Preparation device of FRP container

A preparation device, a technology of glass fiber reinforced plastics, which is applied to household components, household appliances, and other household appliances, etc., can solve problems such as insufficient strength, and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

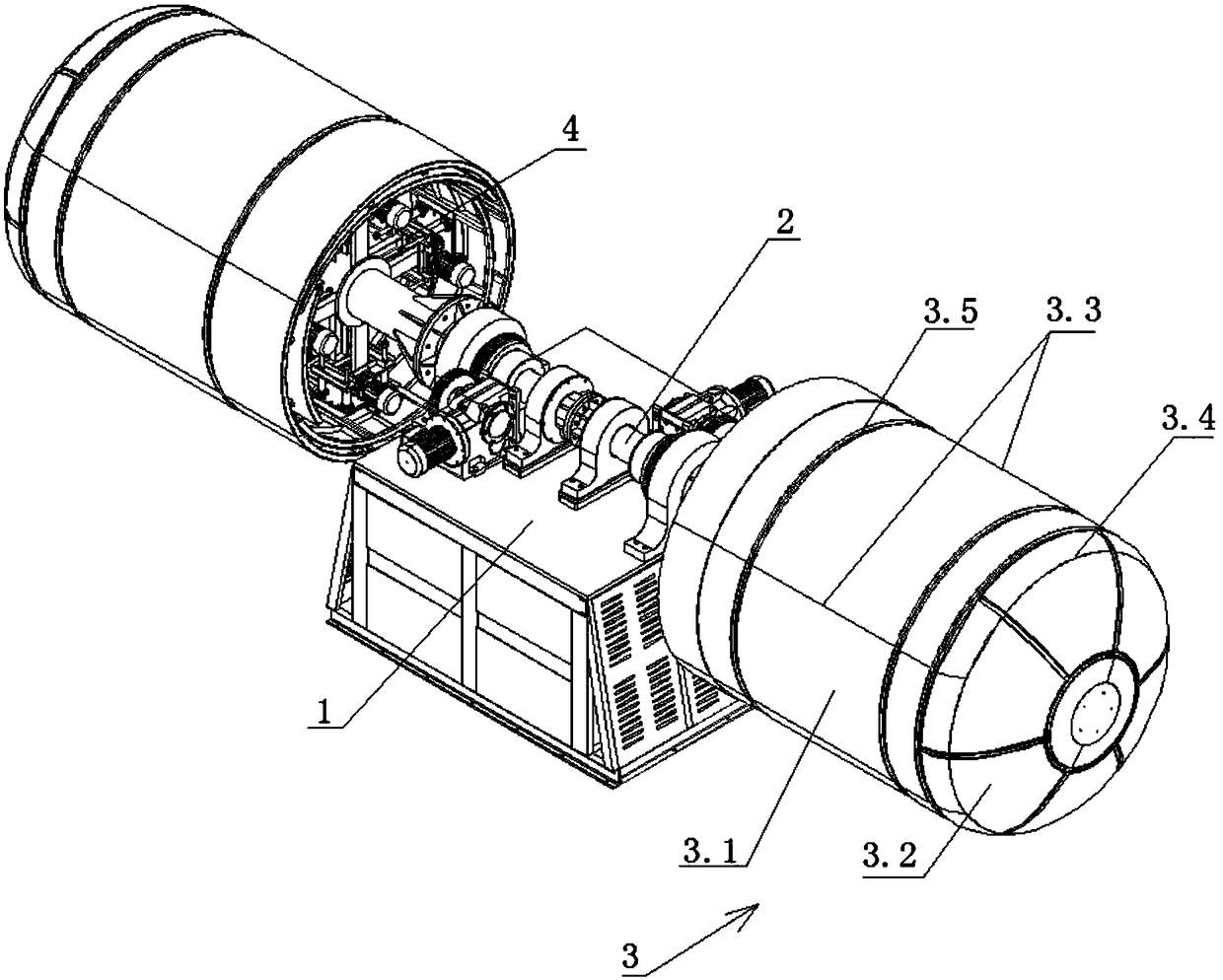

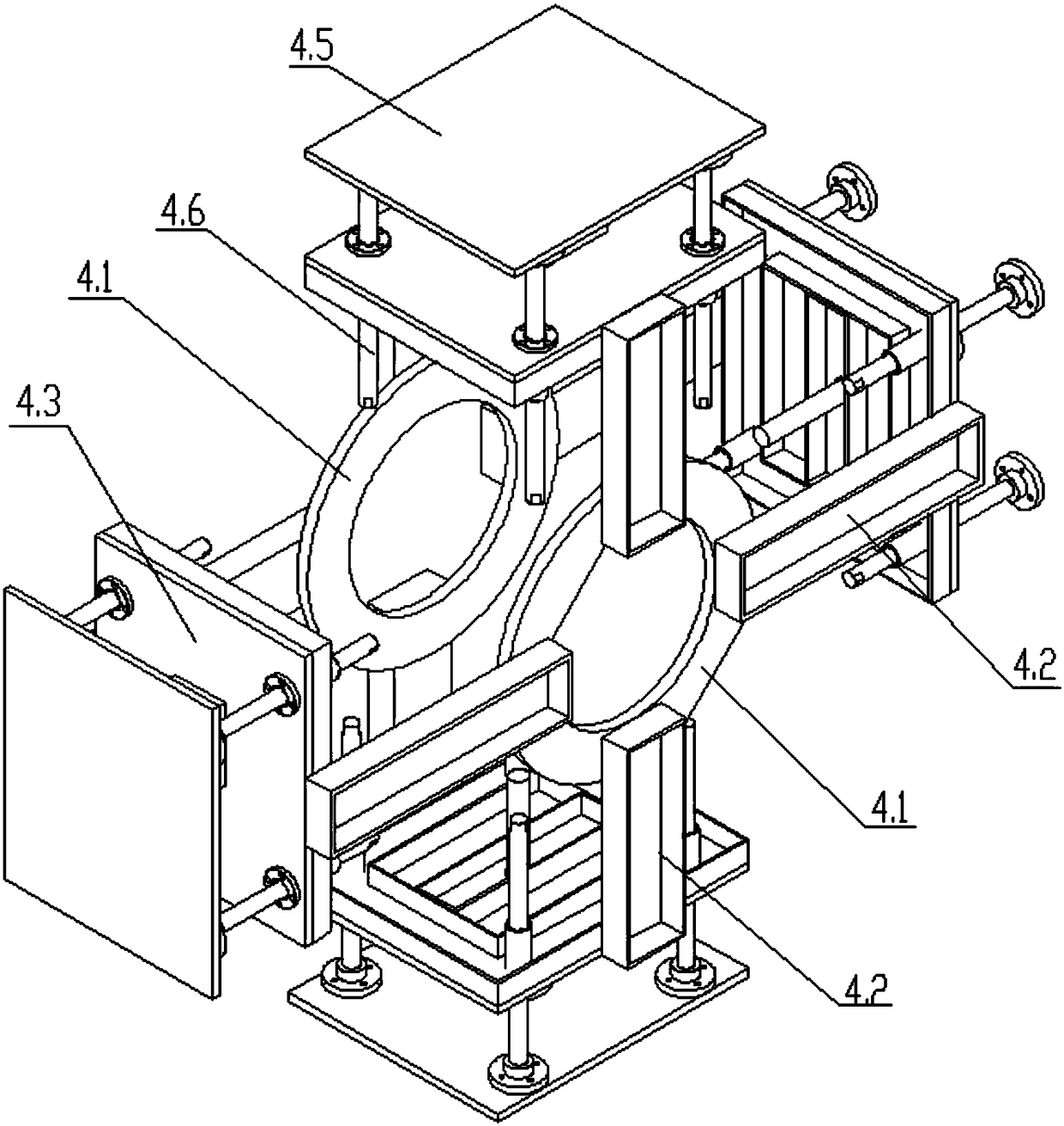

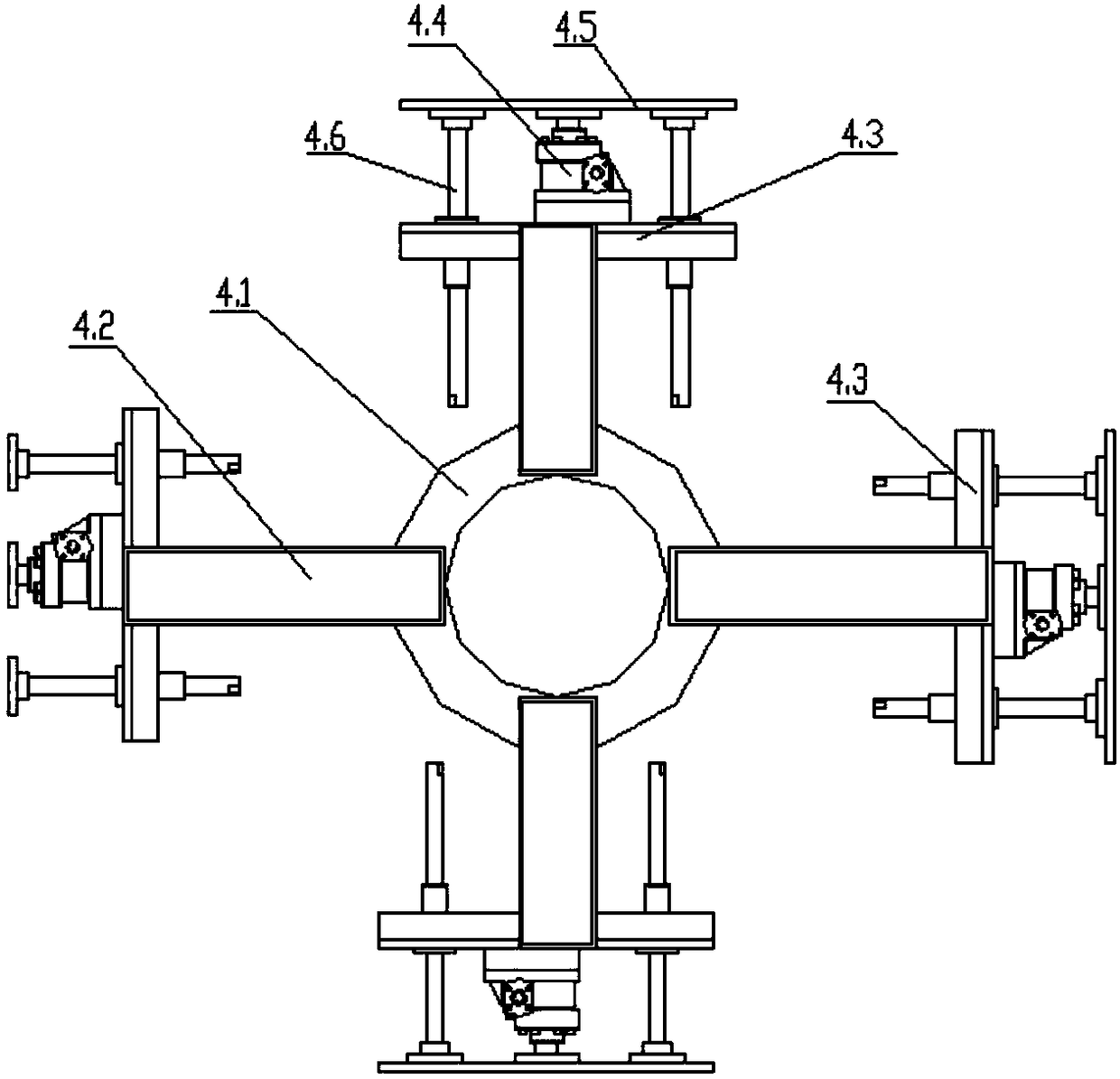

[0018] see Figure 1~4 , a kind of glass fiber reinforced plastic container preparation device that the present invention relates to, and described device comprises support 1, and is installed on support 1 two rotating main shafts 2 driven by power mechanism, and described rotating main shaft 2 is sleeved with a plurality of demoulding Lifting mechanism 4, the mold demoulding lifting mechanism 4 is covered with a forming mold 3, the forming mold 3 includes a cylinder mold and a head top mold 3.2, and the cylinder mold is composed of a plurality of cylinder templates 3.1 along the cylinder mold The axial splicing seam 3.3 is spliced, and the top of the cylinder formwork 3.1 is an inward arc section, and the diameter of the top opening end of the cylinder mold formed by splicing the cylinder formwork 3.1 is smaller than that of the cylinder section of the cylinder mold The diameter of the head top mold 3.2 is spliced with the top open end of the cylinder mold, and an annular j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com