FRP (Fiber Reinforced Polymer) rib pipe and manufacturing method thereof

A manufacturing method and reinforced pipe technology, which are applied in the field of construction engineering technology and conforming materials, can solve the problems of poor lateral force resistance, low precision, and low manufacturing process efficiency, and achieve the improvement of ultimate bearing capacity, reasonable structural design, and high manufacturing efficiency. Efficient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The purpose of the invention of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

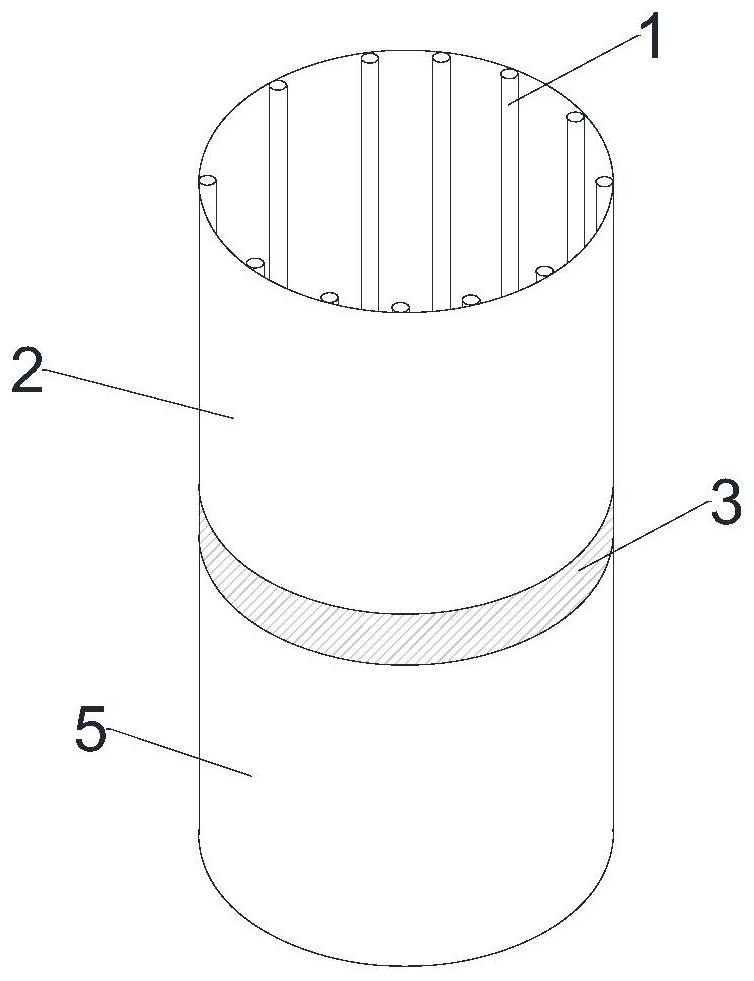

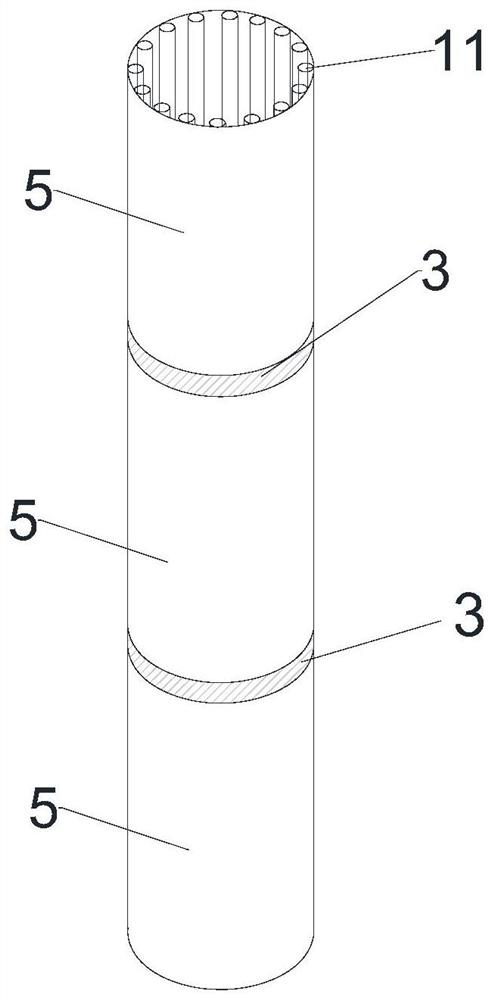

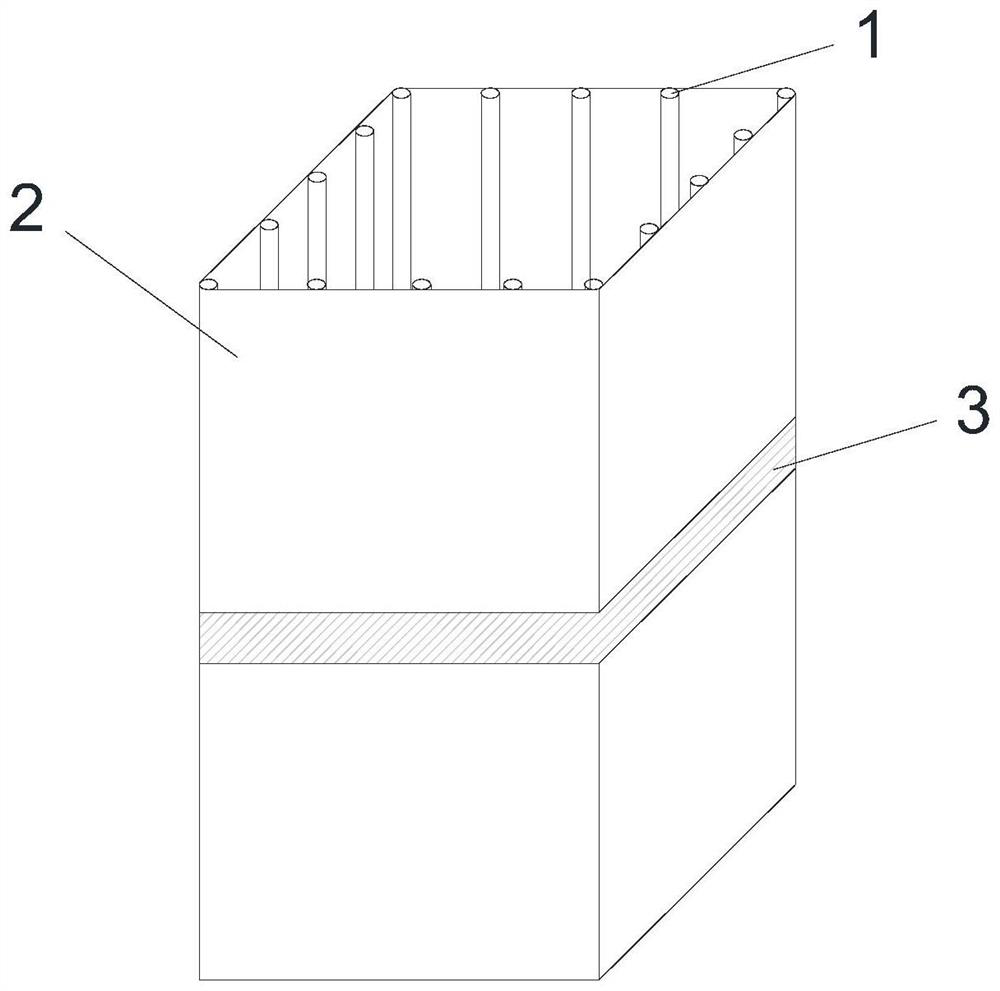

[0032] FRP tendon tube, including FRP fat-impregnated fiber forming tube 2, multiple FRP longitudinal ribs 11 and double-wall casing 3, multiple FRP longitudinal ribs 11 form a longitudinal rib tube 1, and two adjacent longitudinal rib tubes 1 pass through double-wall casings. The wall sleeve 3 is connected, and the longitudinal rib tube 1 is installed on the inner wall of the FRP fat-impregnated fiber forming tube 2 to form a longitudinal rib fiber tube 5. The end of the longitudinal rib fiber tube 5 close to the double-wall sleeve 3 is exposed with a longitudinal rib tube 1, and the exposed The longitudinal rib tube 1 is used to be inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com