Collagen microfiber hemostatic material and preparation method and application method thereof

A technology of hemostatic material and collagen material, applied in the fields of application, pharmaceutical formulation, medical science, etc., can solve the problems of collagen biological activity and hemostatic effect, large size of collagen fiber, denaturation of collagen material, etc., to achieve efficient and fast preparation, hemostasis speed Fast, maintain biologically active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

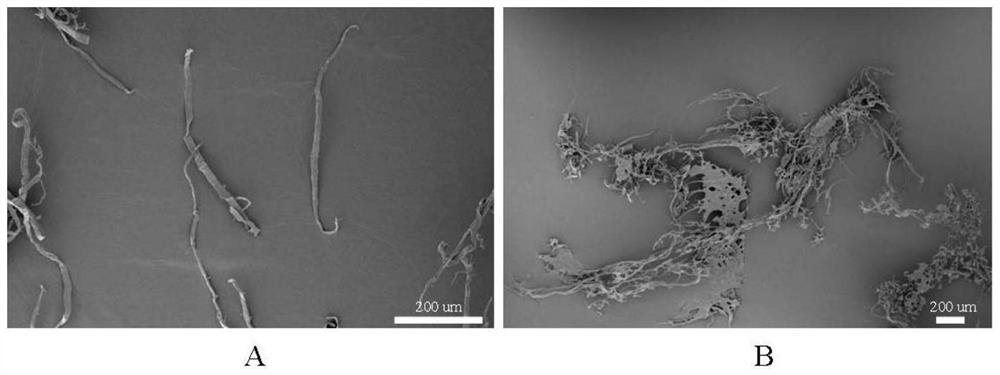

Image

Examples

Embodiment 1

[0035] A preparation method of collagen microfiber hemostatic material, wherein, comprising the following steps in sequence:

[0036] (1) High-speed shearing of 5 g of cross-linked collagen sheets on a high-speed pulverizer, wherein the speed of the high-speed pulverizer is 30000r / min, and the pulverization time is 30s;

[0037] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 500 g of deionized water to prepare a collagen microfiber suspension;

[0038] (3) Filtering the collagen microfiber suspension in step (2) step by step through a 30-150 mesh screen to obtain collagen microfiber raw materials with a length range of 100-500um, and disperse them in water to configure the collagen microfiber suspension;

[0039] (4) add 50mg fibrinogen and 2mg calcium chloride in step (3) collagen microfibril suspension;

[0040] (5) Add 5 mg of glutaraldehyde and 10 mg of NHS ester to the collagen microfibril suspension in step (4), and the reaction time is 30 ...

Embodiment 2

[0045] A preparation method of collagen microfiber hemostatic material, wherein, comprising the following steps in sequence:

[0046] (1) High-speed shearing of 10 g collagen film on a high-speed pulverizer, wherein the speed of the high-speed pulverizer is 20000r / min, and the pulverization time is 20s;

[0047] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 100,000 g of deionized water to prepare a collagen microfiber suspension;

[0048] (3) Filter the collagen microfiber suspension in step (2) step by step through a 16-40 mesh sieve, screen to obtain collagen microfiber raw materials with a length range of 400-1000um, and disperse them in water to configure the collagen microfiber suspension;

[0049] (4) Adding 0.5 mg prothrombinogen and 0.01 mg platelet cofactor I to the collagen microfibril suspension in step (3);

[0050] (5) Add 2g ethylene oxide and 1g proanthocyanidins to the collagen microfiber suspension in step (4), and the reaction ...

Embodiment 3

[0055] A preparation method of collagen microfiber hemostatic material, wherein, comprising the following steps in sequence:

[0056] (1) High-speed shearing of 2g of collagen sponge on a high-speed pulverizer, wherein the speed of the high-speed pulverizer is 60000r / min, and the pulverization time is 10s;

[0057] (2) uniformly dispersing the collagen microfiber raw material in step (1) in 500 g of deionized water to prepare a collagen microfiber suspension;

[0058] (3) Filtering the collagen microfiber suspension in step (2) step by step through a sieve of 80-1000 meshes to obtain collagen microfiber raw materials with a length range of 10-200um, and disperse them in water to configure the collagen microfiber suspension;

[0059] (4) Add 1 mg of prothrombinase to the collagen microfibril suspension in step (3);

[0060] (5) Add 0.02g carbodiimide and 5g genipin to the collagen microfiber suspension in step (4), and the reaction time is 120min;

[0061] (6) freeze-drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com