Production method for titanium oxide coating material in dye sensitized solar battery

A technology for solar cells and coating materials, applied in titanium dioxide, titanium oxide/hydroxide, electrode manufacturing, etc., can solve problems such as incomplete crystallization, large particle size of titanium oxide, unsuitable for screen printing process, etc., to achieve Quick response, good dispersibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

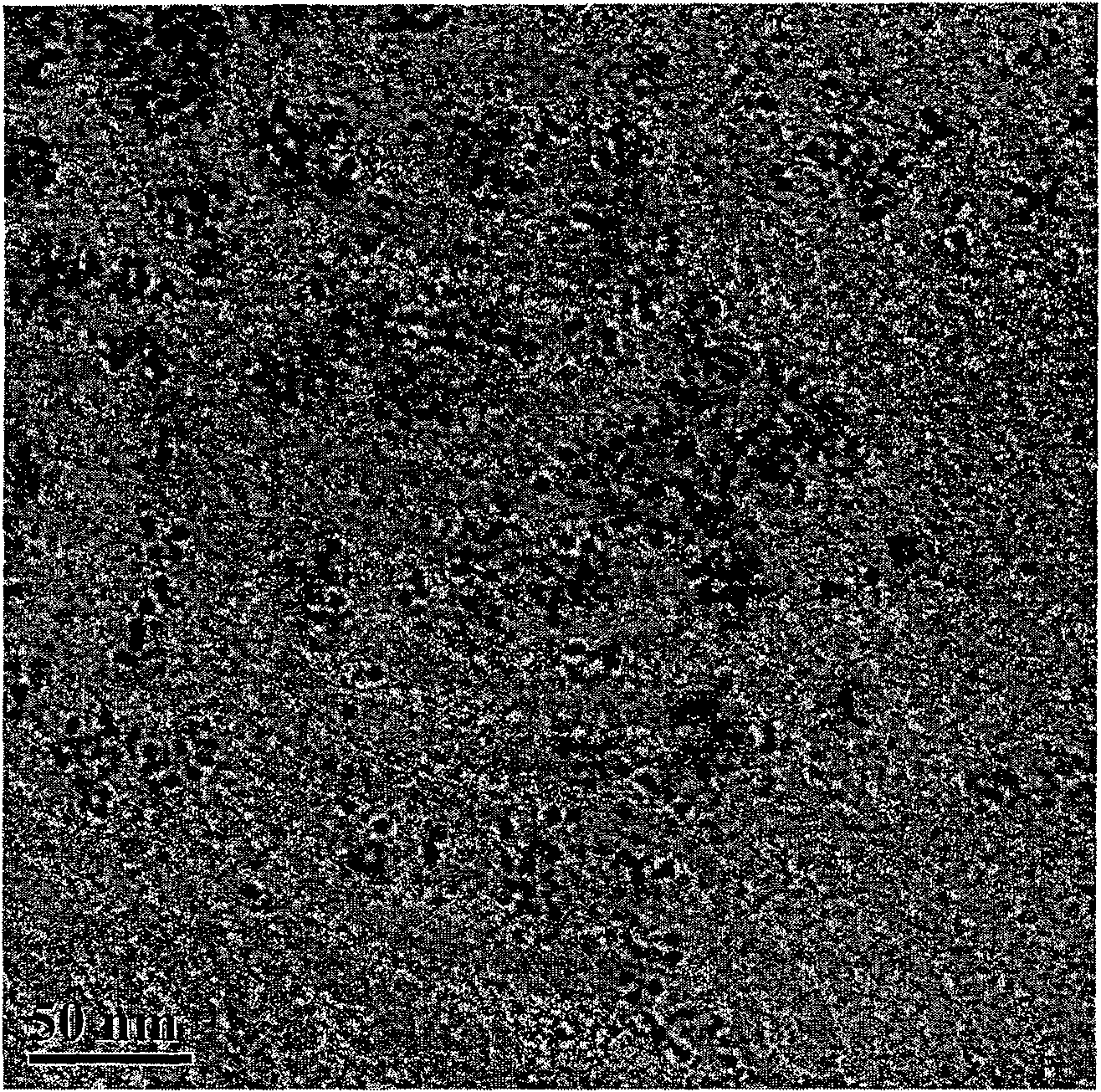

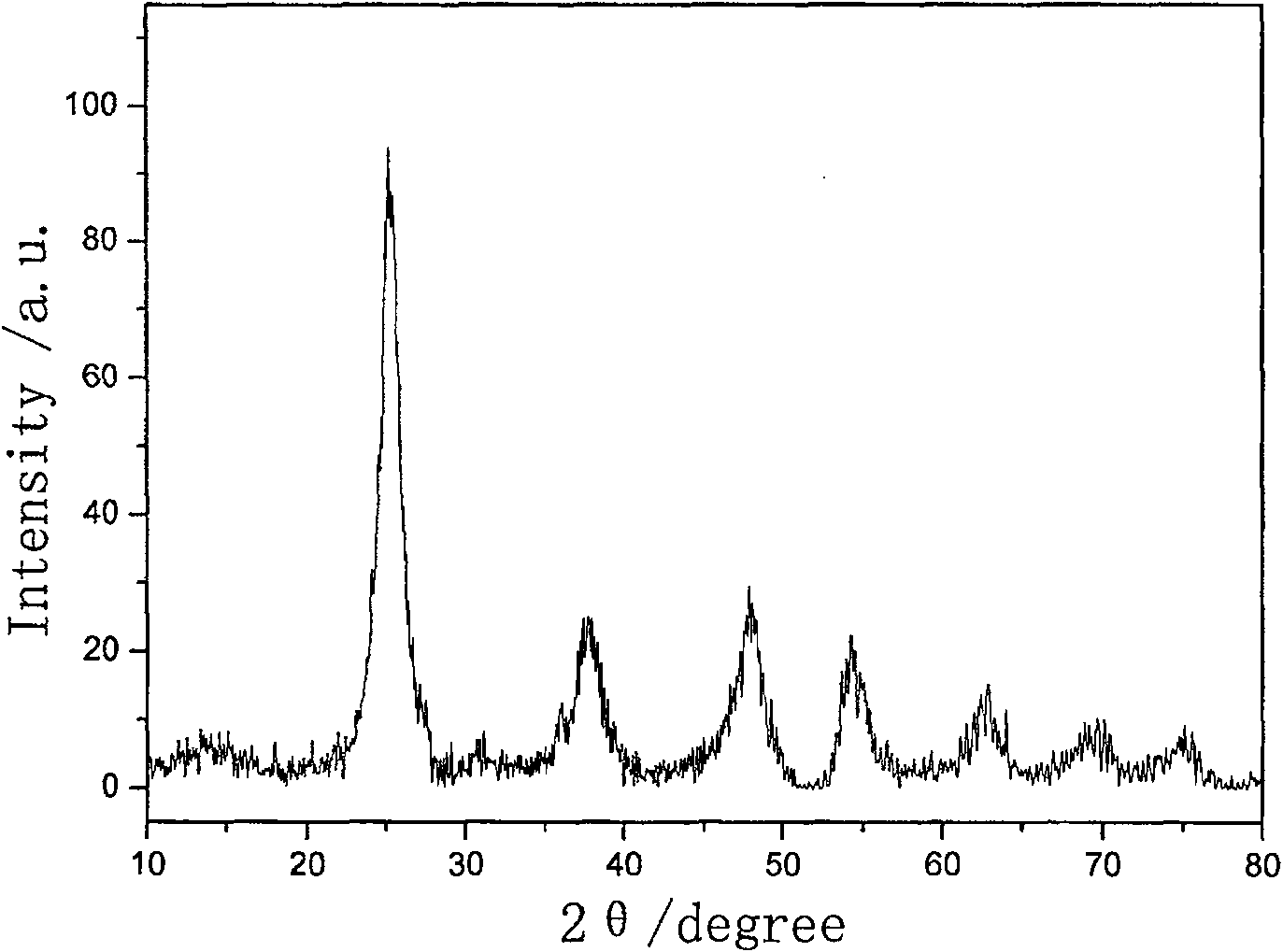

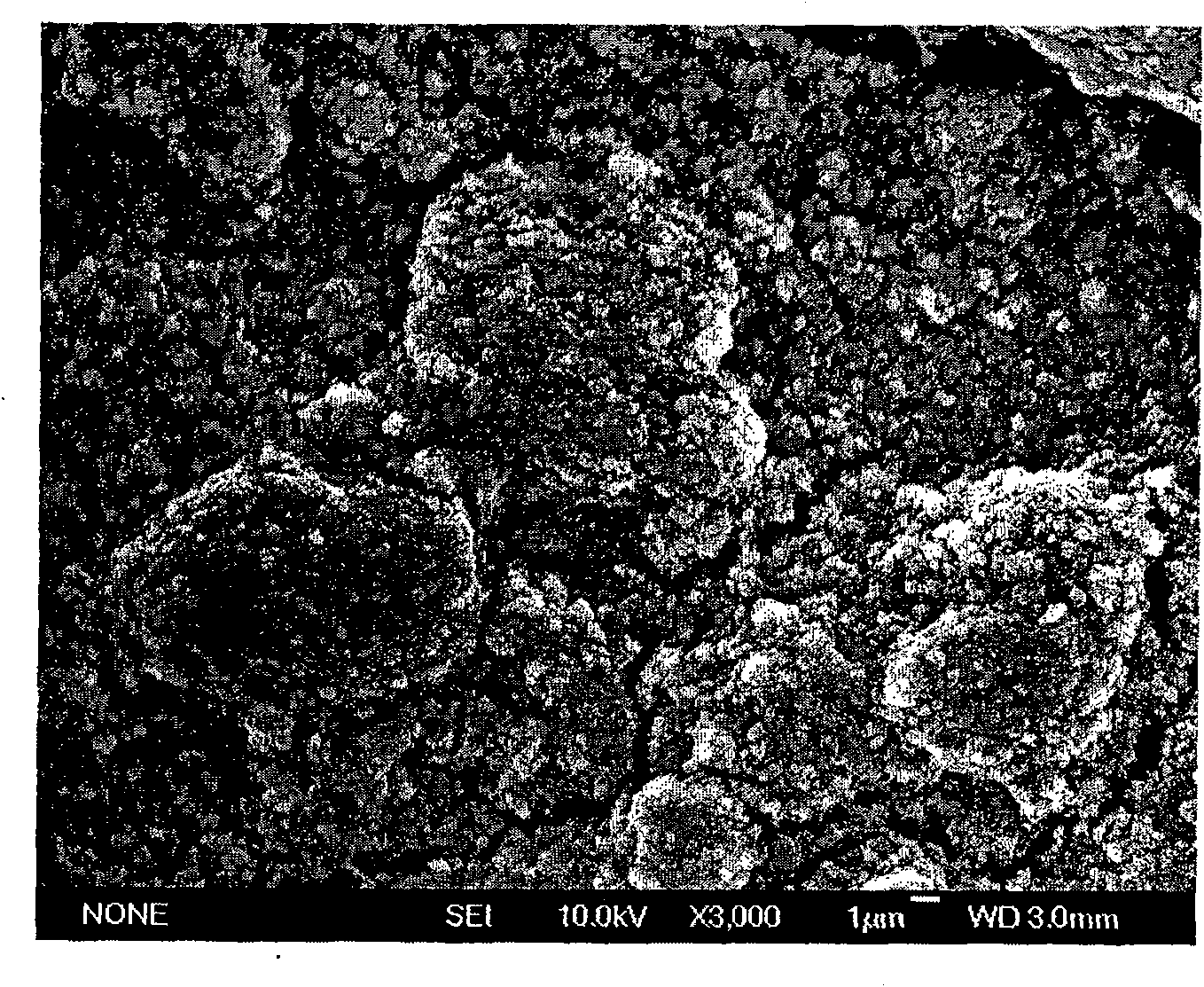

[0038]Firstly, solution A was prepared: 100 mL of n-butyl titanate was added to 200 mL of ethanol solution, and vigorously stirred to obtain a light yellow transparent solution. Slowly drop solution A into 2000 mL of pure water while vigorously stirring to form milky white sol B. Heat sol B to 90°C and keep it warm for 24 hours, add 200 mL of 3M citric acid, stir vigorously, filter and wash with pure water several times until the pH value of the filtrate is neutral, and white filter cake C is obtained. Dry the filter cake C in vacuum at 60°C, add the white loose powder obtained after drying to the ethanol solution of ethyl cellulose, wherein the weight ratio of ethyl cellulose to titanium oxide is 2:1, mix well and then add 200mL The terpineol was mixed by high-speed ball milling to obtain light yellow titanium oxide colloid D. Titanium oxide colloid D is distilled under reduced pressure to remove ethanol with a lower boiling point to obtain a specific concentration of high-v...

Embodiment 2

[0040] First prepare solution A: add 100mL of titanium isopropoxide to 300mL of ethanol solution, stir vigorously to obtain a clear and transparent solution. Slowly drop solution A into 3000 mL of pure water while vigorously stirring to form milky white sol B. Heat sol B to 90°C and keep it warm for 24 hours, add 300 mL of 3M acetic acid, stir vigorously, filter and wash with pure water several times until the pH value of the filtrate is neutral, and white filter cake C is obtained. Dry the filter cake C in vacuum at 60°C, add the white loose powder obtained after drying to the ethanol solution of ethyl cellulose, wherein the weight ratio of ethyl cellulose to titanium oxide is 2:1, mix well and then add 200mL The terpineol was mixed by high-speed ball milling to obtain light yellow titanium oxide colloid D. Titanium oxide colloid D is distilled under reduced pressure to remove ethanol with a lower boiling point to obtain a specific concentration of high-viscosity titanium ox...

Embodiment 3

[0042] Firstly, solution A was prepared: 100 mL of n-butyl titanate was added to 200 mL of ethanol solution, and vigorously stirred to obtain a light yellow transparent solution. Slowly drop solution A into 2000 mL of pure water while vigorously stirring to form milky white sol B. Heat sol B to 90°C and keep it warm for 24 hours, wash and filter several times with 2000 mL of ethanol-benzene mixture directly to obtain white filter cake C. Dry the filter cake C in vacuum at 60°C, and add the ethanol solution of ethyl cellulose after pulverizing the agglomerated matter obtained after drying, wherein the weight ratio of ethyl cellulose to titanium oxide is 2:1, and mix well Then add 200 mL of terpineol, and mix evenly by high-speed ball milling to obtain light yellow titanium oxide colloid D. Titanium oxide colloid D is distilled under reduced pressure to remove ethanol with a lower boiling point to obtain a specific concentration of titanium oxide coating material. The photoele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com