A kind of interwoven braided shoe upper and its manufacturing method

A manufacturing method and technology for shoe uppers, applied in textile/flexible product manufacturing, knitting, shoe uppers, etc., can solve the problems of unreal and beautiful structure, short service life, single function, etc., achieve rich functions, long service life, increase elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

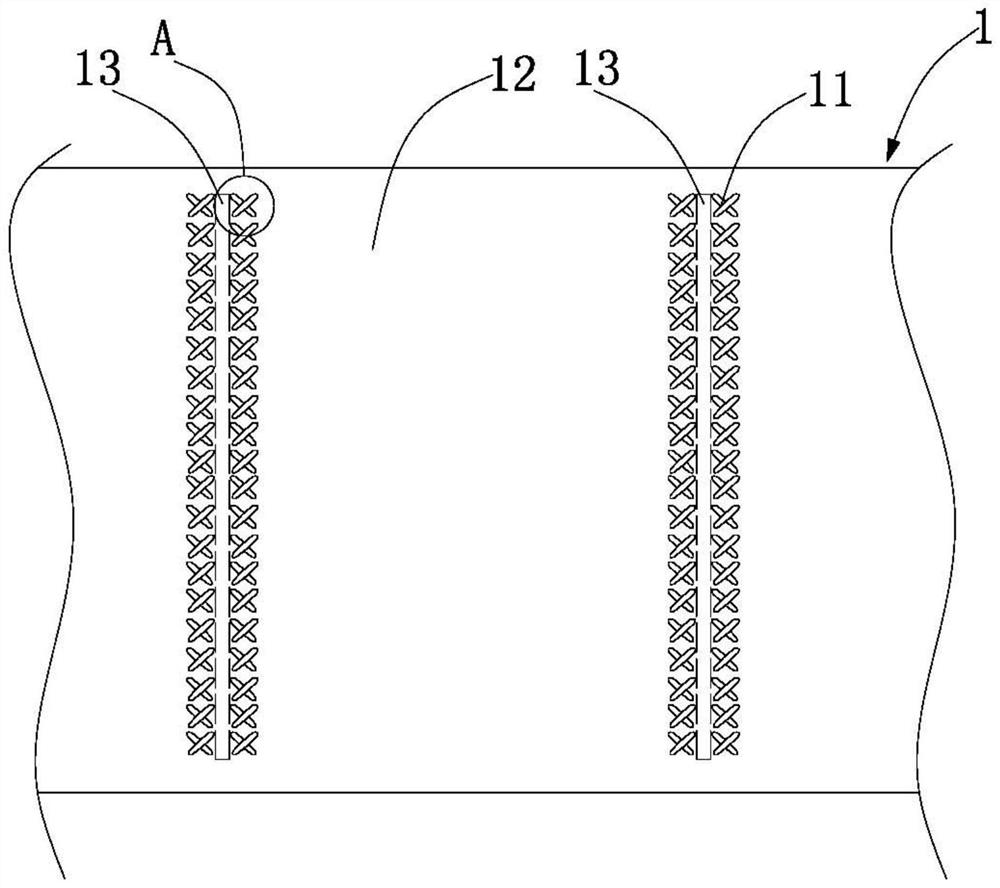

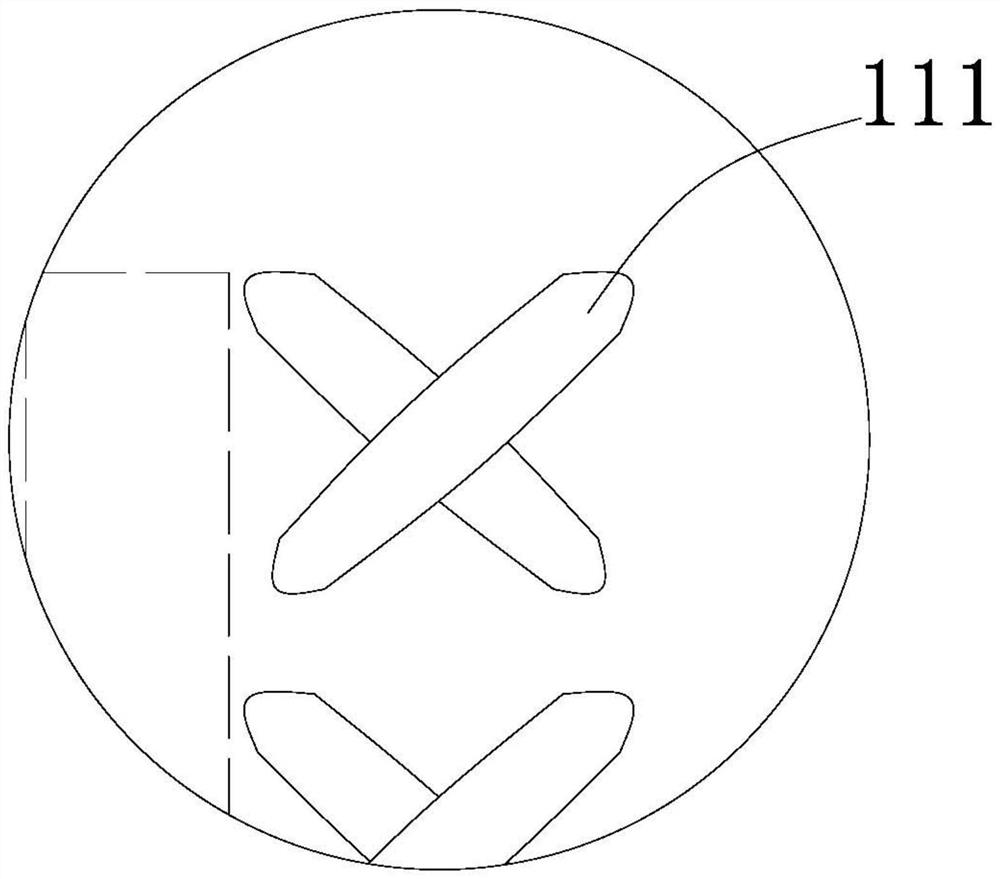

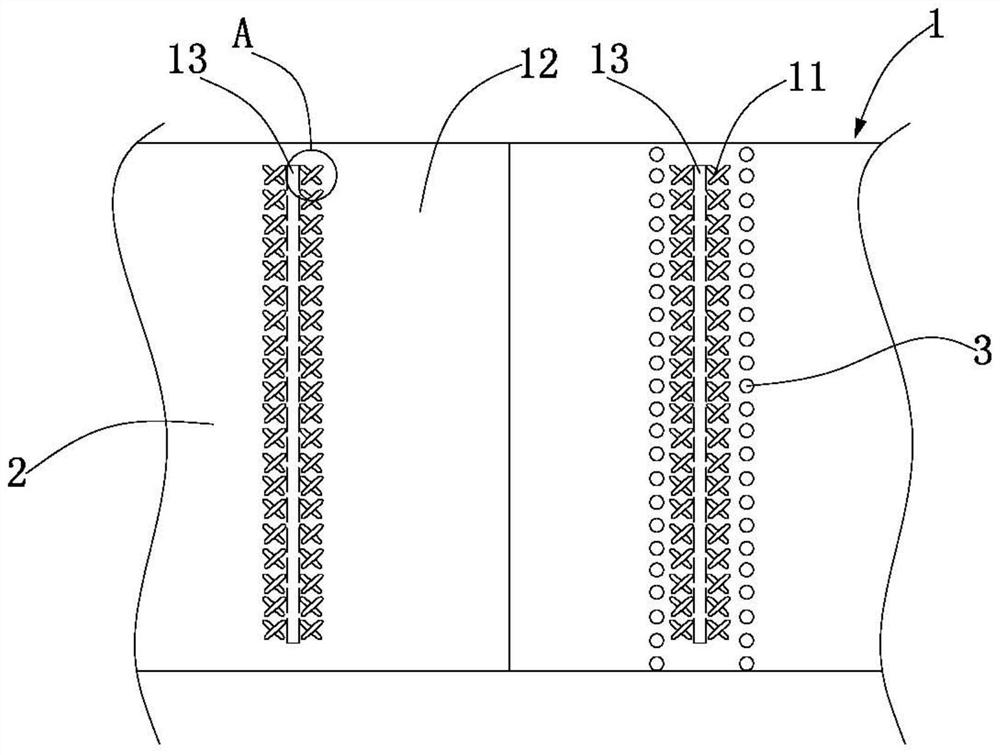

[0084] This embodiment discloses an interwoven woven shoe upper, refer to Figure 1-3 as well as Figure 5 , including the upper body 1, the upper body 1 is woven with at least one overlapping knitting structure 11, the overlapping knitting structure 11 includes at least one knitting layer, and the knitting layer is interlaced by a knitting strip 111 (when 1 yarn When weaving the overlapping weave structure 11, the space where the space is located is one on top). Further, the width of the overlapping woven structure 11 can be freely adjusted (it can be freely adjusted according to usage scenarios and needs). Further, the upper body 1 includes a dense area 2 and a sparse area 3 . Further, the overlapping braided structure 11 is braided in the dense area 2 . Further, the braided strip 111 is any one of the thick wax rope and the elastic yarn, but is not limited to the above two (when the thick wax rope is used, the aesthetics of the upper body 1 is increased; when the elastic...

Embodiment 2

[0086] This embodiment discloses an interwoven knitted upper, refer to Figure 1-3 as well as Figure 5 , including the upper body 1, the upper body 1 is woven with at least one overlapping knitting structure 11, the overlapping knitting structure 11 includes at least one knitting layer, and the knitting layer is interlaced by a knitting strip 111 (when 1 yarn When weaving the overlapping weave structure 11, the space where the space is located is one on top). Further, the width of the overlapping woven structure 11 can be freely adjusted (it can be freely adjusted according to usage scenarios and needs). Further, the upper body 1 includes a dense area 2 and a sparse area 3 . Further, the overlapping braided structure 11 is braided in the sparse area 3 . Further, the braided strip 111 is any one of the thick wax rope and the elastic yarn, but is not limited to the above two (when the thick wax rope is used, the aesthetics of the upper body 1 is increased; when the elastic y...

Embodiment 3

[0088] This embodiment discloses an interwoven knitted upper, refer to Figure 1-3 as well as Figure 5 , including the upper body 1, the upper body 1 is woven with at least one overlapping knitting structure 11, the overlapping knitting structure 11 includes at least one knitting layer, and the knitting layer is interlaced by a knitting strip 111 (when 1 yarn When weaving the overlapping weave structure 11, the space where the space is located is one on top). Further, the width of the overlapping woven structure 11 can be freely adjusted (it can be freely adjusted according to usage scenarios and needs). Further, the upper body 1 includes a dense area 2 and a sparse area 3 . Further, the overlapping braided structure 11 is braided in the sparse area 3 and the dense area 2 respectively. Further, the braided strip 111 is any one of the thick wax rope and the elastic yarn, but is not limited to the above two (when the thick wax rope is used, the aesthetics of the upper body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com