Preparation process of glass fiber reinforced plastic oil tank with inner reinforcing ribs

A preparation process and a technology for internal reinforcing ribs, which are applied in the field of glass fiber reinforced plastic buried horizontal atmospheric pressure vessels, can solve problems such as insufficient strength, and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

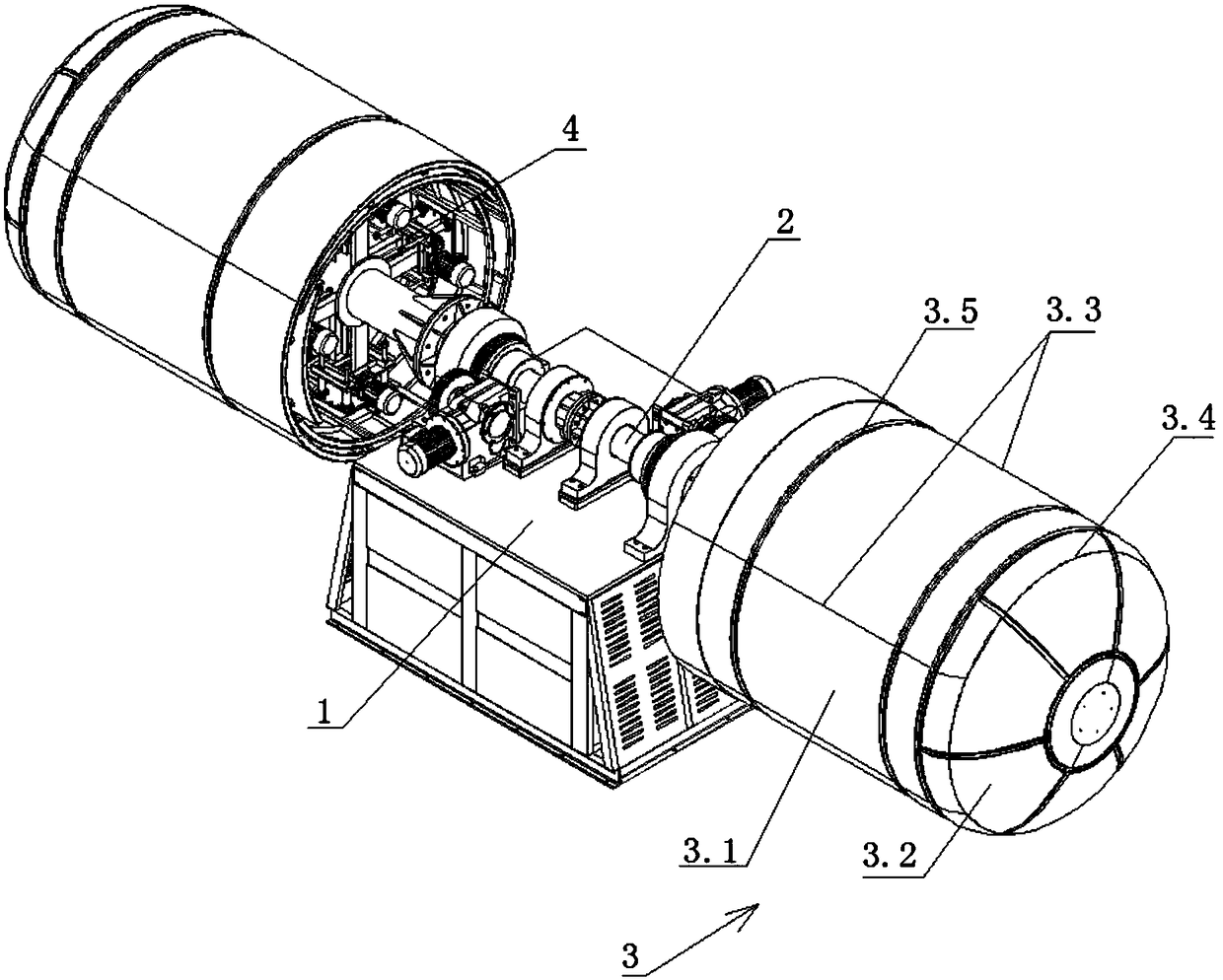

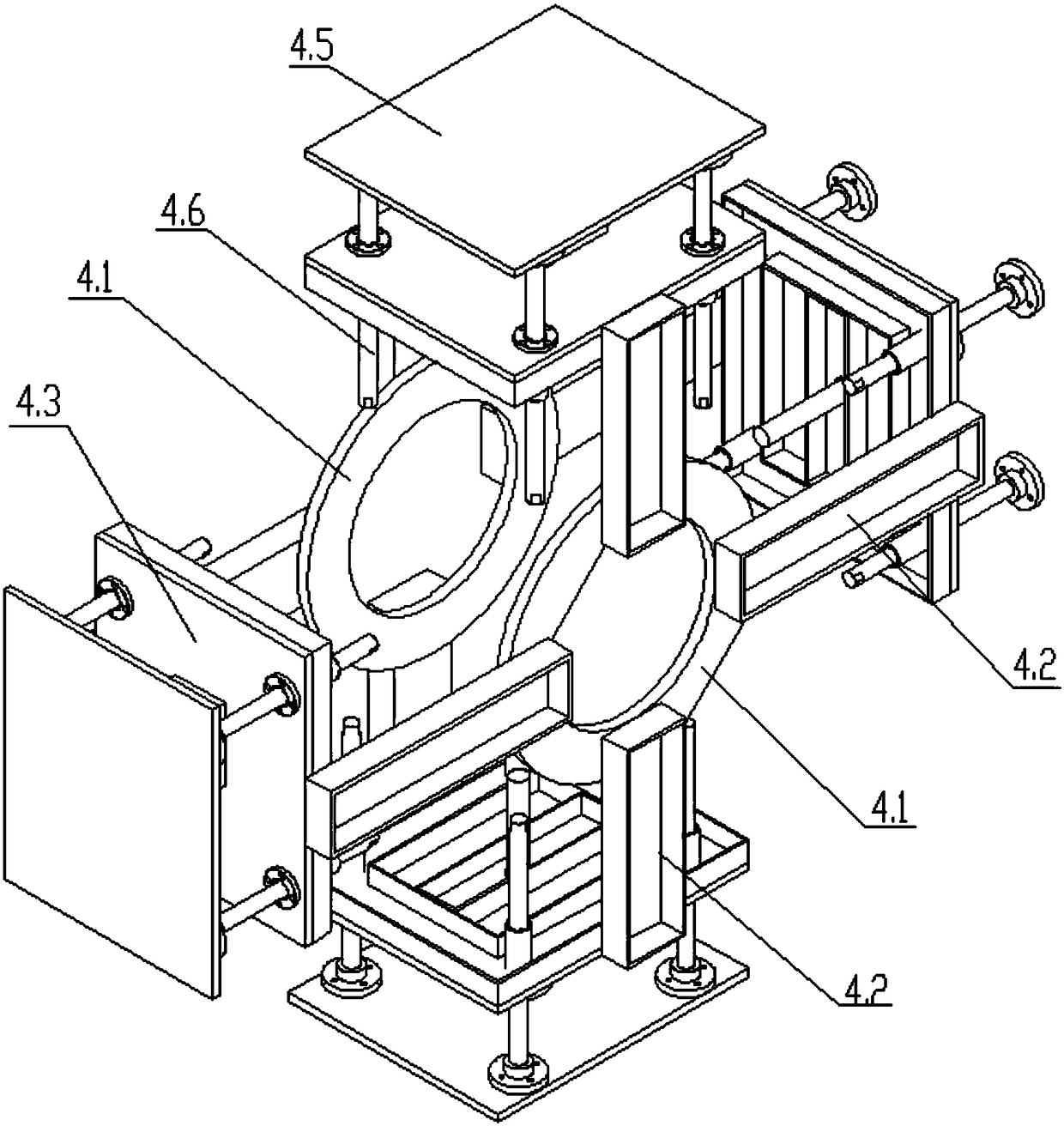

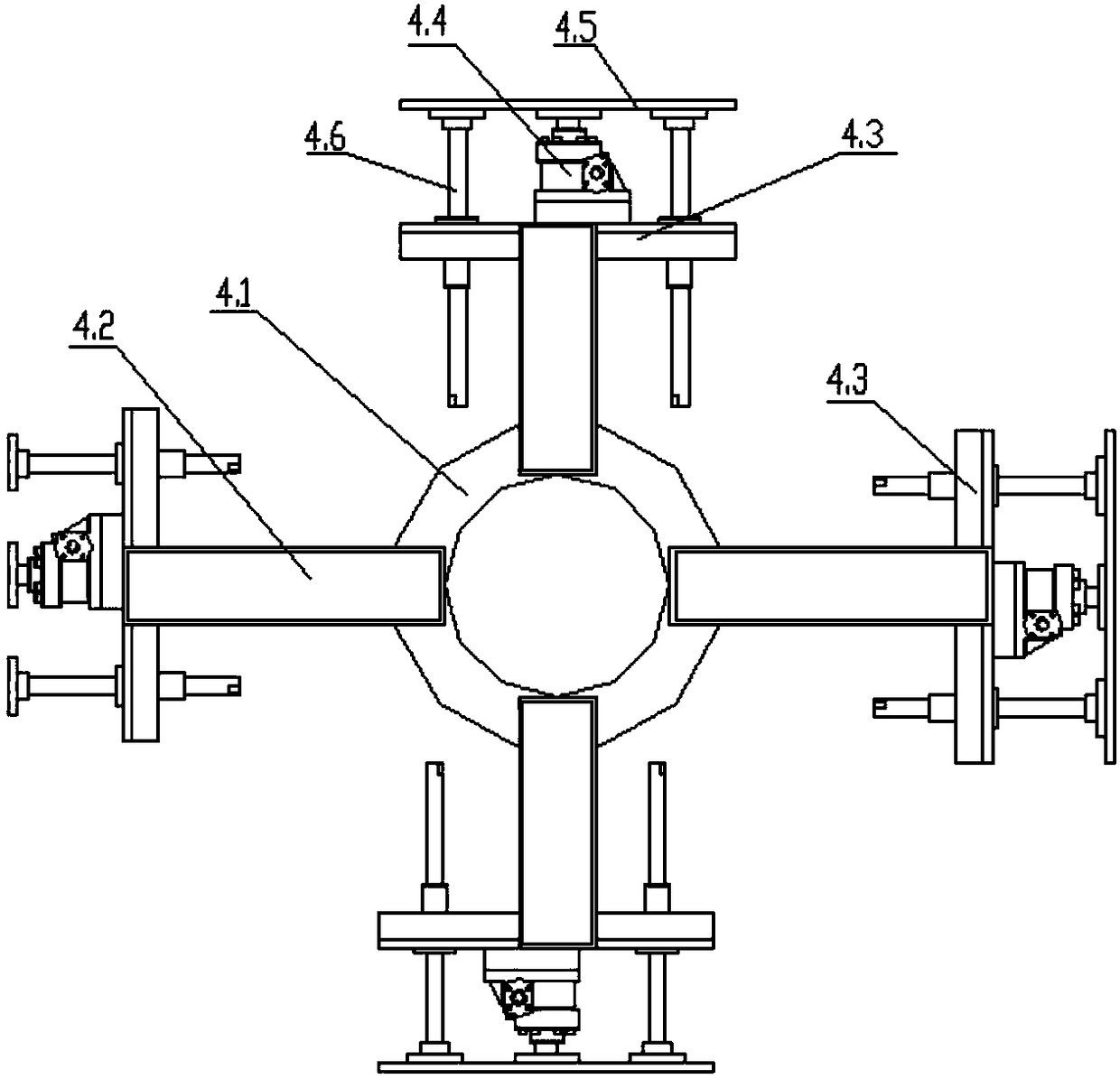

[0022] see Figure 1~4 , a kind of preparation technology that the present invention relates to has the glass fiber reinforced plastic oil tank with internal reinforcement, and described preparation technology comprises the following steps:

[0023] Step 0, wrap the polyester film on the forming mold to facilitate demoulding of the prepared oil tank and other containers;

[0024] Step 1. Spray or spirally wind FRP fibers on the cylinder mold. The cylinder mold has a plurality of ring-shaped reinforcing rib forming grooves, so that the FRP fibers are solidified to form an inner shell with an internal reinforcing rib structure. body;

[0025] Step 2. The cylinder formwork is spliced by multiple cylinder formworks, and the cylinder formwork shrinks radially inward, so that the cylinder formwork is separated from the reinforcing ribs of the inner shell; the inner shell can be pulled out;

[0026] Step 3, spraying on the inner shell or setting glass fiber reinforced plastic fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com