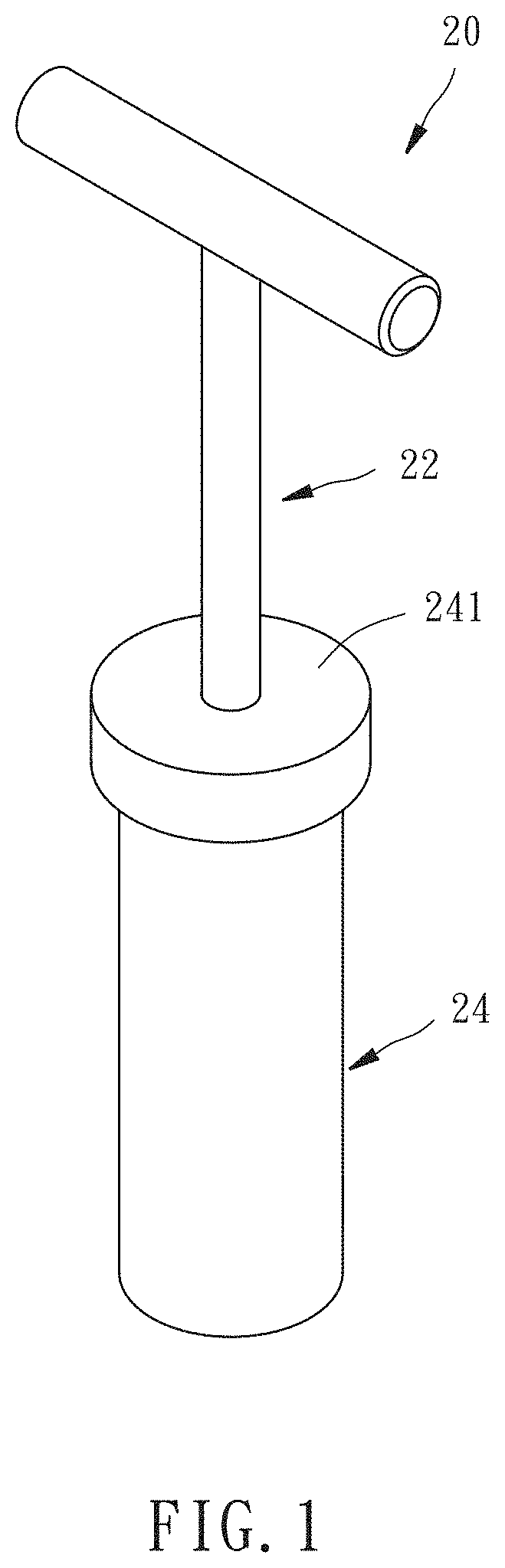

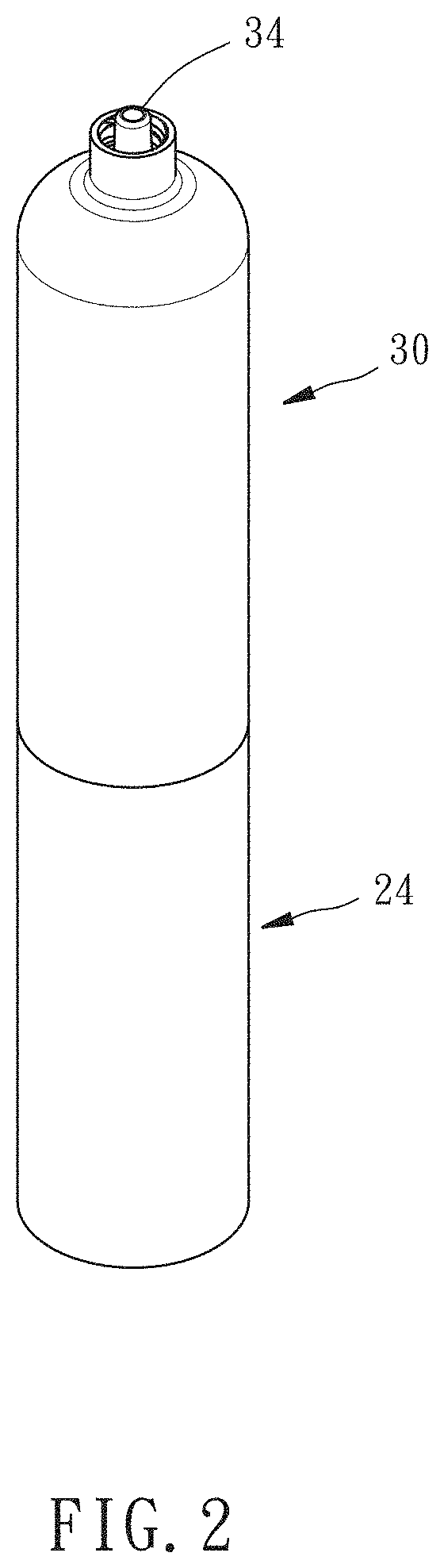

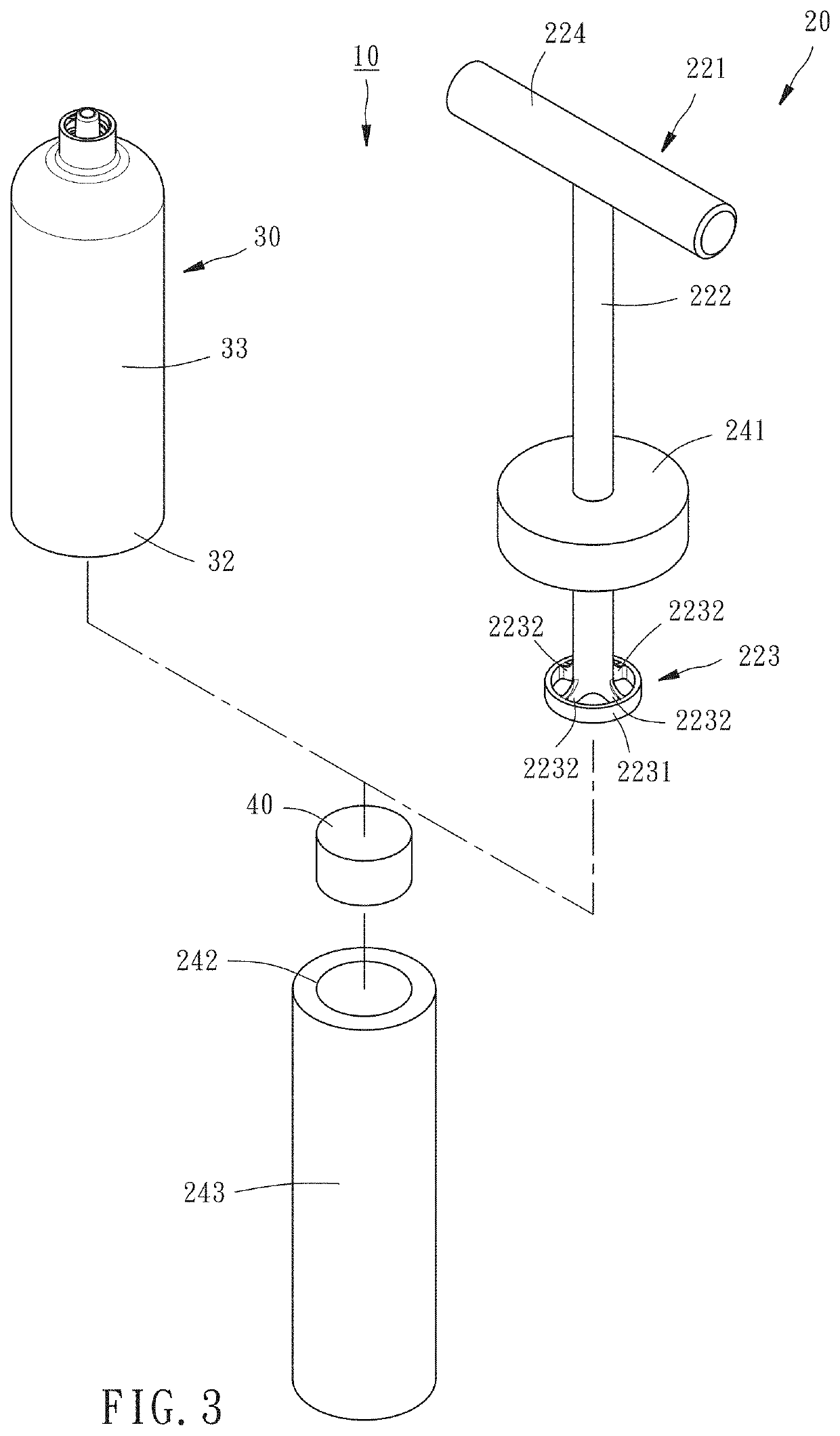

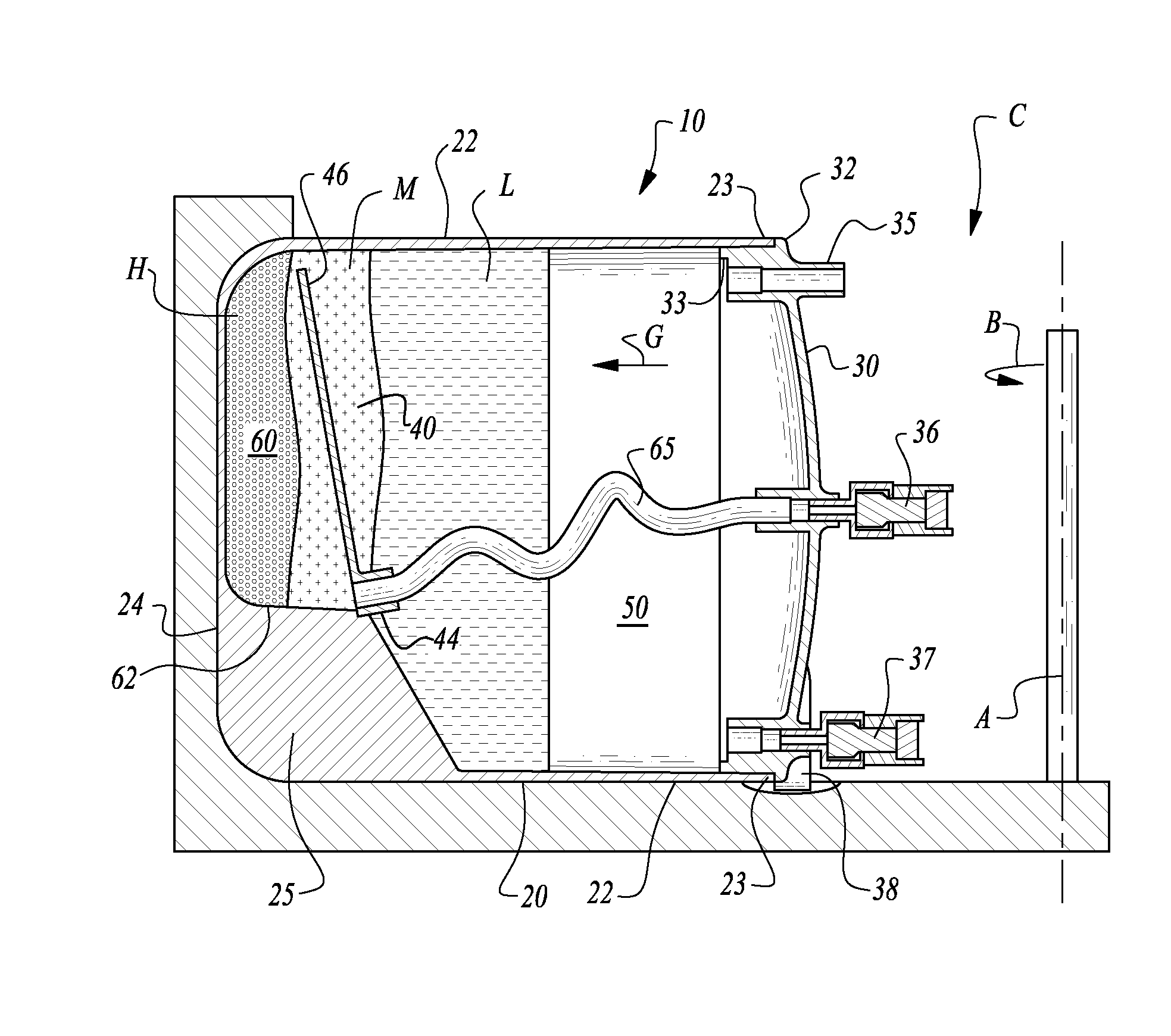

Bone cement mixing assembly

ActiveUS20220175435A1High recovery rateShorten the timeShaking/oscillating/vibrating mixersTransportation and packagingEngineeringBone cement

The invention provides a bone cement mixing assembly including a mixer, a syringe barrel and a movable plug cover. The mixer includes a stirring rod and a stirring barrel. The stirring rod has holding end, a rod body and a stirring end. The stirring barrel has a barrel cover, a first barrel open, a first barrel body, a first barrel bottom, and a stirring space located in the first barrel body. The syringe barrel has a second barrel open, a second barrel body, a second barrel bottom, and an injection space located in the second barrel body. In this way, the complete-stirred bone cement in the stirring barrel can be directly collected and pushed into the syringe barrel through the movement of the movable plug cover to achieve the effect of completing the preparation of the bone cement quickly and efficiently.

Owner:XELITE BIOMED LTD

Apparatus for centrifugation and methods therefore

ActiveUS9440243B2Low densityHigh densityOther blood circulation devicesMedical devicesCentrifugationEngineering

Owner:MICROAIRE SURGICAL INSTR

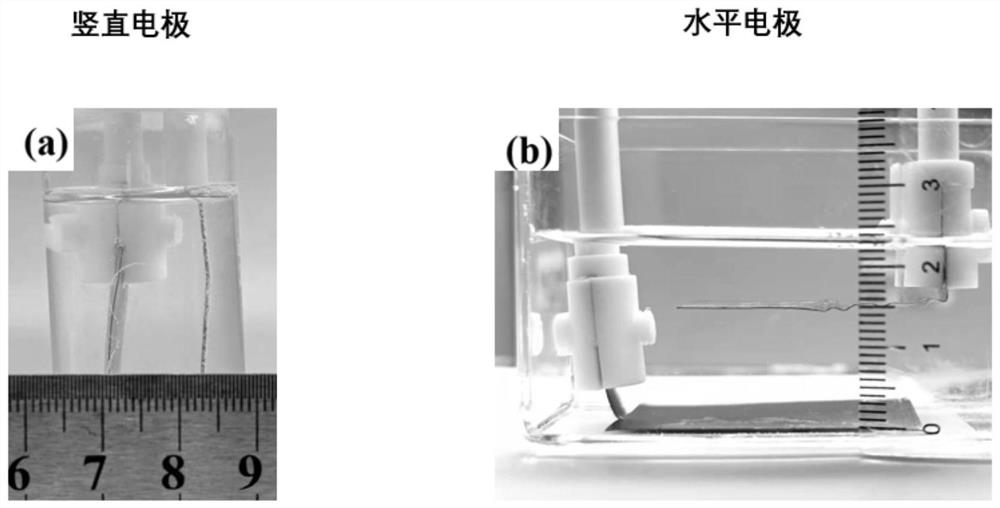

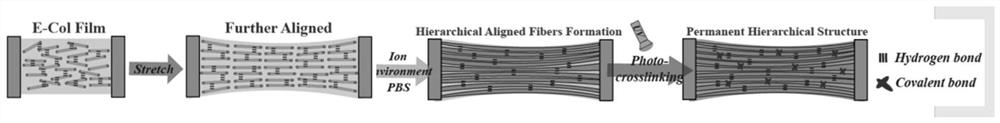

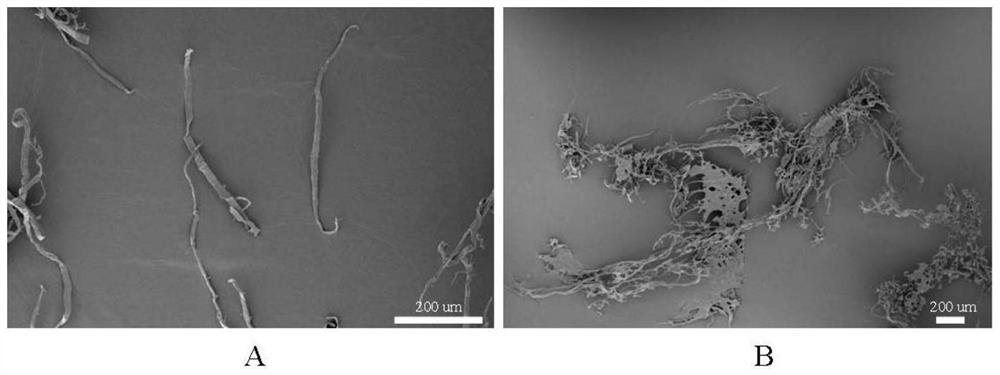

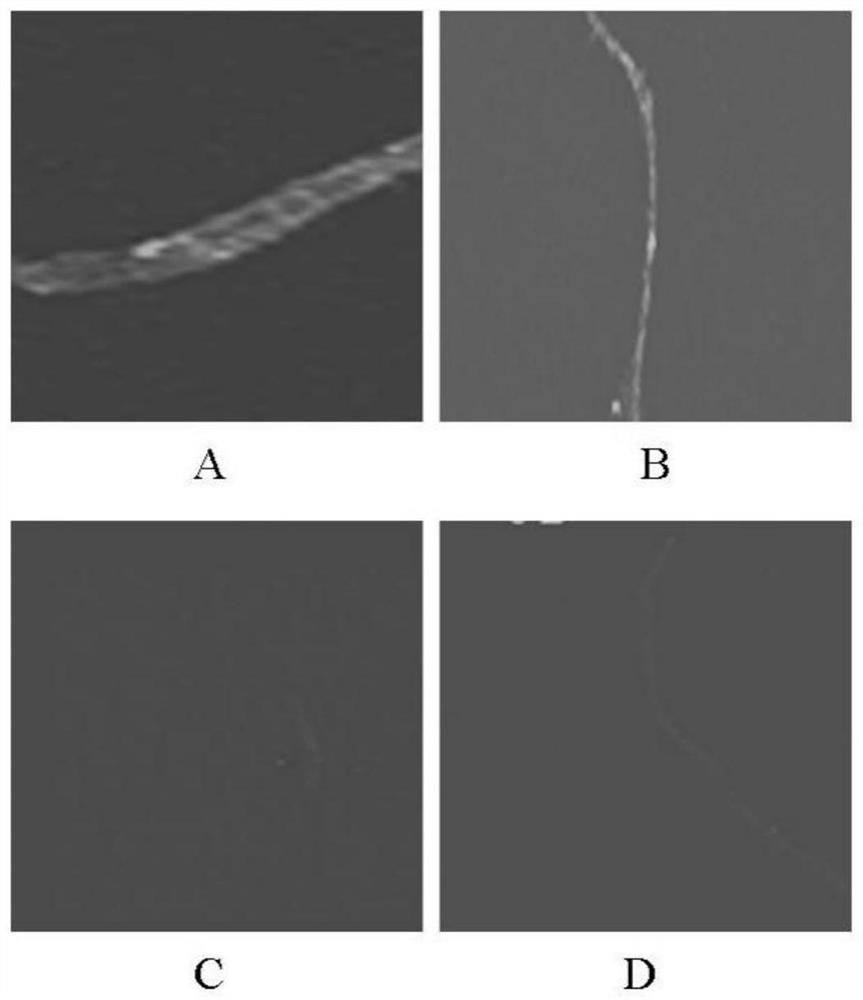

Collagen membrane with highly oriented and crystalline collagen fiber structure and preparation method thereof

ActiveCN114618017AYoung's modulus equivalentWith D-band characteristicsTissue regenerationProsthesisPolymer scienceGenipin

The invention belongs to the field of biomacromolecule assembly, and relates to a collagen membrane preparation method which comprises the following steps: firstly, taking a short-range oriented collagen microfiber membrane, and stretching along the length direction of the collagen membrane, so that microfibers in the collagen membrane are further oriented along the stress direction to form a highly oriented collagen material; secondly, carrying out ion incubation on the highly-oriented collagen material to induce rearrangement of an internal microfiber structure so as to form large-diameter collagen fibers in a crystalline state with D-band characteristics; and finally, carrying out chemical crosslinking through photo-crosslinking, glutaraldehyde crosslinking or genipin or polyphenol. According to the method, the long-range oriented collagen material can be obtained, and the characteristics such as appearance, microstructure, Young modulus and crystal structure are highly similar to those of natural tendons. The preparation method disclosed by the invention is simple and convenient to operate, does not need complex instruments and equipment, and can be used for quickly and effectively preparing the collagen membrane material highly similar to natural tendons or ligaments.

Owner:江苏博创生物科技有限公司

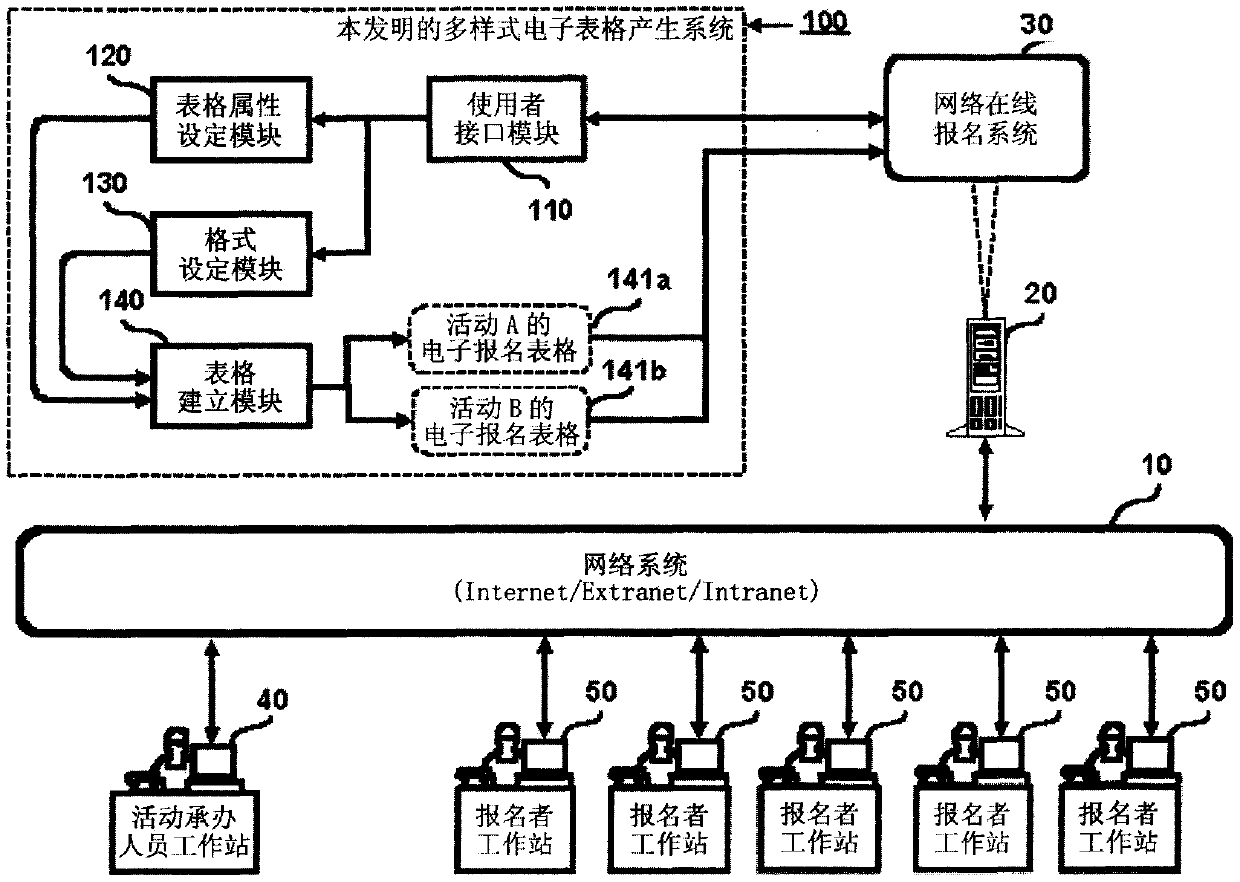

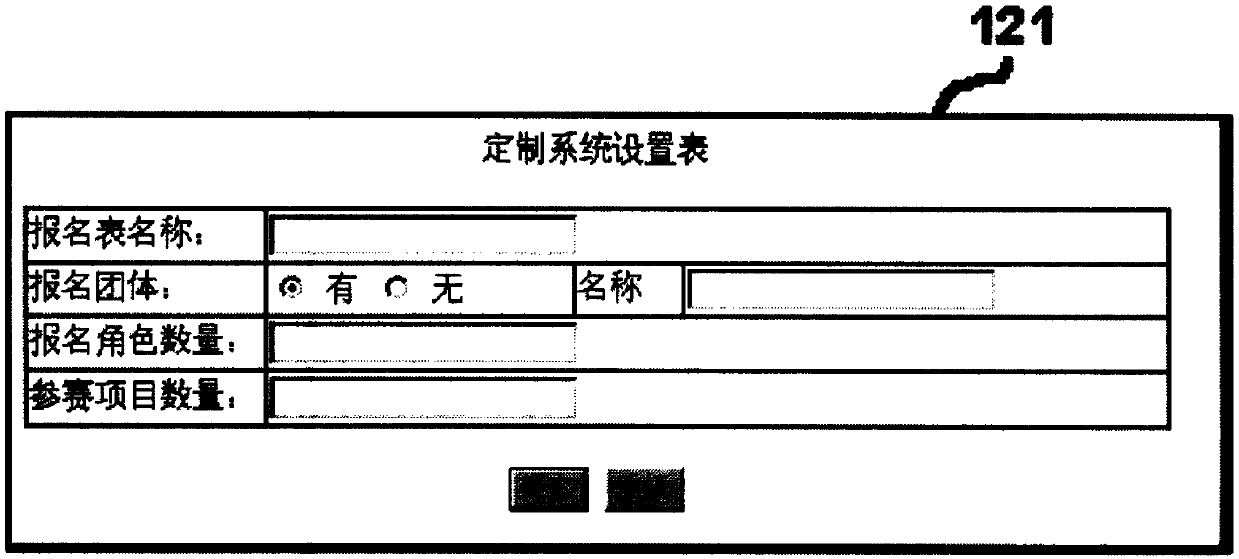

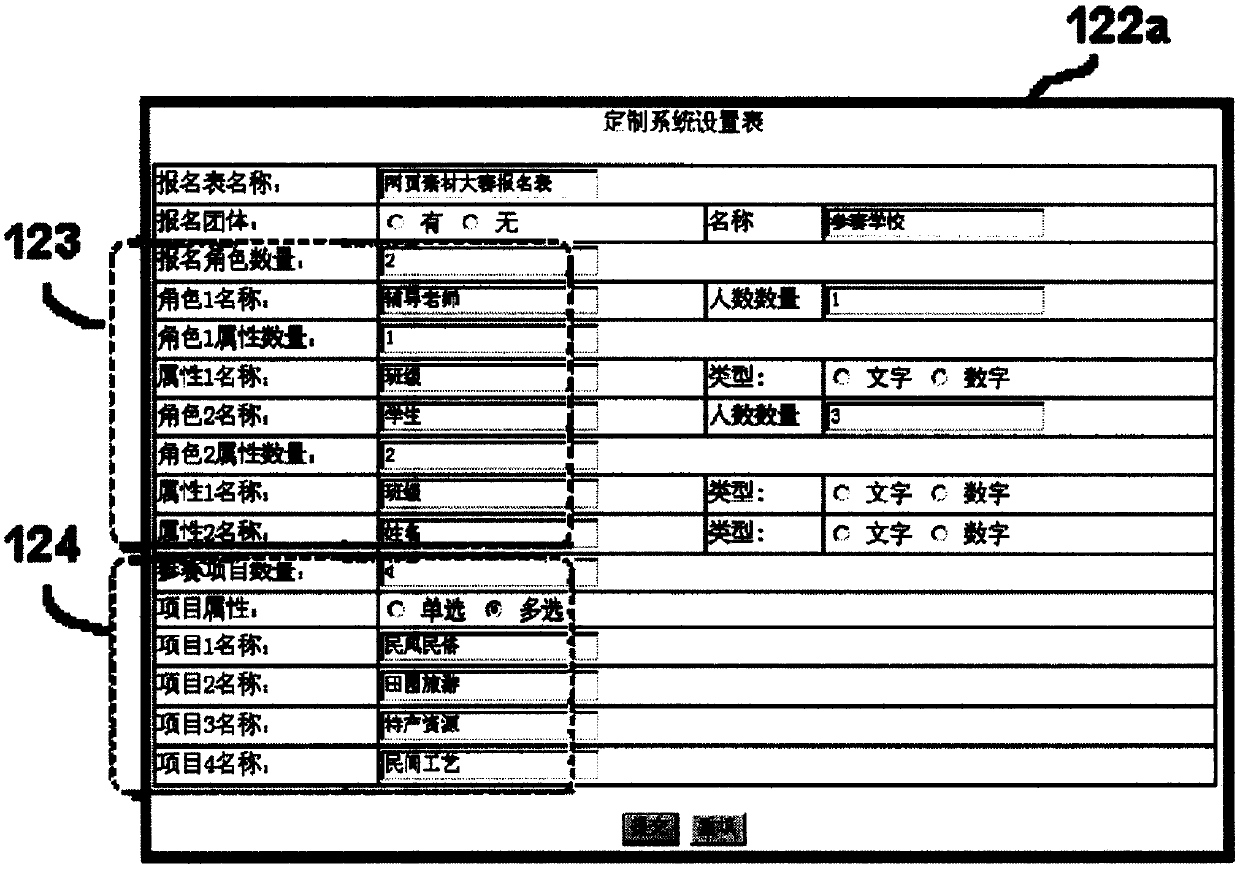

Multi-style spreadsheet generation system and method

InactiveCN109977376AQuick and efficient preparationFast and efficient workText processingSpecial data processing applicationsRegistration systemData mining

The invention discloses a multi-style spreadsheet generation method and system. The method and system at least comprise a user interface module, a table attribute setting module, a format setting module and a table establishing module. The system can serve as an independent system and can also be matched with a network online registration system, so that an organization unit generates an electronic registration table of a corresponding style according to individual special attributes of different activities, and a network user can complete an online registration procedure through the network system; according to the multi-style spreadsheet generation method and system, an activity undertaker does not need to make application forms of different styles manually by using a computer for different types of activities, so that the existing preparation work and work of holding the activities are quicker and more effective.

Owner:广州市顺尔电子科技有限公司

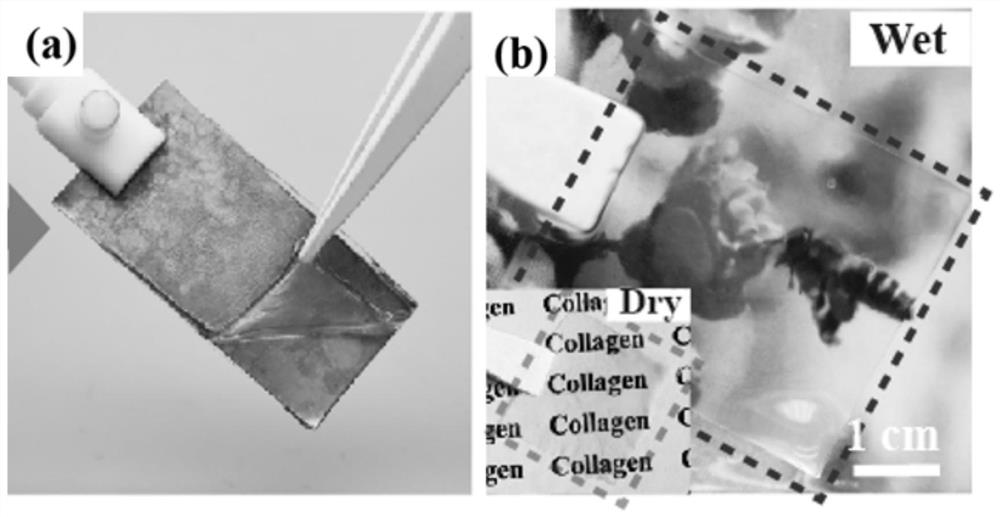

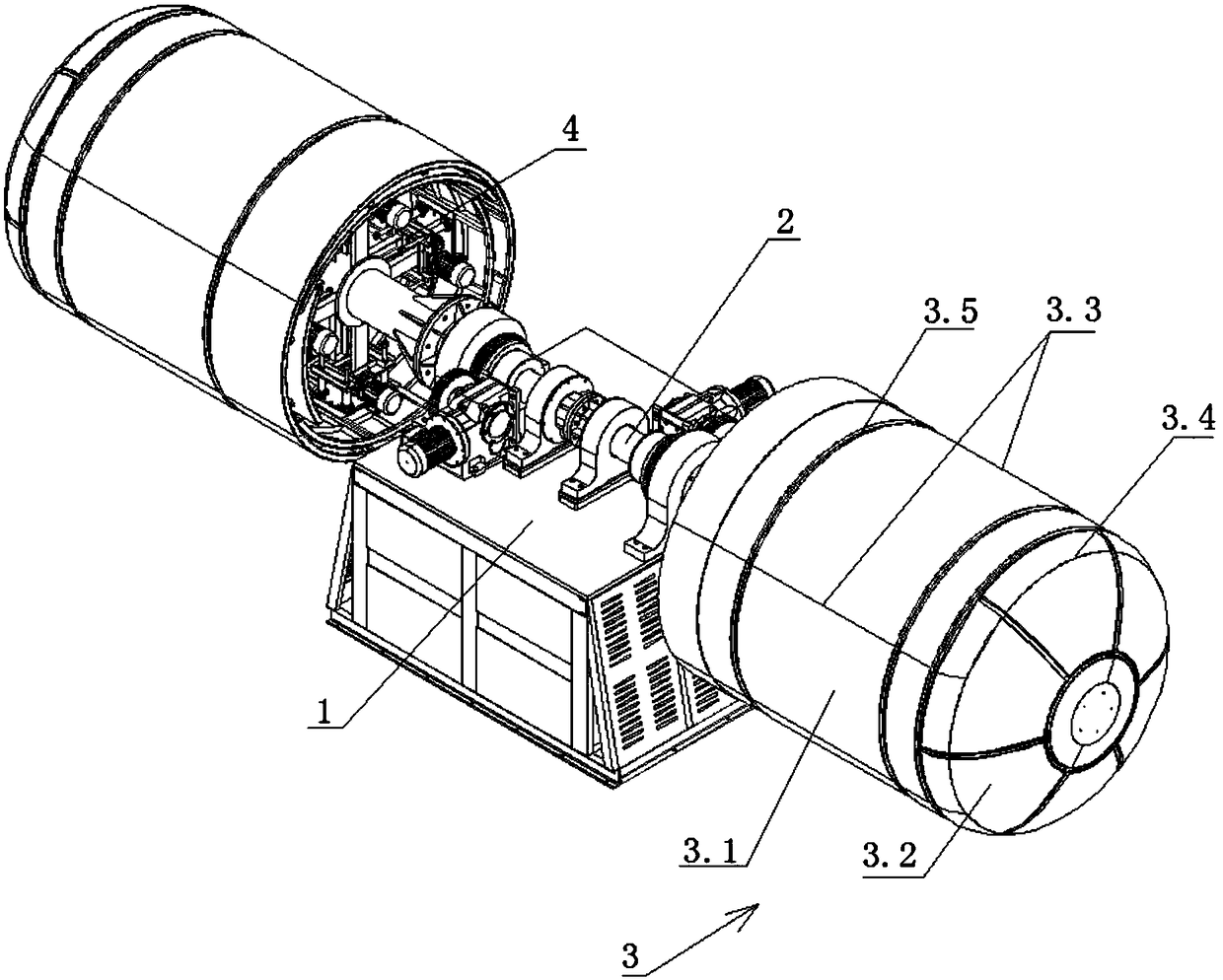

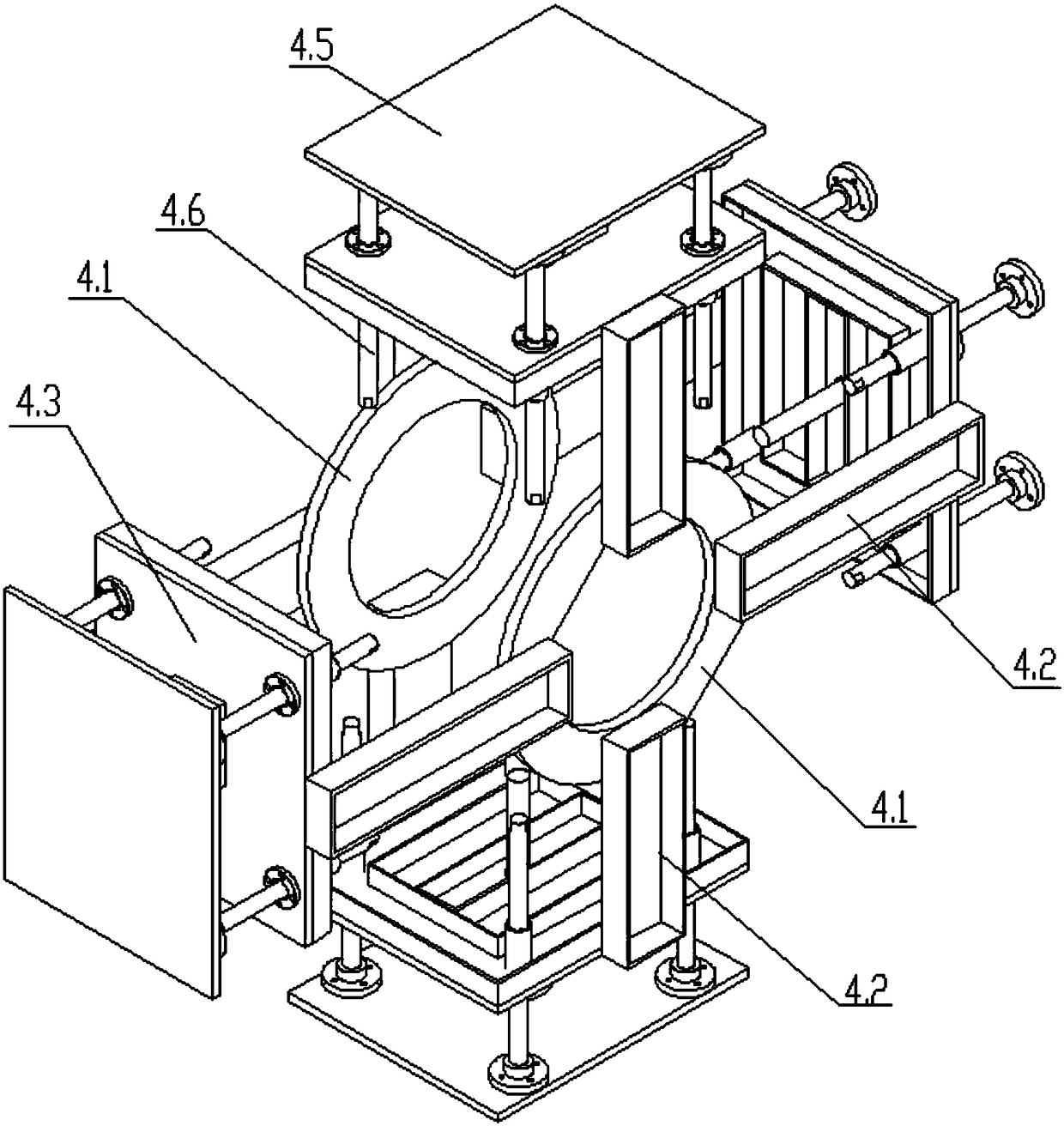

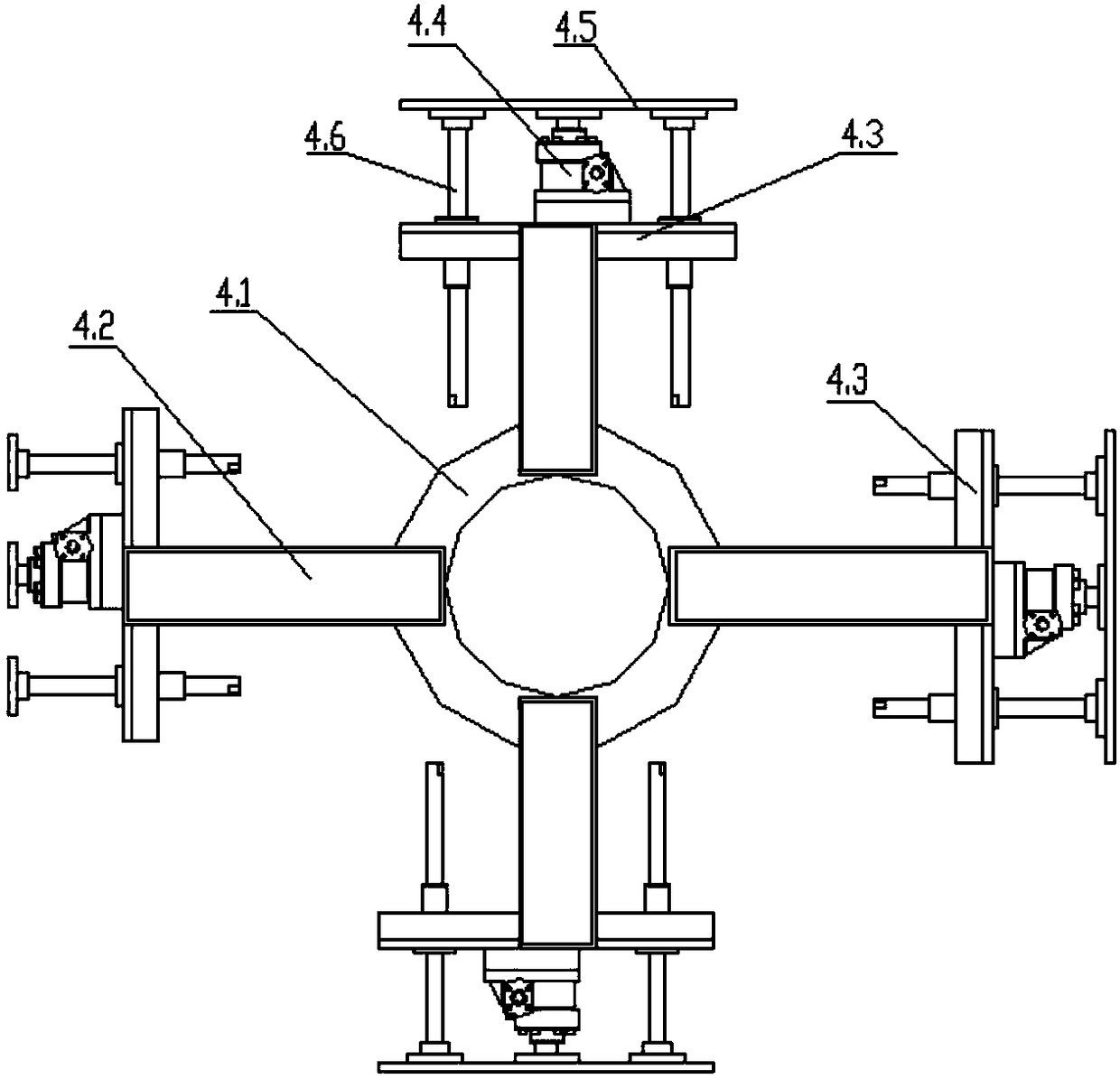

Preparation process of glass fiber reinforced plastic oil tank with inner reinforcing ribs

The invention discloses a preparation process of a glass fiber reinforced plastic oil tank with inner reinforcing ribs. The preparation process comprise step 1, glass fiber reinforced plastic fibers are spirally wound around a barrel body mold, a plurality of annular reinforcing rib forming grooves are formed in the barrel body mold, so that an inner shell body with an inner reinforcing rib structure is formed after the glass fiber reinforced plastic fibers are solidified; step 2, the barrel body mold is formed by splicing a plurality of barrel body mold plates, the barrel body plates shrink inwards in the radial direction, so that the barrel body plates are separated from reinforcing ribs of the inner shell, and the inner shell is pulled out outwards; and step 3, the glass fiber reinforced plastic fibers are wound spirally around the inner shell in a staggered mode to form a shell body. According to the preparation process of an FF oil tank with the inner reinforcing ribs, the FF oiltank with the inner reinforcing rib structure can be produced efficiently and conveniently.

Owner:JIANGYIN FUREN HIGH TECH

Synthetic drug for treating gastroenteritis and preparation method thereof

InactiveCN106215031ASmall side effectsEfficient and quick preparationHeavy metal active ingredientsDigestive systemSynthetic drugsSide effect

The invention discloses a synthetic drug for treating gastroenteritis and a preparation method thereof. The synthetic drug is prepared from the following raw materials in parts by weight: 8 to 12 parts of astragalus, 10 to 14 parts of semen coicis, 8 to 12 parts of codonopsis pilosula, 9 to 15 parts of poria cocos, 7 to 12 parts of carbonized hair, 9 to 11 parts of red halloysite, 6 to 15 parts of white paeony root, 4 to 8 parts of rhizome atractylodis macrocephalae, 4 to 8 parts of radix prismatomeris connatae, 5 to 7 parts of radix bupleuri, 5 to 7 parts of mangnolia officinalis, 4 to 8 parts of coptis chinensis, 8 to 20 parts of endothelium corneum gigeriae galli and 10 to 15 parts of liquorice. The preparation method comprises the following steps: performing reflux extraction on astragalus, semen coicis, poria cocos, radix bupleuri, mangnolia officinalis, coptis chinensis and liquorice in an alcohol extraction manner, thereby obtaining alcohol extraction reflux. The prepared synthetic drug has small toxic and side effects in clinical application and does not cause damage of gastrointestinal mucosa; moreover, the designed preparation method can be used for efficiently and rapidly preparing the synthetic drug.

Owner:成都威迪视特生物科技有限公司

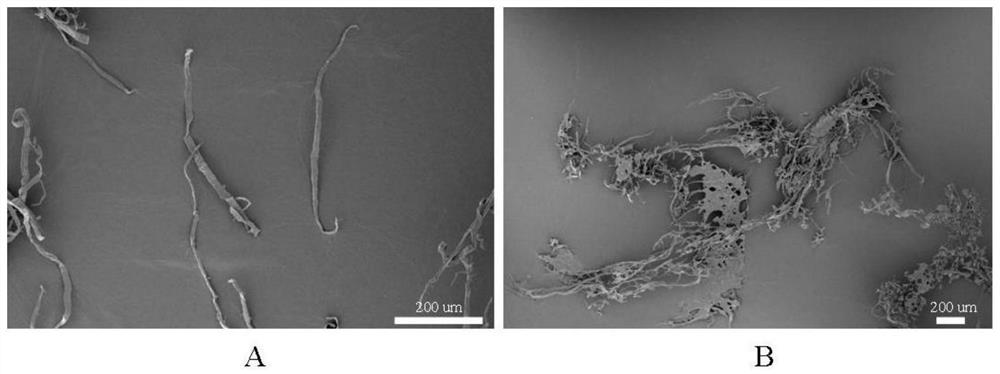

Collagen microfiber hemostatic material and preparation method and application method thereof

ActiveCN112516377ASpray evenlyNo nozzle cloggingSurgical adhesivesPharmaceutical delivery mechanismBULK ACTIVE INGREDIENTWound surface

The invention relates to the field of biological materials, and particularly relates to a collagen microfiber hemostatic material and a preparation method and an application method thereof. The preparation method comprises the following steps of: performing high-speed shearing on a solid collagen material to obtain collagen microfibers, dispersing the collagen microfibers in a water phase, modifying procoagulant active ingredients on the surfaces of the collagen microfibers through connecting molecules, performing freeze-drying treatment, and performing high-speed shearing treatment again to obtain the collagen microfiber hemostatic material. The collagen microfiber hemostatic material can be prepared simply, conveniently and efficiently through high-speed shearing, and the biological activity of the collagen material is kept as much as possible; the length range of the microfibers is 10-1000 microns, and the microfibers have high dispersibility and are favorable for spraying treatment; and the connecting molecules can efficiently and quantitatively load the procoagulant active ingredients on the surfaces of the collagen microfibers, so that the hemostatic effect of the collagen microfibers is enhanced. The collagen microfiber hemostatic material prepared by the preparation method is used for hemostasis of a bleeding wound surface in a spraying manner, such as hemostasis in a brain surgery or liver surgery process, and the effect of non-contact fixed-point hemostasis can be achieved.

Owner:QUANFENG TECH (SHENZHEN) CO LTD

Vertical Grill Assembly

InactiveUS20170027382A1Prepared quickly and efficientlyQuick and efficient preparationRoasters/grillsEngineeringMechanical engineering

A vertical grill assembly. The vertical grill assembly includes a housing having a base, a rear wall, opposing sidewalls, and a top panel defining an interior volume. A plurality of burners are disposed on the interior surface of each opposing sidewall. The vertical grill assembly further includes a grill rack assembly including a first grill rack hingedly secured to a second grill rack via a floating hinge. Food is securable between the first grill rack and second grill rack via a locking ring that holds the first and second grill racks together. The grill rack assembly is insertable into the interior volume and is supported therein via upper and lower rails disposed on upper and lower ends of the sidewalls. The vertical grill assembly allows food to be prepared quickly and efficiently due to the simultaneous application of heat to both sides of the food.

Owner:FIRTEL BURTON

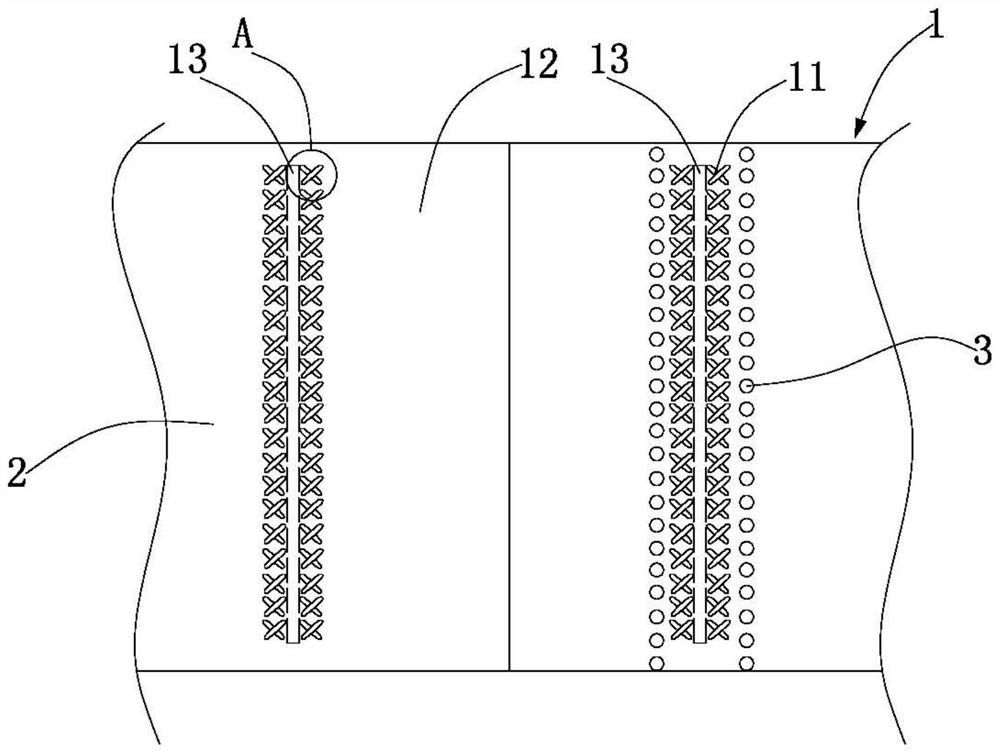

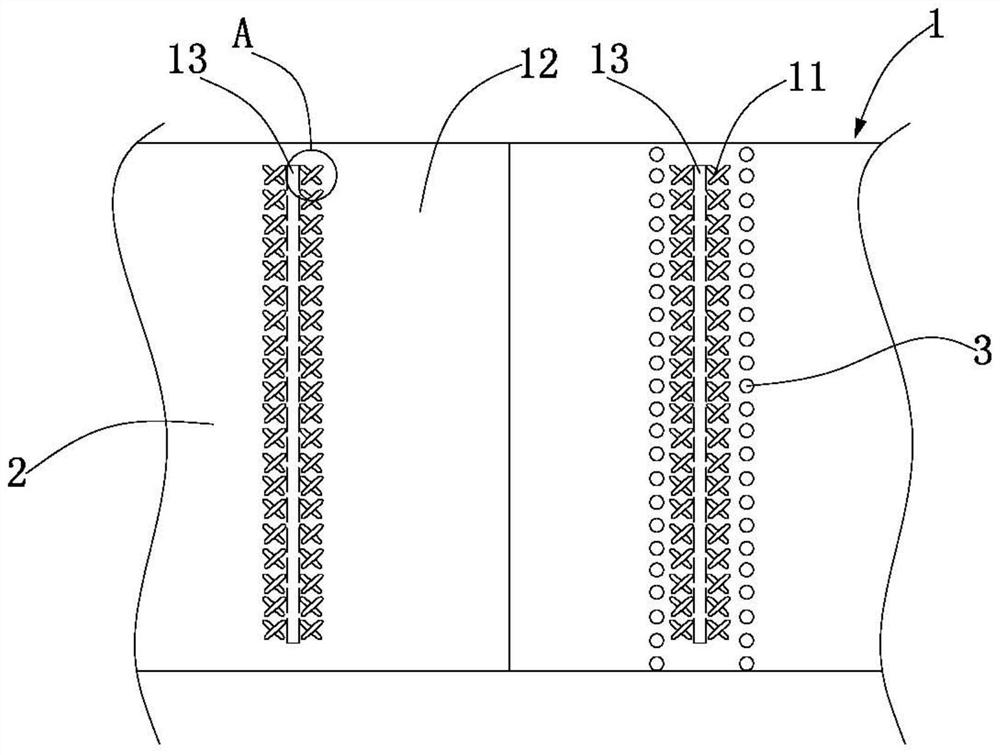

Interwoven vamp and manufacturing method thereof

ActiveCN112442787AIncrease elasticityRich in functionsWeft knittingTextile/flexible product manufactureComposite materialPlain weave

The invention discloses an interwoven vamp. The interwoven vamp comprises a vamp body; at least one overlapping woven structure is woven on the vamp body; and each overlapping woven structure comprises at least one woven layer, each woven layer is formed by weaving at least one woven strip in a staggered mode, and the distance between every two adjacent overlapping woven structures can be freely adjusted. The width of the overlapping woven structure can be freely adjusted, the overlapping woven structure is woven on a plain weave vamp, different woven materials are used, and the made weave effects and functions are different. Decorative materials are used for weaving, so that the function of decorating the vamp can be achieved. Functional weaving materials are used, so that the elasticitycan be improved, the vamp can achieve a more comfortable effect, and compared with model forming, the functional effect is richer.

Owner:SINCETECH FUJIAN TECH CO LTD

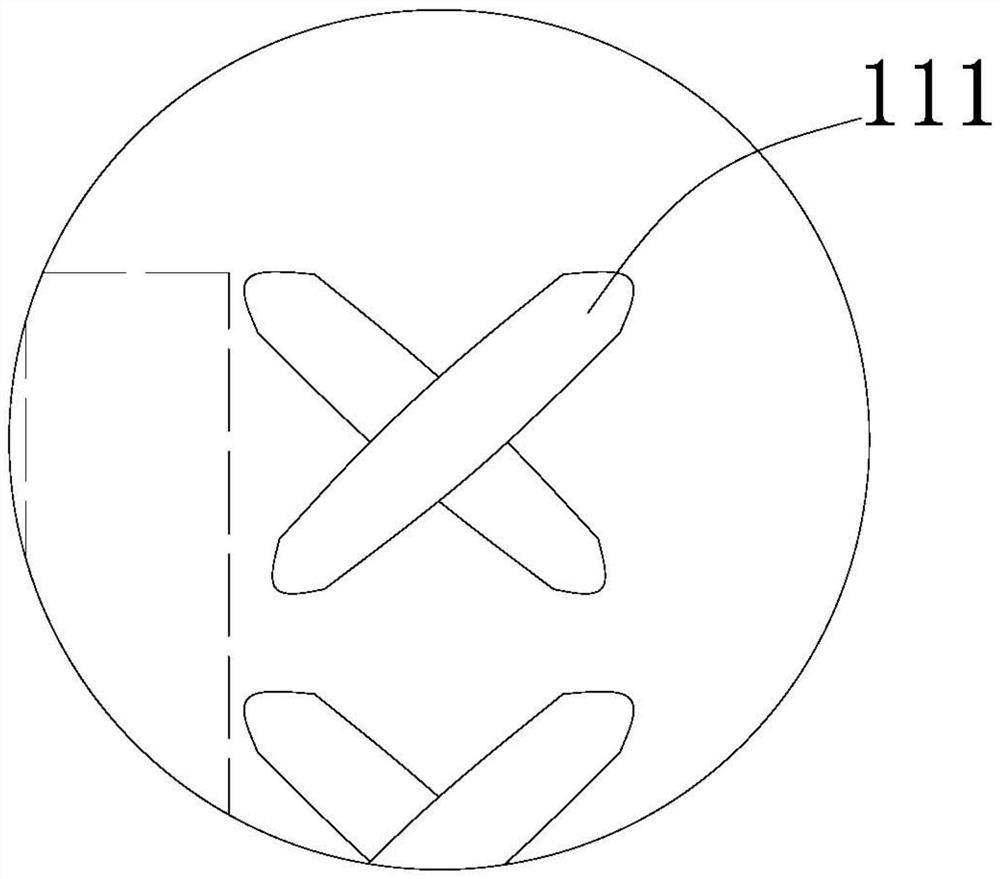

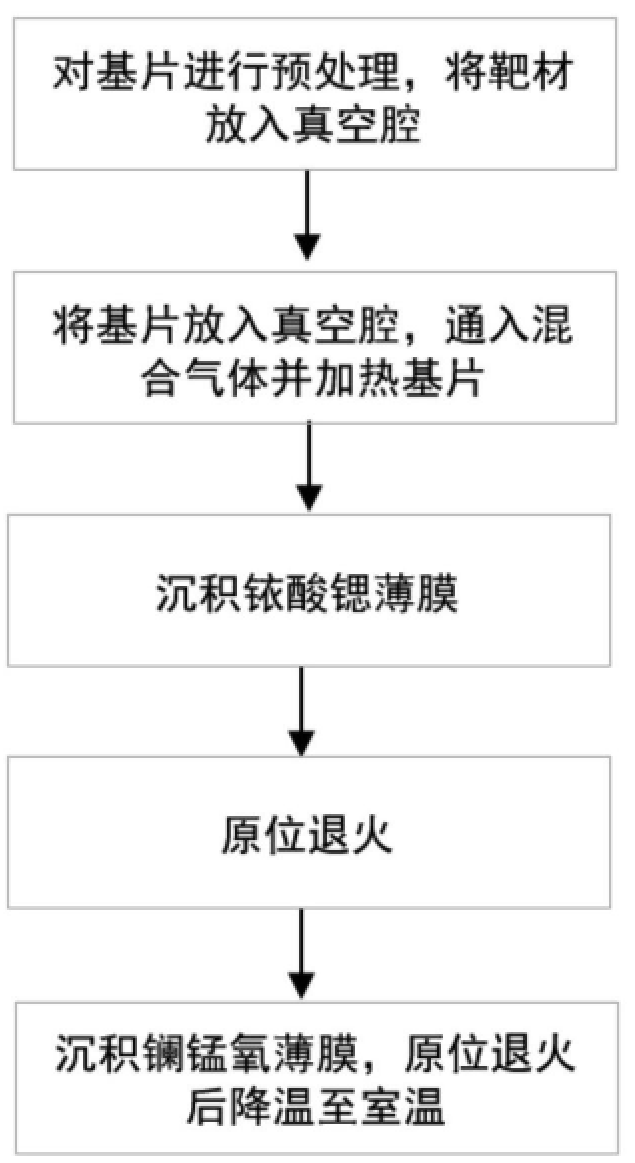

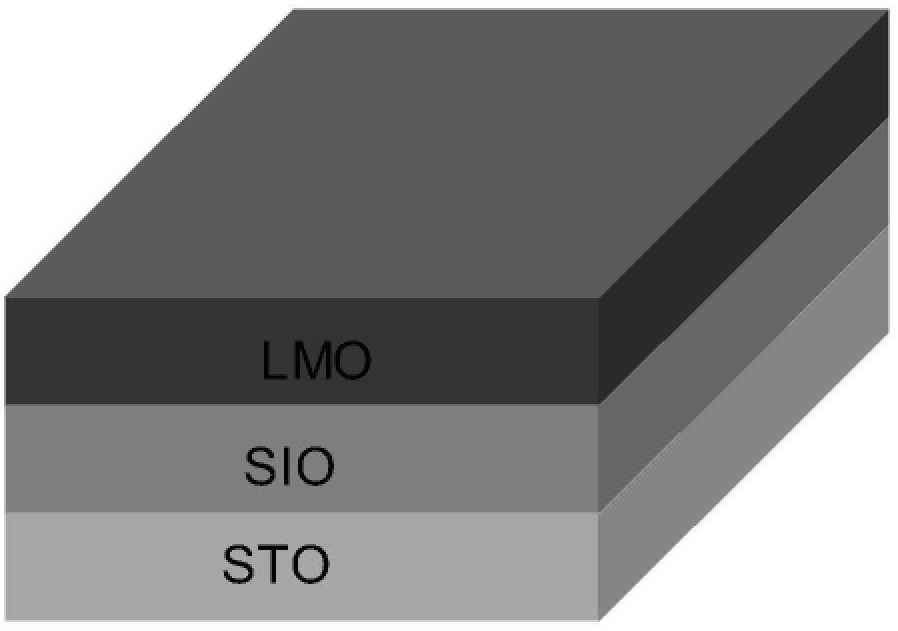

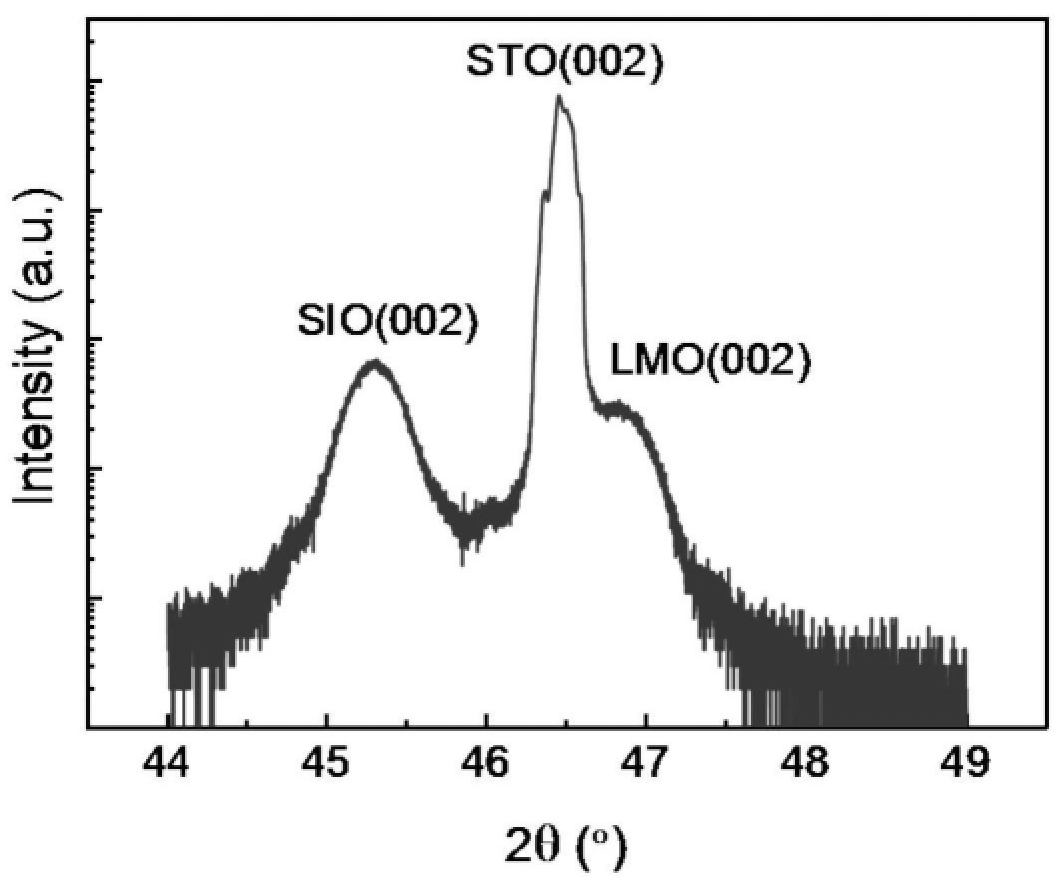

Preparation method of lanthanum manganese oxide/strontium iridate heterojunction film

PendingCN114724955AChange magnetismQuick and efficient preparationVacuum evaporation coatingSputtering coatingPhysicsManganese oxide

The invention discloses a preparation method of a lanthanum manganese oxide / strontium iridate heterojunction thin film, the lanthanum manganese oxide / strontium iridate heterojunction is prepared by adopting a pulse laser deposition method, a pretreated substrate is put into a vacuum chamber to be heated to a certain temperature, and under a certain oxygen pressure condition, the lanthanum manganese oxide / strontium iridate heterojunction thin film is prepared by adopting the pulse laser deposition method. A plasma plume deposition sample generated by bombarding a target material through pulse laser is used, firstly, a strontium iridate film is deposited, in-situ annealing is carried out after deposition is finished, then, a lanthanum manganese oxide film continues to be deposited through the same steps under the same condition, and finally, after in-situ annealing is carried out, the temperature is reduced to the room temperature. The preparation method of the lanthanum manganese oxide / strontium iridate heterojunction is simple and rapid, the prepared lanthanum manganese oxide / strontium iridate heterojunction film has obvious interface magnetism, the interface magnetism of the heterojunction can be effectively regulated and controlled by adjusting the thickness of lanthanum manganese oxide in the heterojunction, and the lanthanum manganese oxide / strontium iridate heterojunction film has wide application prospects in the field of spin electronic devices.

Owner:NANJING UNIV

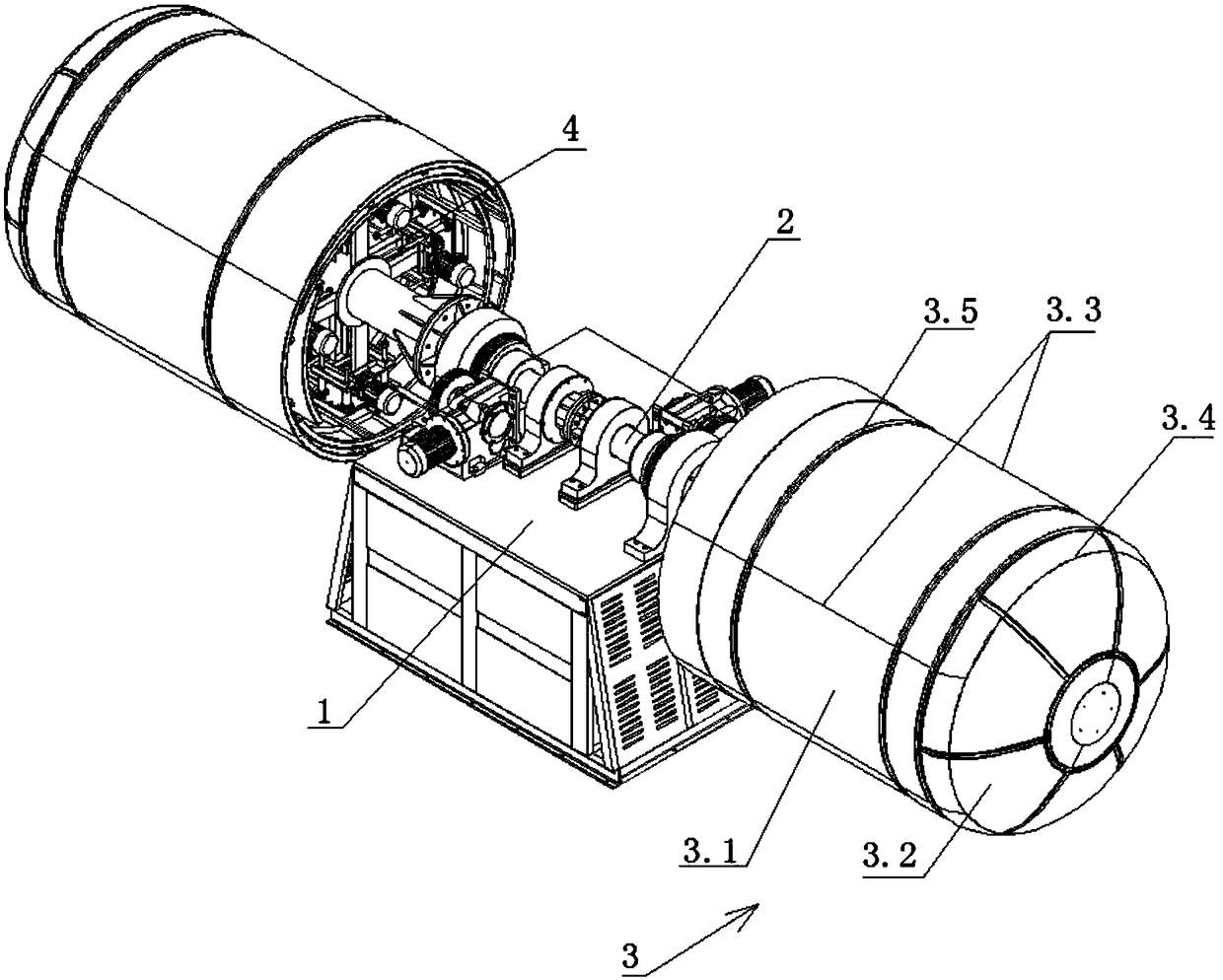

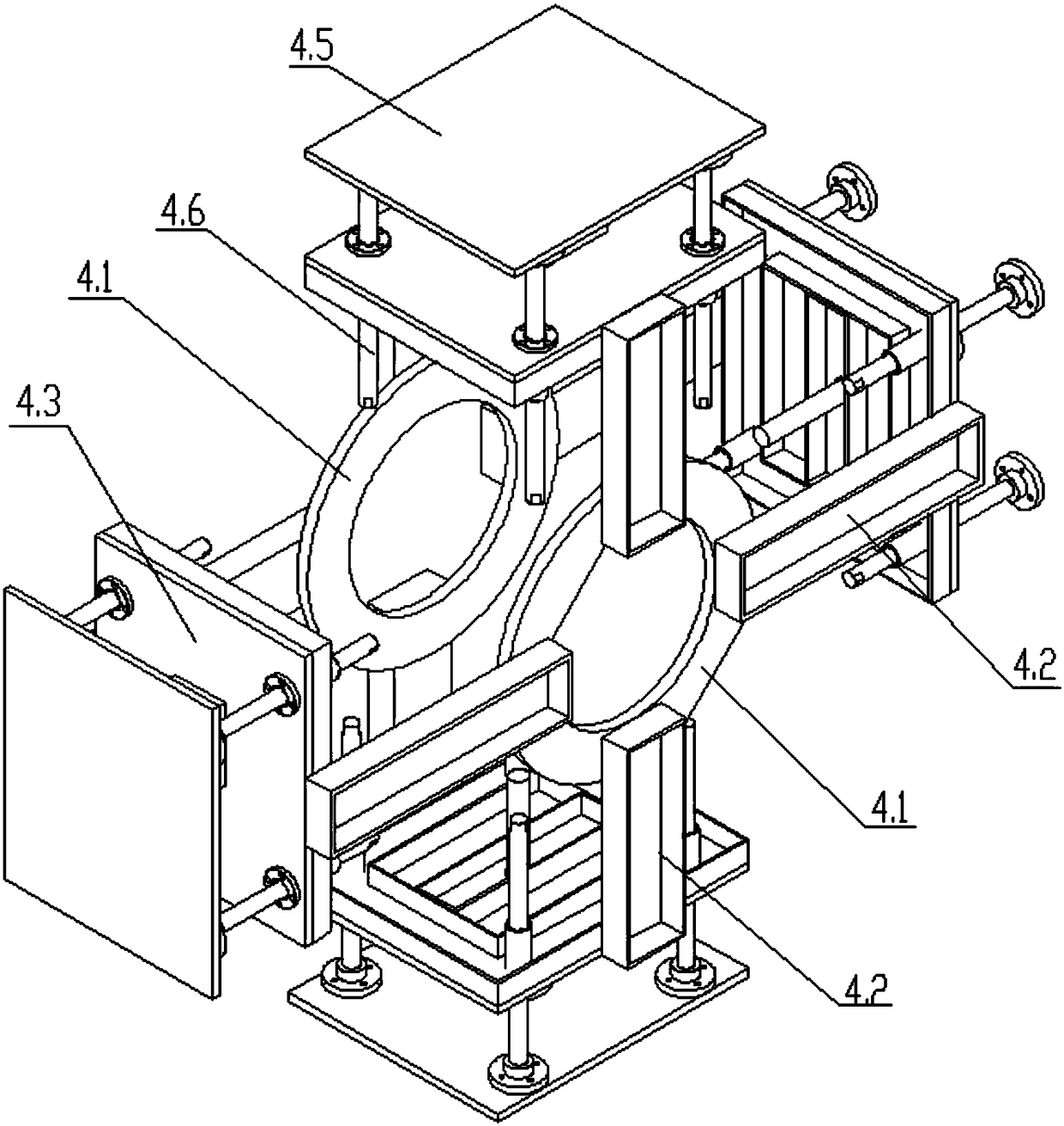

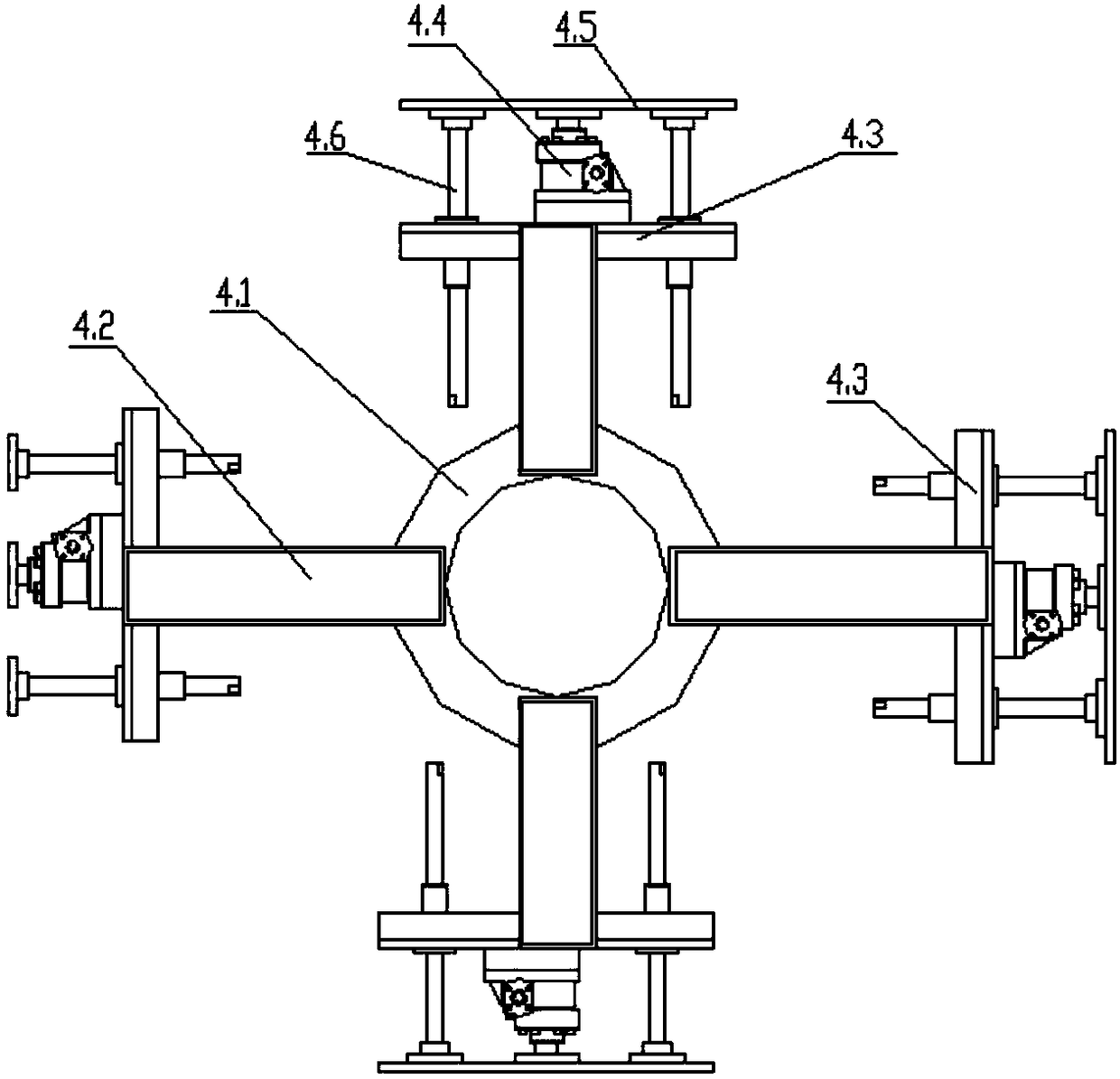

Preparation device of FRP container

InactiveCN109263084AQuick and efficient preparationEasy to demouldDomestic articlesEngineeringMechanical engineering

Owner:JIANGYIN FUREN HIGH TECH

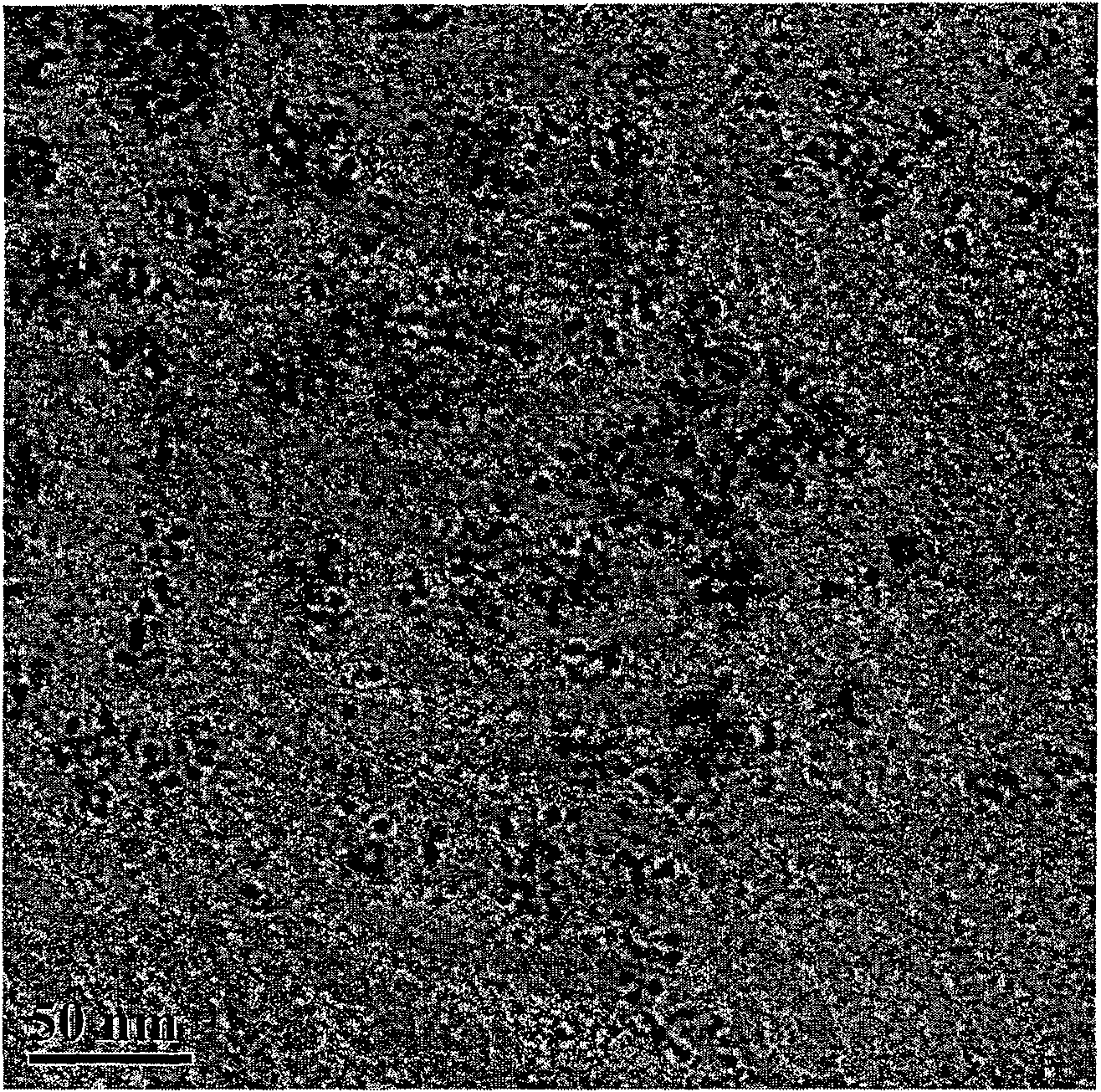

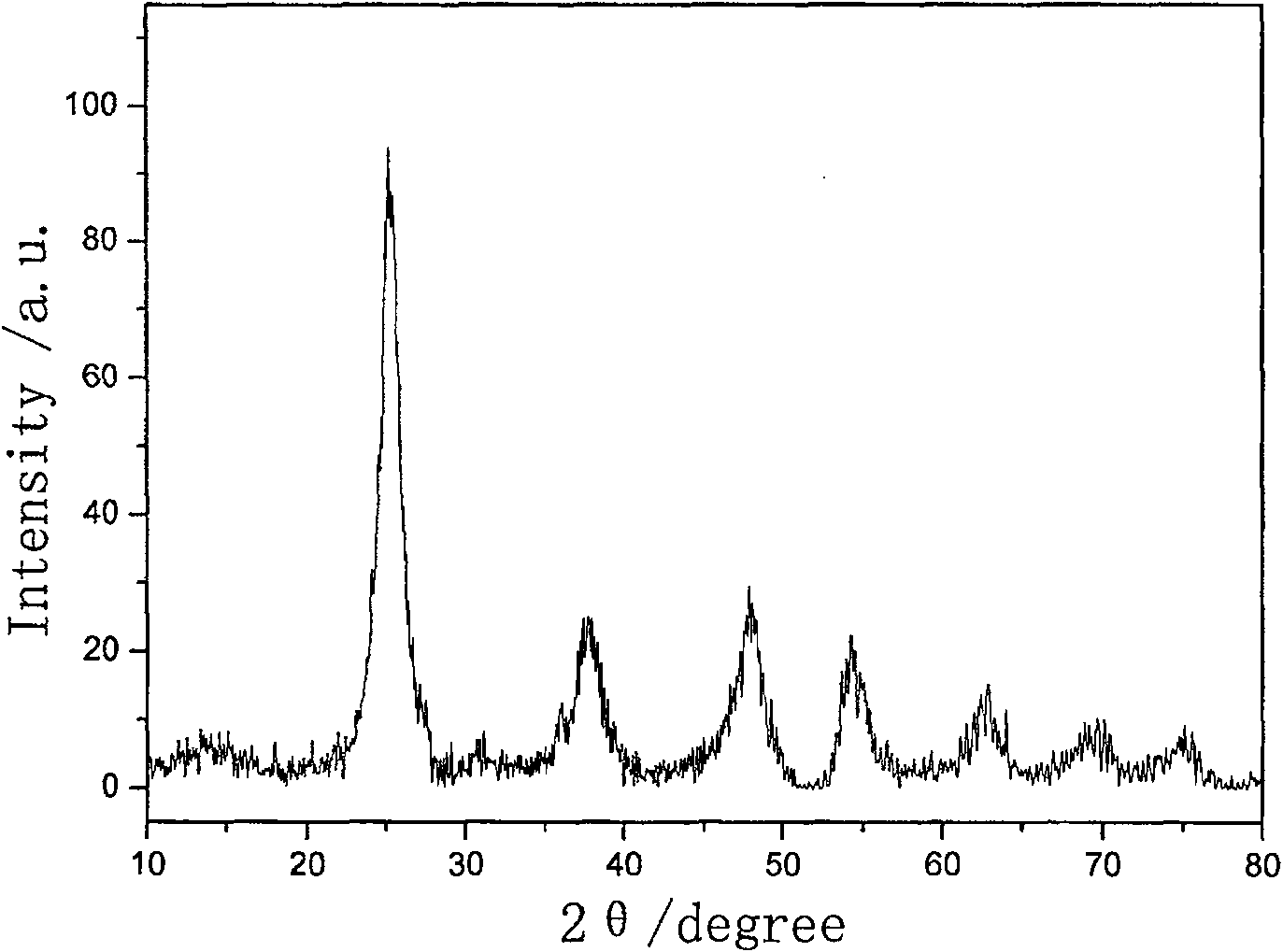

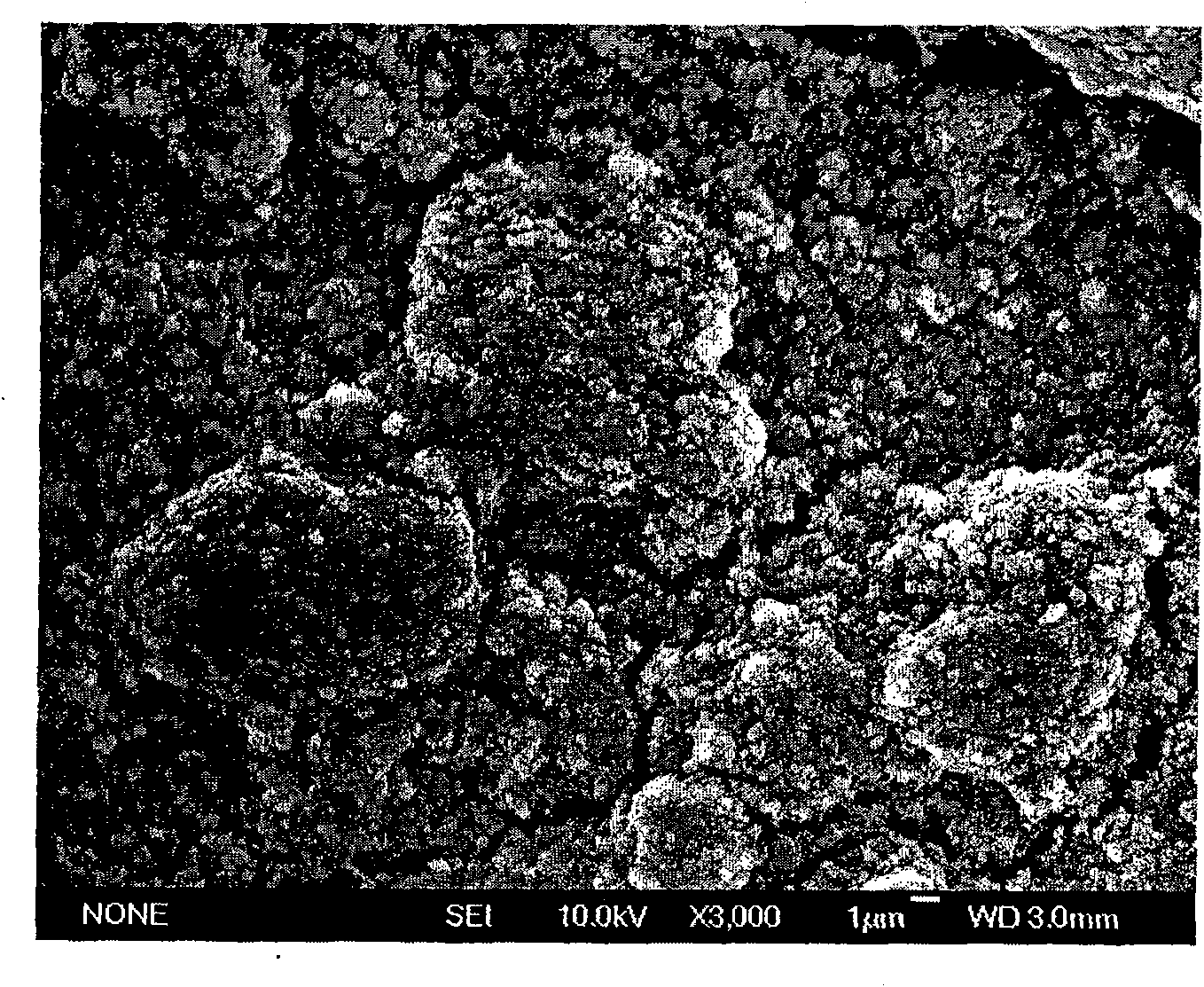

Production method for titanium oxide coating material in dye sensitized solar battery

ActiveCN100583463CUnprotectedQuick and efficient preparationElectrode manufacturing processesFinal product manufactureOrganic solventColloid

The present invention provides a preparation method of titania coating materials applied to the dye sensitization solar battery, which is characterized in that organic titanium alkoxide is adopted as the predecessor body, the colloid of TiO2 that is stably distributed is prepared through the hydrolysis reaction of the organic titanium alkoxide. Organic polybasic acid is added into the colloid of TiO2 to adjust the pH value to be the subacidity (5.5-6.5), the organic residual substances in the colloid of TiO2 is filtered and removed by washing with vast organic solvent. Appropriate amount of industrial viscous agent is added into the clean TiO2 colloid after being washed to be grinded and mixed uniformly at a high speed so as to produce the titania coating material of the dye sensitization solar battery. The present invention has the obvious advantages of simple process, stable quality and friendly environment, and is a method that can be applied to prepare the titania coating material in large scale.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

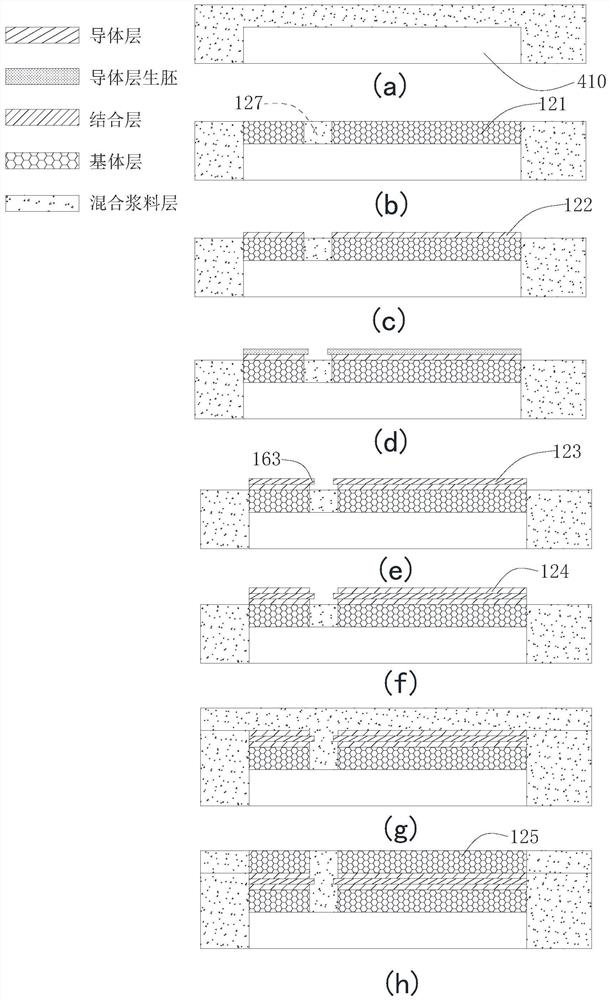

Three-dimensional structure electronic device, manufacturing method and device

PendingCN114226761AThe production process is efficient and fastLow costAdditive manufacturing apparatusLiquid surface applicatorsPhysicsElectrically conductive

The invention relates to a three-dimensional structure electronic device and a manufacturing method and device, and the method comprises the following steps: S1, designing a three-dimensional model of the three-dimensional structure electronic device, and reserving a via hole position; s2, performing layering processing on the three-dimensional model; s3, the mixed slurry is laid on a workbench and cured to form a first base body layer, and a first conductor layer comprises a radiation structure formed at the position of the via hole; s4, spraying a binding agent on the first matrix layer to form a first binding layer; s5, spraying conductive slurry on the first bonding layer to form a first conductor layer; s6, spraying a binding agent on the first conductor layer to form a second binding layer; and S7, the steps S3-S6 are repeatedly executed until the nth conductor layer and the (n + 1) th substrate layer are completed, and the three-dimensional structure electronic device is obtained. And S8, cleaning the three-dimensional structure electronic device, and bending the radiation structure at the position of the via hole. By controlling the technological process, manufacturing of the structure-function integrated three-dimensional structure electronic device is achieved, and interconnection between conductor layers can be achieved without independently plating copper in the via hole.

Owner:杭州华遨科技有限公司

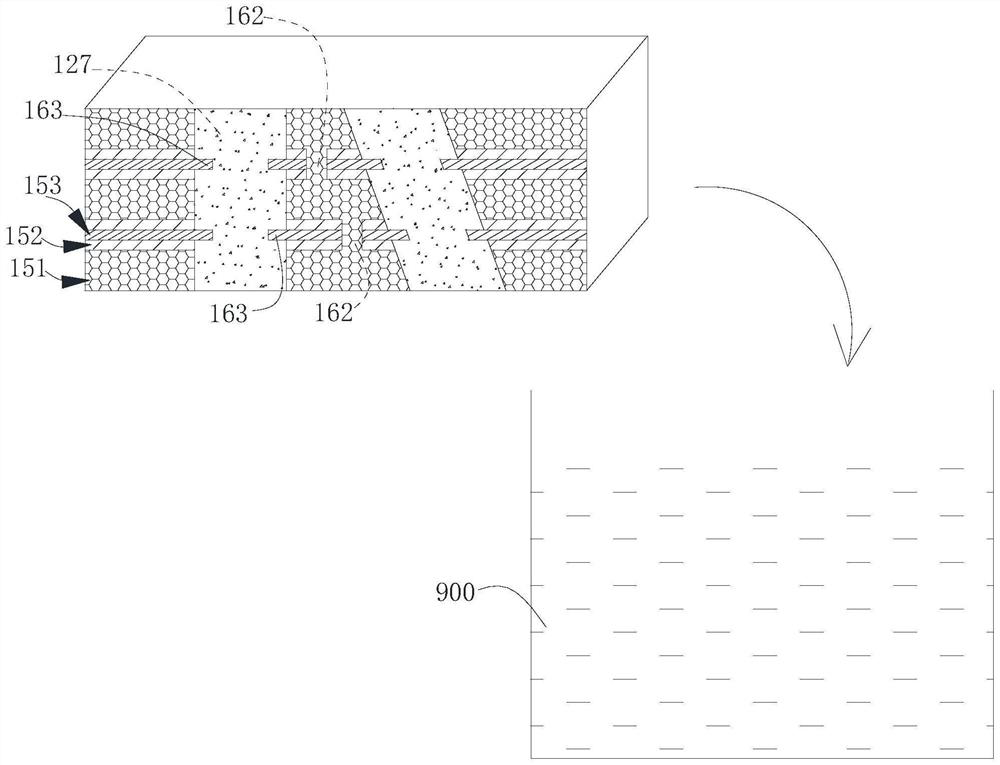

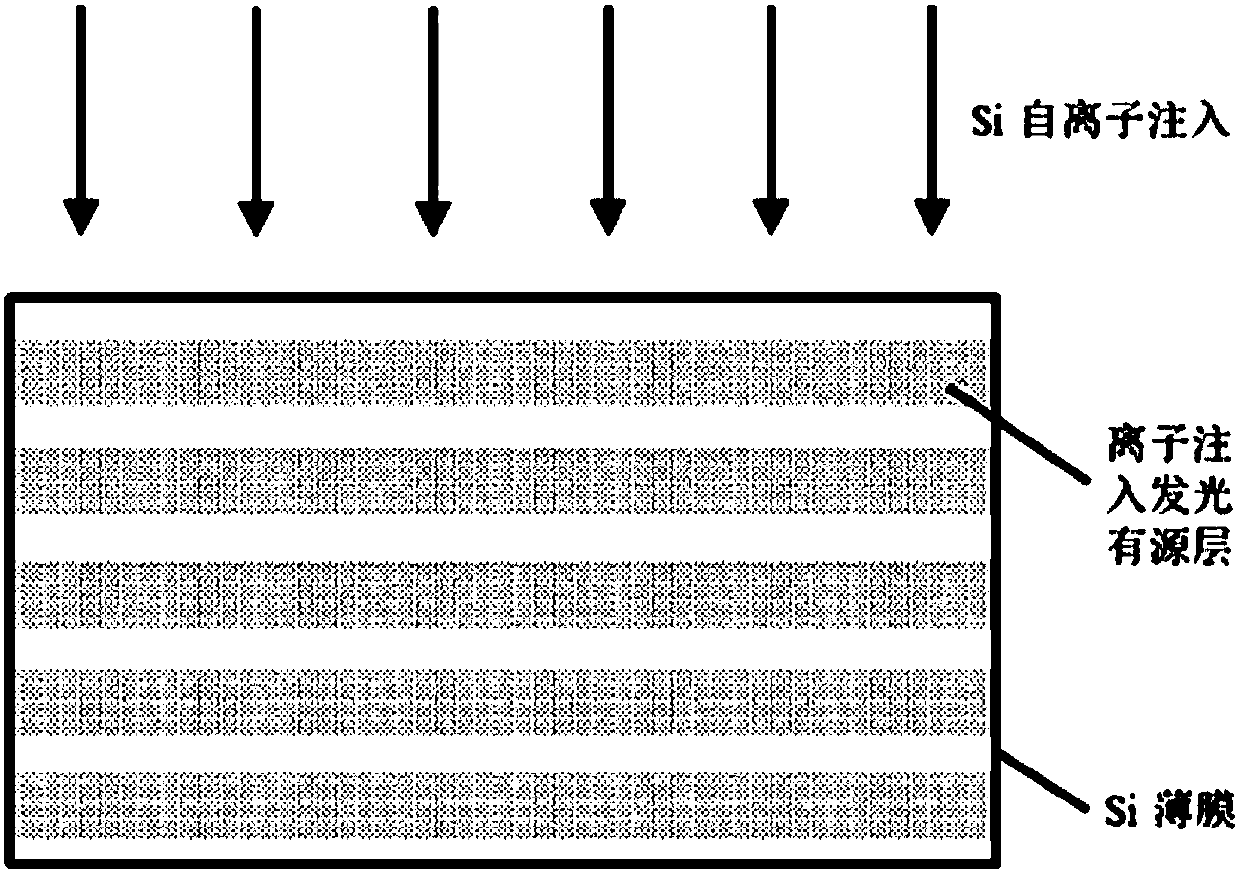

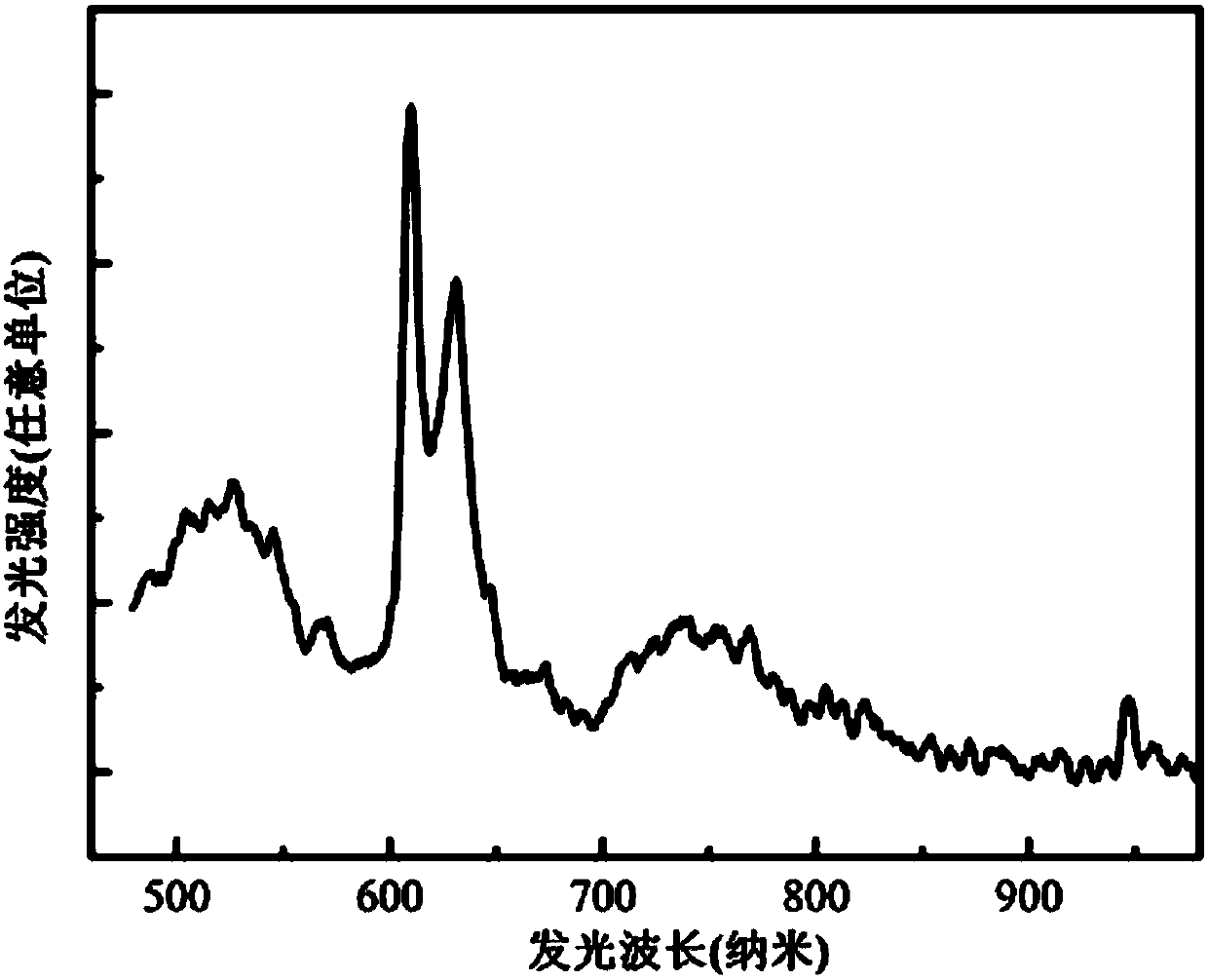

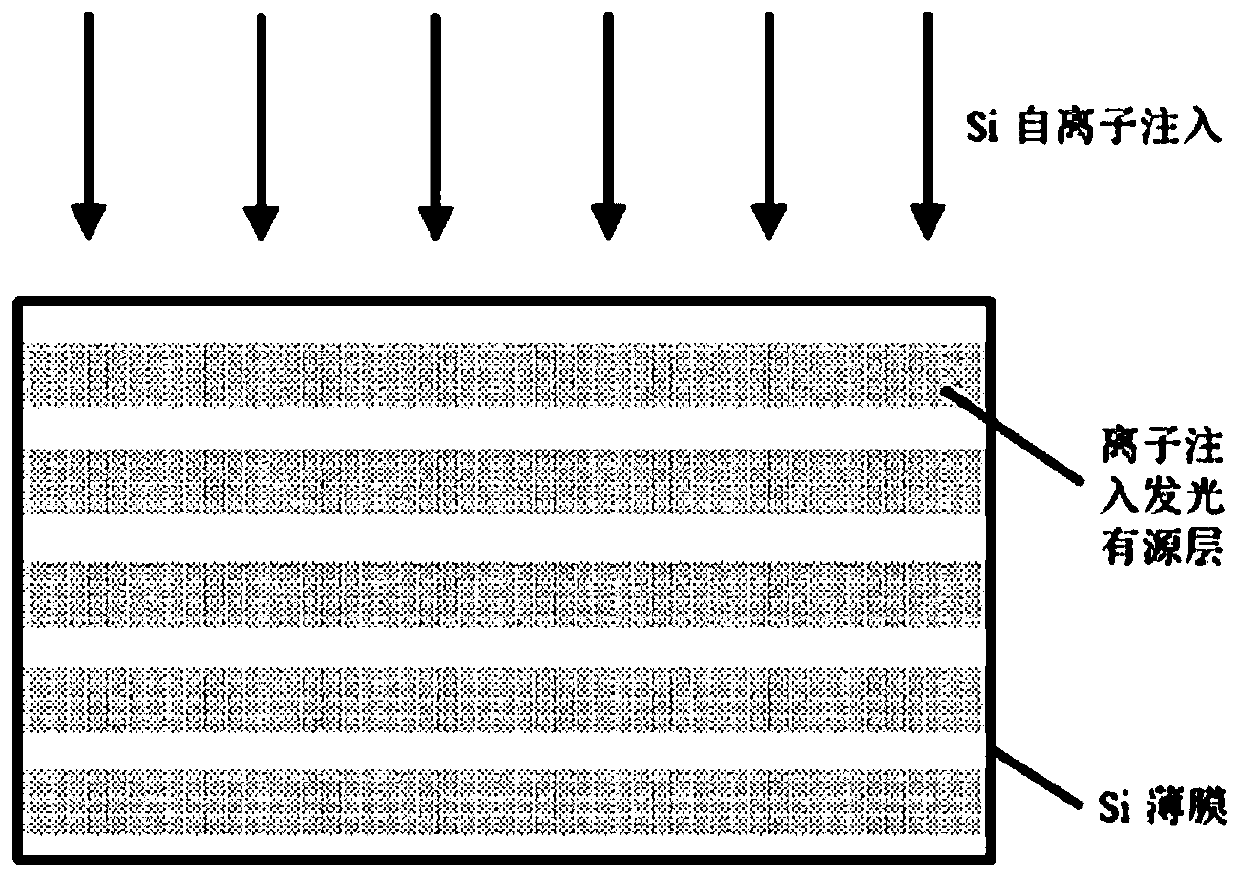

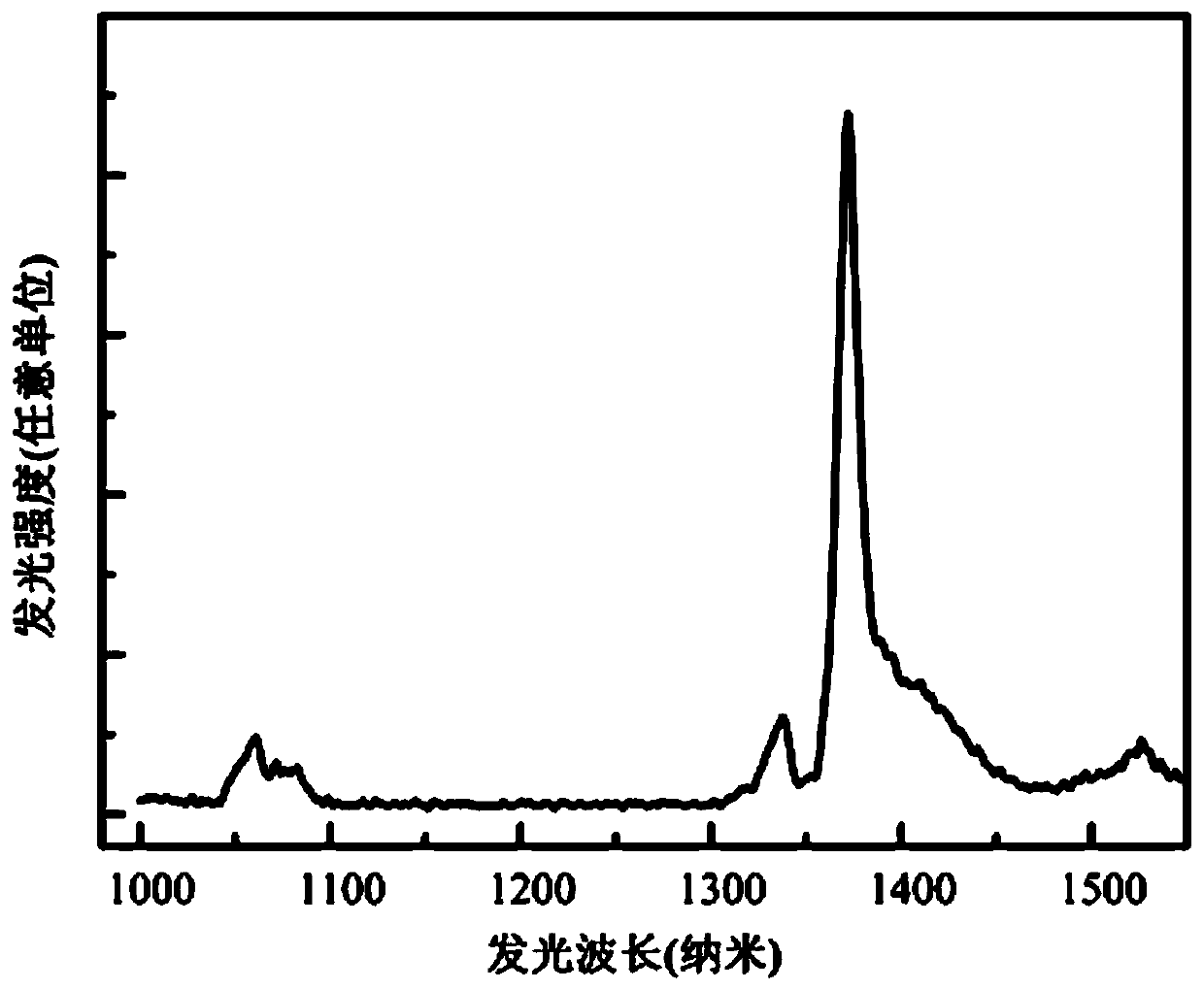

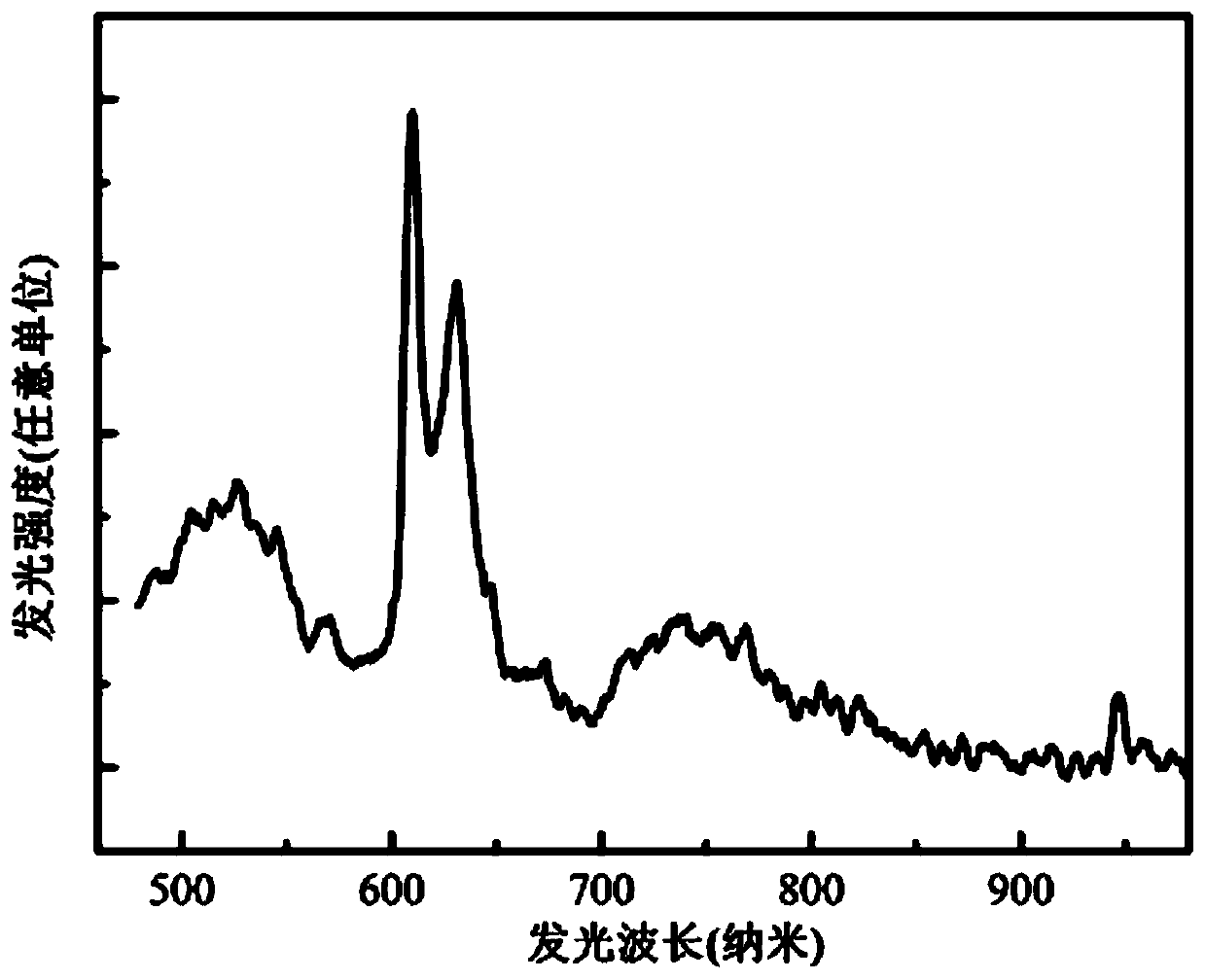

Method for improving light emitting performance by automatically injecting Si ions to silicon-based material

InactiveCN107611023AImprove luminous efficiencyImprove luminous performanceSemiconductor/solid-state device manufacturingFluorescenceOptoelectronics

The invention provides a method for improving light emitting performance by automatically injecting Si ions to a silicon-based material. Based on an ion injection and annealing technology, 3-5 times of Si automatic ion injection of different energy is performed on a silicon thin film of the silicon-based material which refers to an Si substrate or an SOI substrate with the cleaned surface; and next, different parameters of the conventional annealing or quick thermal annealing can be adjusted to obtain the silicon-based light emitting material with excellent light emitting performance. The method has the core that the ion injection technology is adopted, and Si automatic ion injection is performed at the same dosage in an energy gradual decreasing mode, so that ion injection active layer thickness is improved, and the silicon-based light emitting material with high light emitting efficiency, low fluorescence annihilating speed and high temperature stability is achieved.

Owner:YUNNAN UNIV

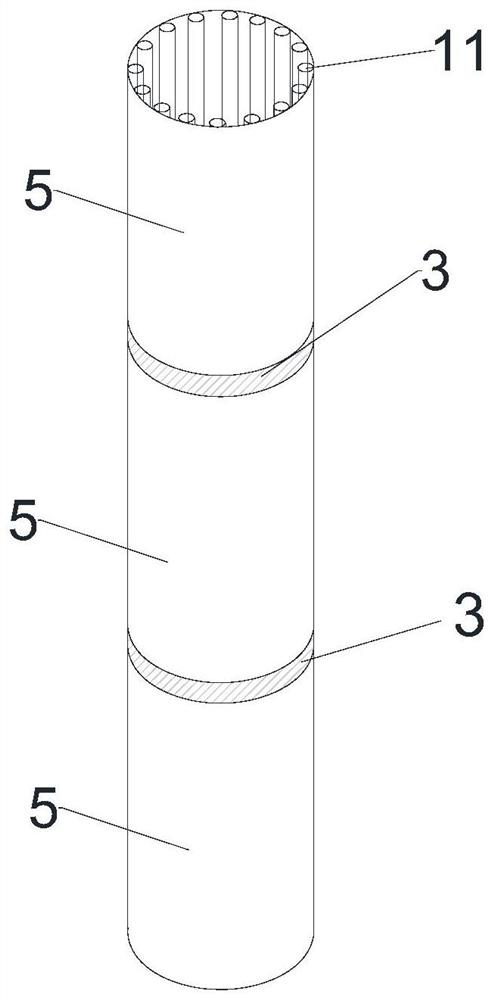

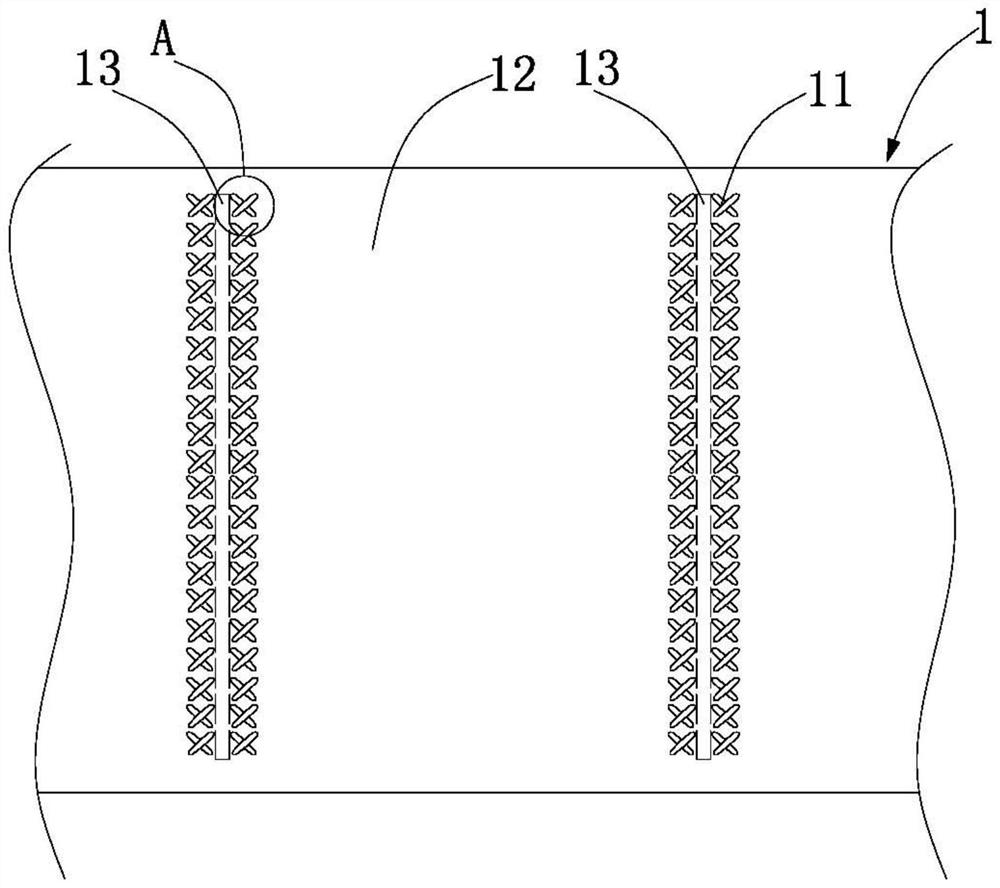

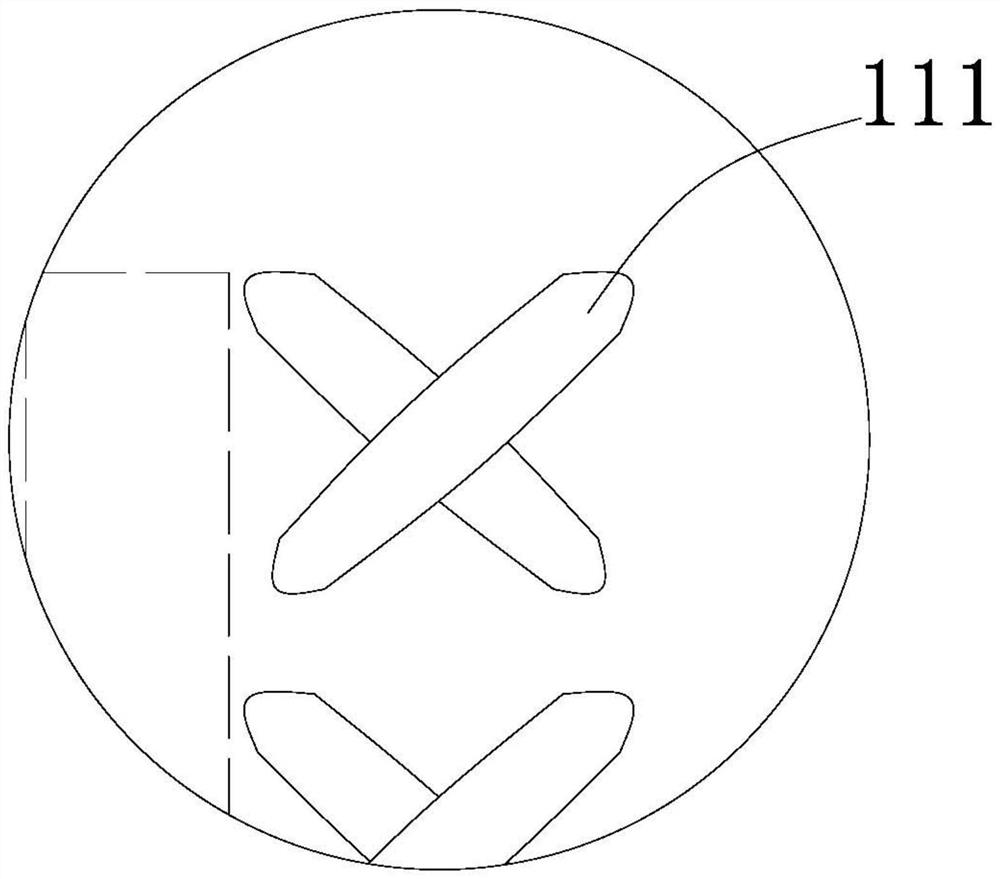

FRP (Fiber Reinforced Polymer) rib pipe and manufacturing method thereof

PendingCN113605605AIncrease ultimate bearing capacityImprove performanceBuilding reinforcementsTubular articlesFiberPolymer science

The invention discloses an FRP (Fiber Reinforced Polymer) rib pipe. The FRP rib pipe comprises an FRP impregnated fiber forming pipe, a plurality of FRP longitudinal ribs and a double-wall sleeve, wherein a longitudinal rib cylinder is defined by the plurality of FRP longitudinal ribs, every two adjacent longitudinal rib cylinders are connected through the double-wall sleeve, the longitudinal rib cylinders are installed on the inner wall of the FRP impregnated fiber forming pipe, the ends, far away from the double-wall sleeve, of the longitudinal rib cylinders are flush with the FRP impregnated fiber forming pipe, and the FRP impregnated fiber forming pipe is connected with the double-wall sleeve. According to the FRP rib pipe, the overall rigidity and lateral resistance can be greatly improved, and the FRP rib pipe is combined with a steel pipe and concrete, so that the ultimate bearing capacity of a combined structure column can be greatly improved, and the performance of FRP materials is fully exerted.

Owner:JINAN UNIVERSITY

Method for rapidly preparing metal device by using metal plates

The invention discloses a method for rapidly preparing a metal device by using metal plates. According to the method for rapidly preparing the metal device by using the metal plate, unified integratedmanagement is adopted for drawing, determining of the plates, machining of the plates and parts, materials are saved, the machining efficiency of the metal device is improved, and the utilization efficiency of the plates is improved. In conclusion, the method for rapidly preparing the metal device by using the metal plates is simple and reliable in process, the metal device is prepared efficiently and rapidly, the use cost of the metal plate is saved, and the use effect is better than that prepared in a traditional mode.

Owner:苏州全佳金属制品有限公司

A collagen microfiber hemostatic material and its preparation method and use method

ActiveCN112516377BSpray evenlyNo nozzle cloggingSurgical adhesivesPharmaceutical delivery mechanismBULK ACTIVE INGREDIENTLiver surgery

The invention relates to the field of biological materials, in particular to a collagen microfiber hemostatic material, a preparation method and a use method thereof. The solid collagen material undergoes high-speed shearing to obtain collagen microfibers. After dispersing the collagen microfibers in the water phase, the procoagulant active ingredients are modified on the surface of the collagen microfibers through linking molecules. Microfiber hemostatic material. Collagen microfiber materials can be easily and efficiently prepared by high-speed shearing, and the biological activity of collagen materials can be kept as much as possible; the length of microfibers ranges from 10um to 1000um, which has high dispersion and is conducive to spraying treatment. Linker molecules can efficiently and quantitatively load procoagulant active ingredients on the surface of collagen microfibrils to enhance their hemostatic effect. The collagen microfiber hemostatic material prepared by the present invention is used for hemostasis on oozing wounds by spraying, such as hemostasis during brain surgery or liver surgery, and can achieve the effect of non-contact fixed-point hemostasis.

Owner:QUANFENG TECH (SHENZHEN) CO LTD

A kind of interwoven braided shoe upper and its manufacturing method

ActiveCN112442787BIncrease elasticityOverlap weave structure is realWeft knittingTextile/flexible product manufactureStructural engineeringMechanical engineering

Owner:SINCETECH FUJIAN TECH CO LTD

A method for improving luminescence performance by self-ion implantation of Si into silicon-based materials

InactiveCN107611023BImprove luminous efficiencyImprove luminous performanceSemiconductor/solid-state device manufacturingFluorescenceSoi substrate

The invention provides a method for improving light emitting performance by automatically injecting Si ions to a silicon-based material. Based on an ion injection and annealing technology, 3-5 times of Si automatic ion injection of different energy is performed on a silicon thin film of the silicon-based material which refers to an Si substrate or an SOI substrate with the cleaned surface; and next, different parameters of the conventional annealing or quick thermal annealing can be adjusted to obtain the silicon-based light emitting material with excellent light emitting performance. The method has the core that the ion injection technology is adopted, and Si automatic ion injection is performed at the same dosage in an energy gradual decreasing mode, so that ion injection active layer thickness is improved, and the silicon-based light emitting material with high light emitting efficiency, low fluorescence annihilating speed and high temperature stability is achieved.

Owner:YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com