bmc mesh speaker mask containing wood fiber and its injection molding process

An injection molding process and wood fiber technology, applied in electrical components, sensors, etc., can solve the problems of poor processing methods, low production efficiency, and unenvironmental protection, and achieve the effects of low cost, less labor hours, and production cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0021] The technical scheme of concrete implementation of the present invention is:

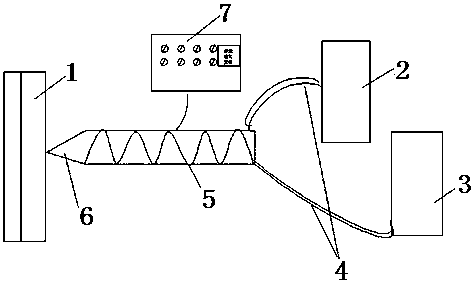

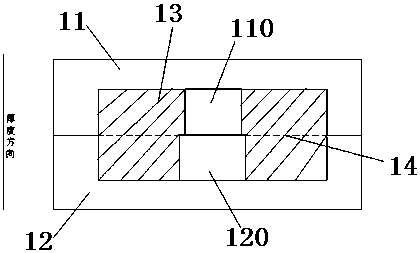

[0022] Such as figure 1 , figure 2 As shown, the present invention provides a BMC mesh speaker mask containing wood fiber, which is injection molded by BMC plastic and wood fiber, and the mesh of the mesh speaker mask is a through hole.

[0023] The present invention also provides the injection molding process of the above-mentioned BMC mesh speaker mask containing wood fiber, comprising the steps of:

[0024] 1) Clean the mold 1, evenly apply a release agent on the inner surfaces of the upper and lower molds 11 and 12, and then close the mold; the release agent is ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com